Septic tank waste treatment apparatus

A septic tank and waste technology, which is applied in the field of septic tank waste treatment devices, can solve problems such as difficulties, serious septic tank silting and clearing, and achieve the effects of convenient operation, avoiding dangerous gas accidents, and reducing and eliminating clearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

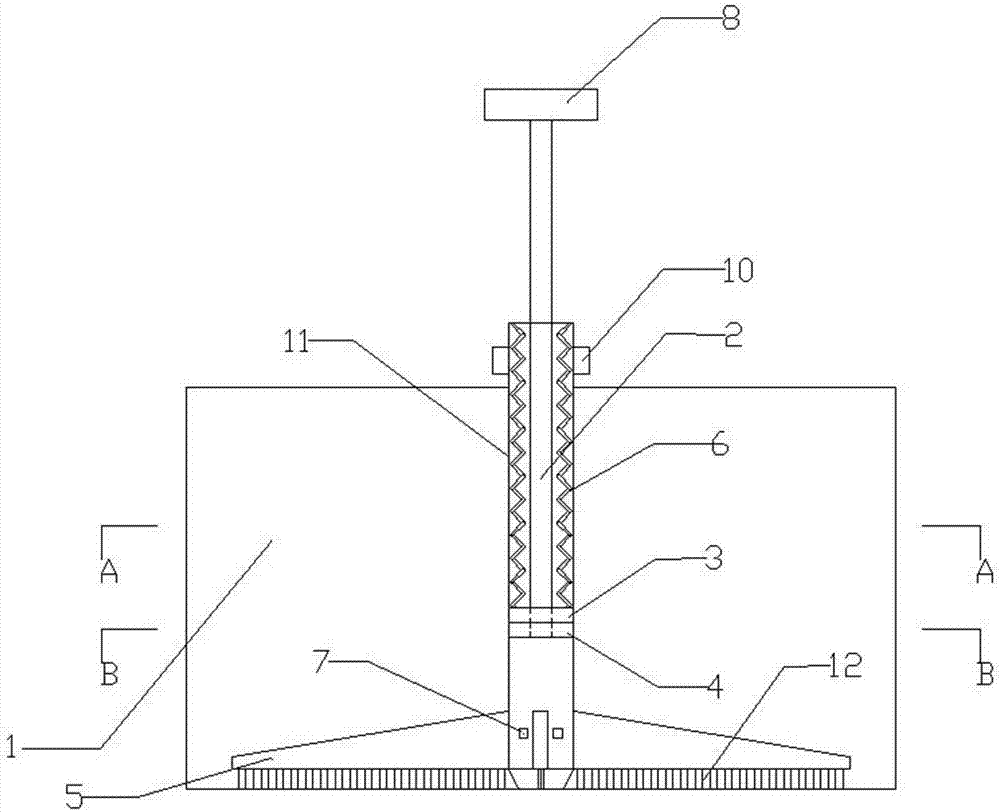

[0037] A septic tank waste treatment device, which is set in the septic tank 1, including a liquid adding device and a stirring device;

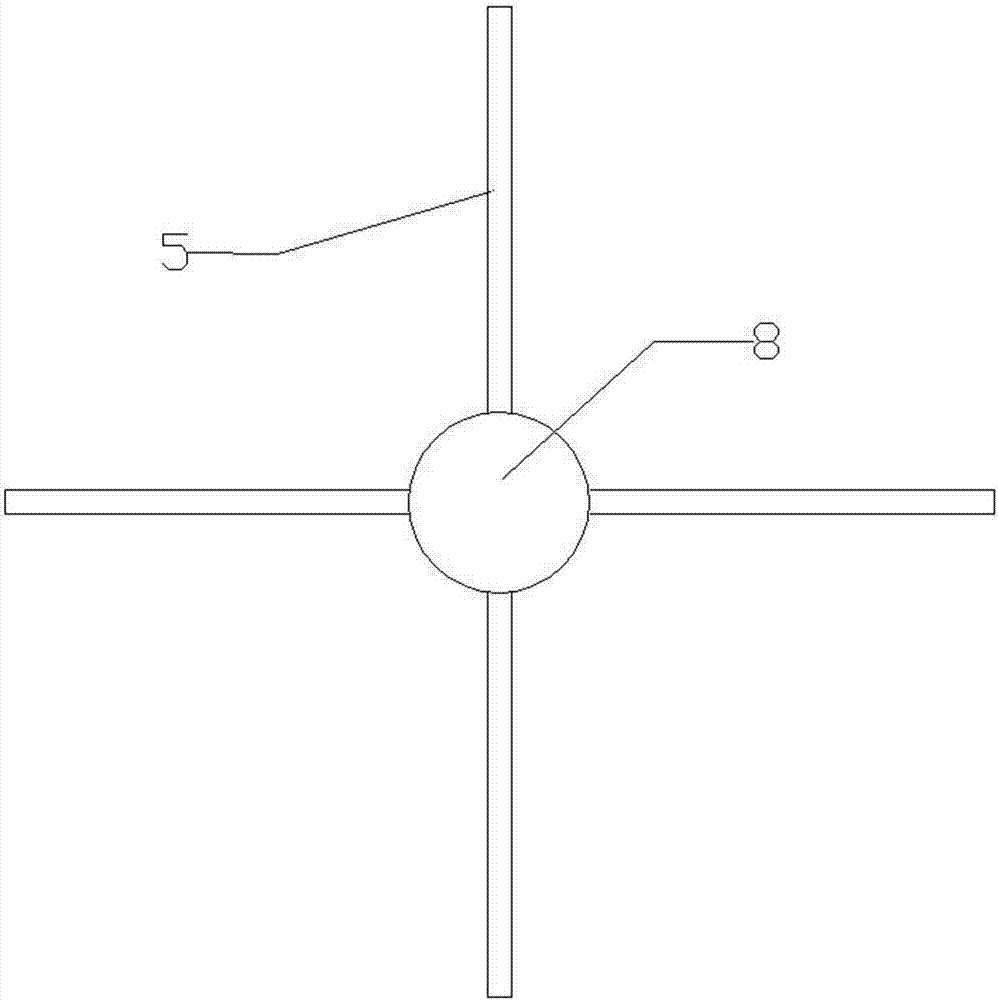

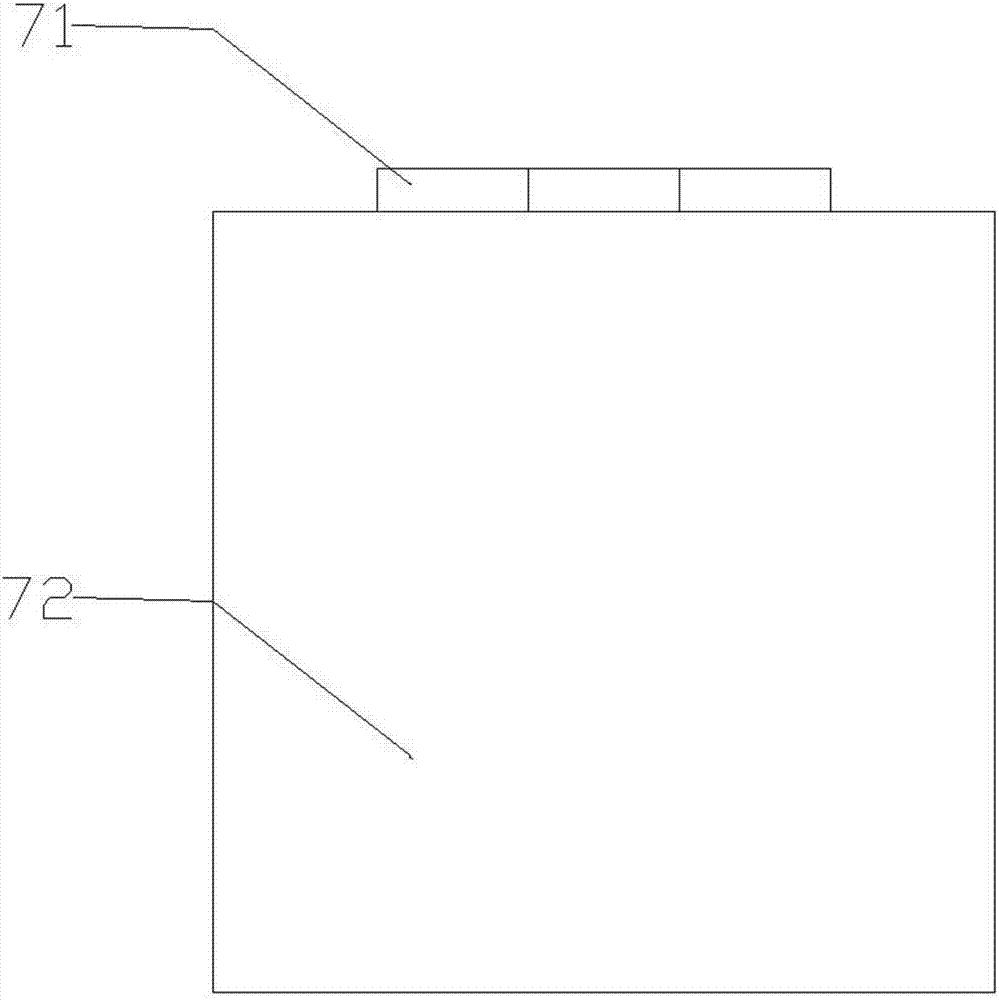

[0038] Such as figure 1 As shown, the liquid adding device includes a piston cylinder 11, a hinge piece 7, a piston and a rebound member 6; as image 3 As shown, the hinge piece 7 includes a spring hinge 71 and a sheet body 72;

[0039] Such as figure 1 As shown, the piston includes a piston handle 8, a piston rod 2 and a piston head; as Figure 6 As shown, the piston head includes a base 3 and a rubber head 4; the rubber head 4 is fixed on the bottom of the base 3;

[0040] The lower part of the piston cylinder 11 is provided with a liquid outlet hole, the hinge piece 7 is fixed on the outer wall of the piston cylinder 11 through the spring hinge 71, the sheet body 72 is sealed and pressed on the liquid outlet hole, and the hinge piece 7 is in a constant state under the elastic force of the spring hinge 71. closed state;

[0041] A thr...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the slide bar 13 extends to the entire height of the piston barrel 11 .

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the slide bar 13 extends to the stroke height of the piston head in the piston cylinder 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com