Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Cyclohexylthiophthalimide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclohexylthiophthalimide (abbreviated CTP) is an organosulfur compound that is used in production of rubber. It is a white solid, although commercial samples often appear yellow. It features the sulfenamide functional group, being a derivative of phthalimide and cyclohexanethiol. In the production of synthetic rubber, CTP impedes the onset of sulfur vulcanization.

Zero degree belt compound of all-steel radial tire

InactiveCN102086275AMeet processing performance requirementsSolve quality defectsSpecial tyresCyclohexylthiophthalimideAlkylphenol

The invention relates to a zero degree belt compound of all-steel radial tire, which is characterized by being prepared from a plurality of raw materials. The raw materials in formula comprises 10# natural rubber, carbon black N375, carbon black N660, hydrated silica, zinc oxide, modified alkylphenol- formaldehyde resin TKM-M, N-(1,3-dimethylbutyl)-N'-phenyl p phenylenediamine, resorcinol formaldehyde resin, cobalt boroacylate, hexamethoxy methyl melamine, N-t butyl-2-benzothiazolesulfenamide, insoluble sulfur HD OT20 and N-cyclohexylthiophthalimide. The invention is used as zero degree belt compound in all-steel radial tire production. The rubber compound of the invention has the advantages of reducing extrusion temperature of the zero degree belt, improving extrusion speed, increasing surface viscosity of the zero degree belt, prolonging holding time of viscosity, improving rubber-coating effect, and effectively solving the quality problems of point-like copper exposition and poor surface viscosity.

Owner:SICHUAN TYRE & RUBBER CO LTD

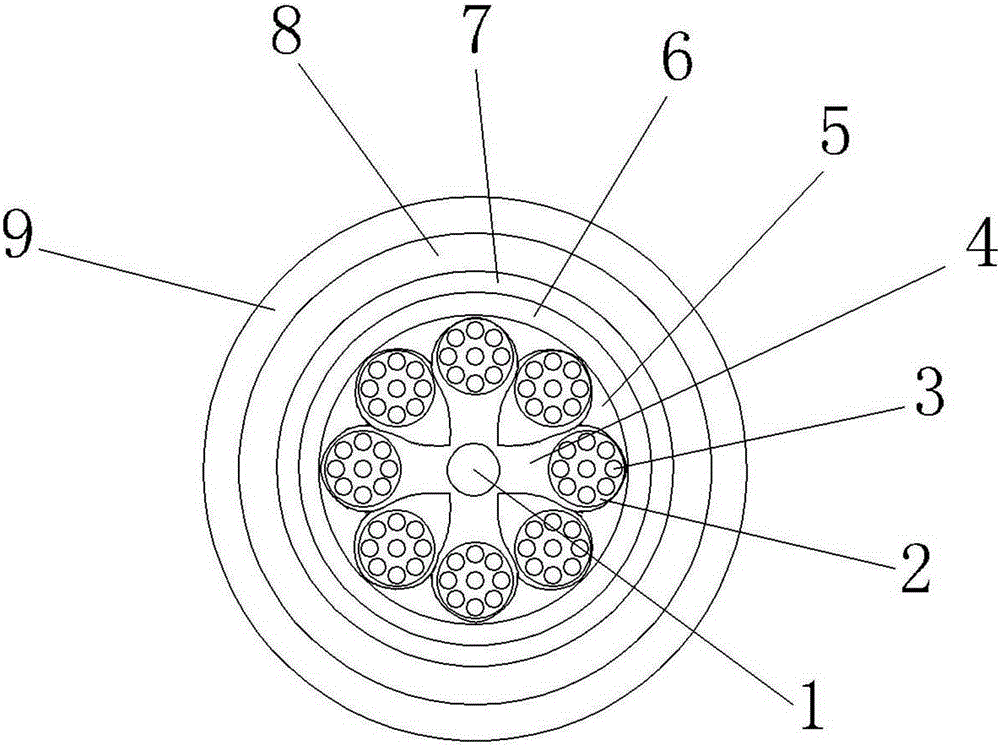

High-intensity wear resistant cable used for construction

InactiveCN105244109AImprove stabilityImprove extrusion resistancePower cables with screens/conductive layersInsulated cablesCalcium silicateWear resistant

The invention discloses a high-intensity wear resistant cable used for construction. A raw material of a sheath layer comprises, by weight, 60-90 parts of terpolymer EP rubber, 30-60 parts of W type chloroprene rubber, 40-80 parts of nitrile rubber, 30-60 parts of polyvinyl fluoride resin, 20-50 parts of EVA resin, 30-60 parts of modified epoxy resin, 12-22 parts of fluorinated polyethylene, 5-12 parts of zinc oxide, 3-8 parts of magnesium oxide, 2-9 parts of calcium stearate, 3-9 parts of nylon, 2-12 parts of active white carbon black, 2-8 parts of nanometer white carbon black, 2-6 parts of active calcium silicate, 3-8 parts of nanometer silica, 1-5 parts of a vulcanizing agent DCP, 2-8 parts of chloranil, 3-9 parts of a promoter DM, 3-9 parts of polyethylene glycol, 2-8 parts of a dispersant CNF, 1-5 parts of an antiager RD, 2-6 parts of an antiager AW, and 1-6 parts of N-cyclohexylthiophthalimide. The cable is high in intensity and highly resistant to wear.

Owner:安徽华峰电缆集团有限公司

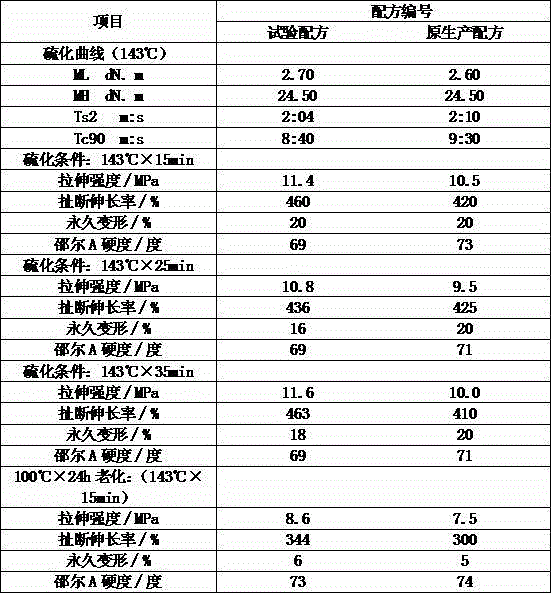

Aircraft tire flap rubber

InactiveCN102977438AHigh hardnessHigh strengthBuilding insulationsCyclohexylthiophthalimideEngineering

The invention discloses an aircraft tire flap rubber which is prepared by using a banbury mixer according to a conventional technology from the following raw materials in parts by weight: 30-50 parts of 20# standard glue, 30-50 parts of butadiene-styrene rubber, 50-70 parts of reclaimed rubber, 1-6 parts of zinc oxide, 1-6 parts of stearic acid, 0-2 parts of anti-aging agent A, 0-2 parts of anti-aging agent D, 0-2 parts of paraffin, 2-6 parts of asphalt, 40-60 parts of N660 carbon black, 5-10 parts of aromatic oil, 1-3 parts of sulfur, 0-2 parts of accelerant TMTD (teramethyl-thiuram disulfide), 0-2 parts of accelerant MBTS (mercaptobenzthiazole disulfide) and 0.1-2 parts of scorch retarder CTP (cyclohexylthiophthalimide). The aircraft tire flap rubber has the advantages of improving hardness and strength of a sizing material by adopting the carbon black N660 as a reinforcing agent; prolonging scorch time without reducing the curing speed in a curing stage and improving processing and storing stabilities of the sizing material by adding the scorch retarder CTP in the formula; and improving plasticity and uniformity of the sizing material, improving technological operation properties of the sizing material and effectively solving various problems in a production process by adopting the aromatic oil as a softening agent.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

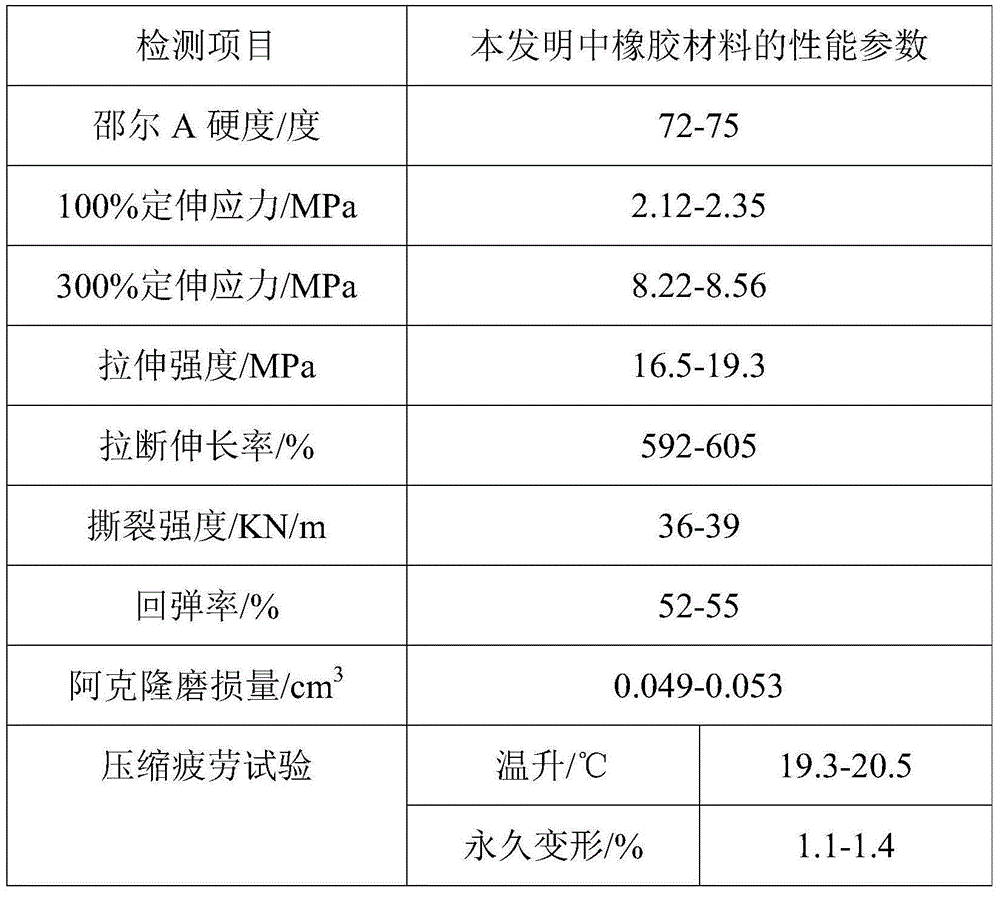

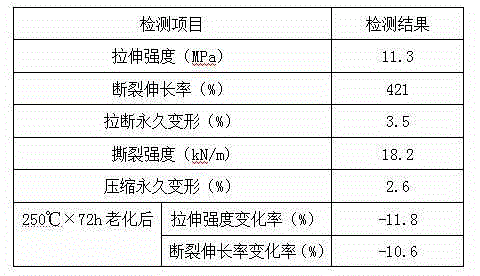

Wear-resistant drilling pump valve sealing gasket and its preparation method

The invention discloses a wear-resistant drilling pump valve sealing gasket and a preparation method thereof. The sealing gasket consists of the following raw materials by weight: 50-60 parts of isoprene rubber (SKI-3), 15-25 parts of styrene butadiene rubber (SBR1712), 10-15 parts of PTFE, 10-15 parts of modified nano diamond, 5-10 parts of nano silicon nitride, 4-7 parts of white factice, 2-3 parts of zinc dibutyl dithiocarbamate, 16-22 parts of high abrasion furnace black N330, 3-4 parts of insoluble sulfur powder M-80, 2-3 parts of zinc oxide, 1-2 parts of manganese dioxide, 1-2 parts of stearic acid, 2-3 parts of 2-(2, 4-dinitrophenyl thio) benzothiazole, and 1-2 parts of N-cyclohexylthiophthalimide. Compared to a traditional sealing gasket, the sealing gasket provided by the present invention has the advantages of low friction wear, good resilience and high compressive strength, and can prolong the service life of the product in the use process in the same conditions.

Owner:TONGLING SIDE TECH

Modified heat-proof anti-oxidation nitrile rubber cable material

InactiveCN103539979AImprove performanceEasy to processInsulated cablesInsulated conductorsLow-density polyethyleneEpoxy

The invention relates to a cable material, and in particular relates to a modified heat-proof anti-oxidation nitrile rubber cable material which is prepared from the following raw materials in parts by weight: 30 to 34 parts of nitrile rubber (N41), 10 to 12 parts of granulated cork, 20 to 24 parts of epichloro-hydrin rubber, 10 to 12 parts of SG-3 polyvinyl chloride, 10 to 12 parts of low-density polyethylene, 24 to 27 parts of N550 carbon black, 30 to 34 parts of N220 carbon black, 7 to 9 parts of adipic acid diester, 4 to 5 parts of N-cyclohexylthiophthalimide, 2 to 3 parts of titanate coupling agent TMC-TTS, 2 to 4 parts of stearic acid, 1 to 2 parts of accelerant Na-22, 12 to 14 parts of nano silicon dioxide, 2 to 3 parts of epoxy flaxseed oil, 1 to 2 parts of sulphur, 3 to 4 parts of zinc oxide, 3 to 4 parts of magnesium oxide and 4 to 5 parts of auxiliary agent. The performance of the traditional nitrile rubber cable material is improved by combining the advantages of the nitrile rubber, the epichloro-hydrin rubber, the SG-3 polyvinyl chloride, the low-density polyethylene and the other raw materials. Thus, the modified heat-proof anti-oxidation nitrile rubber cable material is superior in processability and usability, and has the characteristics of heat resistance, oxidation resistance, aging resistance and the like. Therefore, the modified heat-proof anti-oxidation nitrile rubber cable material can adapt to specific application environment conditions, thereby having broad market application prospect.

Owner:安徽文峰电子科技集团有限公司

High-quality rubber material for bushes of stabilizer bars

The invention provides a high-quality rubber material for bushes of stabilizer bars. The high-quality rubber material comprises, by weight, 80-90 parts of natural rubber, 10-20 parts of tetrapropyl fluoro elastomer, 5-10 parts of chlorosulfonated polyethylene rubber, 35-50 parts of polyacrylate rubber, 3-5 parts of butadiene styrene rubber, 3-5 parts of fluorinated silicone rubber, 40-45 parts of hydrogenated nitrile butadiene rubber, 15-20 parts of N-cyclohexylthiophthalimide, 10-20 parts of epoxy propane rubber, 5-10 parts of copolymerization chlorohydrine rubber, 5-10 parts of ethylene-vinyl acetate rubber, 3-5 parts of aromatic hydrocarbon oil, 3-5 parts of polyether-ether-ketone, 5-10 parts of carbon black, 5-6 parts of nanometer tin dioxide, 3-5 parts of calcined pottery clay, 3-5 parts of dicumyl peroxide, 4-5 parts of zinc oxide, 3-4 parts of magnesium oxide, 1-5 parts of polyamide wax micro-powder, 3-8 parts of magnesium stearate, 5-10 parts of polyisobutylene rubber, 4-5 parts of titanium dioxide powder and 3-5 parts of naphthenic oil. The high-quality rubber material has the advantages that the high-quality rubber material is excellent in resilience, heat resistance and cold resistance, rubber is good in abrasion resistance, heat aging resistance and dynamic fatigue resistance, and accordingly service requirements of the bushes of the stabilizer bars can be met.

Owner:安徽纯启动力科技有限公司

Anti-extrusion cable

The invention discloses an anti-extrusion cable, which comprises a cable core, an insulation layer, a filling layer, a plurality of buffer plates, a wrapping layer, a buffer layer and an armor layer, wherein each buffer plate comprises the following ingredients in parts by weight: 100 parts of natural rubber, 70 parts of chloroprene rubber, 55 parts of silicone rubber, 45 parts of butadiene styrene rubber, 35 parts of butadiene rubber, 40 parts of nitrile rubber, 5.5 parts of zinc oxide, 3 parts of stearic acid, 8.5 parts of polyolefin elastomers, 3 parts of KH550 silane coupling agents, 4 parts of KH570 silane coupling agents, 8 parts of quinone alcohol ester, 4 parts of dicumyl peroxides, 3 parts of vulcanizing agents DCP, 5 parts of chloranil, 6 parts of accelerants DM, 7 parts of active white carbon black, 6 parts of polyethylene glycol, 5 parts of dispersants CNF, 3 parts of anti-aging agents RD, 4 parts of anti-aging agents AW and 4 parts of N-cyclohexylthiophthalimide. The anti-extrusion cable has excellent anti-extrusion performance.

Owner:安徽华峰电缆集团有限公司

Special highly-wear-resistant rubber material used for tire tread

InactiveCN105111517AImprove mechanical propertiesImprove heat resistanceSpecial tyresPolymer scienceWear resistant

The invention discloses a special highly-wear-resistant rubber material used for tire tread. The material comprises the following raw materials: natural rubber, polybutadiene rubber, modified kaolin, stearic acid modified ultrafine cerium oxide, nanometer calcium carbonate, nanometer titanium dioxide, zinc oxide, stearic acid, sulfur, 2-(4-morpholinyl dithio)benzothiazole, organic silicone-acrylate rubber particles, a methyl methacrylate-butadiene-styrene copolymer, lanthanum dioctyldith iocarbamate, cobaltic yttrium glycinemethane dithioate, N-cyclohexylthiophthalimide, an accelerator M, an accelerator CZ, an antiaging agent MB, lanthanum stearate, calcium stearate, trioctyl trimellitate and dimethyl 4-nitrophthalate. The special highly-wear-resistant rubber material used for the tire tread has the advantages of good mechanical property, high heat resistance and excellent wear resistance, and the material is used for the tire tread with good comprehensive performances and long service life.

Owner:合肥市再德高分子材料有限公司

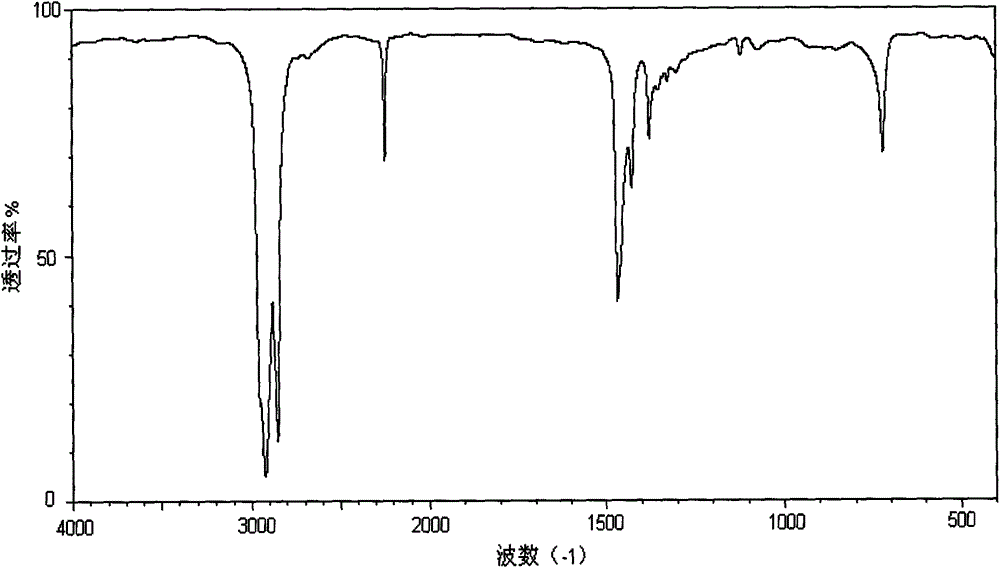

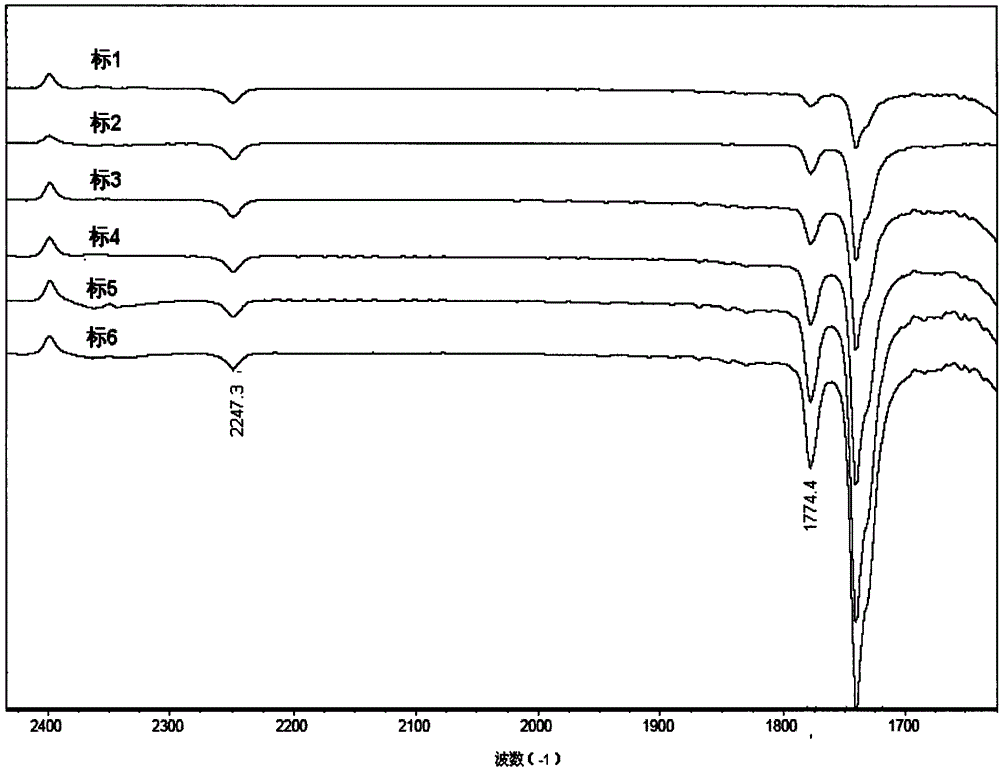

Method for analyzing content of scorch retarder CTP (N-cyclohexylthiophthalimide) in vulcanized rubber

ActiveCN103604770AEliminate the effects ofMaterial analysis by optical meansInternal standardMass ratio

The invention relates to an infrared spectroscopic analysis method for analyzing the dosage of a scorch retarder CTP (N-cyclohexylthiophthalimide) in a formula of vulcanized rubber. In the method, the content of phthalimide in the vulcanized rubber is calculated by use of the mutual relation between an internal standard substance and the characteristic infrared absorption spectrum peak-mass ratio of phthalimide so as to obtain the content of the scorch retarder CTP in the vulcanized rubber. The method provided by the invention is simple to operate, and the analysis result has high accuracy rate and little error.

Owner:BEIJING RED AVENUE INNOVA

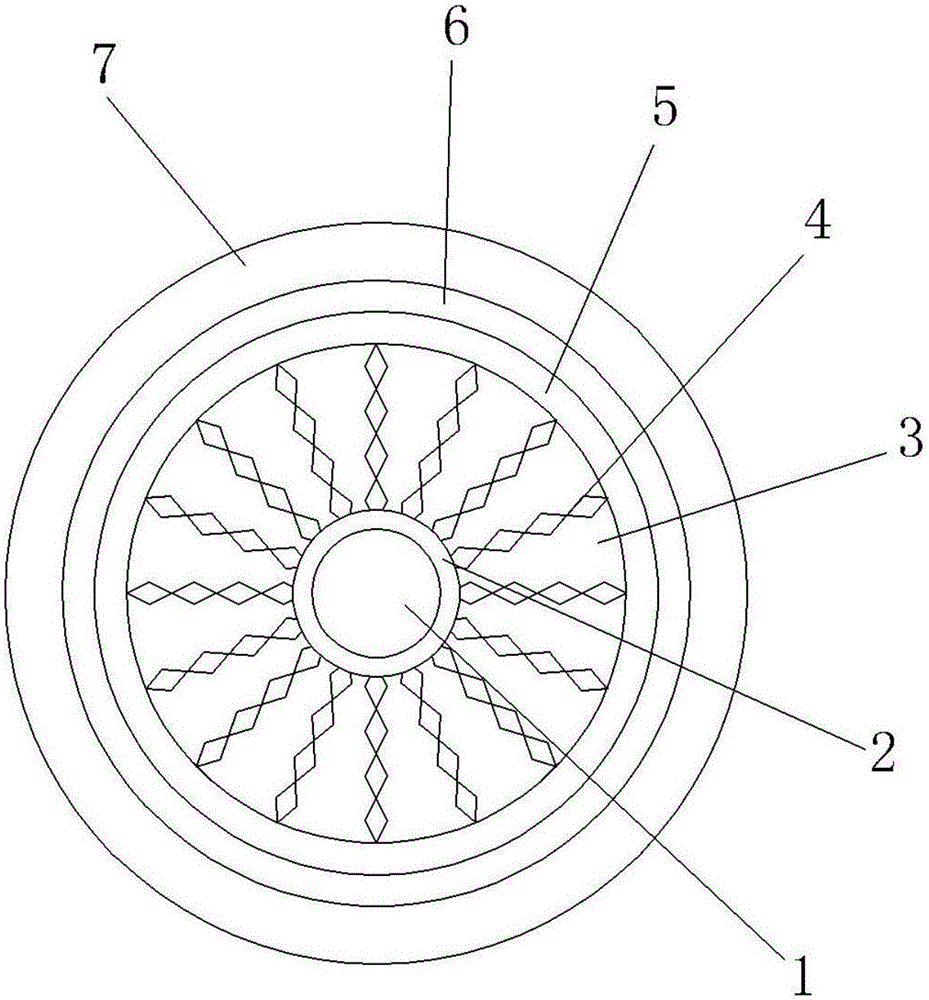

Abrasion-resistant base compound for solid tyres of crane cars

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of crane cars. The abrasion-resistant base compound for the solid tyres of the crane cars comprises raw materials in parts by weight as follows: natural rubber, liquid polybutadiene rubber, carbon black N234, white carbon black, a silicon coupling agent, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc oxide, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, N-cyclohexylthiophthalimide and polyamide fibers. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:SHANDONG YONGTAI CHEM GROUP

Sizing material adhered to belt ply steel wire of truck radial tire and preparation method

The invention discloses a sizing material adhered to a belt ply steel wire of a truck radial tire and a preparation method, relates to a sizing material and a preparation method thereof, and discloses a sizing composition adhered to the belt ply steel wire of the truck radial tire. The sizing material comprises the following components by weight: 100 parts of natural rubber, 40-60 parts of carbon black N330, 3-5 parts of white carbon black, 8-10 parts of zinc oxide, 2-4 parts of anti-aging agent 4010NA, 3-6 parts of adhesive CS-964, 0.8-1.2 parts of adhesion promoter, 0.5-2.5 parts of R-80, 4-6 parts of insoluble sulfur, 1-2 parts of promoter NOBS (N-(Oxidiethylene)-2-benzothiazolyl sulfenamide), 0.1-1 part of anti-scoring agent CTP (Cyclohexylthiophthalimide) and 0.1-1 part of adhesion promoter P-1. By using the technical scheme, the adhesion performance of the sizing material and the copper-plated steel wire can be enhanced, and the coating quality is also better.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Colourfast rubber

The invention relates to a colourfast rubber, which comprises the following components: 100 parts of nitrile-butadiene rubber, 18 parts of DM-300, 5 parts of carbon black N330, 60 parts of white carbon black, 6 parts of zinc oxide, 1.5 parts of SA, 3 parts of polyethylene glycol, 1.5 parts of a rubber dispersing agent L-24, 2 parts of 935P, 2 parts of acrylic resin MB-2, 1 part of RH-150, 2 parts of silicon oil, 3 parts of a rubber accelerator, 0.4 part of a rubber vulcanizing agent, and 0.2 part of N-cyclohexylthiophthalimide. The colourfast rubber provided by the invention has good stability, is colourfast during use and is unlikely to decompose, especially does not decompose to cause raw material pollution when it is used as a raw material tank or contacts with the reactants, and also has good abrasion resistance.

Owner:ANHUI LONGCHUAN RUBBER & PLASTIC TECH CO LTD

Silicone rubber high temperature-resistant rubber pipe

The invention discloses a silicone rubber high temperature-resistant rubber pipe. The silicone rubber high temperature-resistant rubber pipe comprises, by weight, 80-120 parts of modified methyl vinyl silicone rubber, 30-60 parts of an ethylene-propylene-diene monomer, 10-30 parts of tetrafluoroethylene-propylene copolymer rubber, 5-15 parts of a plasticizing softener, 2-8 parts of cyclohexylthiophthalimide, 3-9 parts of nitrile rubber, 4-8 parts of calcium carbonate, 1-5 parts of diglycol, 2-6 parts of carbon black, 4-8 parts of 1, 2-ethylene thiourea, 2-5 parts of white oil, 3-9 parts of a cracking prevention agent, 2-4 parts of fibers, 4-8 parts of dilead tetraoxide, 3-9 parts of dioctyl phthalate and 4-8 parts of Antilux 654. The silicone rubber high temperature-resistant rubber pipe has good high temperature resistance and high toughness and satisfies demands in actual use.

Owner:安徽都邦电器有限公司

High-temperature resistant oil-resistant rubber hose

InactiveCN103601983AImprove high temperature resistanceGood oil resistanceFlexible pipesFiberPolymer science

The invention relates to a high-temperature resistant oil-resistant rubber hose. The high-temperature resistant oil-resistant rubber hose comprises following ingredients, 100 parts of ethylene propylene diene monomer, 4 parts of a plasticizing softener, 6 parts of cyclohexylthiophthalimide, 9 parts of methyl vinyl silicone rubber, 12 parts of butadiene-acrylonitrile rubber, 1 part of calcium carbonate, 2 parts of diethylene glycol, 3 parts of carbon black, 2 parts of ethlenethiourea, 6 parts of a plasticizing softener, 4 parts of white oil, 3 parts of an anticracking additive, 2 parts of fiber, and 4 parts of a plasticizing softener. The high-temperature resistant oil-resistant rubber hose possesses excellent high-temperature resistance and oil resistance; and is capable of maintaining excellent elasticity, is impervious, and will not become soft at high temperature and under conditions with the presence of fuels containing a plurality of additives; carbon black with excellent insulating properties is added, and the high-temperature resistant oil-resistant rubber hose possesses relatively high insulativity because of excellent non-conductivity and insulation performance of carbon black; and production cost is reduced to a certain degree.

Owner:QINGDAO JIALIFU ENVIRONMENTAL PROTECTION TECH

Nanometer zinc oxide modified natural rubber sealing gasket

InactiveCN104558706AImprove high temperature resistanceImprove sealingPolymer scienceSodium stearate

The invention discloses a nanometer zinc oxide modified natural rubber sealing gasket, and relates to the technical field of natural rubber processing. The nanometer zinc oxide modified natural rubber sealing gasket is prepared from the following raw materials in parts by mass: 100 to 110 parts of natural rubber, 10 to 15 parts of nanometer zinc oxide, 8 to 10 parts of magnesium carbonate, 4 to 8 parts of diphenyl silandiol , 3 to 5 parts of trioctyl trimellate, 4 to 7 parts of coumarone-indene resin, 2 to 5 parts of rosin, 3 to 8 parts of decabromodiphenyl ethane, 1 to 4 parts of sodium stearate, 4 to 9 parts of ethyl carbamate, 1 to 4 parts of propolis, 3 to 6 parts of N-cyclohexylthiophthalimide, 1.5 to 3 parts of maleic anhydride, 2 to 5 parts of an antioxidant and 3 to 7 parts of kaolin. According to the nanometer zinc oxide modified natural rubber sealing gasket, nanometer zinc oxide is used for modifying natural rubber, and the modified natural rubber sealing gasket is prepared under the synergistic effects of the other components, and is high in high temperature resistance, sealing performance, flame resistance and wear resistance and long in service life.

Owner:郎溪县恒通塑业有限公司

Wear-resistant high-strength slipper sole and production technology and application thereof

The invention discloses a wear-resistant high-strength slipper sole and a production technology and an application thereof. According to the invention, a rubber is taken as a main material, linear low-density polyethylene and polyvinyl chloride are subjected to performance composite, a wear-resisting agent is added for increasing the wear resistant performance of the product, so that the final product has good elasticity and excellent wear resistant performance, white carbon black and carbon black are taken as a double-purpose strengthening agent for further increasing the intensity performance of the final product, the auxiliary agents of N-cyclohexylthiophthalimide, azodicarbonamide, dicapryl phthalate, acetyl tri-n-butyl citrate, and zinc oxide are added for adjusting the formula, processing property is good, and the yield rate and performance stability of the product are increased.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

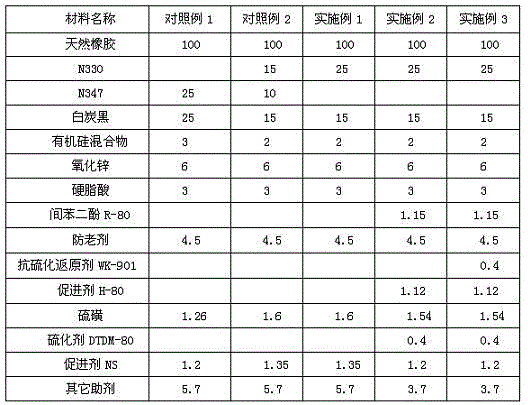

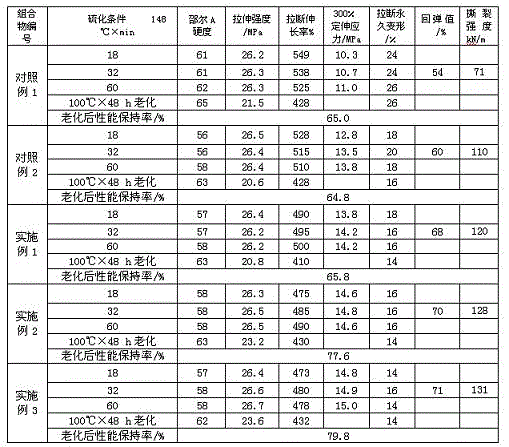

Rubber composition for base rubber of radial giant engineering tire and preparation method thereof

InactiveCN105542241ALow heat resistanceLow reversion resistancePolymer scienceHexamethylenetetramine

The invention relates to the technical field of rubber, specifically to a rubber composition for base rubber of a radial giant engineering tire and a preparation method thereof. The rubber composition comprises: with 100 parts of natural rubber by weight as a reference, 25 to 35 parts of carbon black, 7 to 15 parts of white carbon black, 1 to 3 parts of a silane coupling agent, 1.25 to 1.38 parts of resorcinol-80, 0 to 3 parts of tackifying resin, 4 to 8 parts of zinc oxide, 2 to 3.5 parts of stearic acid, 1 to 2 parts of protective wax, 1 to 4 parts of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine, 1 to 2 parts of a 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 0 to 0.5 part of an anti-reversion agent, 1.25 to 1.58 parts of a mixture composed of 80% of hexamethylenetetramine and 20% of a cemented body and a dispersant, 1.4 to 1.8 parts of sulfur, 0 to 0.5 part of a mixture composed of 80% of dithiodimorpholine and 20% of the cemented body and the dispersant, 1.28 to 1.65 parts of a vulcanizing accelerator N-tert-butyl-2-benzothiazolyl sulfonamide and 0.2 to 0.4 part of a scorch retarder N-cyclohexylthiophthalimide.

Owner:TRIANGLE TIRE

Low compression permanent deformation silicon rubber compound and preparation method thereof

InactiveCN104312156AReduce distortionHigh mechanical strengthOther chemical processesPolymer scienceCyclohexylthiophthalimide

The invention discloses a low compression permanent deformation silicon rubber compound and a preparation method thereof. The rubber compound consists of the following raw materials by weight: 72-96 parts of methyl phenyl silicone rubber, 26-44 parts of a thermoplastic polyurethane elastomer, 15-25 parts of an ethylene-methyl acrylate copolymer, 6-12 parts of 1,2-polybutadiene, 10-15 parts of aluminum borate whisker, 2-4 parts of tert-butyl monoperoxymaleate, 3-5 parts of zinc sulfide, 4-6 parts of ethylene-bis-stearamide, 5-8 parts of bisphenol A diglycidyl ether, 7-14 parts of magnesium carbonate, 5-10 parts of C5 petroleum resin, 2-3 parts of trimethyl thiourea, 1-2 parts of N-Cyclohexylthiophthalimide and 2-4 parts of an assistant. The silicon rubber compound provided by the invention has low compression permanent deformation, high mechanical strength, good corrosion resistance, fatigue resistance, aging resistance and temperature resistance, is especially suitable for the production of rubber seals and other rubber products, and has the advantages of simple preparation process, low cost and huge market prospects.

Owner:天长市荣盛有机硅科技有限公司

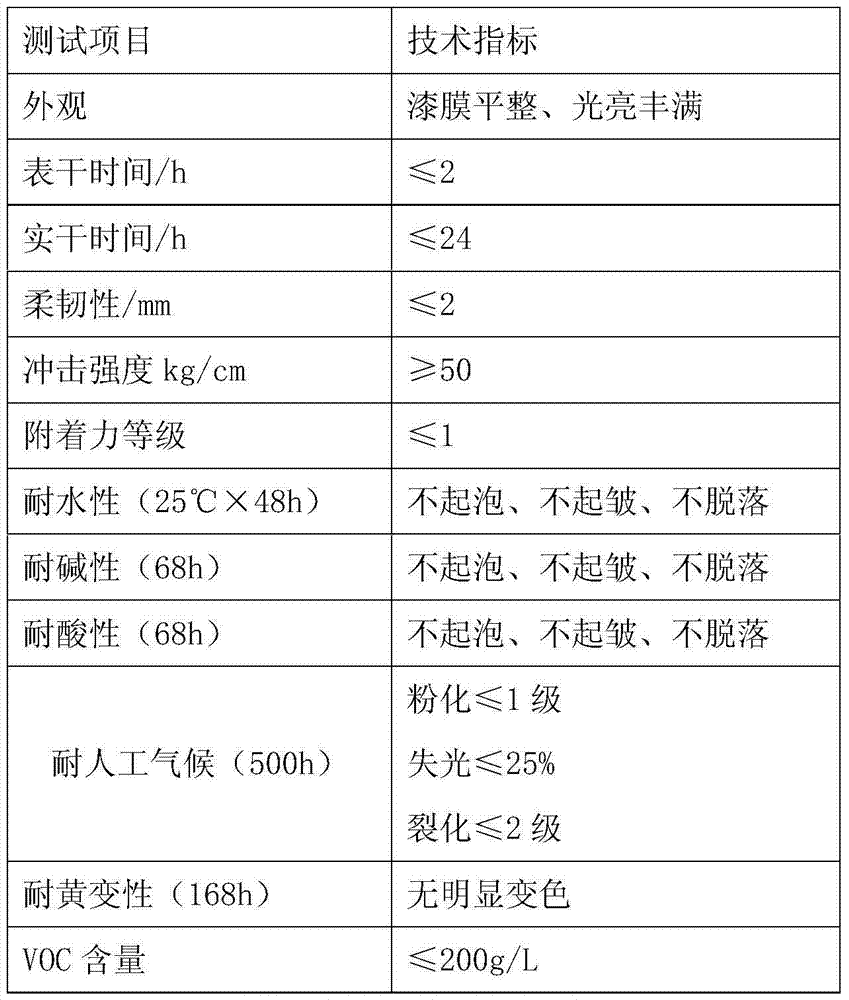

Environment-friendly anticorrosive yellowing-resistant amino resin paint

InactiveCN103694843AStrong adhesionNot easy to fall offAnti-corrosive paintsThio-Cyclohexylthiophthalimide

The invention relates to paint and particularly relates to environment-friendly anticorrosive yellowing-resistant amino resin paint. The paint disclosed by the invention is prepared from the following raw materials in parts by weight: 30-32 parts of amino resin, 10-12 parts of phenol-formaldehyde resin, 3-4 parts of aluminum tripolyphosphate, 1-2 parts of zinc phosphate, 2-3 parts of zinc oxide, 2-3 parts of sodium dehydroacetate, 3-5 parts of rutile titanium white, 3-5 parts of isopropanol, 5-8 parts of ethoxylated trimethylolpropane triacrylate, 1-2 parts of tetrabutylphosphonium chloride, 4-5 parts of cycloalkane dicarboxylic monoester, 2-3 parts of styrene, 4-5 parts of N-cyclohexyl-thio-phthalimide, 2-3 parts of titanate coupling agent TMC-TTS, 5-6 parts of glycidyl acrylate, 5-6 parts of auxiliaries, 10-12 parts of xylene and 10-12 parts of butyl acetate. The paint disclosed by the invention has the advantages of strong paint film adhesion, low probability of falling, safety, environmental friendliness, rust protection, corrosion prevention, weather ageing resistance, irradiation yellowing resistance, durability in color retention, water resistance, damp resistance, safety and reliability and can be applied to the decoration and protection of objects in various environments.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Stabilizer bar bush and preparation method thereof

The invention discloses a stabilizer bar bush. The stabilizer bar bush comprises the following raw materials in parts by weight: 60 to 100 parts of natural rubber, 0 to 40 parts of butadiene rubber, 30 to 80 parts of carbon black, 1 to 3 parts of a 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1 to 3 parts of N-isopropyl-N'-phenyl-p-phenylene diamine, 0.1 to 0.5 part of N-cyclohexylthiophthalimide, 1 to 3 parts of insoluble sulfur, 0.5 to 3 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1 to 3 parts of stearic acid, 1 to 3 parts of a lubricant WB212, 1 to 3 parts of AFLUX25, 1 to 3 parts of rubber microcrystalline wax, 0 to 10 parts of erucamide and 0 to 10 parts of aromatic oil. The invention also discloses a preparation method for the above-mentioned stabilizer bar bush. The stabilizer bar bush provided by the invention has the advantages of good durability, high strength, high elongation, aging resistance and good low temperature performance.

Owner:宁国九鼎橡塑制品有限公司

Heat-resisting nylon conveyor belt rubber composite material

InactiveCN104672638AHas heat aging resistanceWith wear resistanceConveyorsCyclohexylthiophthalimideAntimony trioxide

Owner:QINGDAO ALLPOLY CONVEYOR BELT

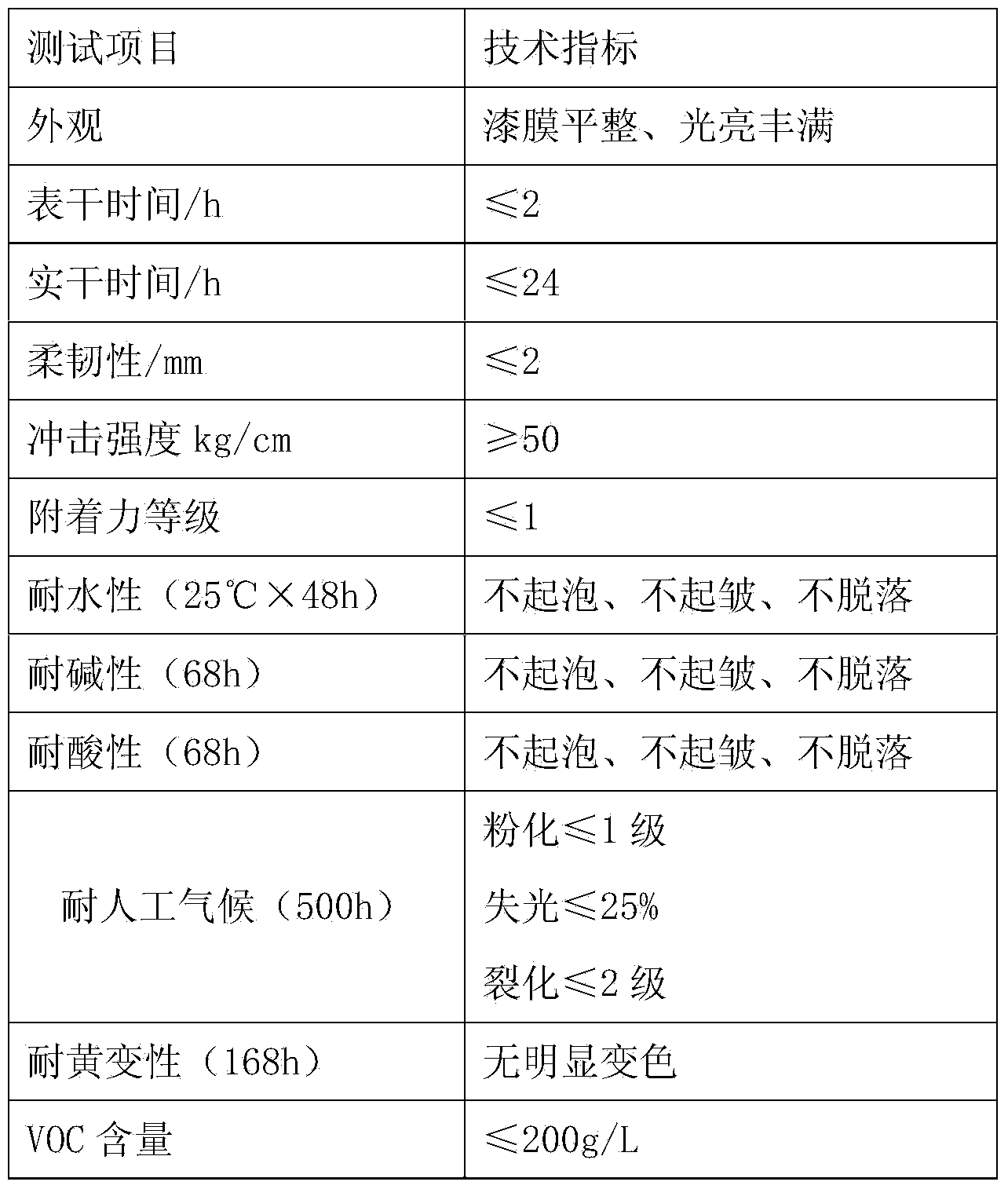

Environment-friendly antiseptic and anti-yellowing amino resin coating

InactiveCN103881443AStrong adhesionNot easy to fall offAnti-corrosive paintsCyclohexylthiophthalimideResin coating

The invention relates to an oil paint, and particularly relates to an environment-friendly antiseptic and anti-yellowing amino resin coating. The oil paint disclosed by the invention is prepared from the following raw materials in parts by weight: 30-32 parts of amino resin, 10-12 parts of phenolic resin, 3-4 parts of aluminum triphosphate, 1-2 parts of zinc phosphate, 2-3 parts of zinc oxide, 2-3 parts of sodium dehydroacetate, 3-5 parts of rutile titanium dioxide, 3-5 parts of isopropanol, 5-8 parts of ethoxide trimethylolpropane triacrylate, 1-2 parts of tetrabutylphosphonium chloride, 4-5 parts of naphthenic dicarboxylic acid monoester, 2-3 parts of styrene, 4-5 parts of N-cyclohexyl glucosinolates phthalates formyl imine, 2-3 parts of titanate coupling agent TMC-TTS, 5-6 parts of glycidyl acrylate, 5-6 parts of assistants, 10-12 parts of xylene and 10-12 parts of butyl acetate. The oil paint film disclosed by the invention is strong in adhesive force, not easy to fall off, safe and environment-friendly, rustproof, corrosion-resistant, ageing-resistant, irradiation yellowing-resistant, waterproof and damp-proof, safe and reliable, can keep color for a long time and can be applied to decoration and protection of objects in a plurality of environments.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Low-hysteresis-loss crown compound for solid tyres of heavy trucks

The invention belongs to the technical field of rubber production, and particularly relates to a low-hysteresis-loss crown compound for solid tyres of heavy trucks. The low-hysteresis-loss crown compound for the solid tyres of the heavy trucks comprises raw materials in parts by weight as follows: natural rubber, ethylene propylene diene monomer, carbon black N550, ester oil, poly-2,3,4-trimethyl-1,2-dihydroquinoline, microcrystalline wax, para aminobenzoic acid, zinc oxide, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, sulfur, N-cyclohexylthiophthalimide, flat pottery clay and polyolefin fibers. The crown compound has the excellent rebound resilience, so that the lower hysteresis loss is obtained; and meanwhile, the reversion resistance is kept good, the performance retention rate is basically unchanged and kept at the higher level, and the excessive sulfur phenomenon is avoided.

Owner:SHANDONG YONGTAI CHEM GROUP

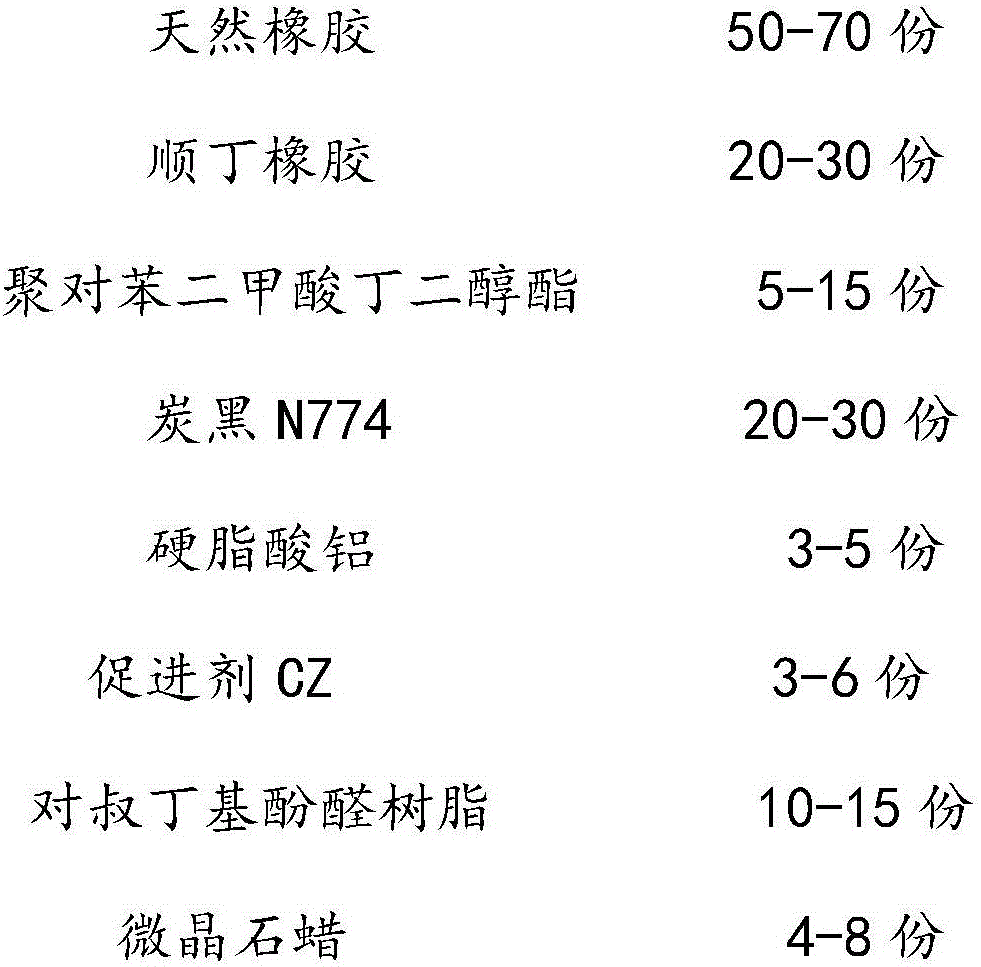

Sheathing compound for cable

InactiveCN106146930AImprove flex resistanceExtended service lifeInsulated cablesInsulated conductorsMicrocrystalline waxUltraviolet

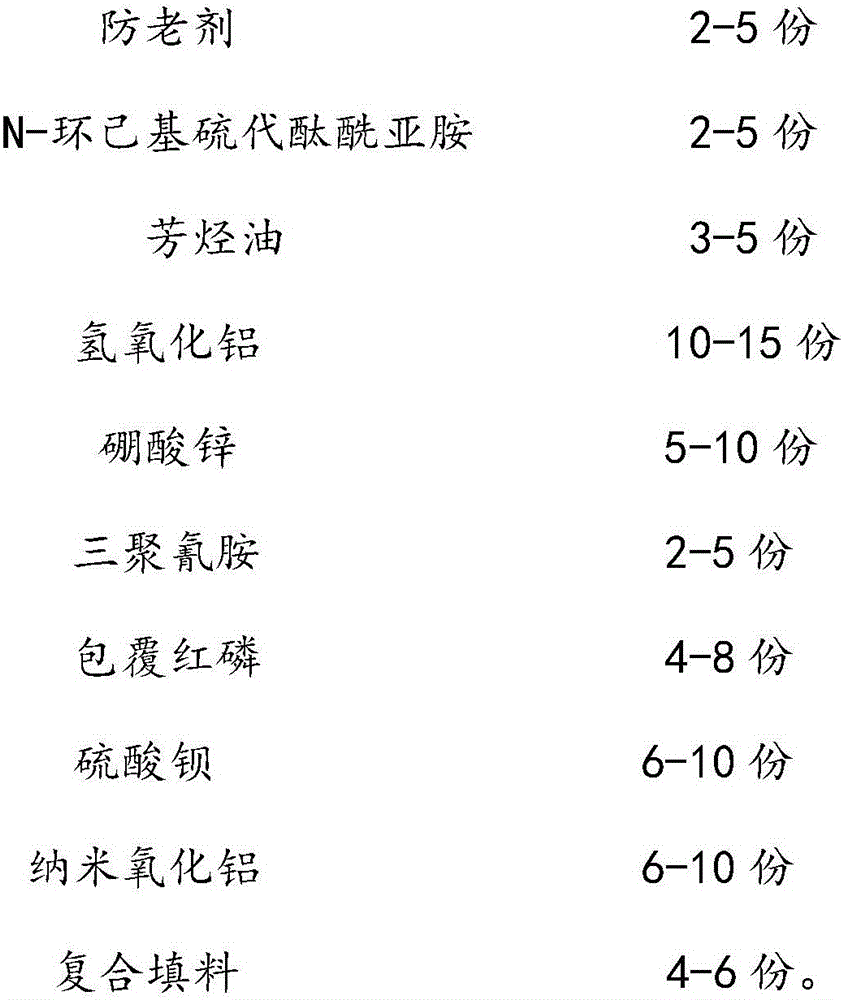

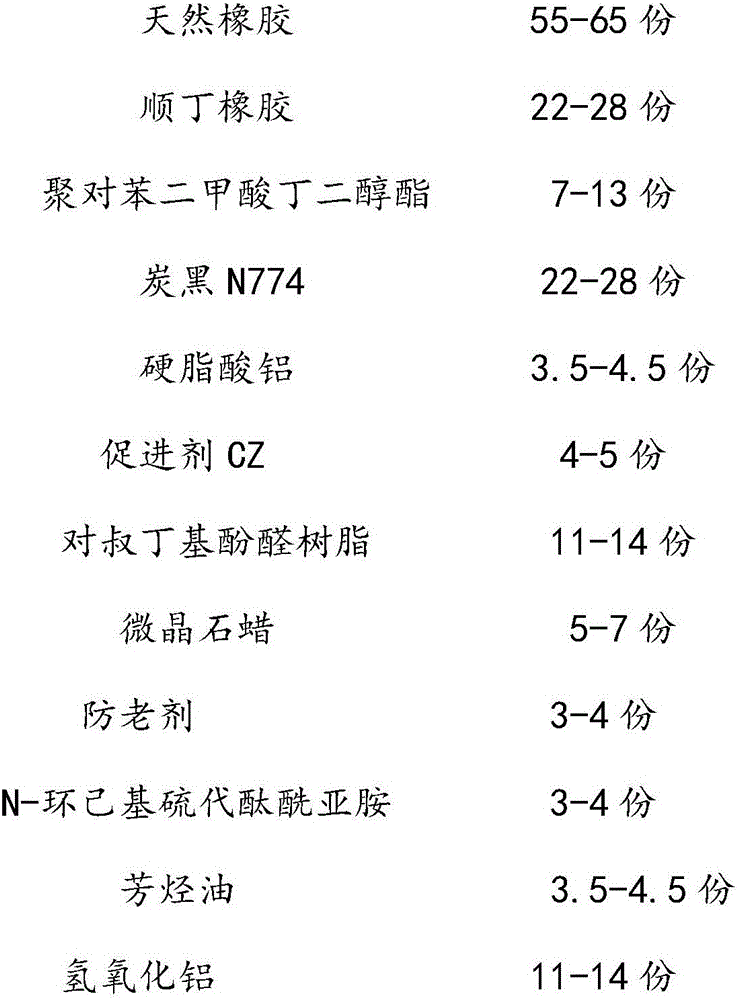

The invention discloses a sheathing compound for a cable. The sheathing compound is prepared from the following raw materials in parts by weight: 50 to 70 parts of natural rubber, 20 to 30 parts of butadiene rubber, 5 to 15 parts of polybutylene terephthalate, 20 to 30 parts of carbon black N774, 3 to 5 parts of aluminum stearate, 3 to 6 parts of promotor CZ, 10 to 15 parts of para-tert-butyl phenolic resin, 4 to 8 parts of microcrystalline wax, 2 to 5 parts of anti-aging agent, 2 to 5 parts of N-cyclohexylthiophthalimide, 3 to 5 parts of aromatic hydrocarbon oil, 10 to 15 parts of aluminum hydroxide, 5 to 10 parts of zinc borate, 2 to 5 parts of tripolycyanamide, 4 to 8 parts of encapsulated red phosphorous, 6 to 10 parts of barium sulfate, 6 to 10 parts of nanometer aluminum oxide and 4 to 6 parts of composite filler. The sheathing compound disclosed by the invention has the advantages of excellent properties of heat resistance, wear resistance, ageing resistance, ultraviolet ray radiation resistance, oil resistance, acid-base resistance and the like, and is durable.

Owner:安徽顺驰电缆股份有限公司

Heat-resisting and toughened modified plastic material

The invention discloses a heat-resisting and toughened modified plastic material. The heat-resisting and toughened modified plastic material is prepared from the following raw materials: epoxy resin, methylvinyl silicone rubber, polypropylene alcohol, trimethyl phosphate, dioctyl phthalate, cyclohexylthiophthalimide, kaolin, glass micro-bead, carbon black, titanium dioxide, dilead tetroxide, PE (Polyethylene) wax, glycerol, jute fiber, poly(L-lactic acid), polyhexanedioic acid, butylene terephthalate, an antioxygen, a lubricant, a silane coupling agent KH-570, a modification auxiliary agent A and a modification auxiliary agent B. The modified plastic provided by the invention has excellent heat-resisting and toughness properties.

Owner:TIANCHANG KANGNING PLASTIC TECH

Rubber material for braking

InactiveCN104292662AImprove high temperature resistanceAvoid deformationRubber materialPolymer science

The invention relates to a rubber material for braking, which is prepared from the following raw materials in parts by weight: 6-10 parts of dioctyl ester, 3-9 parts of titanium white, 8-14 parts of ethylene propylene diene monomer rubber, 3-5 parts of microcrystalline wax, 4-9 parts of hindered phenol antioxidant, 4-7 parts of trichloropropylphosphate, 4-6 parts of peroxide vulcanizing agent, 3-7 parts of hypalon, 6-8 parts of hydrogenated nitrile-butadiene rubber, 2-8 parts of semi-reinforcing carbon black, 3-9 parts of cyclohexylthio phthalimide and 1-5 parts of stearic acid. The rubber material for braking has the advantages of excellent high temperature resistance, friction resistance and low deformation tendency.

Owner:QINGDAO MEIJIALONG PACKAGING MACHINERY

High-temperature coupling agent and preparation method thereof

ActiveCN106556364AGuarantee the accuracy of thickness measurementIncrease contactUsing subsonic/sonic/ultrasonic vibration meansTO-18Coupling

The invention discloses a high-temperature coupling agent and a preparation method thereof, which belong to the technical field of industrial coupling agents. The high-temperature coupling agent is composed of the following raw materials: by weight, 40 to 43 parts of silicone oil, 33 to 37 parts of lubricating grease, 4 to 7 parts of an anti-aging agent, 2 to 5 parts of a scorch retarder and 12 to 18 parts of a filler, wherein the filler is formed by mixing titanium dioxide, kaolin powder and graphite powder according to a weight ratio of 2-4 to 5-8 to 4-7; the scorch retarder is N-cyclohexylthiophthalimide; and the anti-aging agent is antioxidant RD. the high-temperature coupling agent has a high heat-resisting temperature and high-temperature stability, and thickness measurement accuracy in a high-temperature condition can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP

Acid and alkali resistant fireproof cable and preparation method thereof

InactiveCN104861404ASoft textureWear-resistant and high-temperature resistantCopper conductorPhosphate

The invention relates to an acid and alkali resistant fireproof cable which comprises a polyvinyl chloride jacket layer, an acid and alkali resistant layer and an insulated fireproof layer from the exterior to interior, wherein a copper conductor is arranged in the insulated fireproof layer; the acid and alkali resistant layer consists of the following substances: high active magnesium oxide, silicone oil, carbon black, aluminum trioxide powder, ethylene-propylene-diene monomer rubber, butadiene-acrylonitrile rubber, stearic acid, a vulcanized body, cyclohexylthiophthalimide, decabrominated dipheny ethane and polyamide wax micro-powder; and the insulated fireproof layer consists of the following substances: acrylic resin, ammonium polyphosphate, pentaerythritol, vermiculite, expanded graphite, tri(2-chloroethyl)phosphate and poly-diorgano-siloxane. The product disclosed by the invention has the advantages of high weather resistance, deformation resistance, tensile strength, large elongation and high adaptability on base contraction and cracking deformation, is excellent in acid resistance, alkali resistance, corrosion resistance and fire resistance and is convenient to use according to the needs.

Owner:广安金侑达电业科技有限公司

High-and-low-temperature-resistant anti-aging chloroprene rubber

InactiveCN110577682AImprove anti-aging propertiesLower glass transition temperaturePolymer scienceCyclohexylthiophthalimide

The invention provides high-temperature-resistant and low-temperature-resistant anti-aging chloroprene rubber, belonging to the technical field of rubber. The high-temperature-resistant and low-temperature-resistant anti-aging chloroprene rubber of the invention comprises the following components in parts by weight: 45 to 53 parts of chloroprene rubber, 5 to 8 parts of butyl rubber, 4 to 6 parts of polyether type polyurethane rubber, 4 to 5.4 parts of light magnesium oxide, 5 to 6 parts of white carbon black, 26 to 31 parts of carbon black, 6 to 8.5 parts of a plasticizer, 3 to 4.6 parts of octylated diphenylamine, 1 to 2.3 parts of cyclohexylthiophthalimide, 0.8 to 1.4 parts of zinc oxide, 0.5 to 0.8 part of tetramethylthiuram disulfide and 0.6 to 1.1 parts of ethylene thiourea. Since thebutyl rubber and the polyether type polyurethane rubber are added into chloroprene rubber, the glass transition temperature of a final rubber product is reduced, and the low temperature resistance ofthe final rubber product is improved; and the light magnesium oxide, the octylated diphenylamine and the cyclohexylthiophthalimide in an anti-aging system can effectively improve the anti-aging capability of the rubber.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

Tire tread rubber composition and preparation method

ActiveCN102634077BImprove wear performanceReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceCyclohexylthiophthalimide

The invention relates to the technical field of rubber, in particular relates to a tire tread rubber composition. The tire tread rubber composition is characterized by taking 100 parts of natural rubber as reference, also comprising 5-10 parts of LBR-50 liquid butadiene rubber, 40-55 parts of N234 carbon black, 5-15 parts of white carbon black, 2.5-3.0 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of silane coupling agent mixed by triethoxysili tetrasulfide and inertia dispersing agent with a weight ratio of 1:1, 1-3 parts of N-(1, 3-dimethylbutyl)-N'-phenyl-p-phenylenediamine anti-aging agent, 1-2 parts of 2, 2, 4-trimethyl-1, 2-dihydroquinoline polymer anti-aging agent, 1-2 pats of Rhine wax 111 protective wax, 1-1.5 parts of sulphur, 1.0-1.5 parts of N-tert-butyl-2-benzothiazolylsulfenamide vulcanization accelerator, and 0.1-0.3 parts of cyclohexylthiophthalimide anti-scorching agent in part by weight. In the tire tread rubber composition, the tire wear property can be increased, the tire rolling resistance can be lowered, the tire slippery property is improved, and the comprehensiv use property of the tire can be enhanced.

Owner:TRIANGLE TIRE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com