Sheathing compound for cable

A cable and raw material technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor flex resistance of the sheath and cannot meet market demand, and achieve the effects of superior flex resistance, extended service life, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

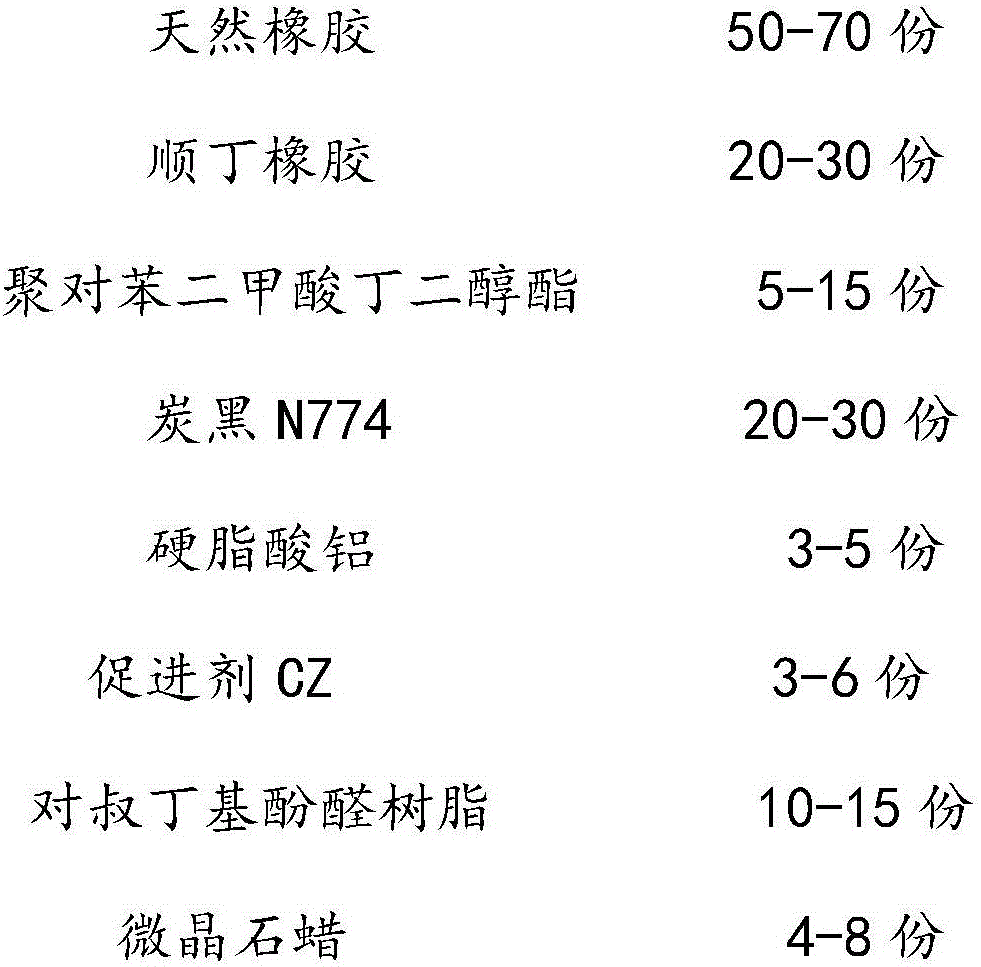

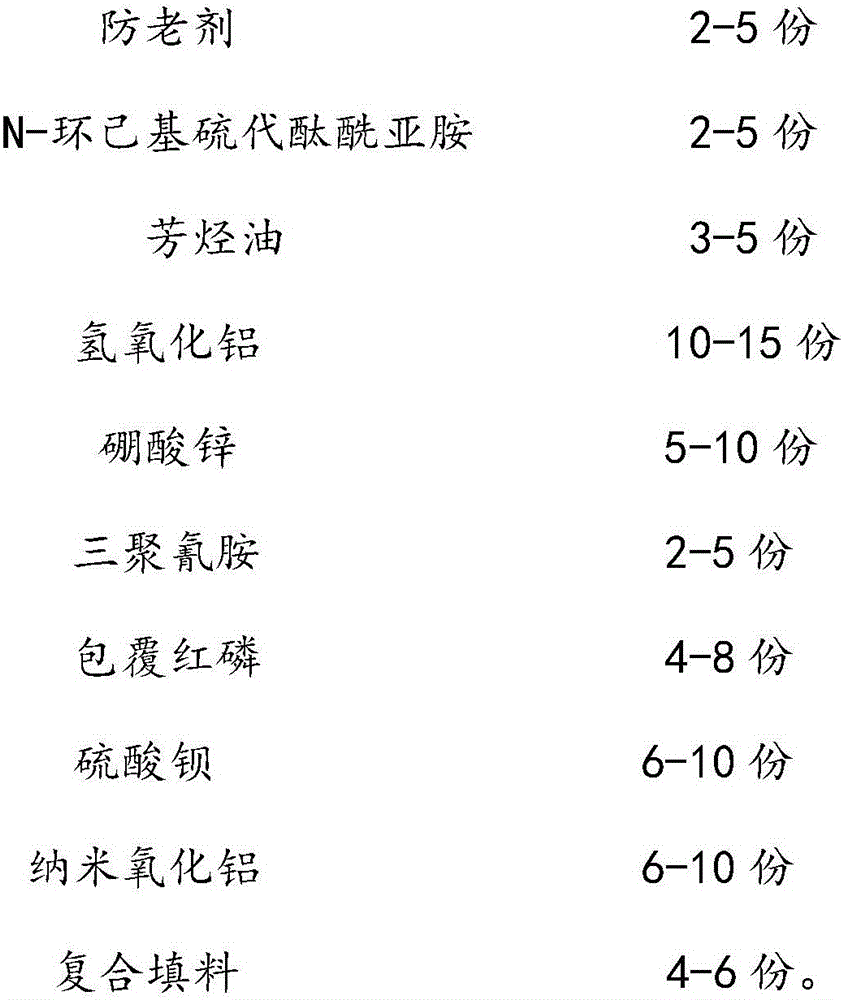

[0027] The invention provides a casing material for cables, the raw materials of which include by weight:

[0028]

[0029]

[0030] The preparation method of composite filler is as follows:

[0031] a. Weigh kaolin, pulverize and ball mill for 10 hours, then dry at 130°C, then calcinate at 550°C for 1 hour, cool to room temperature, add appropriate amount of water to make a slurry with a concentration of 40-50%, and then add A hydrochloric acid solution with a concentration of 10-15% is used to adjust the pH of the slurry to 4.0-5.0, and then a sodium hydroxide solution with a concentration of 15-20% is used to adjust the pH of the slurry to neutrality, and then sodium hexametaphosphate with a weight of 2-3% of the slurry is added , 3-5% polyacrylic acid, 2-3% water-soluble silica sol, 1-2% hydroxyethyl cellulose and 0.5-1% ethylene glycol butyl ether acetate, grind at high speed for 20-30min, bake Dry, pass through a 200-300 mesh sieve;

[0032] b. Add 1-2% nano-alum...

Embodiment 2

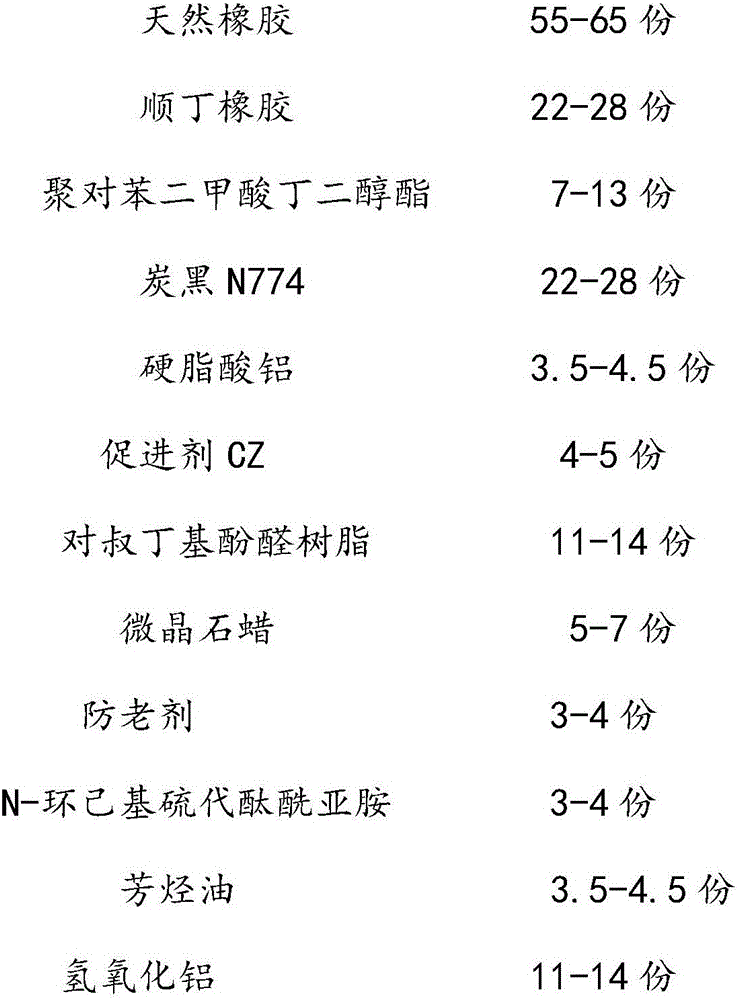

[0040] The invention provides a casing material for cables, the raw materials of which include by weight:

[0041]

[0042]

[0043] The preparation method of composite filler is as follows:

[0044] a. Weigh kaolin, pulverize and ball mill for 10 hours, then dry at 130°C, then calcinate at 550°C for 1 hour, cool to room temperature, add appropriate amount of water to make a slurry with a concentration of 40-50%, and then add A hydrochloric acid solution with a concentration of 10-15% is used to adjust the pH of the slurry to 4.0-5.0, and then a sodium hydroxide solution with a concentration of 15-20% is used to adjust the pH of the slurry to neutrality, and then sodium hexametaphosphate with a weight of 2-3% of the slurry is added , 3-5% polyacrylic acid, 2-3% water-soluble silica sol, 1-2% hydroxyethyl cellulose and 0.5-1% ethylene glycol butyl ether acetate, grind at high speed for 20-30min, bake Dry, pass through a 200-300 mesh sieve;

[0045] b. Add 1-2% nano-alum...

Embodiment 3

[0053] The invention provides a casing material for cables, the raw materials of which include by weight:

[0054]

[0055]

[0056] The preparation method of composite filler is as follows:

[0057] a. Weigh kaolin, pulverize and ball mill for 10 hours, then dry at 130°C, then calcinate at 550°C for 1 hour, cool to room temperature, add appropriate amount of water to make a slurry with a concentration of 40-50%, and then add A hydrochloric acid solution with a concentration of 10-15% is used to adjust the pH of the slurry to 4.0-5.0, and then a sodium hydroxide solution with a concentration of 15-20% is used to adjust the pH of the slurry to neutrality, and then sodium hexametaphosphate with a weight of 2-3% of the slurry is added , 3-5% polyacrylic acid, 2-3% water-soluble silica sol, 1-2% hydroxyethyl cellulose and 0.5-1% ethylene glycol butyl ether acetate, grind at high speed for 20-30min, bake Dry, pass through a 200-300 mesh sieve;

[0058] b. Add 1-2% nano-alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com