Method for preparing nano alumina fiber film material

A technology of nano-alumina and nano-fiber membranes, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., and can solve the problem of less research on quasi-one-dimensional nano-alumina fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

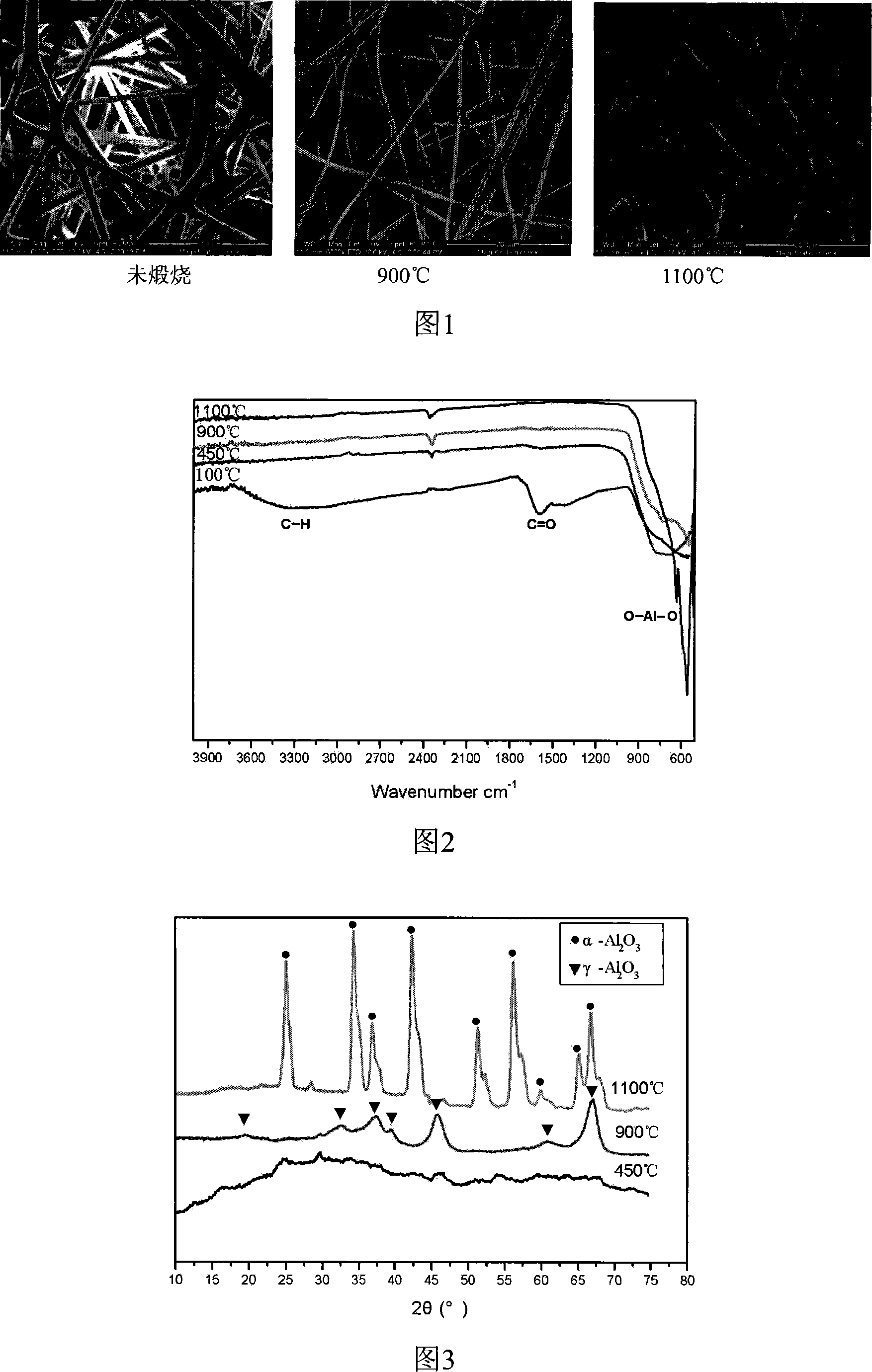

[0022] Take 3g of polyvinylpyrrolidone with a viscosity-average molecular weight of 600,000 and pour it into 57mL of ethanol solvent, stir at a high speed until completely dissolved to obtain a 5% polyvinylpyrrolidone ethanol solution, weigh 1g of anhydrous aluminum chloride and dissolve In 9mL of distilled water, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into an electrospinning device, and extrude at a voltage of 25kV. The aluminum chloride / polyvinylpyrrolidone nanofiber membrane was electrospun under the conditions of a speed of 10mL / min and a receiving distance of 10cm; finally, the prepared aluminum chloride / polyvinylpyrrolidone nanofiber membrane was placed in a muffle furnace at 50 The temperature was raised to 450°C at a rate of °C / h, and dried for 5 hours to obtain a dry nano-alumina fiber membrane.

Embodiment 2

[0024] Take 3g of polyvinylpyrrolidone with a viscosity-average molecular weight of 900,000 and pour it into 47mL of ethanol solvent, stir at a high speed until completely dissolved, and obtain a 6% polyvinylpyrrolidone ethanol solution, weigh 2g of anhydrous aluminum chloride and dissolve In 8mL of distilled water, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into an electrospinning device, and extrude at a voltage of 30kV. The aluminum chloride / polyvinylpyrrolidone nanofiber membrane was electrospun at a speed of 5 mL / min and a receiving distance of 10 cm; finally, the prepared aluminum chloride / polyvinylpyrrolidone nanofiber membrane was placed in a muffle furnace and heated at 50 The temperature was raised to 450°C at a rate of °C / h, and calcined for 5 hours to obtain an amorphous nano-alumina fiber membrane.

Embodiment 3

[0026] Take 3g of polyvinylpyrrolidone with a viscosity-average molecular weight of 1.1 million and pour it into 40mL of ethanol solvent, stir at high speed until it is completely dissolved to obtain a 7% polyvinylpyrrolidone ethanol solution, weigh 2g of anhydrous aluminum chloride and dissolve In 10mL of distilled water, then mix the two solutions and stir at high speed for 1 hour to obtain a sol-gel electrospinning solution; inject the prepared sol-gel spinning solution into an electrospinning device, and extrude at a voltage of 30kV. The aluminum chloride / polyvinylpyrrolidone nanofiber membrane was electrospun at a speed of 8 mL / min and a receiving distance of 15 cm; finally, the prepared aluminum chloride / polyvinylpyrrolidone nanofiber membrane was placed in a muffle furnace and heated at 50 The temperature was raised to 900°C at a rate of °C / h, and calcined for 5 hours to obtain a γ-shaped nano-alumina fiber membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com