Treating method for sewage containing sodium sulfate and sodium chloride

A treatment method, a technology containing sodium sulfate, applied in the direction of heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the pollution of the environment, hinder the removal of impurities, and purify industrial sewage. and other issues to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

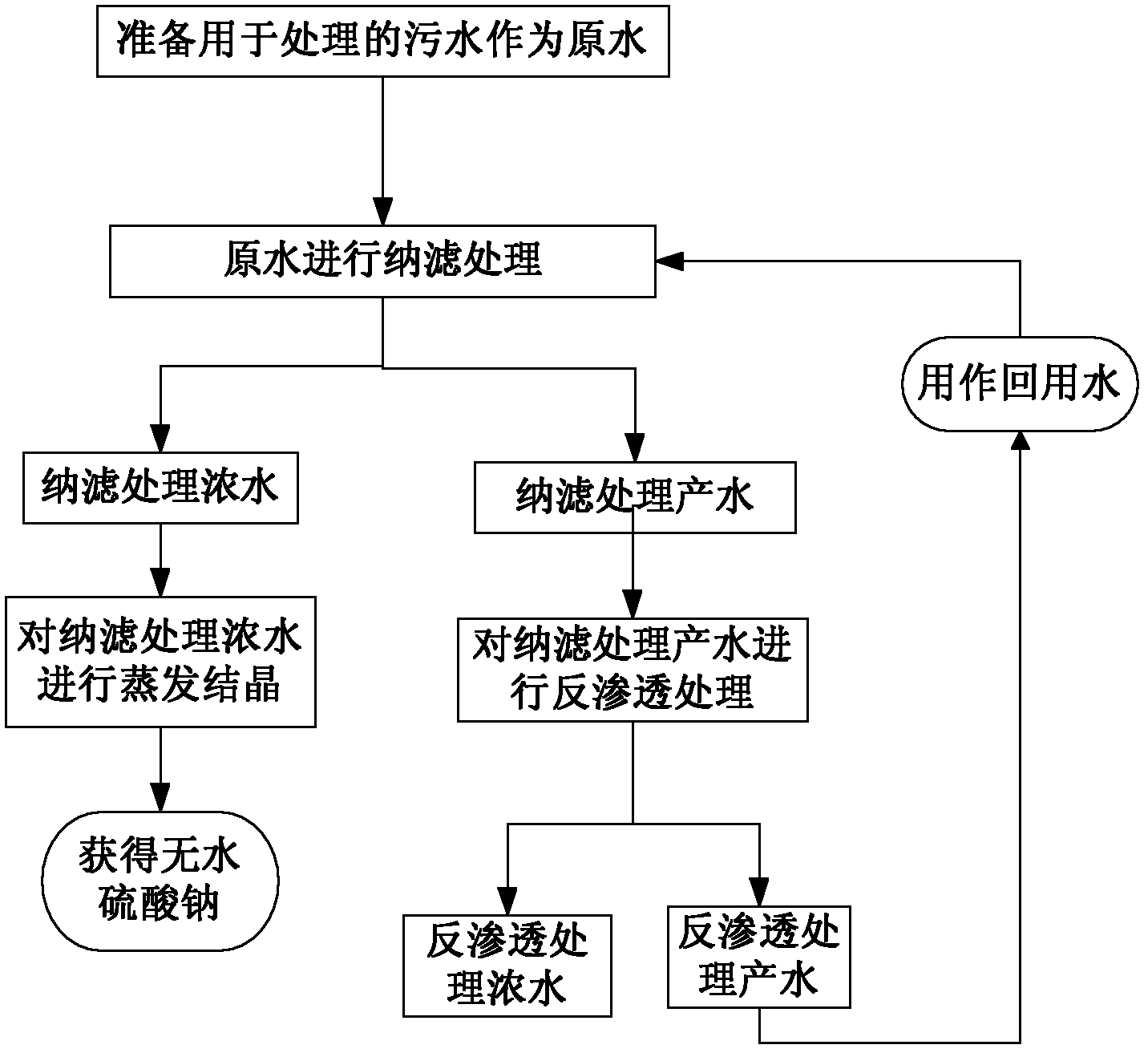

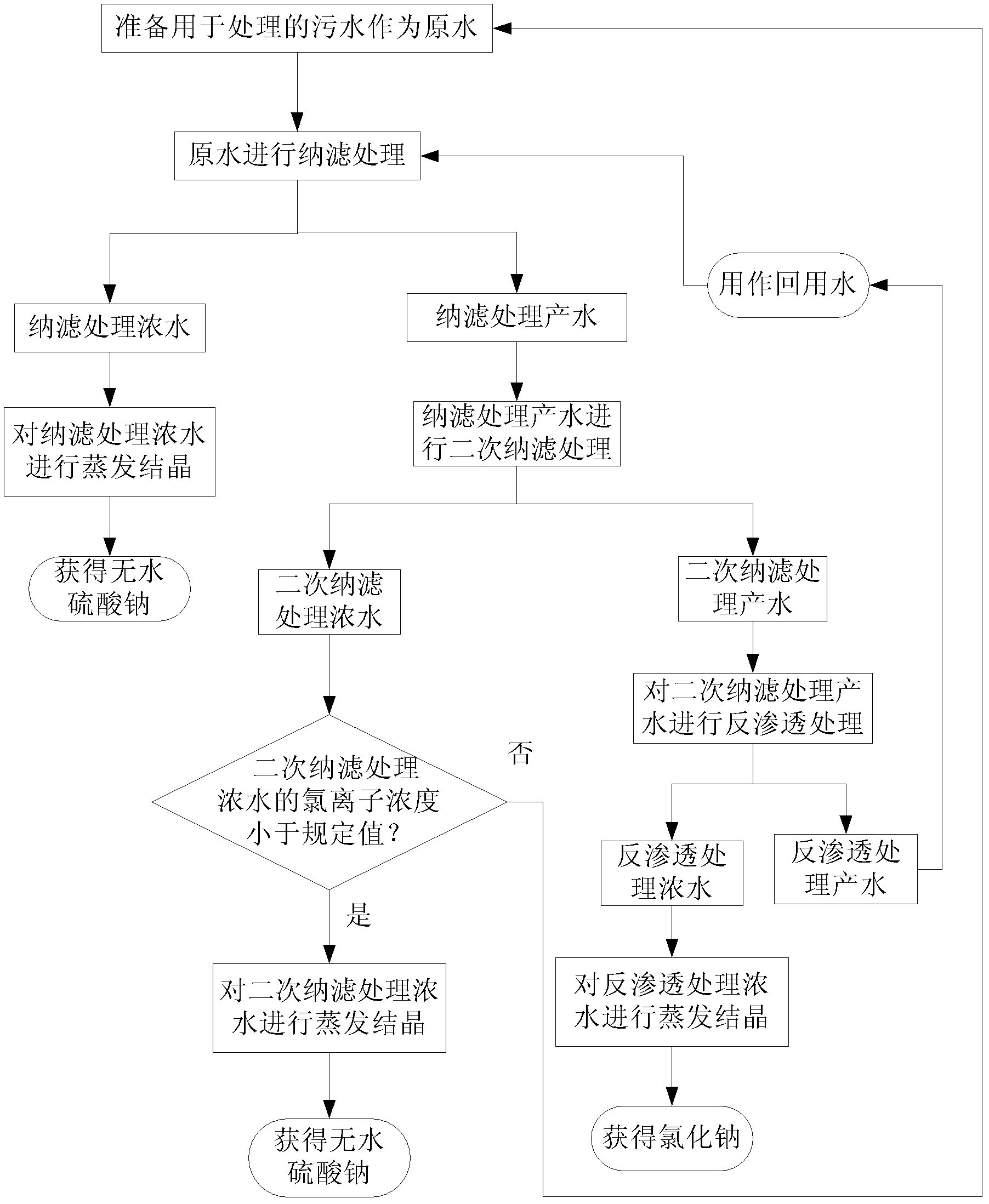

[0024] Illustrate according to the treatment method of the sewage containing sodium sulfate and sodium chloride of the present invention below in conjunction with accompanying drawing.

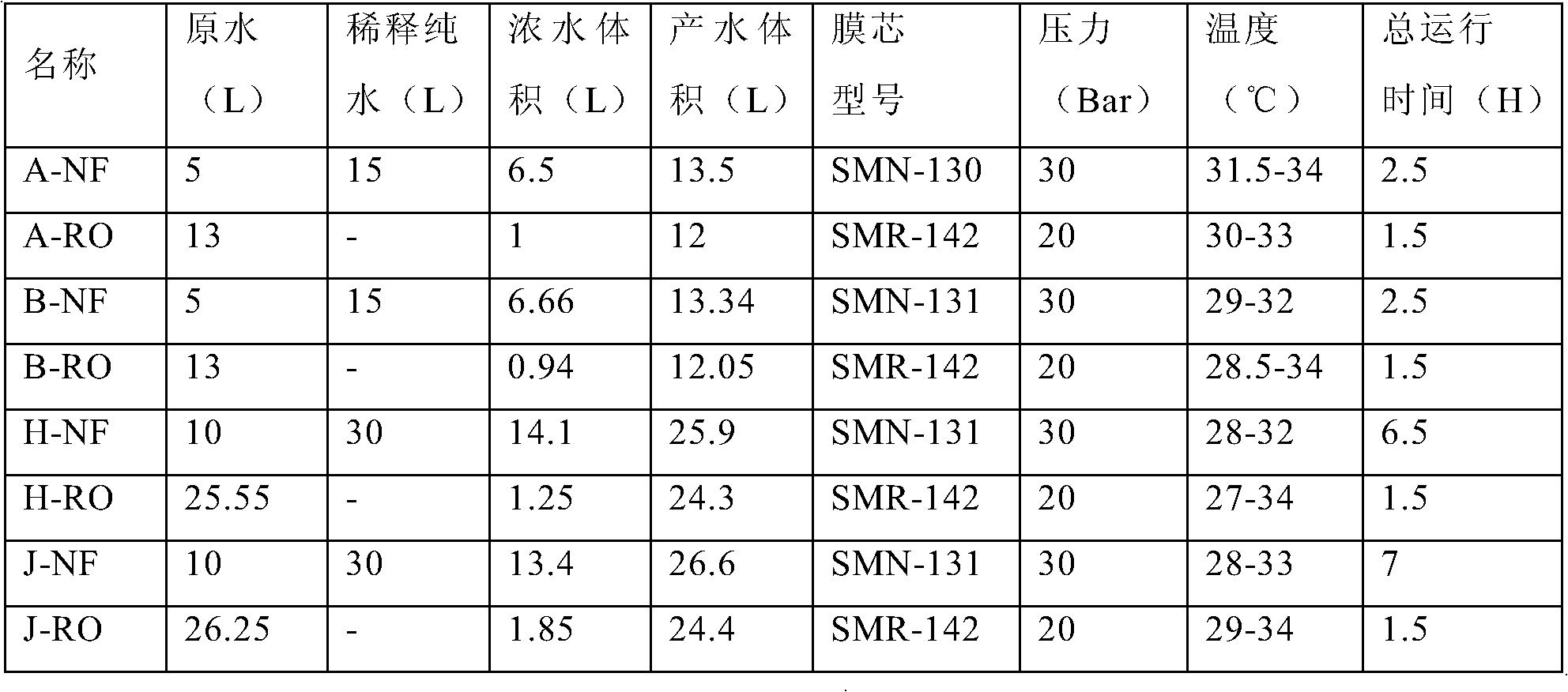

[0025] Such as figure 1 Shown, according to the treatment method of the sewage containing sodium sulfate and sodium chloride of the present invention comprises the steps: prepare the sewage for processing as raw water; water. Thus, the separation of sodium sulfate and sodium chloride in sewage is effectively realized. Preferably, the technological conditions of the nanofiltration treatment are as follows: the temperature is 5-40° C., the pressure is 15-30 bar, and the pH value of the raw water is 2-11. More preferably, the technological conditions of the nanofiltration treatment are as follows: the temperature is 28-34° C., the pressure is 30 bar, and the pH value of the raw water is 10-11. Preferably, the nanofiltration membrane is an organic roll composite nanofiltration membrane. For ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com