Method for mining and machining water-soluble potassium salt mine

A potash mine, water-soluble technology, applied in the fields of mining fluids, earthwork drilling, alkali metal chlorides, etc., can solve problems such as being unfavorable to large-scale production, unable to fully utilize geothermal heat, and low brine concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

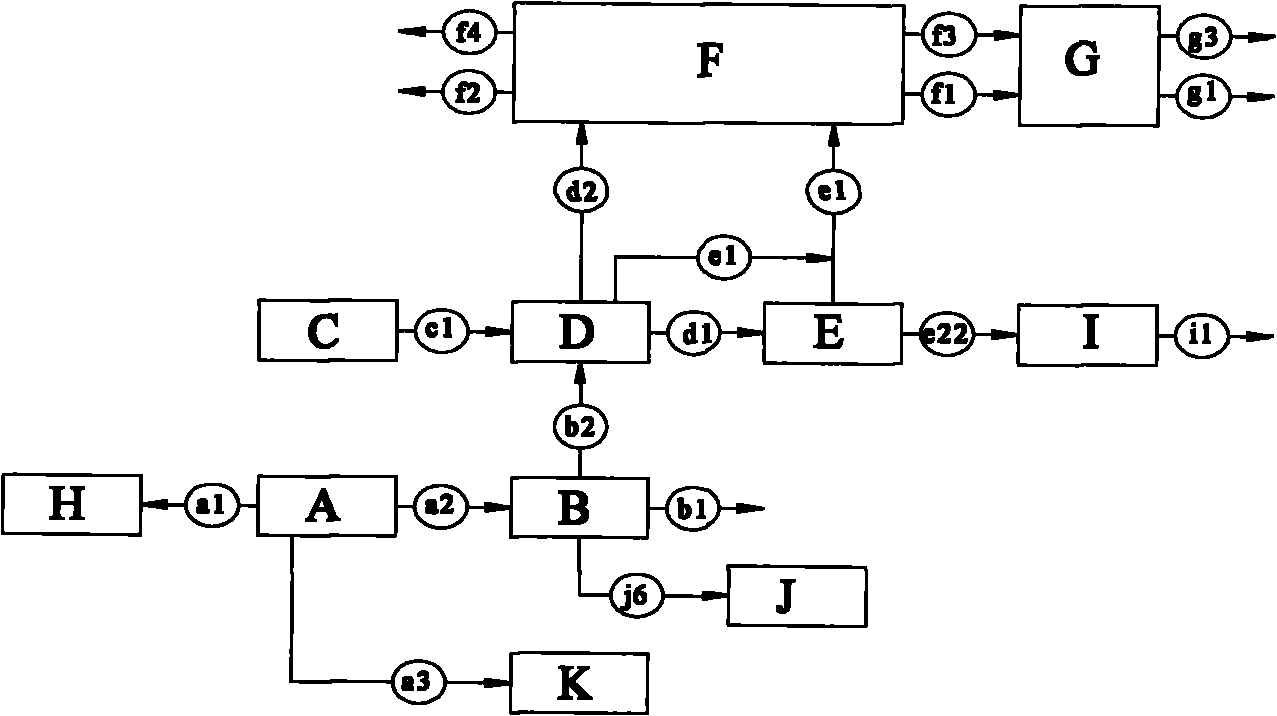

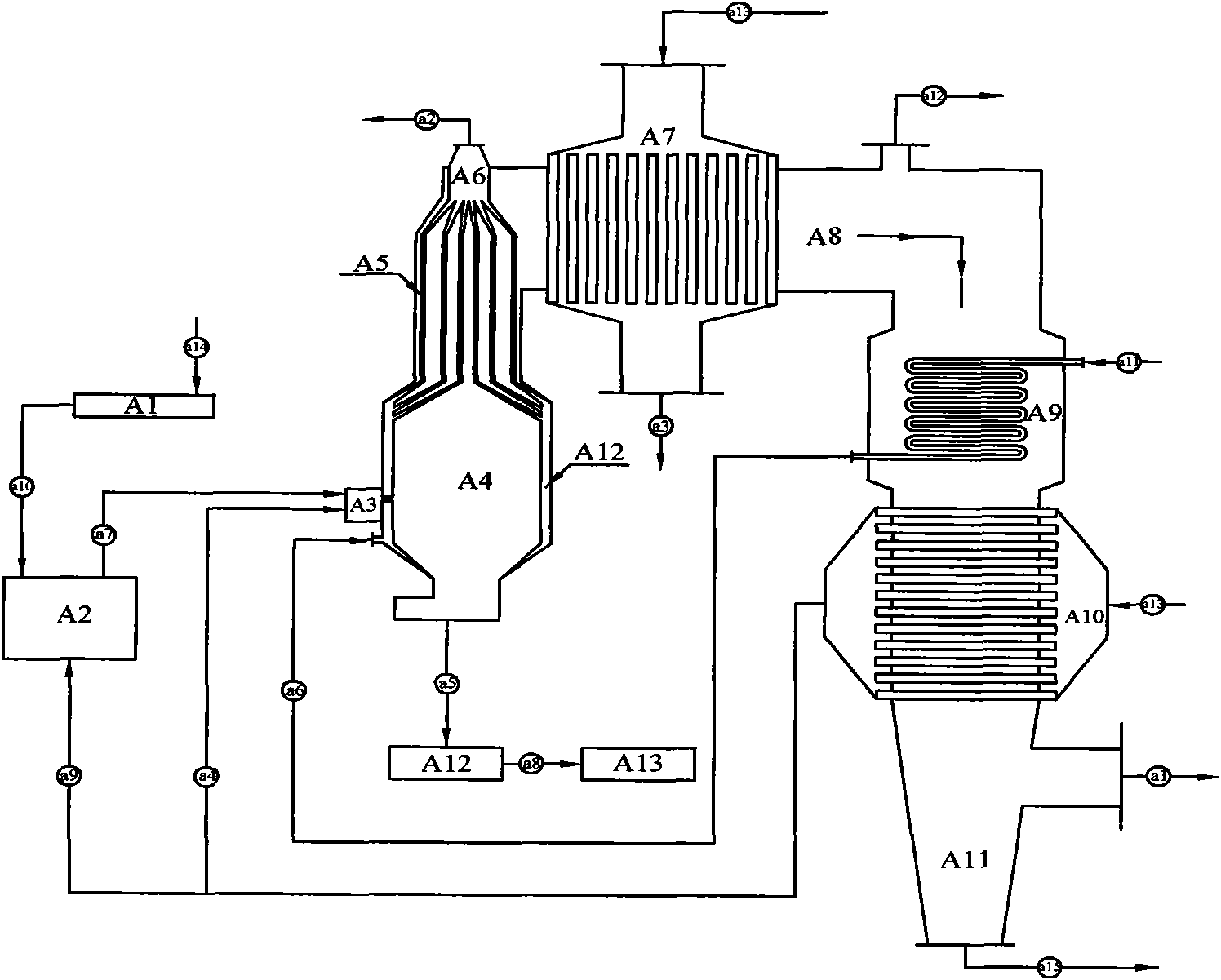

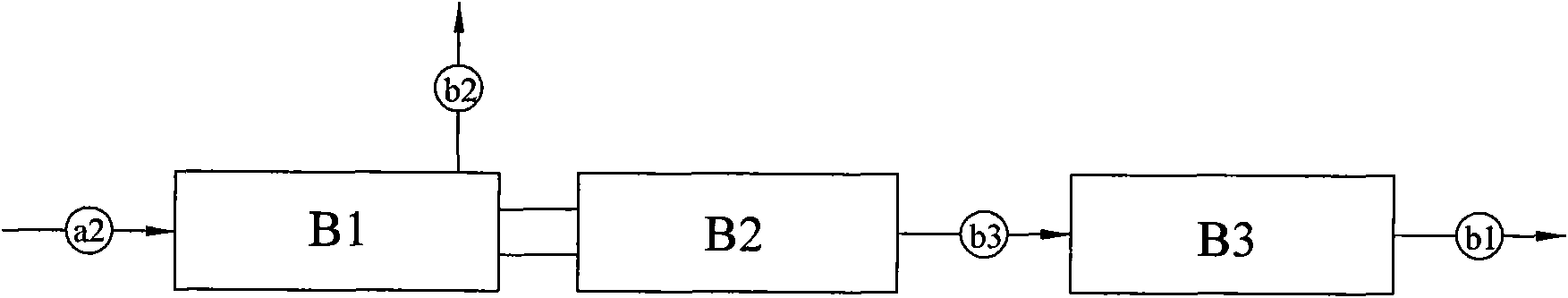

Method used

Image

Examples

Embodiment 1

[0266] Drilling and mining part:

[0267] Taking carnallite ore as an example, when the buried depth of the mine is 150-600 meters, the total thickness of the ore layer is 1.5-75m, the content of potassium oxide is 6%-22%, and the content of sodium chloride is 10%-40%. The drilling method is as follows: Drill a vertical well on the ground with an ordinary drilling rig, and the diameter of the final hole is 240mm. After reaching 100 meters above the mine floor, the inclination is increased, and the horizontal drilling is used when reaching the mine floor. The vertical well in the middle is drilled at a distance of 1600 meters from the first well in the rectangular limited area. The diameter of the final hole is 150 mm. For horizontal drilling, dock with the horizontal section of the first well, then drill horizontally in the opposite direction, and repeat this until the distance between the vertical wells at both ends reaches 3,200 meters. Alloy steel pipes with a diameter of 2...

Embodiment 2

[0286] Drilling and mining part:

[0287] Taking potassium halite as an example, when the buried depth of the mine is 1500-4500 meters, the total thickness of the ore seam is 0.95-55m, the content of potassium oxide is 6%-24%, and the content of sodium chloride is 20%-40%, the following drilling methods are adopted:

[0288] Ordinary drilling rigs are used to drill vertical wells on the ground. The diameter of the final hole is 120mm. After reaching 100 meters above the mine floor, the inclination is increased. When reaching the mine floor, horizontal drilling is used for horizontal drilling. The horizontal drilling distance is 600m. In the limited area, at a distance of 1,200 meters from the first well, the vertical well in the middle is drilled, the diameter of the final hole is 85mm, and after reaching 100 meters above the floor of the mine, the inclination is increased, and the floor of the mine is changed to horizontal drilling. Dock with the horizontal section of the fir...

Embodiment 3

[0305] Drilling and mining part:

[0306] Taking potash rock salt mine as an example, when the buried depth of the mine is below 4500 meters, the total thickness of the ore seam is 2.5-35m, the content of potassium oxide is 6%-30%, and the content of sodium chloride is 20%-40%, the following drilling methods are adopted:

[0307] Ordinary drilling rigs are used to drill vertical wells on the ground. The diameter of the final hole is 120mm. After reaching 150 meters above the mine floor, the inclination is increased. When reaching the mine floor, horizontal drilling is used for horizontal drilling. The horizontal drilling distance is 1000m. 2,000 meters away from the first well in the limited area, the vertical well in the middle is drilled down, the diameter of the final hole is 85mm, and after 150 meters above the bottom of the mine, the inclination is increased, and the bottom of the mine is changed to horizontal drilling. Dock with the horizontal section of the first well, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com