Acesulfame synthesis and acylation production process

A production process, the technology of acesulfame potassium, applied in the direction of organic chemistry, sulfuric acid amide preparation, etc., can solve the problems of long process reaction time, high production cost, low conversion rate, etc., to shorten the reaction time, improve production efficiency, and reduce impurities The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

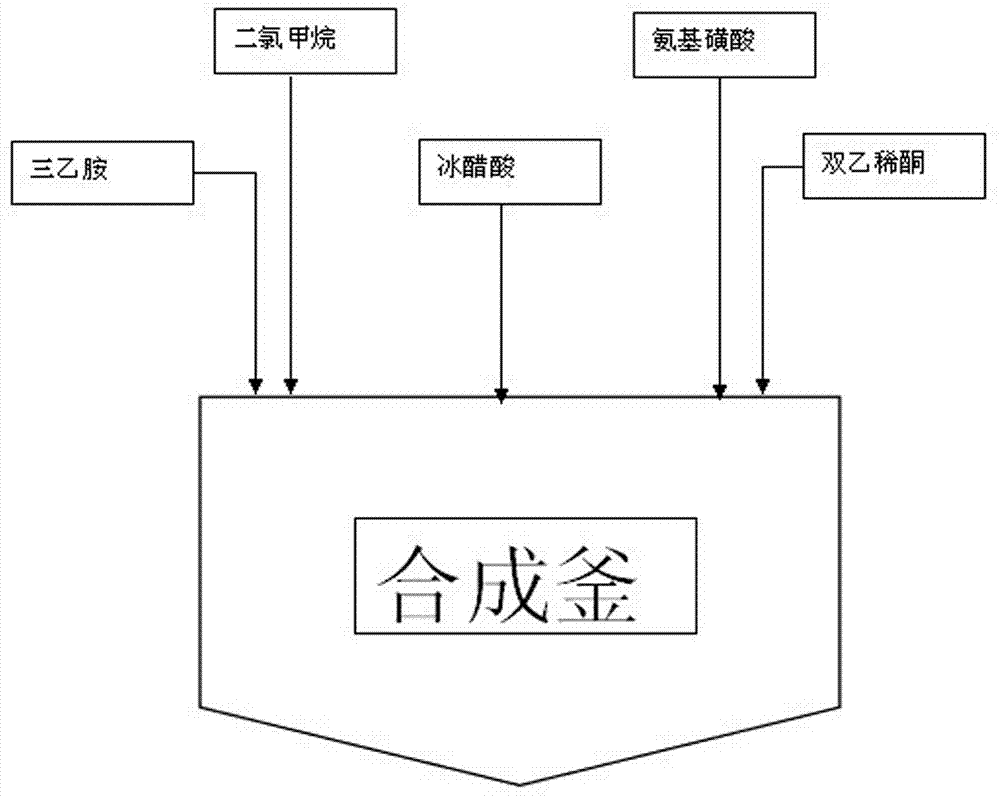

Image

Examples

Embodiment 1

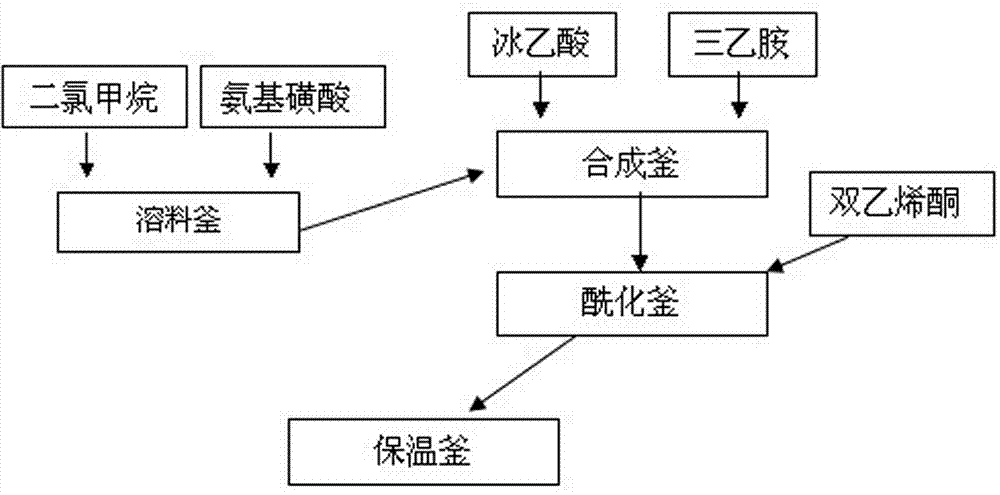

[0019] Example 1, such as figure 2 Shown:

[0020] 1. Accurately batch 3325kg (2500L) of dichloromethane, open the valve of the dichloromethane metering tank, add 2000L of dichloromethane into the dry material melting kettle, start the stirring and circulation pump; put in 1000kg of sulfamic acid from the feeding hole. Close the circulation valve, open the feeding valve, and send the mixed material in the melting tank to the dry synthesis tank. After feeding, the remaining 500L dichloromethane in the metering tank was put into the material dissolving kettle, and then sent into the synthesis kettle after circulation (dichloromethane and sulfamic acid are just mixed together, without chemical reaction, so use 500L dichloromethane Chloromethane flushes the remaining sulfamic acid in the dissolving kettle to ensure that the batching process is accurate at normal temperature. The feeding process of the dissolving kettle is carried out at normal temperature).

[0021] 2. Turn on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com