Preparation method of special epoxy resin for aqueous ultraviolet solidifying coating

A technology of epoxy resin and curing coating, applied in epoxy resin coatings, coatings, latex paints, etc., can solve the problems of slow reaction speed, affecting reaction conversion rate, and increasing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

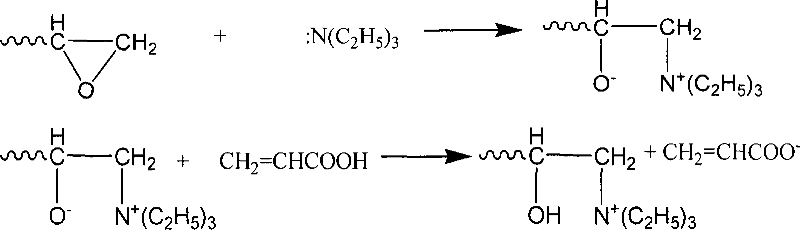

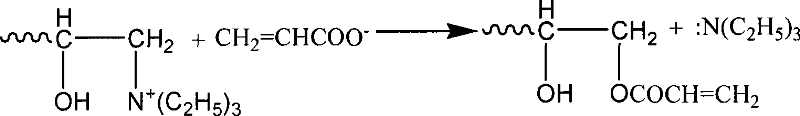

Method used

Image

Examples

Embodiment 1

[0038] The technique of the present embodiment is: a, according to proportioning bisphenol A type epoxy resin and acrylic acid are raw material by the mol ratio of epoxy group and acrylic acid is 0.95~1.05: 0.95~1.05 feeds intake, bisphenol A type epoxy resin epoxy The equivalent is 186g / eq. Add the catalyst triethylamine to account for 8‰ of the mass ratio of the reaction system and the polymerization inhibitor p-hydroxyanisole 6‰, react at 90°C for 1.5 hours, and react until the mass concentration of acrylic acid drops by 40-50%, then raise the temperature to 110°C and react for 5.5 hour, generate epoxy acrylate;

[0039] b. React maleic anhydride and epoxy acrylate in a molar ratio of 0.8:1.0 to generate water-based epoxy acrylate, add catalyst triethylamine to account for 8‰ of reaction system mass ratio and polymerization inhibitor p-hydroxyanisole 6‰, The reaction temperature was 80°C. The reaction time is 60 minutes, and dimethylethanolamine is added for neutralizatio...

Embodiment 2

[0045] The technique of the present embodiment is: a, according to proportioning bisphenol A type epoxy resin and acrylic acid are raw material by the mol ratio of epoxy group and acrylic acid is 0.95~1.05: 0.95~1.05 feeds intake, bisphenol A type epoxy resin epoxy The equivalent is 189g / eq. Add the catalyst triethylamine to account for 5‰ of the mass ratio of the reaction system and the polymerization inhibitor p-hydroxyanisole 5‰, react for 1.5 hours at 100°C, and react until the mass concentration of acrylic acid drops to 40-50%, then raise the temperature to 115°C for reaction 5.5 hours, generate epoxy acrylate;

[0046] b. Reaction of maleic anhydride and epoxy acrylate in a molar ratio of 0.9:1.0 to generate water-based epoxy acrylate, adding catalyst triethylamine accounted for 5‰ of reaction system mass ratio and polymerization inhibitor p-hydroxyanisole 5‰, The reaction temperature was 80°C. The reaction time is 90 minutes, and dimethylethanolamine is added for neut...

Embodiment 3

[0052] The technique of present embodiment is: a, by proportioning bisphenol A type epoxy resin and acrylic acid are raw material and be 0.95~1.05: 0.95~1.05 feed intake by the mol ratio of epoxy group and acrylic acid. Add the catalyst triethylamine to account for 3‰ of the mass ratio of the reaction system and the polymerization inhibitor p-hydroxyanisole 4‰, react for 2 hours at 100°C, and react until the mass concentration of acrylic acid drops to 40-50%, then raise the temperature to 115°C for reaction 5 hours, generate epoxy acrylate;

[0053] b. React maleic anhydride and epoxy acrylate in a molar ratio of 1.0:1.05 to generate water-based epoxy acrylate, add catalyst triethylamine to account for 3‰ of reaction system mass ratio and polymerization inhibitor p-hydroxyanisole 4‰, The reaction temperature was 85°C. The reaction time is 90 minutes, and dimethylethanolamine is added for neutralization. Add pure water to form a water-based epoxy acrylate with a solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com