Preparing method of polyimide aerogels and hybrid aerogels thereof

A polyimide and airgel technology, applied in the field of airgel, can solve the problems of large specific surface area, high porosity, low thermal conductivity, etc., achieve high specific surface area, reduce shrinkage, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

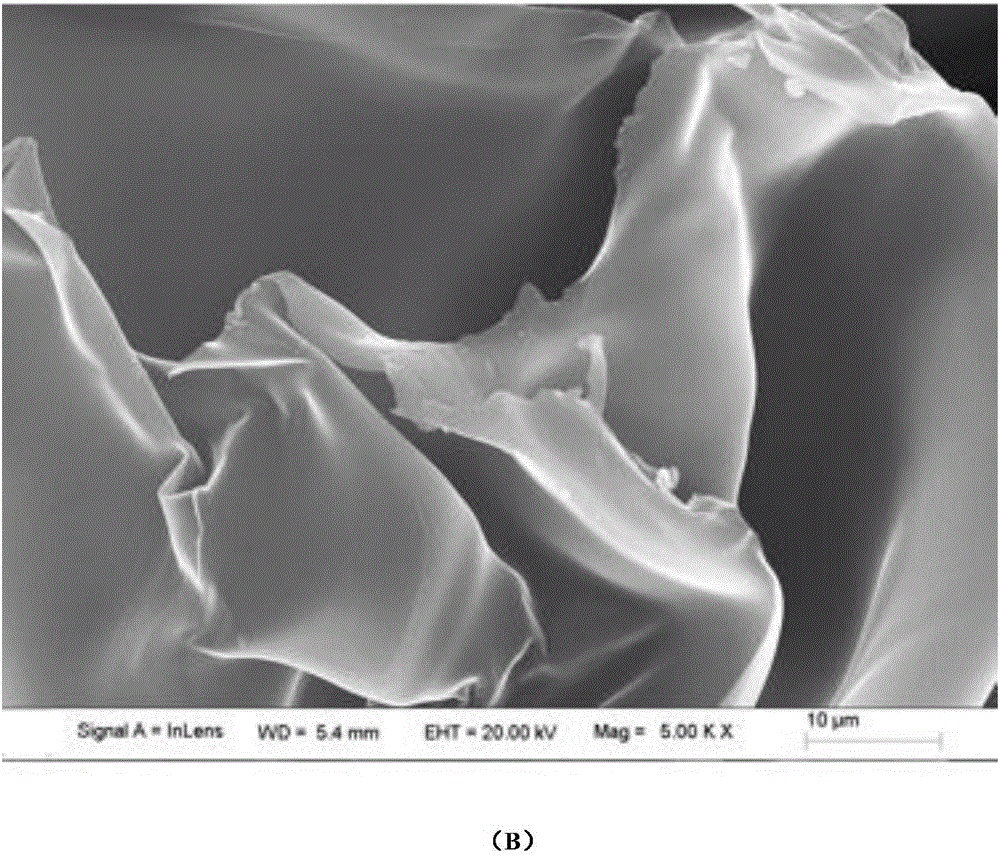

[0050] Embodiment 1, preparation of solid content 2% BPDA / ODA polyimide airgel:

[0051] 1) Weigh 1g of polyamic acid precipitated fiber, 49ml of deionized water, and 1.23g of triethylamine (TEA), stir magnetically, and dissolve for 2 hours. Divide into three 50ml syringes, and the thickness of the sample should not exceed 3cm.

[0052] 2) Put it into a refrigerator or liquid nitrogen to freeze into a solid, pull out the piston, and freeze-dry for 48 hours.

[0053] 3) Place the obtained polyamic acid airgel in a nitrogen atmosphere to control the temperature program, that is, heat up from room temperature to 135°C for 60 minutes, and keep it for 1h; Amine airgel, denoted as PI-0.

[0054] The obtained airgel is light yellow and cylindrical airgel with dense structure and flat surface, with a thickness of 1.2cm, a diameter of 1.35cm, and a density of 0.0676g / cm 3 . The dielectric constant is 1.2, and the dielectric loss is 10 -3 -10 -5 between. When the compression rate...

Embodiment 2

[0055] Example 2, preparation of solid content 2% BPDA / ODA polyimide-graphene nanocomposite airgel:

[0056] 1) Weigh 60mg of graphene oxide powder, dissolve it in 49ml of deionized water, and seal it for 0.5h. Add 1.23g triethylamine, 1g polyamic acid precipitation fiber magnetic stirring, dissolve for 3h to form a homogeneous dilute solution, 200W, ultrasonic for 20min.

[0057] 2) Put it in the refrigerator to freeze into a solid, freeze-dry for 48 hours, and obtain the polyamic acid-graphene oxide nanocomposite airgel.

[0058] 3) Put the obtained polyamic acid-graphene oxide nanocomposite airgel in a tube furnace in a nitrogen atmosphere to control the temperature program, that is, from room temperature to 135°C for 60 minutes, and keep it for 1 hour; from 135°C to 300°C, heat up for 90 minutes , and keep warm for 2h; the polyimide-graphene nanocomposite airgel can be obtained, which is denoted as rGO-PI-60.

[0059] The obtained hybrid airgel is a black, cylindrical ai...

Embodiment 3

[0060] Example 3, preparation of solid content 2% BPDA / ODA polyimide / -OH carbon nanotube nanocomposite airgel:

[0061] 1) Weigh 80mg-OH carbon nanotube powder, dissolve it in 49ml deionized water, crush the cells with 800W power, and sonicate for 30min. Add 1.23g triethylamine, 1g polyamic acid precipitation fiber magnetic stirring, dissolve for 3h to form a homogeneous dilute solution, 200W, ultrasonic for 20min.

[0062] 2) Put it in the refrigerator to freeze into a solid, and freeze-dry for 48 hours to obtain polyamic acid / -OH carbon nanotube nanocomposite airgel.

[0063] 3) Put the obtained polyamic acid / -OH carbon nanotube nanocomposite airgel in a tube furnace in a nitrogen atmosphere to control the temperature program, that is, from room temperature to 135 ° C for 60 minutes, and keep it for 1 hour; 135 ° C to 300 ° C , heating up for 90min, and keeping warm for 2h; the polyimide / -OH carbon nanotube nanocomposite aerogel can be obtained, denoted as -OH CNTs-PI-80. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com