Method for separating ternary alloy of lead, tin and stibium

A ternary alloy and lead separation technology, applied in the direction of improving process efficiency, etc., can solve problems such as long segregation time, easy oxidation of antimony, intermittent operation, etc., achieve good separation effect, high recovery rate, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

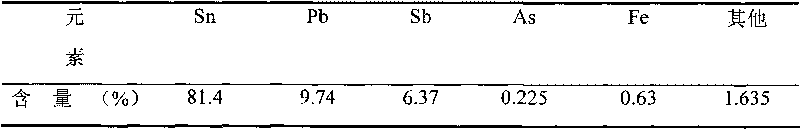

[0017] Table 1 The weight percentage of raw materials

[0018]

[0019] Put 1500g of raw materials into a graphite crucible and place them in a vacuum furnace. Pump the vacuum of the vacuum furnace to 5~15Pa; start to heat up at a rate of 5℃ / min. When the temperature in the furnace rises to the melting point of raw materials 480℃, keep the temperature constant for 50min , Then heat up to 950°C at a rate of 15°C / min, keep the temperature for 20 minutes and then to 1200°C at a rate of 15°C / min for 40 minutes, turn off the power to start cooling, continue to open the vacuum pump to ensure the vacuum environment in the furnace and prevent materials After being oxidized, when the temperature in the furnace drops to 60-100°C, the vacuum pump is turned off, the furnace is opened to take materials, and the residues and volatiles are respectively recovered and tested. The product composition obtained is shown in Table 2.

[0020] Table 2 Product ingredient weight percentage

[0021]

[0022]...

Embodiment 2

[0024] Table 3 The weight percentage of raw materials

[0025]

[0026] Put 2000g of raw material into a graphite crucible and place it in a vacuum furnace, pump it to 5~15Pa, and raise the temperature at a rate of 5℃ / min. When the temperature in the furnace rises to the melting point of the raw material 410℃, keep it at a constant temperature for 50min, then 15℃ / The temperature is increased to 950°C at a rate of min for 10 minutes, and then to 1200°C at a rate of 15°C / min for 40 minutes. The lead-antimony alloy volatilizes completely. Turn off the power and start cooling to ensure the vacuum environment in the furnace. When the temperature in the furnace drops At 60°C, the vacuum pump was turned off, the furnace was opened to take materials, and the residues and volatiles were recovered and tested respectively. The product composition obtained is shown in Table 4.

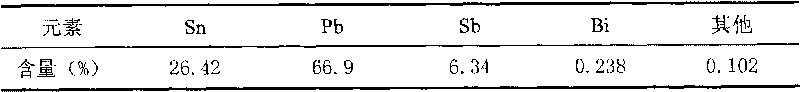

[0027] Table 4 Product ingredient weight percentage

[0028]

[0029] The recovery rates of lead, tin, and antimony ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com