Method for preparing 5-hydroxymethylfurfural by degrading carbonhydrate through ionic liquid

A technology of carbohydrates and hydroxymethylfurfural, applied in the direction of organic chemistry, can solve the problem of difficult separation of products, achieve the effect of short reaction time, simple device, and promotion of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

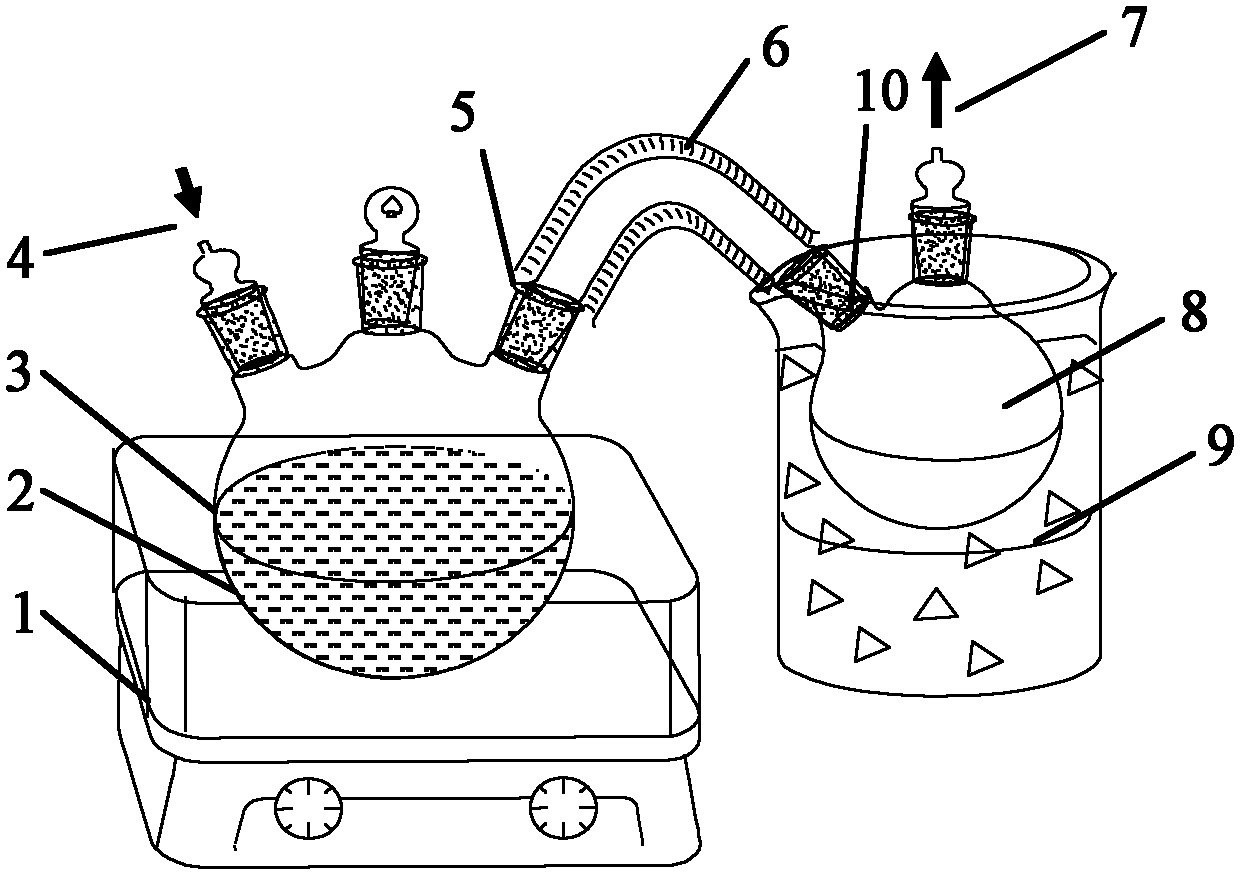

[0028] use as figure 1 Shown reaction unit, a kind of method that ionic liquid degrades carbohydrate and prepares 5-hydroxymethylfurfural (5-HMF) is as follows:

[0029] Weigh 20 g of [OMIM]Cl and place it in reactor 3 of a three-necked flask, and raise the temperature of the oil bath to 180°C. Weigh 2g fructose and 0.065g IrCl 3 ·(1-2)H 2 O (approximately equivalent to 7 mol% of the amount of fructose) was quickly added to reactor 3 of the three-necked flask. Nitrogen gas was introduced as an entrainer, and the high vacuum oil pump was started to continuously evacuate the reaction system, maintaining the vacuum degree at 300Pa-500Pa, and the reaction was terminated after 10 minutes. The product deposited in the connecting pipe and the two-necked flask separator 8 and the product remaining in the three-necked flask reactor 3 were collected, and the absolute mass of the product was calculated by HPLC.

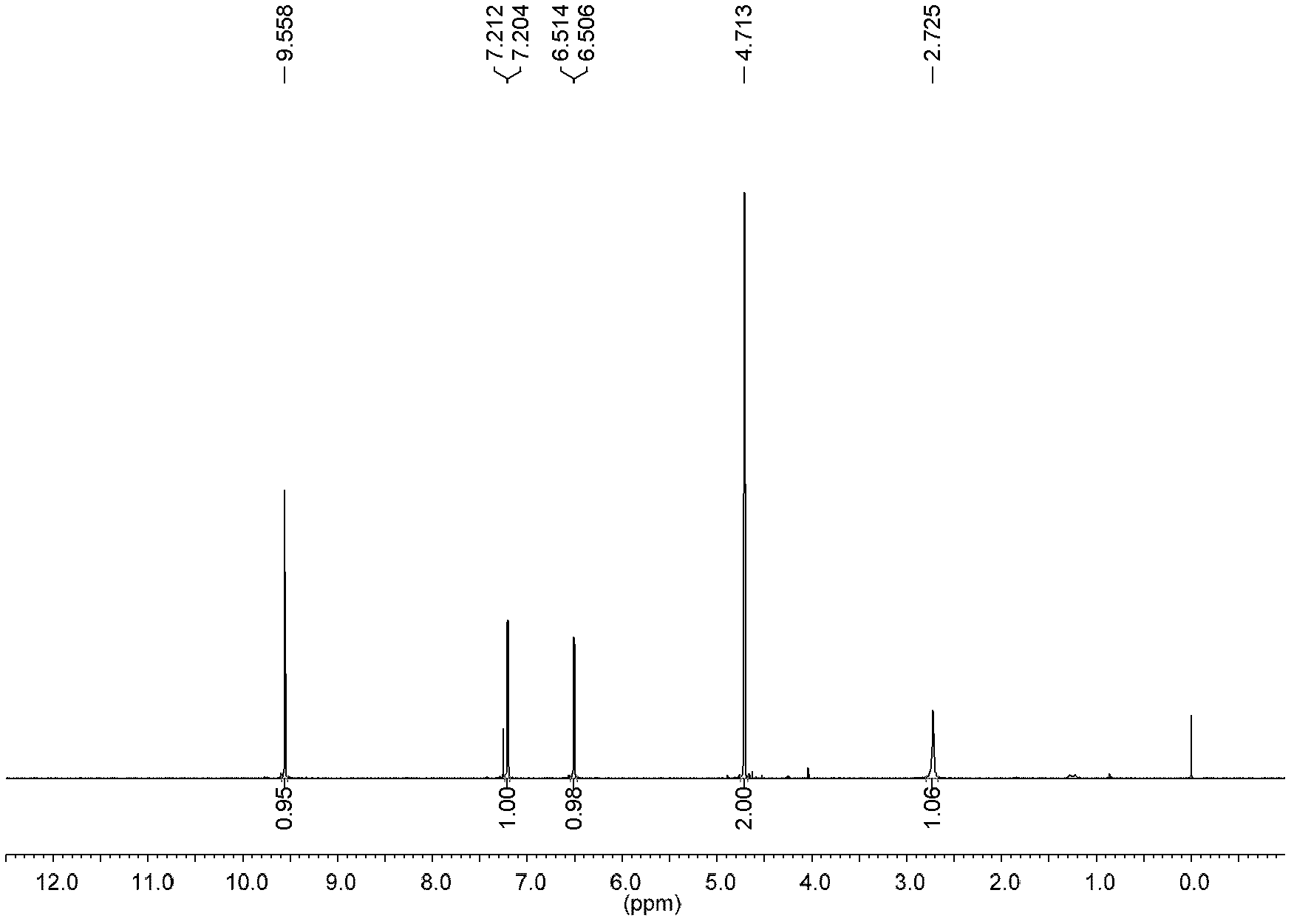

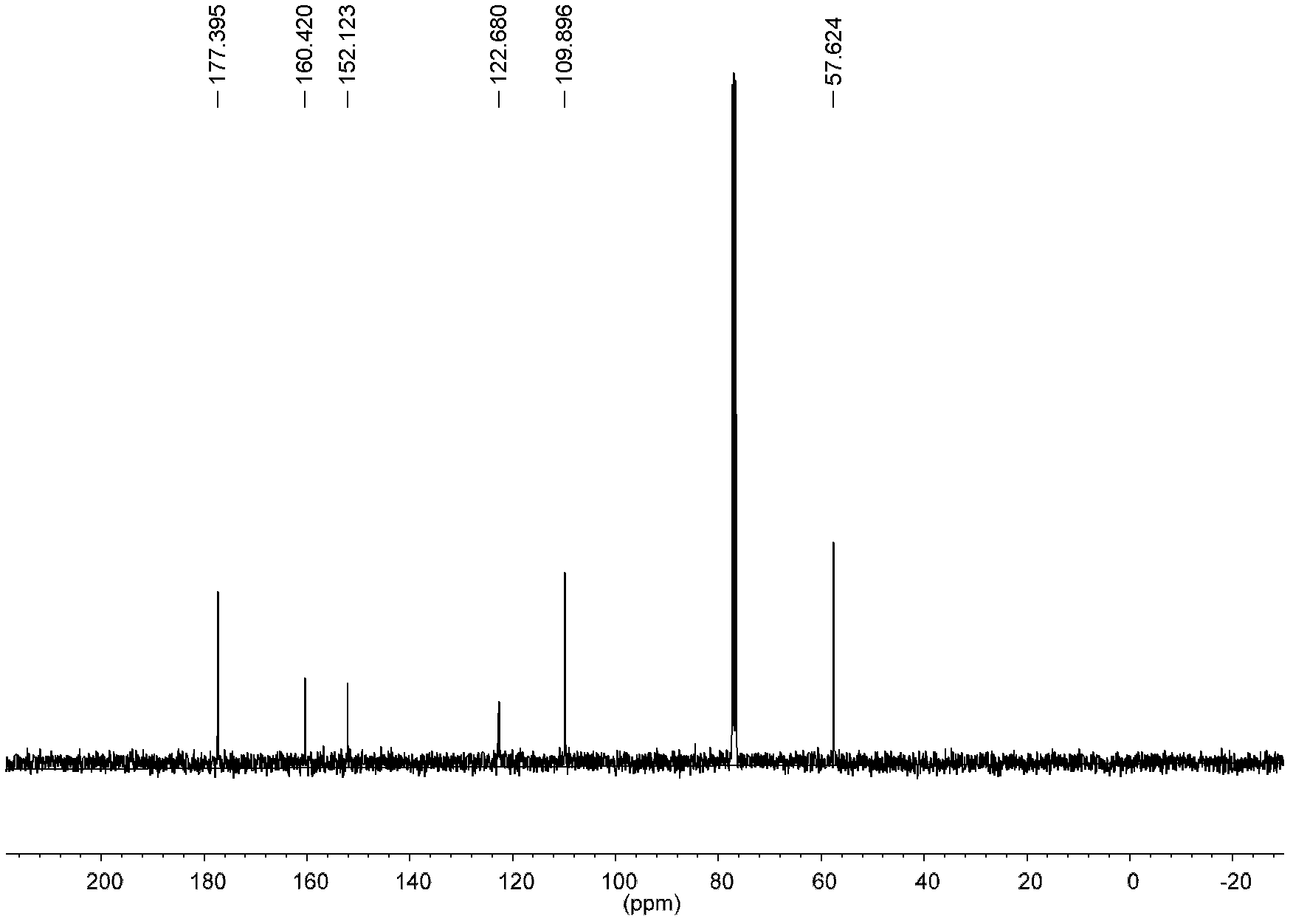

[0030] product through 1 H-NMR and 13 C-NMR to characterize, respecti...

Embodiment 2~16

[0034] Take the same method and process as Example 1 to prepare 5-hydroxymethylfurfural, the difference is only in the reaction substrate and reaction conditions.

[0035] In Examples 2-16, the ionic liquid is [OMIM]Cl, the entrainer is nitrogen, n-hexane or methyl isobutyl ketone organic vapor, and the vacuum degree of the reaction system is maintained at 300-500Pa.

[0036] When the carbohydrate is fructose, the raw material ratio is: 2g carbohydrate and 0.065g IrCl 3 ·(1-2)H 2 O is dissolved in 20 g [OMIM]Cl.

[0037] When the carbohydrate is glucose, sucrose, α-starch or cellulose, the raw material ratio is: 2g carbohydrate and 0.049g CrCl 3 ·6H 2 O is dissolved in 20 g [OMIM]Cl.

[0038] The reaction substrate, entrainer, reaction temperature and reaction time taken by each embodiment are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com