Method for recycling tin from lead bullion

A crude lead and lead-tin technology, which is applied in the metallurgical field combining pyrotechnics and wet processes, can solve the problems of increasing secondary smelting costs, increasing tin recovery procedures, and high secondary smelting costs, thereby reducing refining costs and processing costs. The effect of low and high yield of tin products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

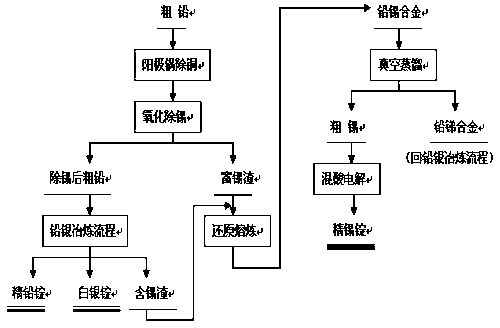

[0020] Embodiment 1: as figure 1 Shown, the concrete operation of the method for reclaiming tin in this crude lead is as follows:

[0021] (1) Crude lead originates from the sintered agglomerate after conventional sintering and desulfurization of lead concentrate and the high-leaching lead slag produced in zinc smelting, which is mixed and pressed into balls, and then reduced and smelted in a blast furnace together to contain tin-containing crude lead. After removing copper by melting in the anode pot, the composition is Pb92.68%, Sb5.02%, Cu0.052%, Sn0.92%, Ag2080g / t. Add saltpeter to 1.0 times the mass of the tin in the crude lead for oxidation, then add caustic soda to capture 1.3 times the mass of the tin in the crude lead to form sodium salt, add table salt to 0.4 times the mass of the tin in the crude lead, and make slagging when adding saltpeter additives The situation is carried out several times in batches, the temperature of the tin removal process is always kept at...

Embodiment 2

[0026] Embodiment 2: the method concrete operation of reclaiming tin in this crude lead is as follows:

[0027] (1) Crude lead originates from the sintered agglomerate after conventional sintering and desulfurization of lead concentrate and the high-leaching lead slag produced in zinc smelting, which is mixed and pressed into balls, and then reduced and smelted in a blast furnace together to contain tin-containing crude lead. The composition of crude lead after copper removal by melting in the anode pot is Pb91.83%, Sb5.21%, Cu0.050%, Sn1.37%, Ag2180g / t, the temperature of crude lead after copper removal is raised to 410°C, press Add saltpeter to 0.5 times the total amount of tin in crude lead for oxidation, then add caustic soda to capture 1.0 times the total amount of tin in crude lead to make sodium salt, add table salt according to 0.2 times the total amount of tin in crude lead, and then add saltpeter Additives etc. are carried out several times in batches depending on th...

Embodiment 3

[0032] Embodiment 3: the concrete operation of the method for reclaiming tin in this crude lead is as follows:

[0033] (1) Crude lead comes from the vacuum distillation and volatilization of low-tin crude lead purchased from a smelter. The crude lead composition after the tin-containing crude lead is smelted in the anode pot to remove copper is Pb92.05%, Sb5.11%, Cu0 .051%, Sn1.21%, Ag2109g / t, raise the temperature of the crude lead after copper removal to 410°C, add saltpeter at 0.8 times the total amount of tin in the crude lead for oxidation, and then add 1.1 times the total tin in the crude lead Add caustic soda twice to capture sodium salt, add salt at 0.1 times the total amount of tin in crude lead, and add saltpeter additives in batches for several times depending on the slagging situation. The temperature of the tin removal process is always kept at 430°C for tin removal. After 3.9 hours, the composition of the output tin removal slag is Pb35.51%, Sb3.31%, Sn11.89%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com