Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180results about How to "Reduce refining costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

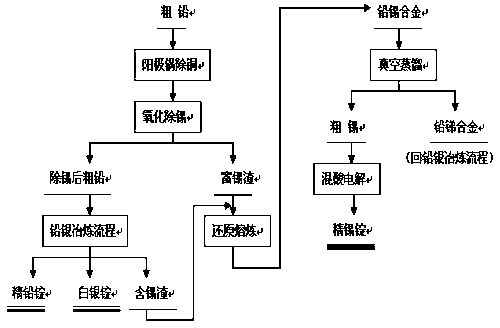

Method for recycling tin from lead bullion

InactiveCN104141152AImprove efficiencyImprove production costsPhotography auxillary processesElectrolysisLead smelting

The invention discloses a method for recycling tin from lead bullion, and belongs to the technical field of pyrogenic process and wet process combined metallurgy. The method comprises the steps that after liguation decoppering processing is carried out on the lead bullion, caustic soda, caustic soda and salt are added into the lead bullion according to the content of the tin in the lead bullion to gather and remove the tin in the lead bullion, and tin-rich slag is obtained; sodium carbonate and reduction coal are added into the tin-rich slag and all tin-containing slag produced by a lead smelting system, and the tin-rich slag and the tin-containing slag generate terne metal through reduction smelting; the terne metal is processed through vacuum distillation to obtain crude tin; highly purified precipitated tin is obtained from the crude tin through electrolytic refining of mixed acid with silicofluoric acid-sulfuric acid as an electrolytic medium, and the precipitated tin is processed through simple smelting to obtain a tin ingot product meeting the national standard. The method sets the precedent for producing tin ingot products through comprehensive utilization of tin resources obtained from lead through smelting, has the advantages of being concise in technology, high in tin product yield, low in processing cost and the like, particularly separates tin alloys through introduction of vacuum distillation, and has the significant advantages in the aspects such as energy conservation and environment protection.

Owner:蒙自矿冶有限责任公司

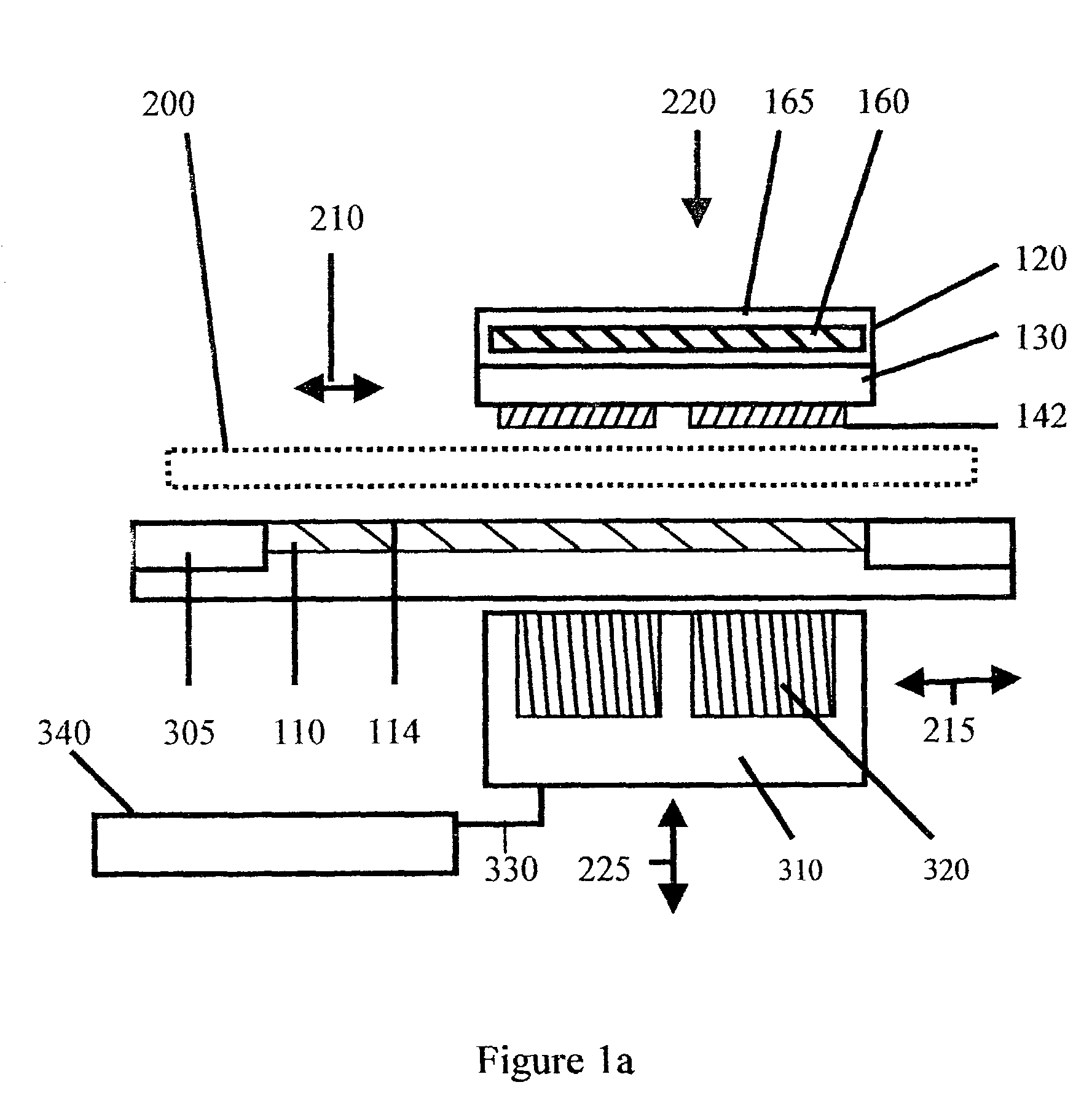

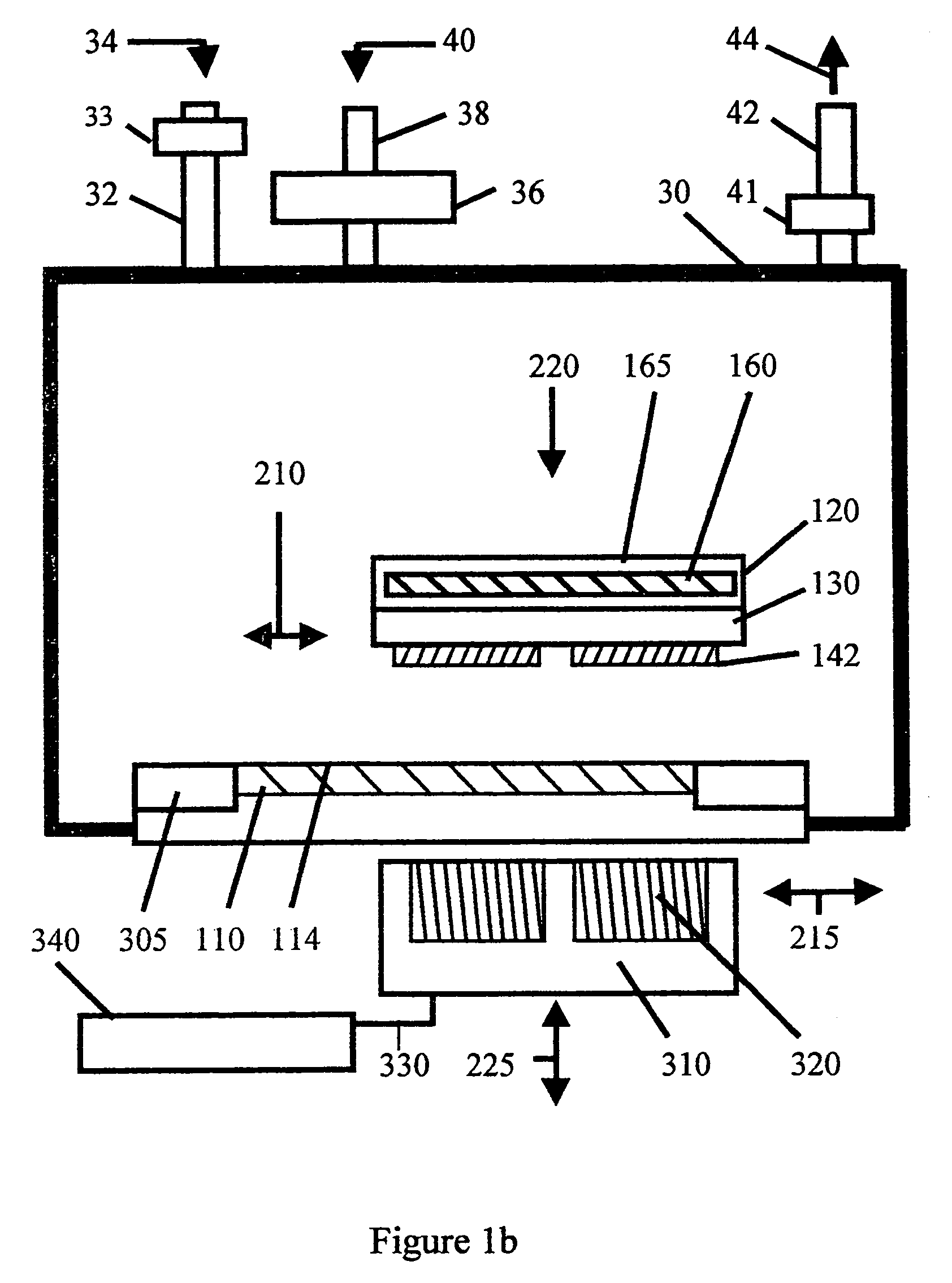

Advanced wafer refining

InactiveUS7008300B1Accessible costImprove refining methodSemiconductor/solid-state device testing/measurementSolid-state devicesManufacturing cost reductionElectrolysis

A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements solely through magnetic coupling forces to improve refining quality and versatility. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining chamber can be used. New methods of control are refining disclosed. The new magnetic refining methods, apparatus, and magnetically responsive refining elements can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductors wafers. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. A method to use business calculations combined with physical measurements to improve control is discussed. Use of business calculations to change the cost of finishing semiconductor wafers is discussed. The method can help cost of manufacture forecasting for pre-ramp-up, ramp-up, and commercial manufacture. Actively based accounting can be preferred for some applications. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

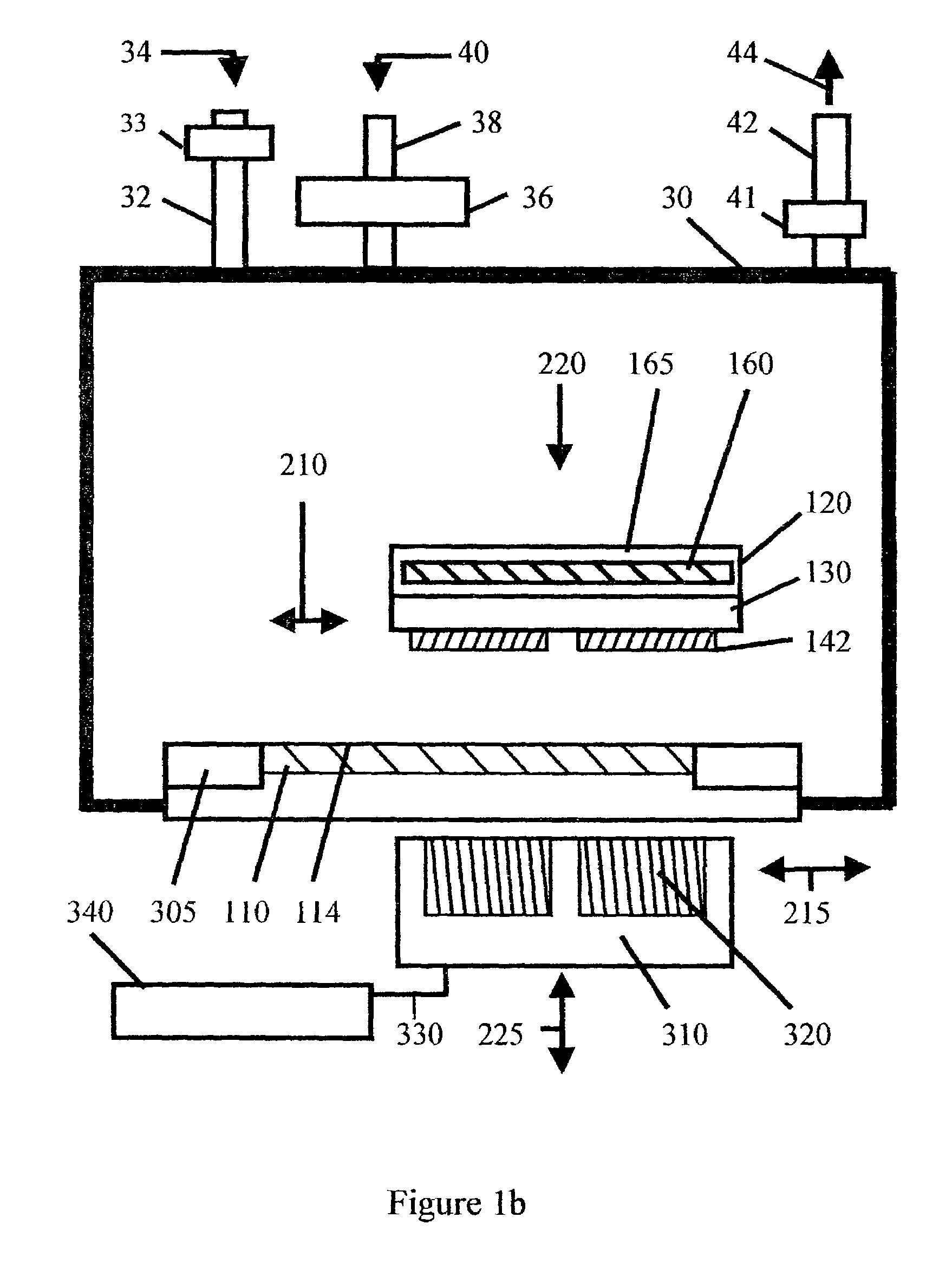

Process for producing starch sugar

ActiveCN102337316AQuality improvementImprove function and effectAnimal feeding stuffAccessory food factorsActivated carbonChaptalization

The invention discloses a process for producing starch sugar. The process comprises the following steps of: pulp-conditioning edible starch; liquefying; passing liquefied starch through a primary floating clarifier, guiding an upper floating sugar dreg liquid into a primary buffer tank, and then entering a primary disc-type centrifuge to be centrifugated and separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the primary disc-type centrifuge and a clear sugar liquid flowing out of the primary floating clarifier and flowing into a saccharifying tank to be saccharified into a saccharified liquid; passing the saccharified liquid through a secondary floating clarifier, guiding an upper floating sugar dreg liquid into a secondary buffer tank, and then enteringa secondary disc-type centrifuge to be separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the secondary disc-type centrifuge and a clear sugar liquid flowing out ofthe secondary floating scum clearing device and filtering by passing through a membrane micro-filtration system; and flowing a micro-filtered concentrated liquid containing dregs back to the secondary buffer tank, entering a micro-filtered clear sugar liquid into an ion exchange system to be decolorized and desalted, and then finally concentrating into a product. According to the process for producing the starch sugar disclosed by the invention, filter aids and activated carbon are not required in the clarification and the filtration processes, and high-purity sugar liquid can be obtained through the efficient operation of solid-liquid separation equipment; and meanwhile, sugar dregs without the filter aids and the activated carbon are extracted and can be used as a feedstuff raw materialfor animals, thereby changing waste into valuable, and no discharge of filtered solid wastes during the whole process exists.

Owner:双桥(厦门)有限公司

Versatile wafer refining

InactiveUS7377836B1Easy to organizeReduce manufacturing costElectrolysis componentsSemiconductor/solid-state device testing/measurementManufacturing cost reductionElectrolysis

Methods of refining using a plurality of refining elements are discussed. A refining apparatus having refining elements that can be smaller than the workpiece being refined are disclosed. New refining methods, refining apparatus, and refining elements disclosed. Methods of refining using frictional refining, chemical refining, tribochemical refining, and electrochemical refining and combinations thereof are disclosed. A refining apparatus having magnetically responsive refining elements that can be smaller than the workpiece being refined are disclosed. The refining apparatus can supply a parallel refining motion to the refining element(s) for example through magnetic coupling forces. The refining apparatus can supply multiple different parallel refining motions to multiple different refining elements for example solely through magnetic coupling forces to improve refining quality and versatility. A refining chamber can be used. New methods of control are refining disclosed. The new refining methods, including magnetic refining methods, apparatus, and refining elements, including magnetically responsive refining elements, can help improve yield and lower the cost of manufacture for refining of workpieces having extremely close tolerances such as semiconductor wafers. New methods of control are also discussed. Methods and apparatus which use processor readable memory devices are discussed. Refining fluids are preferred. Reactive refining aids are preferred. Electro-refining for adding and removing material is disclosed. New methods and new apparatus for non-steady state refining control are disclosed.

Owner:SEMCON TECH

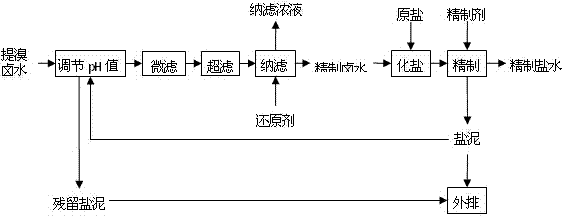

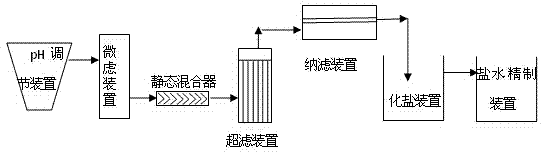

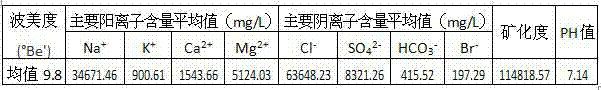

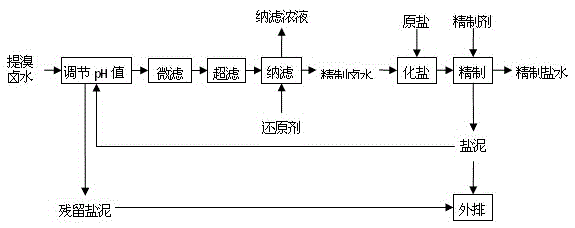

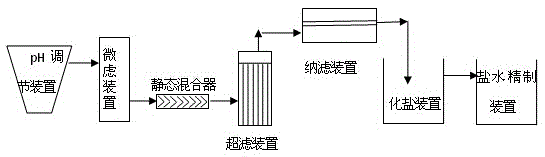

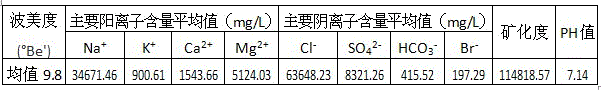

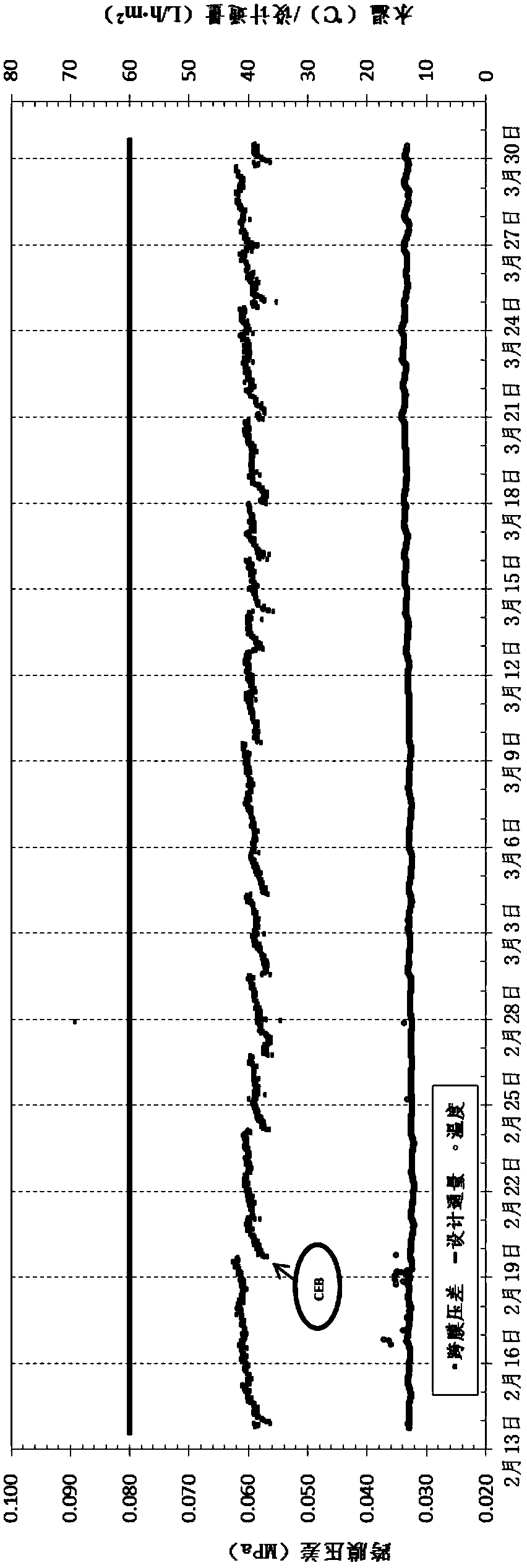

Method and device for producing refined brine by utilizing bromine extraction brine

ActiveCN104743582AReduce acidityReduce refining costsAlkali metal halide purificationSludgeSolid particle

The invention discloses a method and a device for producing refined brine by utilizing bromine extraction brine. The method comprises the following steps: adjusting the pH value of the bromine extraction brine to 5-8, intercepting solid particles and mechanical impurities through mechanical microfiltration, adding a reducing agent to remove oxidized substances, carrying out ultrafiltration to remove small particles, colloids and macromolecular organic compounds, then, removing most of sulphate radicals and calcium and magnesium ions through nanofiltration interception so as to obtain brine dissolved raw salt, preparing the brine dissolved raw salt into saturated brine, further refining to remove the calcium and magnesium ions by adopting a chemical method so as to obtain refined brine and brine sludge, and returning the brine sludge back to the first step to adjust the pH value of the bromine extraction brine. By means of the method disclosed by the invention, high-efficiency utilization of sodium chloride in the bromine extraction brine is realized; the sun-curing and dissolving processes of a part of sodium chloride are saved; the leakage loss of underground salt brine resources in the salt basking process is avoided; the recovery rate of raw salt in the bromine extraction brine is increased; furthermore, the brine refining cost of a sodium carbonate factory is lowered, so that the production cost is lowered.

Owner:CHINA NAT OFFSHORE OIL CORP +1

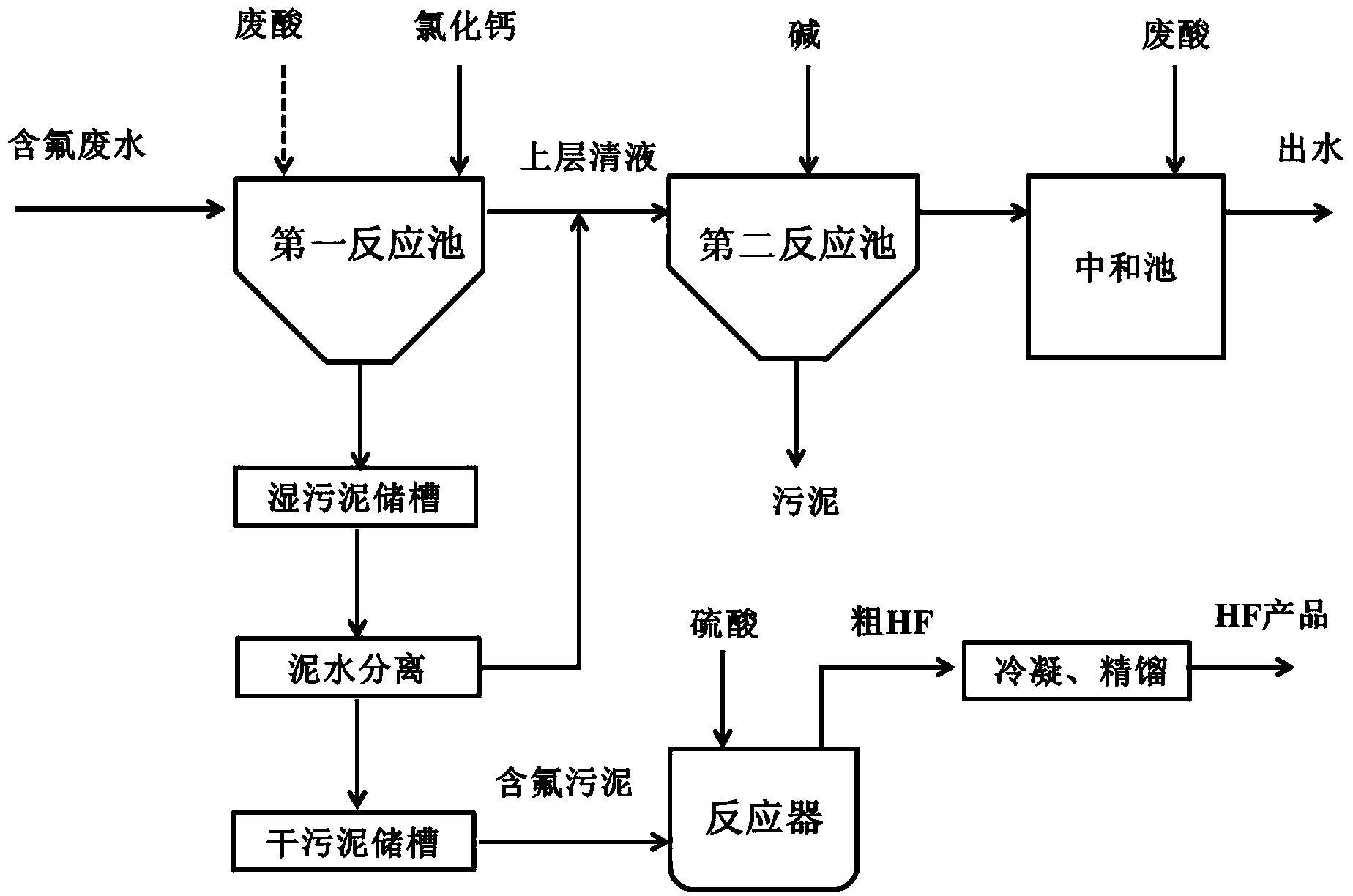

Method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater

ActiveCN103848522ATreatment up to standardReduce dosageSludge treatmentWater contaminantsSludgeImpurity

The invention discloses a method for treating fluorine-containing wastewater and recycling fluorine-containing sludge produced by treatment of fluorine-containing wastewater. The method comprises the steps of reacting the fluorine-containing wastewater with calcium chloride under the acidic condition formed by adding a waste acid matter, performing crystallization sedimentation to remove most fluorine ions from the wastewater to form high-purity fluorine-containing sludge, removing dissolved calcium fluoride and other impurities from supernate through alkali sedimentation to form a small amount of fluorine-containing sludge with relatively low purity, then neutralizing the supernate, and discharging effluent, wherein the concentration of fluorine ions of the effluent is lower than 10 mg / L and accords with national discharge standards; drying the high-purity fluorine-containing sludge, then adding the dried sludge and excessive sulfuric acid into a reactor with a stirring device, reacting at 150-300 DEG C to prepare hydrogen fluoride, and condensing and rectifying the obtained crude hydrogen fluoride gas to obtain an anhydrous hydrogen fluoride product.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

Method for producing magnesium ammonium phosphate composite fertilizer

ActiveCN101456759AImprove economic efficiencyLow costAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFertilizerMagnesium ammonium phosphate

The invention relates to a method for producing an ammonium magnesium phosphate compound fertilizer, which comprises: taking phosphorus-magnesium waste residue generated during wet-method phosphoric acid refining as a raw material, and adding a small amount of compounds containing Mg<2+> to make up for the deficiency of magnesium in the waste residue; adding ammonia water, taking an alkaline solution as an acidity regulator, and performing mixing and stirring reaction at room temperature, wherein the reaction time is not less than 60 minutes, the stoichiometric mol ratio of the Mg<2+> to NH4<+> to PO4<3-> in the mixed reaction liquid is 1-1.2:1:1, and the pH value of the reaction liquid is controlled to be between 8.0 and 10.0; and performing solid-liquid separation, wherein solid material is the ammonium magnesium phosphate compound fertilizer containing phosphorus, ammonia and magnesium. By adoption of the method to prepare the ammonium magnesium phosphate compound fertilizer, the economic benefit can be increased; the wet-method phosphoric acid refining cost can be reduced; resource waste can be prevented; and the economic benefit can be improved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for producing ferronickel alloy grain by directly reducing lateritic nickel ore by rotary kiln

The invention belongs to the technical field of metallurgical chemical industry and particularly relates to a method for producing ferronickel alloy grain by directly reducing lateritic nickel ore by a rotary kiln, comprising the following steps of: breaking and grinding the raw lateritic nickel ore free from drying; adding carbonaceous reducing agent and complex additive; removing natural moisture by a ball-pressing preheater; directly reducing in the rotary kiln; carrying out quenching and ore grinding to produced material; carrying out high-intensity magnetic separation to obtain the ferronickel alloy grain; and desulphurizing by using shell powder of which the activity is 40 times of that of the common lime stone. The ferronickel alloy grain contains less than 0.03% of sulphur, coal consumption of the method is 20% of that of the traditional process, The nickel recovery rate is more than 95%, the ferrum recovery rate is 70%, the tailing contains less than 0.08% of nickel, the reduction time is shortened, and the cost of the method is 1 / 3 of that of the traditional process. The tail gas of the rotary kiln can be used for generating electricity, the operation is simple and is easy to control, and the product is smelted by an electric furnace to directly smelt the ferronickel alloy grain; the quality of the product is good; a new path is provided for producing the ferronickel alloy grain; and the problems of high ore smelting grade, complex process, long flow, high energy consumption and environmental pollution can be solved.

Owner:徐伟

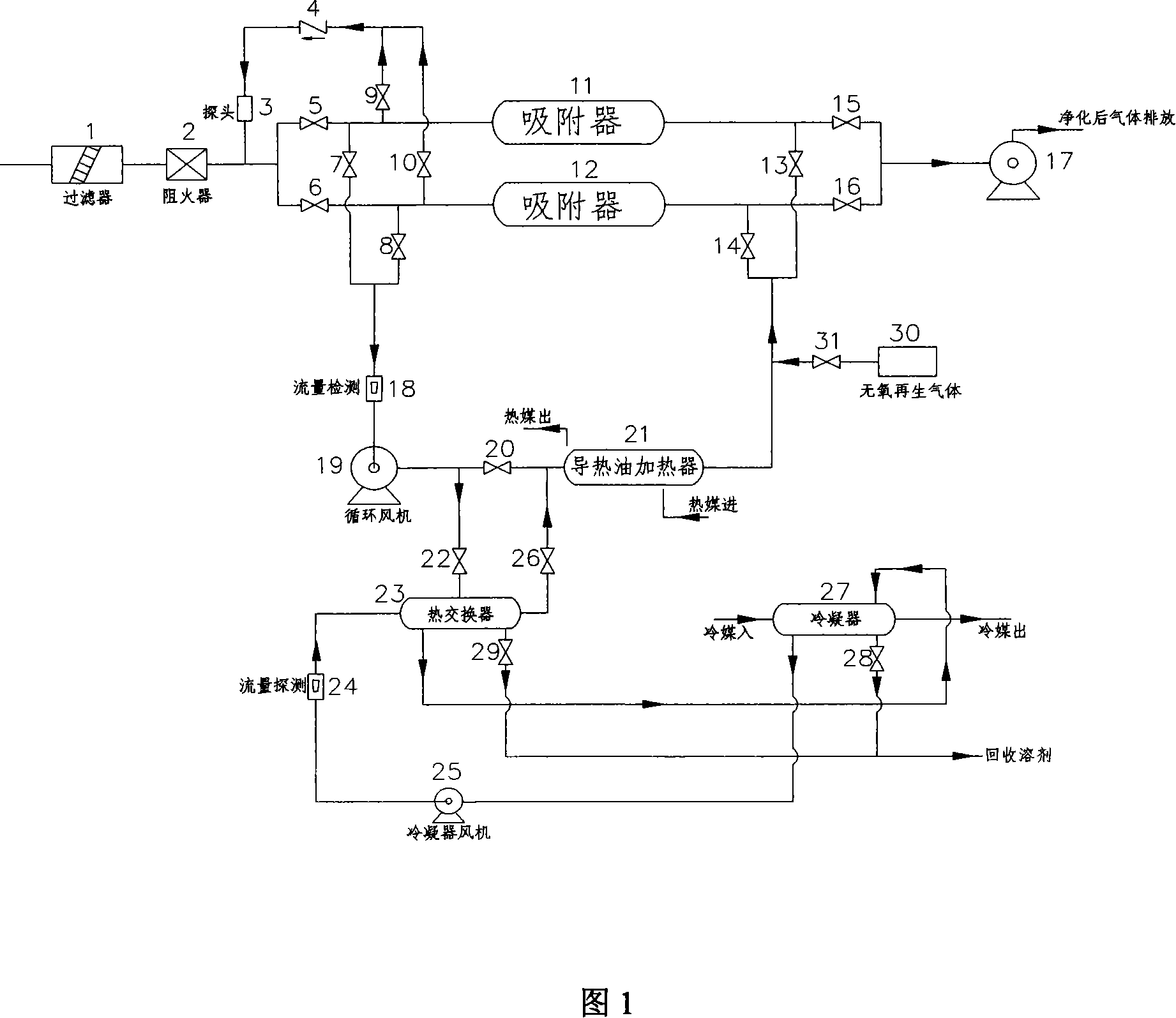

Adsorbent bed circulating desorption distributary recovery regeneration process and device thereof

InactiveCN101081361AIncrease partial pressureControl total oxygenOther chemical processesDispersed particle separationOrganic solventDesorption

The present invention belongs to the field of chemical separating and environment protecting technology, and is especially circular desorbing, shunting, recovering and regenerating process in an adsorbing bed and the apparatus. The technological process includes circular desorbing on hot gas in an adsorbing bed, and by-pass heat exchange and condensing recovery of partial desorbed gas flow. The present invention has the advantages low power consumption, low cost and high purity of the recovered organic matter, and is especially suitable for use in chemical adsorbing and separating process, contaminated gas purifying, organic solvent recovery, etc.

Owner:TONGJI UNIV

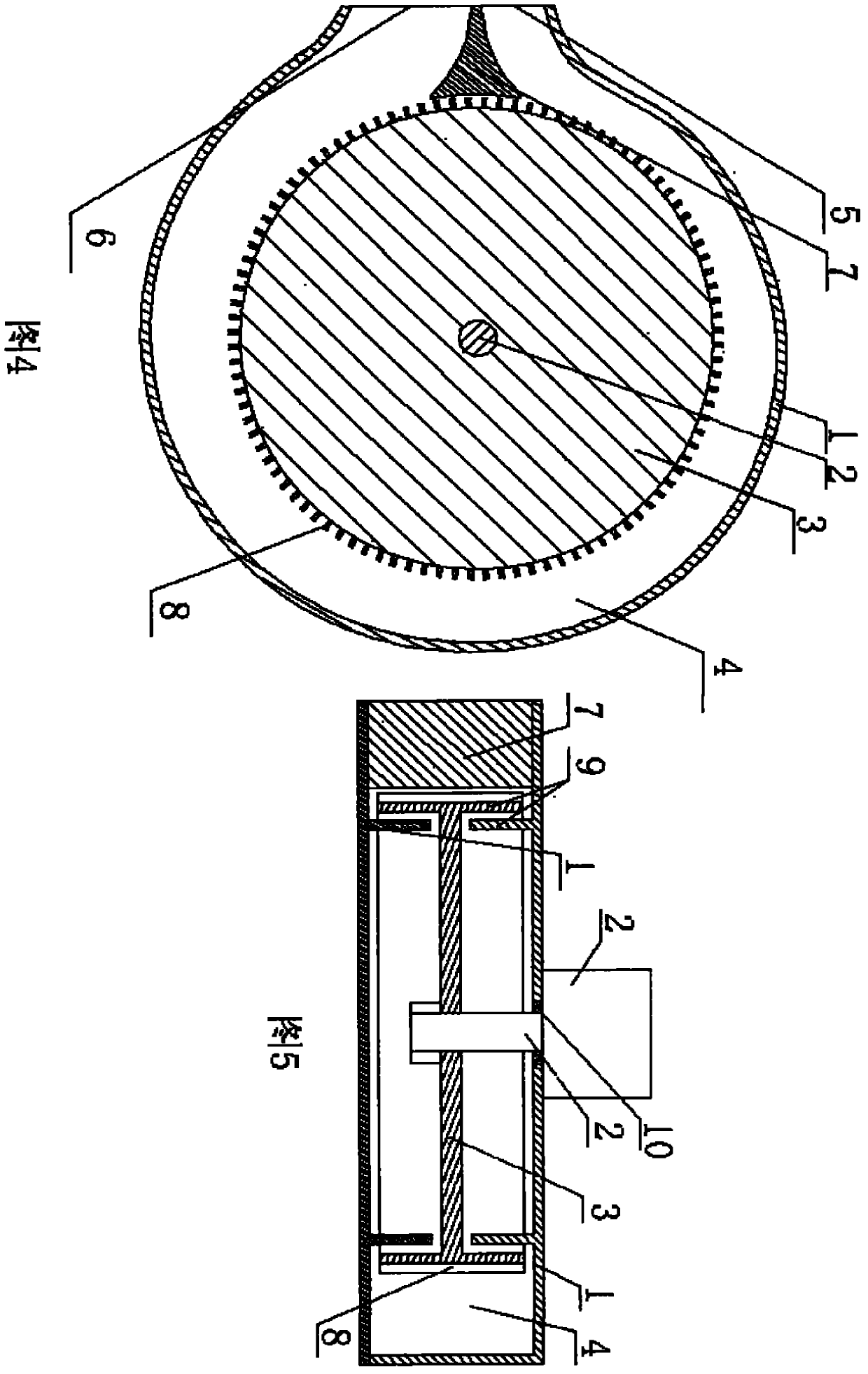

Circulator

InactiveCN103216450AWonder Material PropertiesAchieve separationCircumferential flow pumpsPump componentsDust controlEngineering

The invention relates to a circulator. The circulator comprises a shell body and a transmission device, wherein the transmission device is mounted on the shell body, a rotary wheel is mounted on the transmission device, a plurality of vanes are arranged on the periphery of the rotary wheel, the rotary wheel is arranged in the shell body, a circulation cavity is formed in the inner wall of the shell body at the periphery of the rotary wheel, a circulation cavity port A is formed in one end of the circulation cavity, a circulation cavity port B is formed in the other end of the circulation cavity, and an isolating body is arranged on the inner wall of the shell body between the circulation cavity port A and the circulation cavity port B. According to the circulator provided by the invention, circular motion and fluid motion are used sufficiently; torsion is better converted into pressure through fluid; pressure is better converted into torsion through the fluid; and the fluid separation is realized by using vortex. The circulator provided by the invention can serve as a water pump, a slurry pump, a sewage pump, a blower, a compressor, spray equipment, a reactor, a steam turbine, vacuum equipment or a separator and be applied to wastewater treatment, seawater desalination, marine chemical engineering, mineral processing, waste disposal, hydrogen production, carbon dioxide decomposition, harmful gas decomposition, air purification, dedusting, dust absorption, refrigeration, oxygen production, oil refining and the like; and the blue sky and water can be completely realized, and foamed materials can be produced so as to bring a material revolution.

Owner:陈久斌

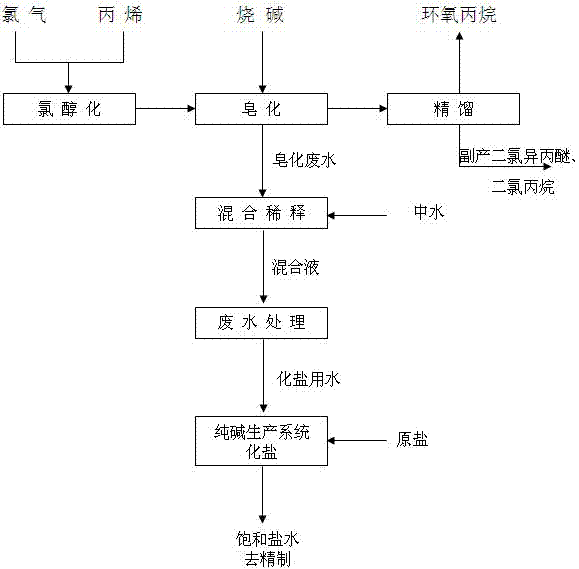

Process for producing epoxypropane by adopting caustic soda saponification method

ActiveCN102952101AAchieving zero emissionsFriendly Clean Production ProcessEther preparation by ester reactionsPreparation by halogen additionSalt waterWastewater

The invention discloses a process for producing epoxypropane by adopting a caustic soda saponification method. Caustic soda is used as a saponification agent in the production of epoxypropane. Epoxypropane is produced through chlorohydrination, caustic soda saponification and rectification; and after being treated, saponification wastewater generated in the production process is used as salt-melting water in the production of sodium carbonate by adopting an ammonia-soda process; therefore, water resources and salt resources in the saponification wastewater can be comprehensively utilized, and brine purification cost in the process of producing sodium carbonate by adopting the ammonia-soda process can be lowered, no waste residue is generated in the whole process, and zero emission of wastewater is realized. The process is an environment-friendly cleaner production process.

Owner:SHANDONG HAIHUA GRP CO LTD

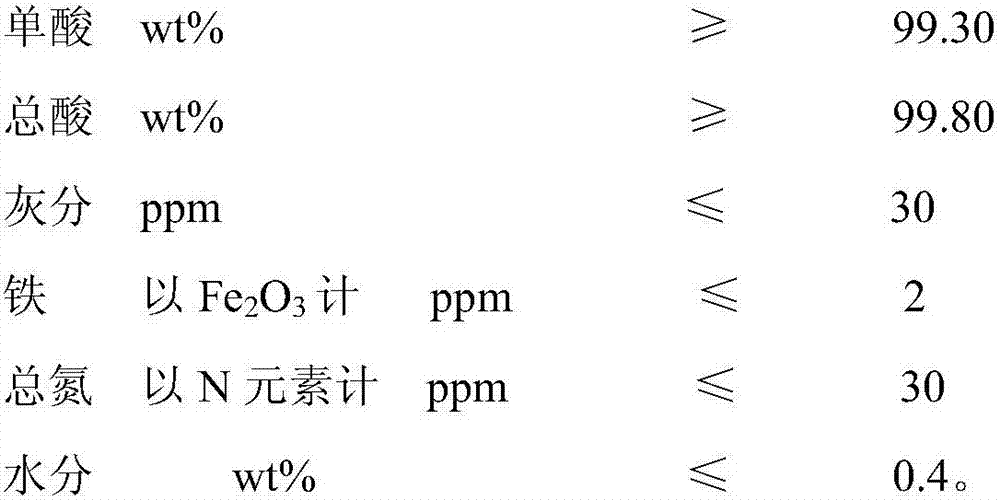

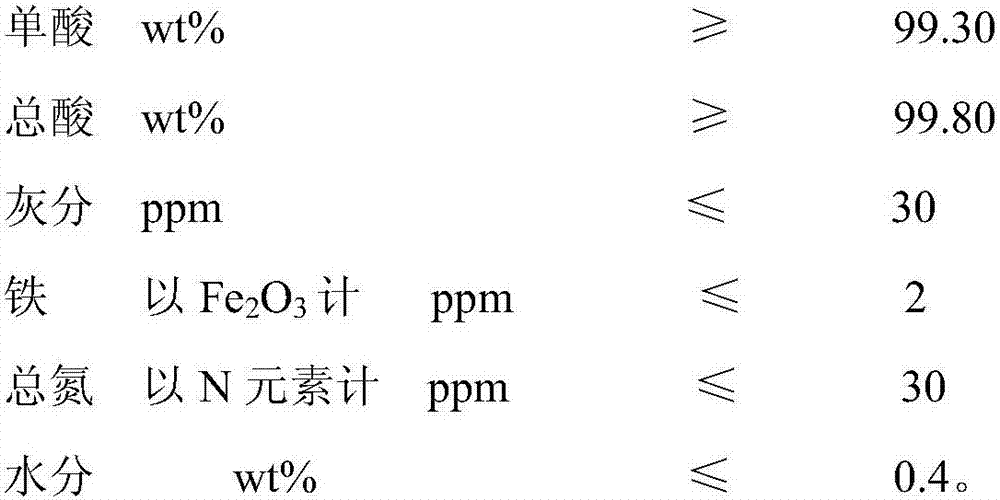

Refining and purifying method of long carbon chain dicarboxylic acid

InactiveCN108003015AReduce out-of-phase nucleation issuesGood crystal formCarboxylic compound separation/purificationCarboxylic acidCarbon chain

The invention provides a refining and purifying method of long carbon chain dicarboxylic acid. The refining and purifying method is characterized in that the raw material moisture content of a long chain binary acid coarse product is controlled to be smaller than or equal to 1.0 wt%; the content of solvent acetic acid is larger than or equal to 95.0 wt%; the crystallization process adopts three-section gradient cooling, and induction seed crystal is added after second-section cooling to induce crystallization; crystalized filter cake is firstly sprayed by acetic acid, is next washed by water and is then subjected to centrifugal filtering; then the filter cake is washed by the water at environment temperature; an acetic acid solvent generated in the refining process is totally recycled through an azeotropic distillation method; a cleaning solution and a mother solution which are generated in the refining process are totally recycled. The refining and purifying method, high in product yield, low in refining cost and high in purity, of long carbon chain dicarboxylic acid is provided. The total acid content of long carbon chain dicarboxylic acid after being refined and purified reaches99.90%, the single acid content reaches 99.45%, the total nitrogen content reaches 6ppm, the ferric ion content reaches 0.5 ppm, the ash content is smaller than or equal to 10 ppm, and the moisture content is smaller than or equal to 0.16%. The purifying comprehensive yield reaches 98.64%. All quality technical indexes meet a user's requirements.

Owner:ZIBO GUANGTONG CHEM

Calcium pressing refining slag for steel production and preparation method thereof

InactiveCN102876849ALow melting pointReduce manufacturing costProcess efficiency improvementCalcium in biologySteelmaking

The invention discloses calcium pressing refining slag for steel production and a preparation method thereof. The refining slag comprises the following components: 30-50% of CaO, 30-50% of Al2O3, not more than 6.0% of SiO2, not more than 2.0% of F<->, 4-6% of MgO, not more than 12% of alkali and not more than 5% of the balance. The production raw materials are industrial wastes rich in calcium oxide and alumina. The preparation method comprises the following steps: grinding the raw materials to powder, mixing according to a certain proportion, and pressing to blocky refining slag rich in CaO and Al2O3 at a predetermined particle size by a high pressure granulator. The refining slag, provided by the invention, has the advantages of stable performance, no degeneration, no water absorption, no dusting, low fluorine, convenience for storage and transportation, and convenience for environmental protection; slugging is promoted and the smelting time is reduced in a steel production process, and the molten steel is refined and desulfurized in a steel discharge process or in an LF furnace.

Owner:LIAONING TIANHE TECH

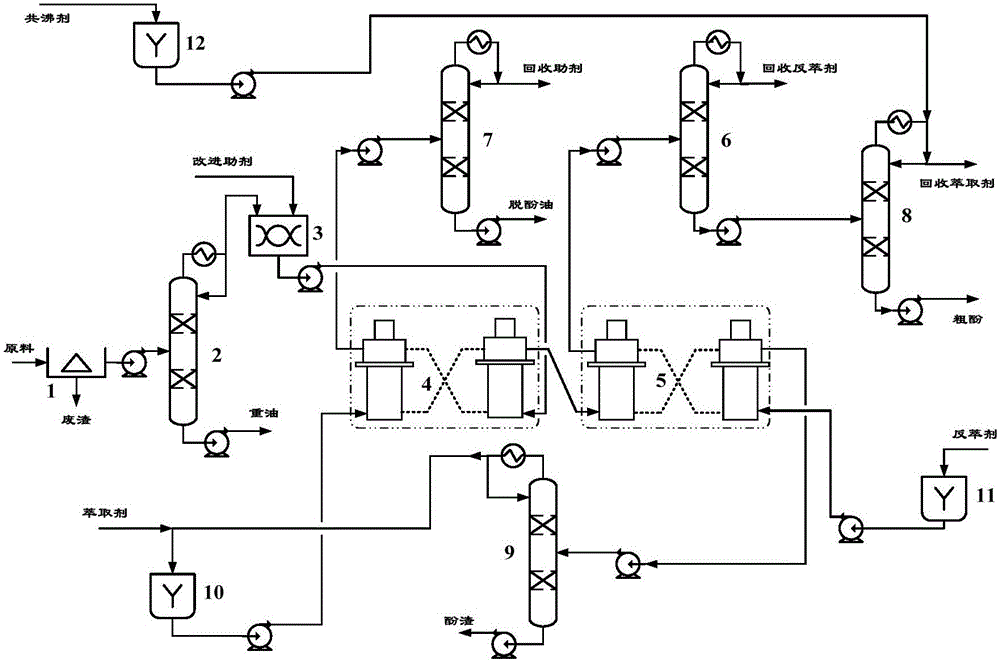

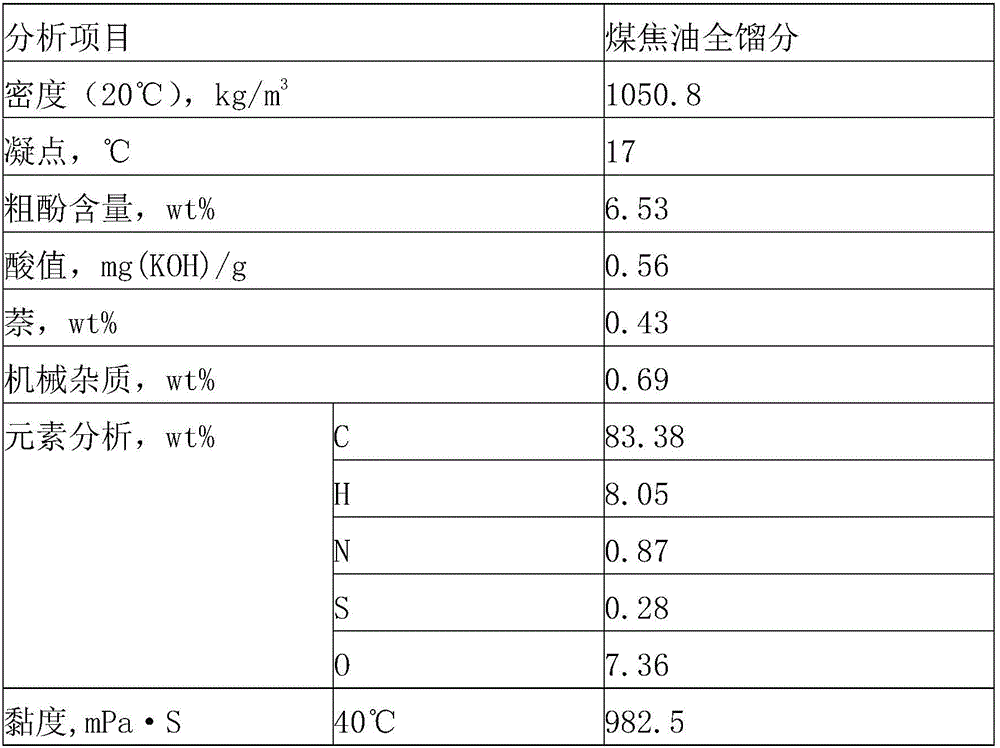

Method and device for extracting and separating phenolic compounds from coal derived oil

InactiveCN106278827AAvoid it happening againGood quality indexOrganic chemistryOrganic compound preparationAzeotropic distillationCoal

The invention discloses a method and device for extracting and separating phenolic compounds from coal derived oil. The method comprises the following steps of performing distillation and cutting to obtain phenol-enriched distillation fractions: performing distillation, distillation fraction and cutting on the coal derived oil, and cutting out a phenol-enriched distillation fraction of a certain temperature segment; performing centrifugation, extraction and separation on a solvent: performing centrifugation and separation on the phenol-enriched distillation fraction, an extraction agent and an addition agent so as to obtain a liquid phase containing an extraction agent, wherein a light phase of the liquid phase containing the extraction agent is a dephenolization oil-addition agent solution, a heavy phase of the liquid phase containing the extraction agent is an enriched phenolic compound, and the extraction agent is an aqueous solution of one or more selected from butanone, cyclohexanol, dihydric alcohol and glacial acetic acid; performing centrifugation, backward extraction and separation; recovering the addition agent; recovering reverse extraction agents; and refining crude phenols: performing azeotropic distillation and separation on crude phenol raw materials containing a few extraction agents so as to obtain the extraction agent and crude phenol products.

Owner:CCTEG CHINA COAL RES INST +1

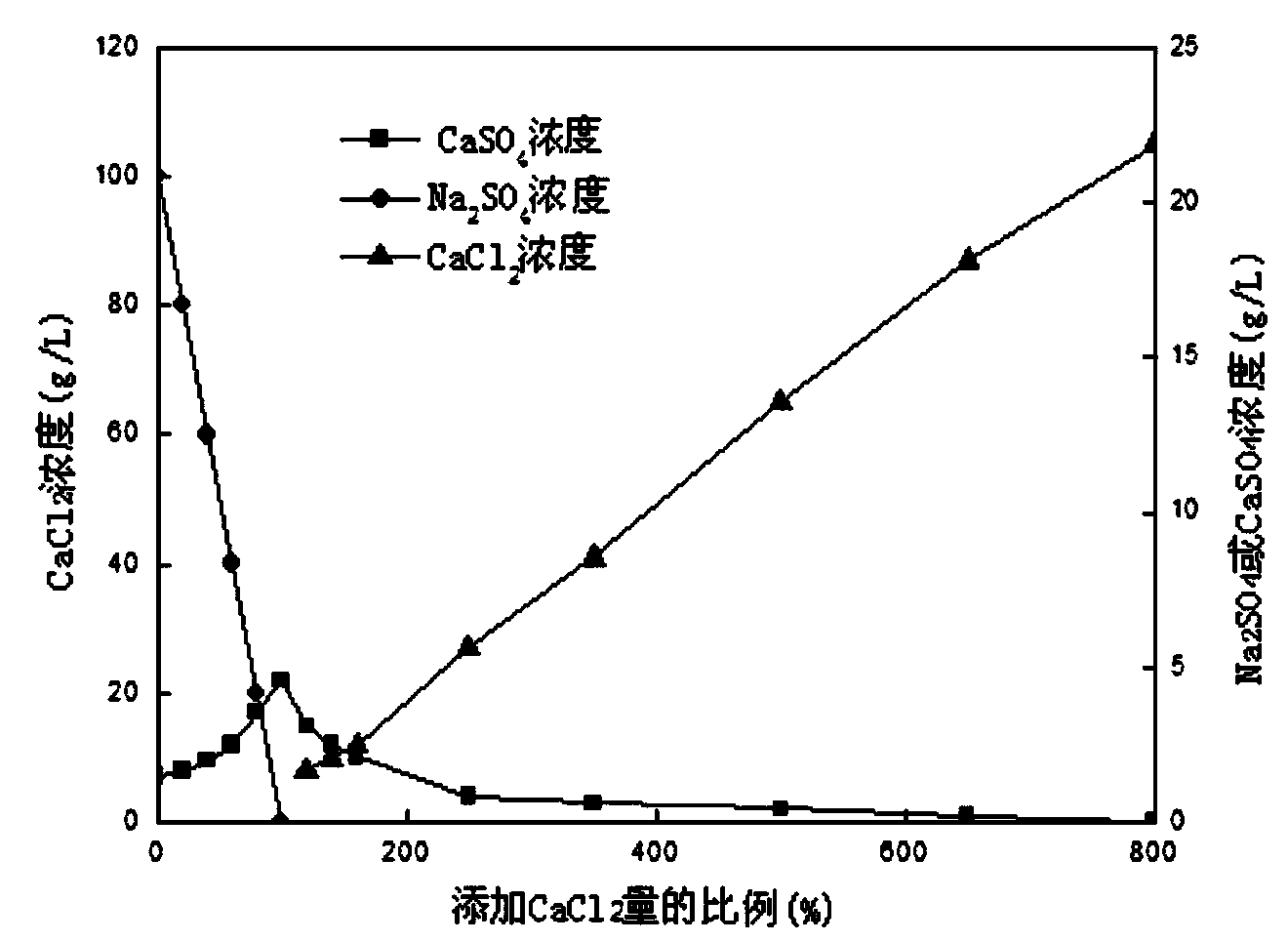

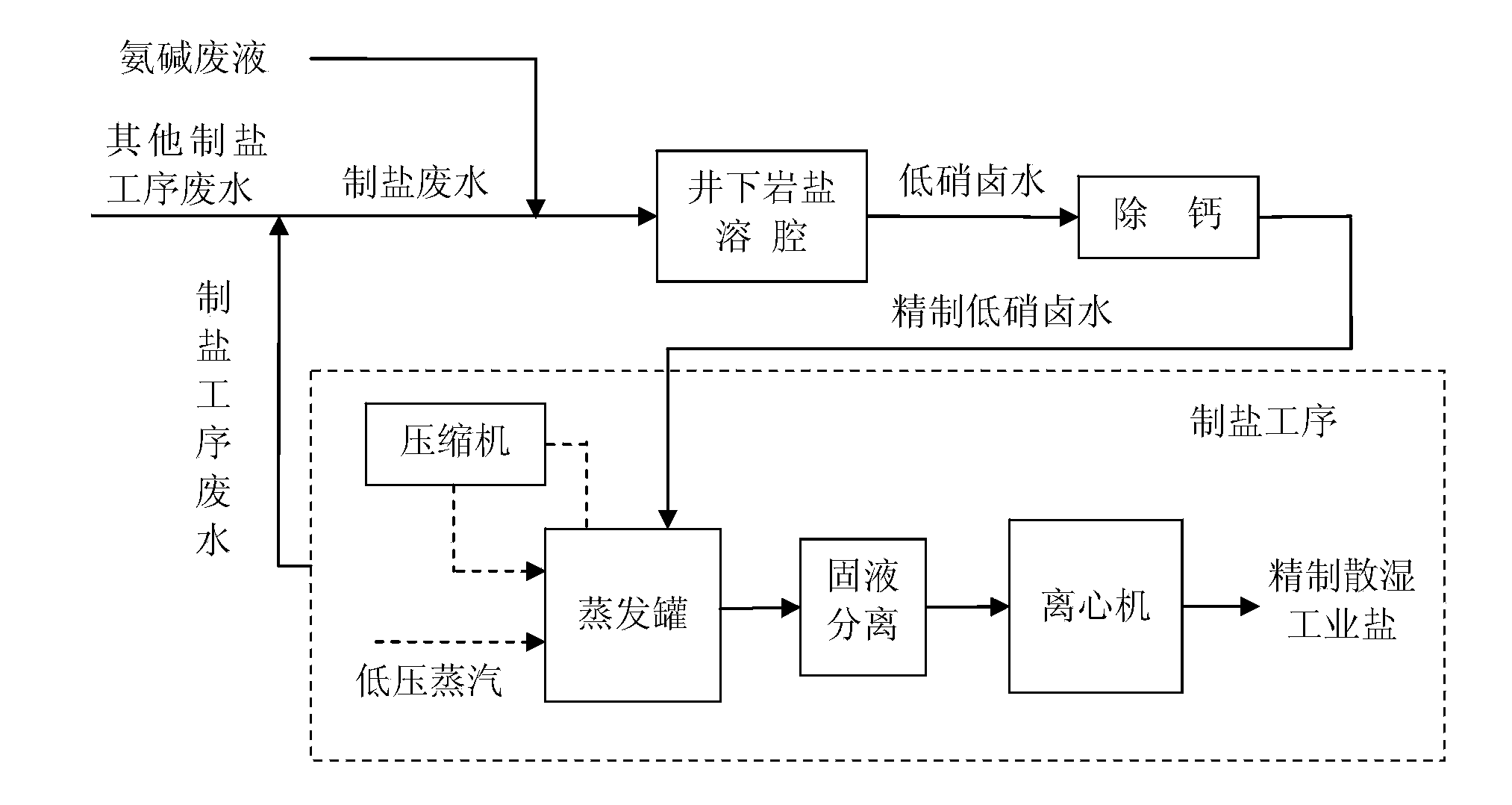

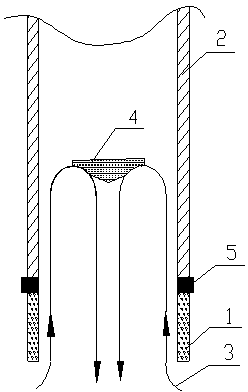

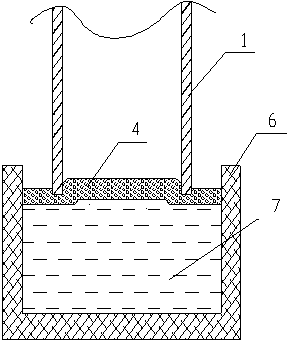

Method for producing refined moisture diffusion industrial salt based on underground recycling of waste liquid

The invention discloses a method for producing refined moisture diffusion industrial salt based on underground recycling of waste liquid. The method comprises the following steps: (1) mixing waste water of salt production with ammonia alkali waste liquid in proportion; (2) injecting the mixed waste liquid obtained in step (1) into an underground mirabilite type rock salt cavern; after sufficient reaction and natural sedimentation, extracting low-nitrate brine; (3) injecting the low-nitrate brine obtained in step (2) into a reaction barrel, injecting a sodium carbonate solution into the barrel, and adding a certain amount of sodium polyacrylate as a coagulant aid; then, stirring and standing, and removing calcium ions out of the brine to obtain refined low-nitrate brine; (4) carrying out secondary preheating on the refined low-nitrate brine obtained in the step (3), carrying out evaporation, concentration, crystallization and solid-liquid separation, and carrying out centrifugal separation on underflow salt slurry to obtain a refined moisture diffusion industrial salt product; (5) with liquid obtained by solid-liquid separation and centrifugal separation in the step (4) as the waste water of salt production, supplying the waste water into the step (1), blending the waste water with the ammonia alkali waste liquid in proportion, and injecting the mixture into the underground rock salt cavern as a brine extracting source, thus realizing the recycling of waste liquid.

Owner:江苏苏盐井神股份有限公司 +1

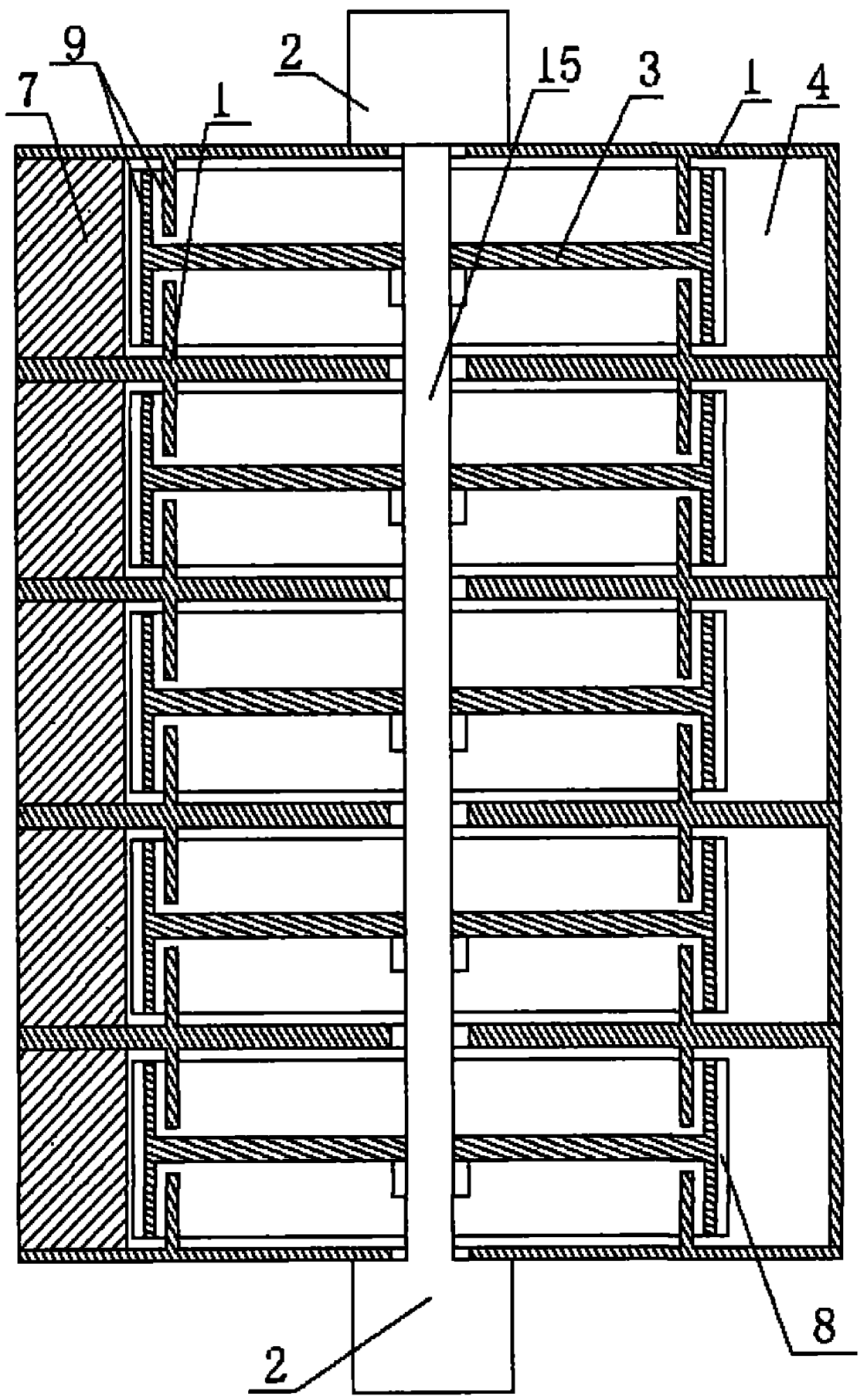

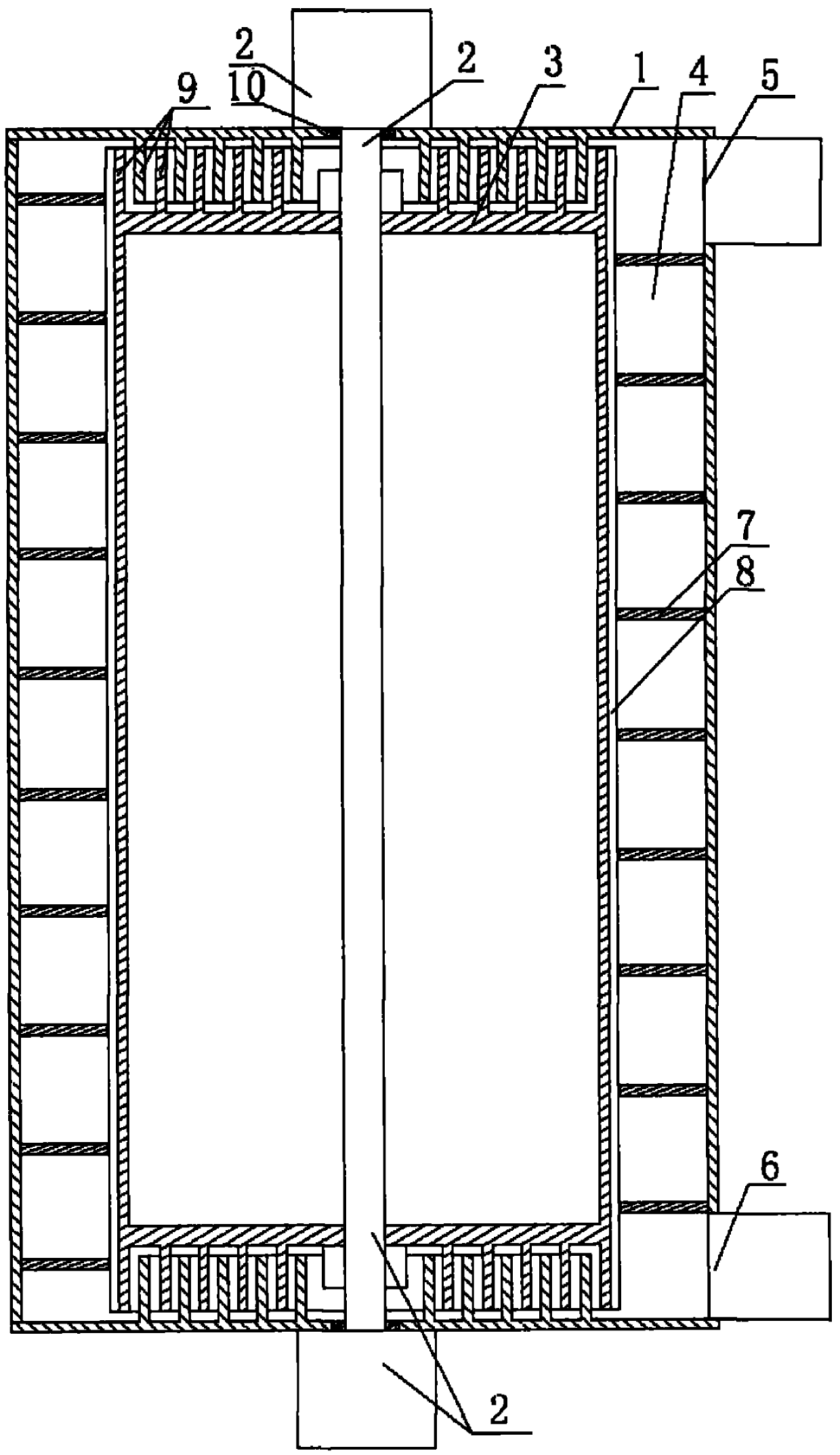

Single-dip-pipe vacuum refining device and using method thereof

The invention discloses a single-dip-pipe vacuum refining device, which comprises a vacuum chamber and a dip pipe, wherein the dip pipe is inserted into molten steel in a ladle during vacuum refining. The device is characterized in that blow nozzles are arranged hierarchically at the circumference of the single dip pipe, the nozzles on the same layer are arranged in groups and controlled independently, and argon gas is blown into the dip pipe through the blow nozzles on the inner wall of the dip pipe. During vacuum refining, by increasing the blowing capacity of the nozzles on the dip pipe, molten steel form a circular flow rising along the periphery of the vacuum chamber and falling along the center of the vacuum chamber to achieve deep decarbonization and deep devulcanization in vacuum. By adopting the device, the molten steel circulating manner of an existing vacuum refining device is changed, so that the problem that the refining process is interrupted because a ladle bottom blowing brick is clogged or bottom blowing gas deviates from a dip pipe due to steel flow disorder is overcome, meanwhile, the corrosion of refractory materials in the vacuum chamber is also alleviated, and the refining cost is also reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Desulfurization deordorization refining method of crude sulfate turpentine

ActiveCN104449395ASimple refining processReduce energy consumptionTurpentine spiritsMolecular sieveSorbent

The present invention provides after-oxidation waster-washing separation and adsorption combined process so as to achieve efficient refining of crude sulfate turpentine. According to the present invention, the oxidant is a sodium hypochlorite solution with an effective chlorine content of 3-10%, and the adsorbent is a mixture of modified active carbon and a water absorption molecular sieve; the key of the specific refining method is that the primary after-oxidation waster-washing separation is performed, and then adsorption with the adsorbent is performed to remove irritating odor, such that the organic sulfur content in the crude sulfate turpentine can be efficiently removed, and the total sulfur content can meet the 10 ppm standard required by the industrial application requirement; and with the excessive oxidation, the application of the modified active carbon and water absorption molecular sieve mixture as the adsorbent, and other means, the refining process is simplified, the energy consumption is reduced, and the refining cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

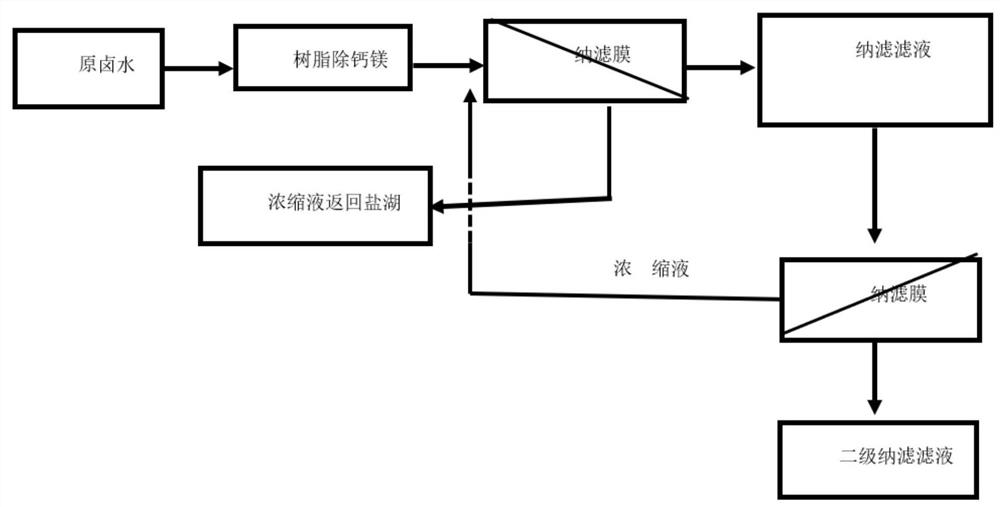

A method and device for producing refined brine using bromine-extracting brine

ActiveCN104743582BReduce acidityReduce refining costsAlkali metal halide purificationSaline waterSulfate radicals

The invention discloses a method and a device for producing refined brine by utilizing bromine extraction brine. The method comprises the following steps: adjusting the pH value of the bromine extraction brine to 5-8, intercepting solid particles and mechanical impurities through mechanical microfiltration, adding a reducing agent to remove oxidized substances, carrying out ultrafiltration to remove small particles, colloids and macromolecular organic compounds, then, removing most of sulphate radicals and calcium and magnesium ions through nanofiltration interception so as to obtain brine dissolved raw salt, preparing the brine dissolved raw salt into saturated brine, further refining to remove the calcium and magnesium ions by adopting a chemical method so as to obtain refined brine and brine sludge, and returning the brine sludge back to the first step to adjust the pH value of the bromine extraction brine. By means of the method disclosed by the invention, high-efficiency utilization of sodium chloride in the bromine extraction brine is realized; the sun-curing and dissolving processes of a part of sodium chloride are saved; the leakage loss of underground salt brine resources in the salt basking process is avoided; the recovery rate of raw salt in the bromine extraction brine is increased; furthermore, the brine refining cost of a sodium carbonate factory is lowered, so that the production cost is lowered.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Bittern or seawater ultrafiltration pre-treatment process and system

ActiveCN104211203AReduce refining costsSimple refining processReverse osmosisWater/sewage treatment bu osmosis/dialysisUltrafiltrationSeawater

The invention discloses a bittern or seawater ultrafiltration pre-treatment process and system. The bittern or seawater ultrafiltration pre-treatment process and system can provide filtered water meeting water feeding requirements of nanofiltration. Every process cycle of the bittern or seawater ultrafiltration pre-treatment process sequentially comprises a filtering step, a water producing step, a cleaning step and a discharging step, wherein the cleaning step comprises processes including gas wiping, gas-water backwashing and gas exhausting. Bittern or seawater is filtered through a cartridge filter and precisely-filtered liquor is filtered through a ultrafilter membrane filtering device to produce water; the gas exhausting process comprises that, during a membrane module exhaust process, oilless compressed air is inlet to the water inlet side of membrane yarns, and compressed air and water are mixed and oscillated to act on the surface of the membrane yarns; during the gas exhaust process, the water level decreases continuously, the gas-water washing strengths of the cross sections at different horizontal heights change, so that the membrane yarns can be cleaned from top to bottom. The bittern or seawater ultrafiltration pre-treatment process enables the bittern and seawater to be treated in a membrane filtering mode, thereby reducing the purification cost and simplifying the purification process, and through stable water output, prolongs the service life of nanofiltration membranes and guarantees stable operation of a nanofiltration system.

Owner:TIANJIN MOTIMO MEMBRANE TECH +1

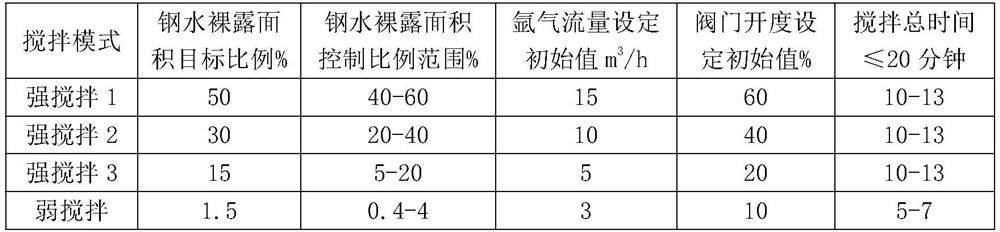

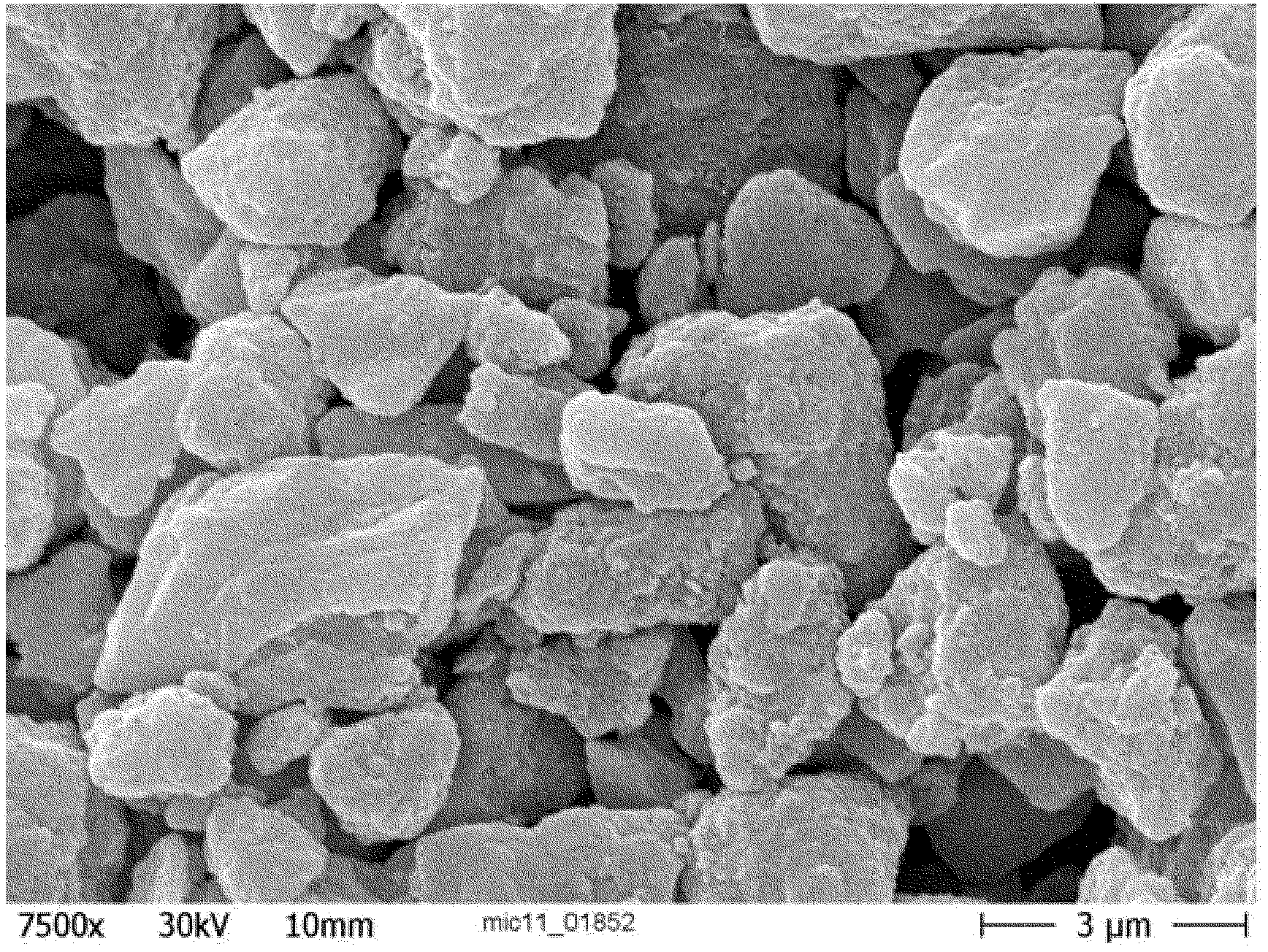

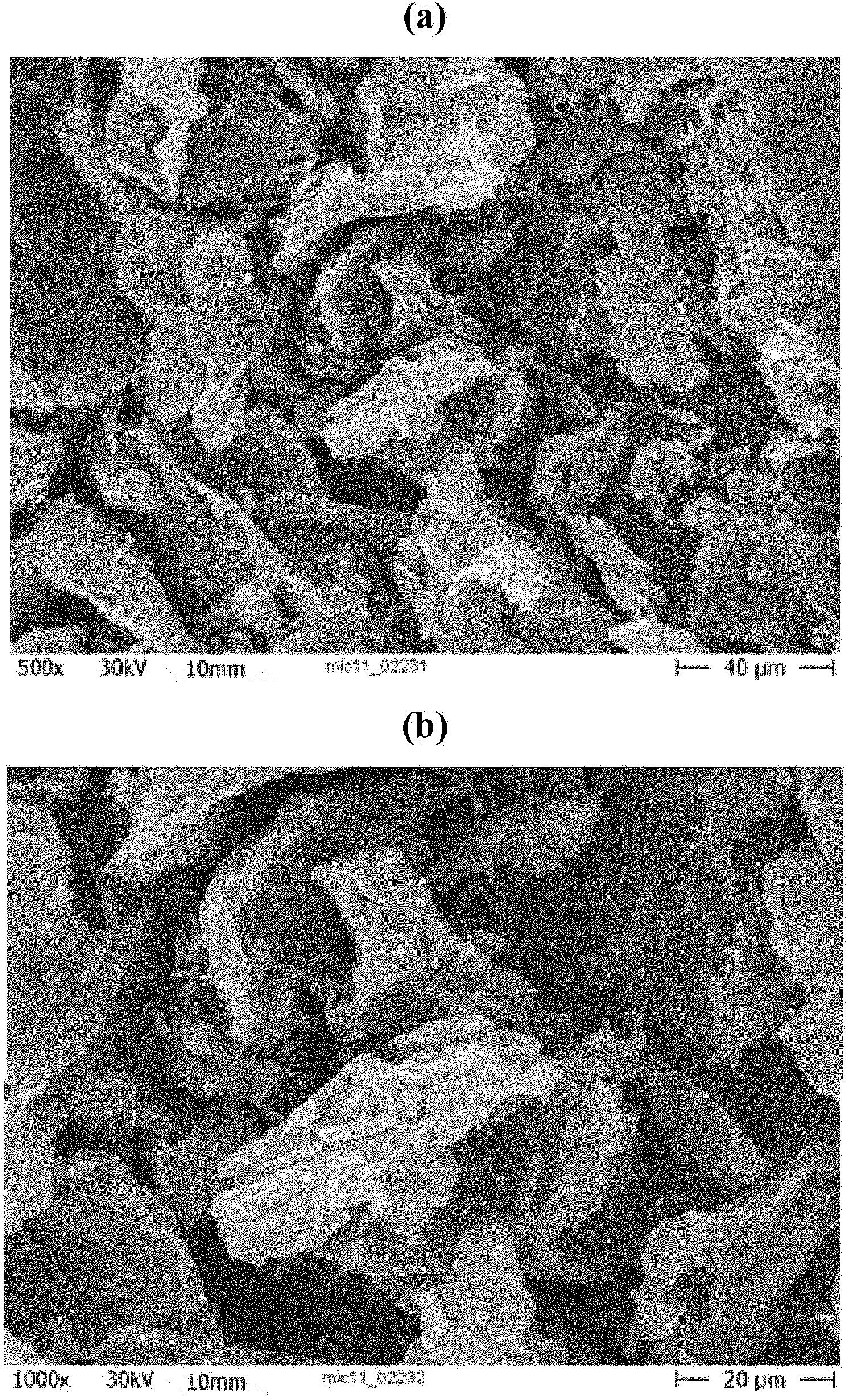

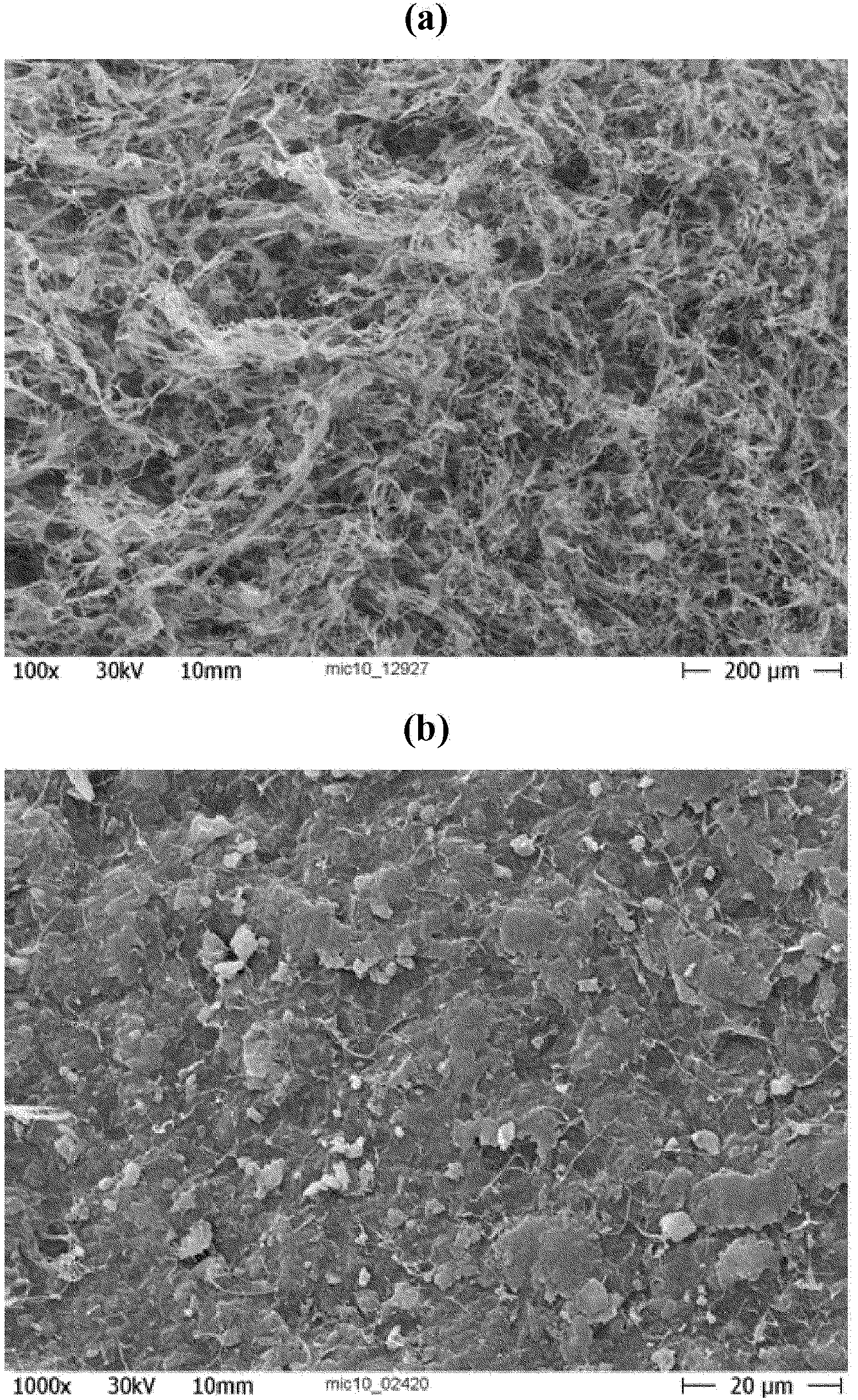

Device and method for regulating and controlling ladle bottom argon blowing flow

ActiveCN111679622AUniform compositionQuality improvementFlow control using electric meansProgramme control in sequence/logic controllersImage manipulationEngineering

The invention discloses a device and a method for regulating and controlling ladle bottom argon blowing flow, which mainly solve the technical problems of low control precision and low automation degree of the existing ladle bottom argon blowing flow. The scheme of the invention is as follows: the device for regulating and controlling ladle bottom argon blowing flow comprises a steel ladle bottomargon blowing valve opening degree control PLC and a steel ladle bottom argon blowing flow regulating valve, wherein the ladle bottom argon blowing flow regulating valve is fixedly arranged on a ladlebottom argon blowing pipeline, the ladle bottom argon blowing valve opening degree control PLC is connected with the ladle bottom argon blowing flow regulating valve through a communication cable, and the ladle bottom argon blowing flow regulating valve is an electric valve; the device further comprises a visual sensor, an image processing unit and a steel ladle bottom blowing valve opening degree control unit which are installed above the steel ladle, the visual sensor is connected with the image processing unit through a communication cable, and the steel ladle bottom blowing valve openingdegree control unit is a steel ladle bottom blowing valve opening degree control computer. The molten steel refining cost is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Integral process for preparing acetylene by means of continuous coking of coal and plasma pyrolysis

InactiveCN1380376AIncrease added valueGuaranteed continuityOrganic chemistryCoke ovensForming gasCoal chemical industry

The present invention adopts the external heating process to heat coal and makes coal continuously coke, so that its first-stage high-temp. pyrolyzed gas can be directly used as raw material for preparing acetylene by means of plasma pyrolysis, and its second-stage high-temp. pyrolyzed gas can be used as flow-forming gas for preparing acetylene by means of plasma pyrolysis. Said invention can utilize low energy consumption to produce acetylene and coke, and the partial high-temp. pyrolyzed gas and acetylene tail gas can be used as heating fuel for continuously coking coal.

Owner:TAIYUAN UNIV OF TECH

Method for refining industrial salt

InactiveCN1666957AReduce the burden onSolve the emission problemAluminium fluoridesFiltrationWastewater

This invention relates to a method of fuulyrefined industrial salt. The procedures are that waste water with fluorine is prepared to solution of pH=6-8, then industrial salt is added into the solution to get turbid salt water, pure salt water is got after filtration. The industrial salt water made by this invention can be used as material of clay bittern method to produce cryolite technique, materials can be cyclic used and cost is reduced. The content of calcium ion and magnesium ion in the industrial salt can be reduced from 1-2% to 0.01% and the content of calcium ion and magnesium ion in saturated industrial salt water can be reduced from 3g / l to below 0.03g / l.

Owner:DO FLUORIDE CHEM CO LTD

Process for manufacturing coated substrates

ActiveCN103608185AImprove efficiencyGood printabilityPhotovoltaic supportsSolar heating energyPolysaccharideMaterials science

The present invention relates to a process for manufacturing coated substrates by providing a substrate, providing at least one mineral material, providing a polysaccharide material comprising one or more polysaccharides, coating the substrate with the at least one mineral material, and coating the resulting pre-coat layer of mineral material with the gel comprising one or more polysaccharides, as well as the coated substrate obtained by this process and its use.

Owner:OMYA INT AG

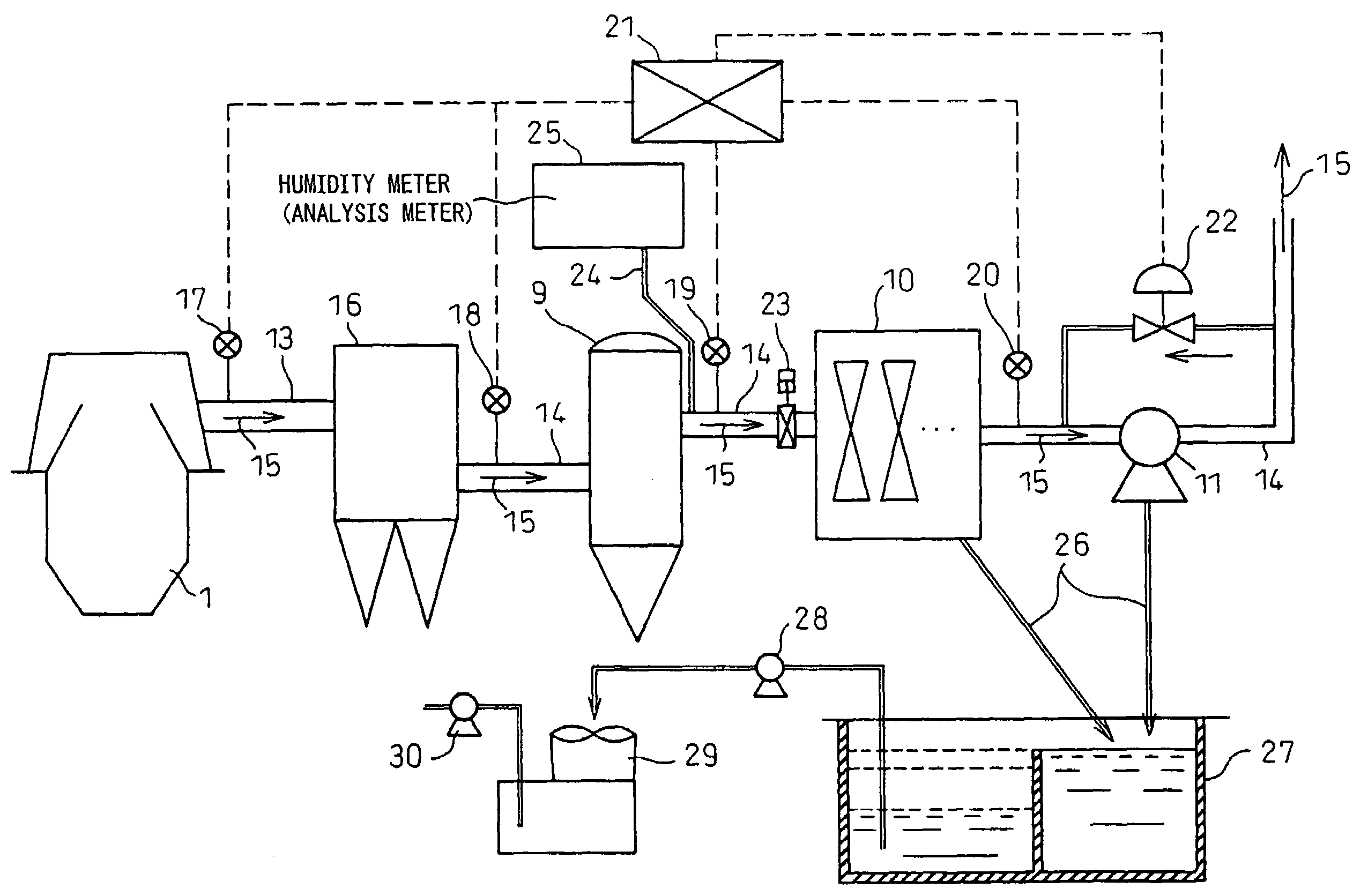

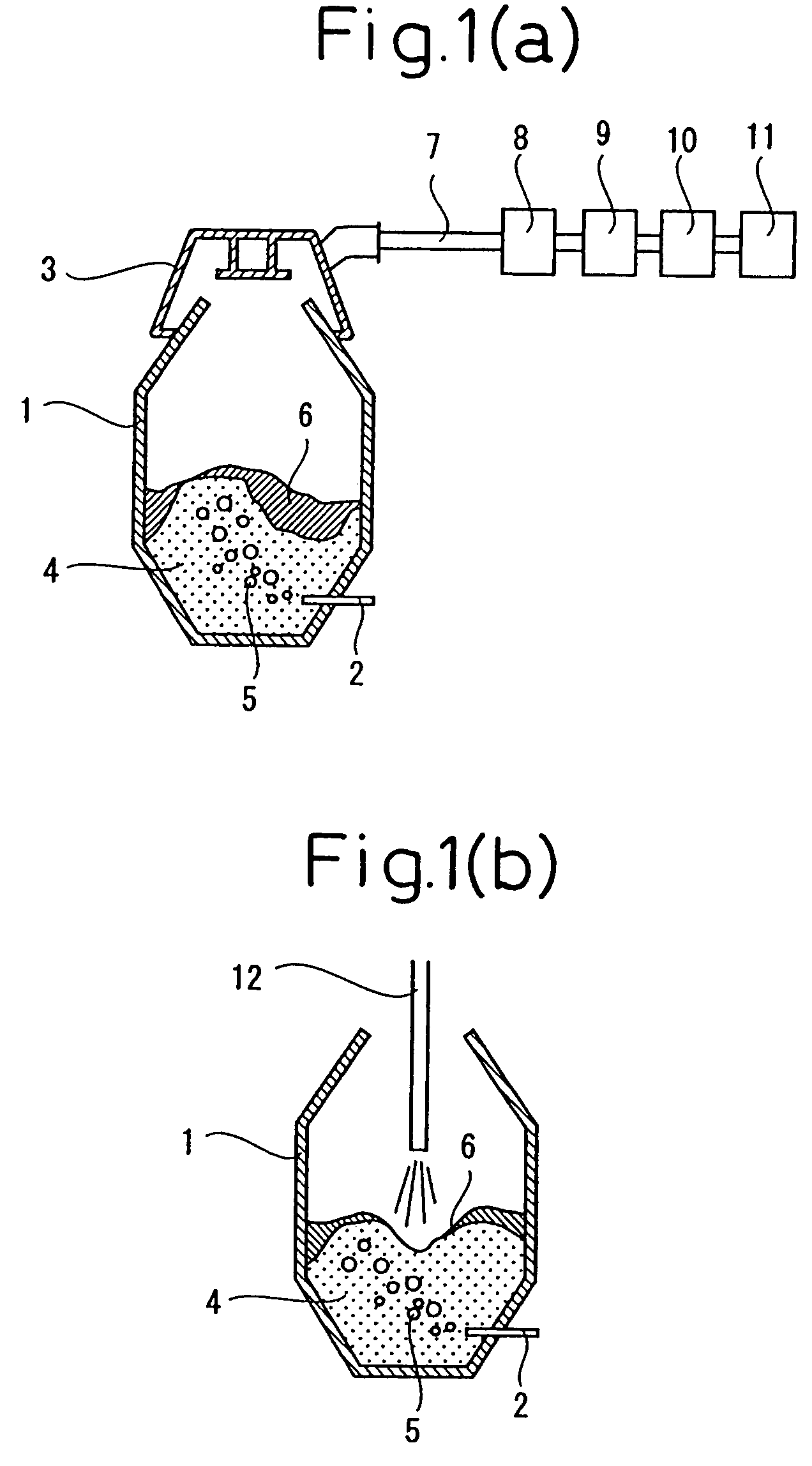

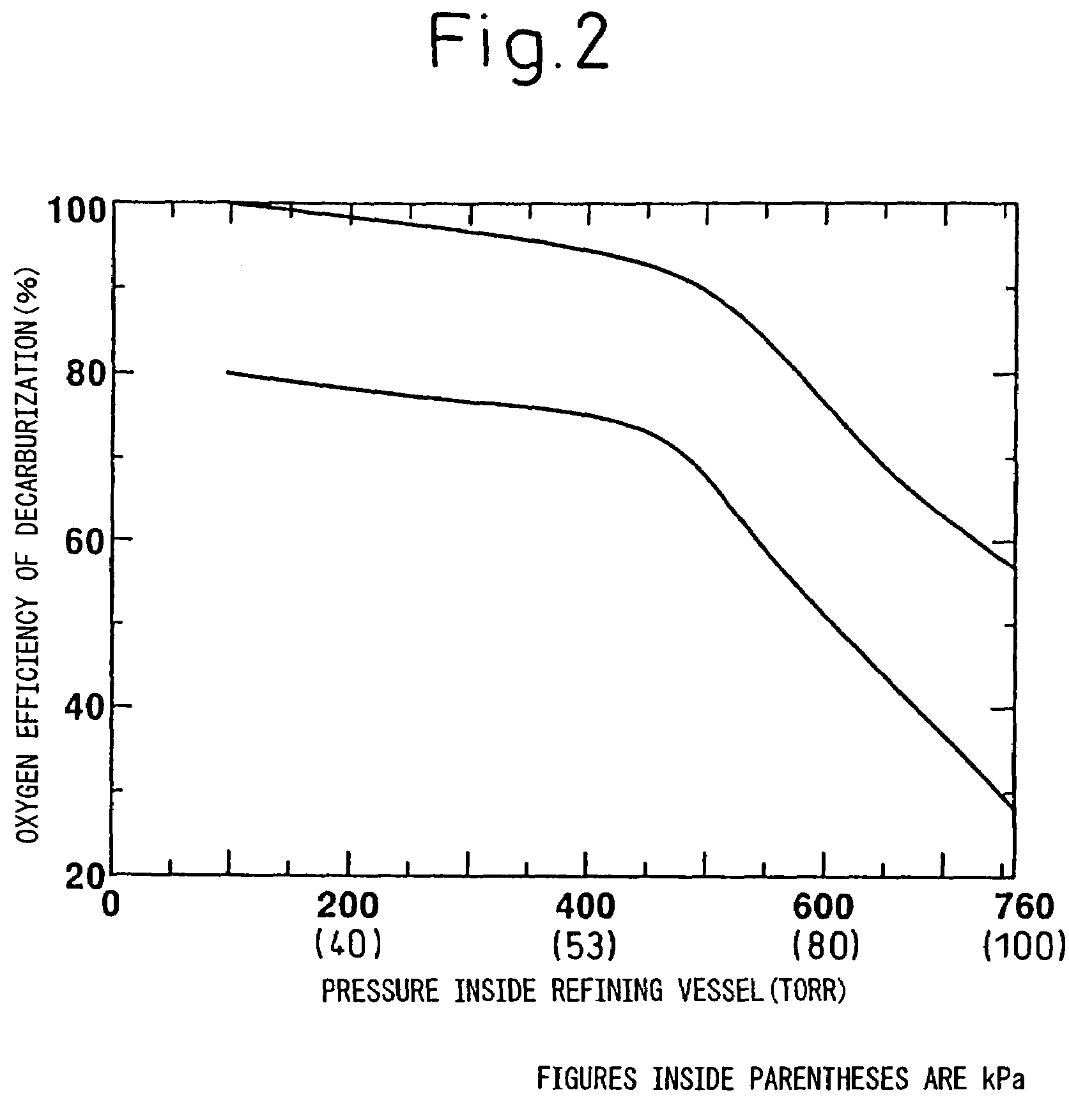

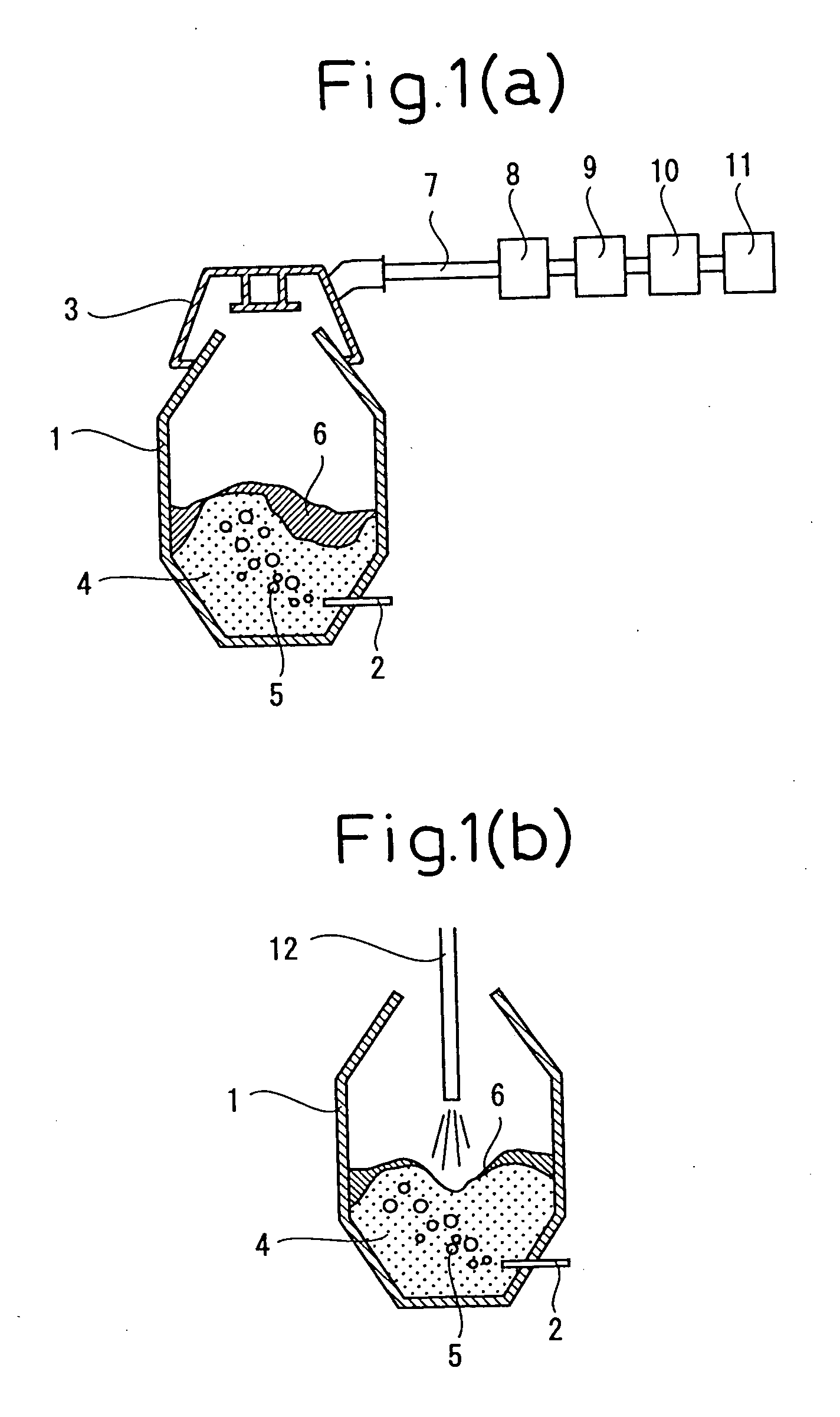

Refining method and refining apparatus for chromium-contained molten steel

InactiveUS7497987B2Reduce usageReduce refining timeCharge manipulationManufacturing convertersMolten steelIndustrial engineering

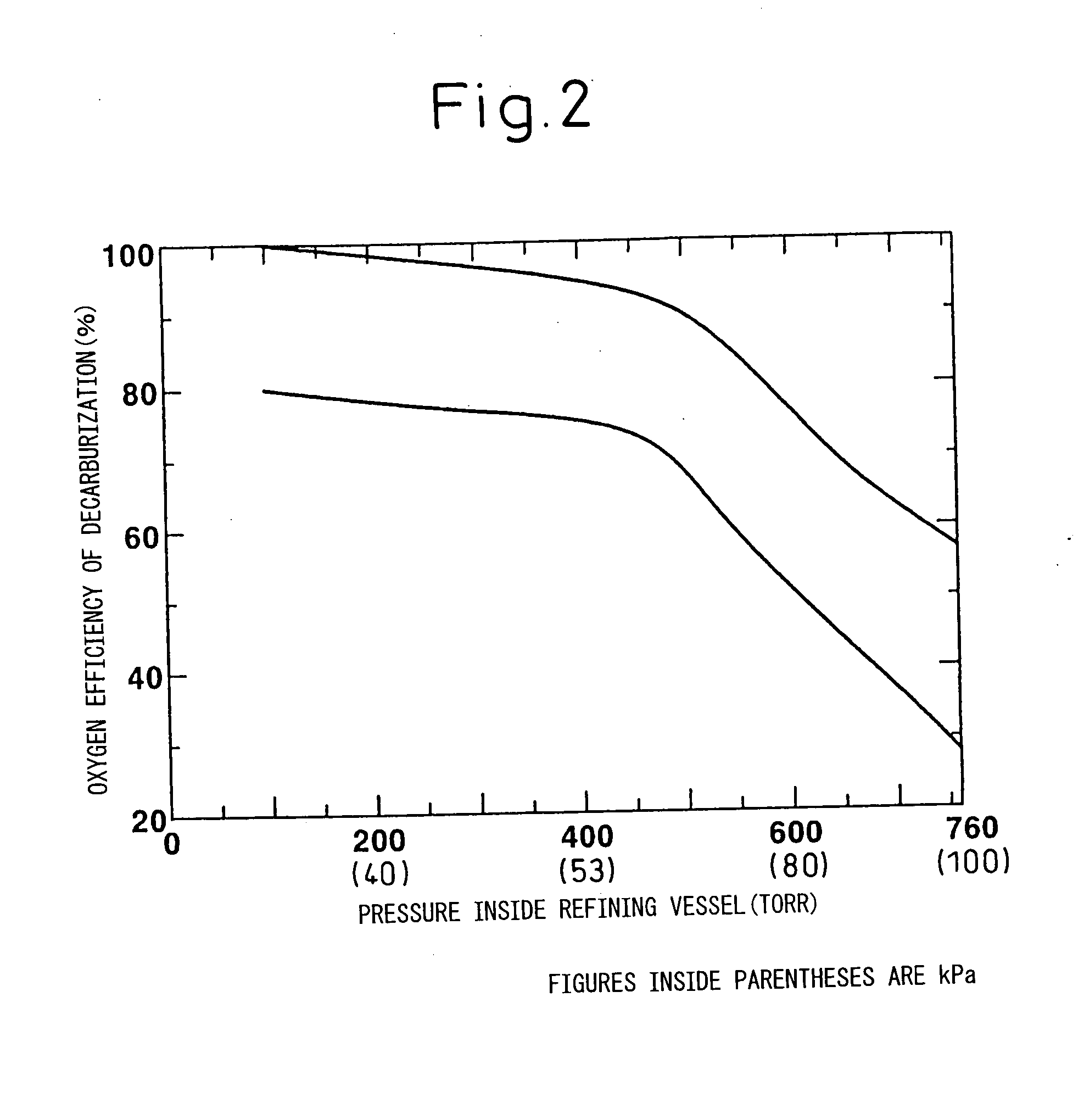

A refining method and apparatus for decarburization refining of chromium containing molten steel in a vessel having a first step of blowing oxygen while the inside of the vessel is at a pressure of between 400 Torr and atmospheric pressure, a second step of blowing oxygen while evacuation the inside of the vessel to 250 to 400 Torr and a third step of blowing gas while evacuating the vessel to not more than 250 Torr. Further, a refining method and apparatus for ultra-low carbon chrome melt by performing a first vacuum refining until the third step, then restoring the pressure in the vessel to at least 400 Torr, then performing second vacuum refining while making the bottom blowing gas blow rate at least 0.4 Nm3 per to steel.

Owner:NIPPON STEEL CORP +1

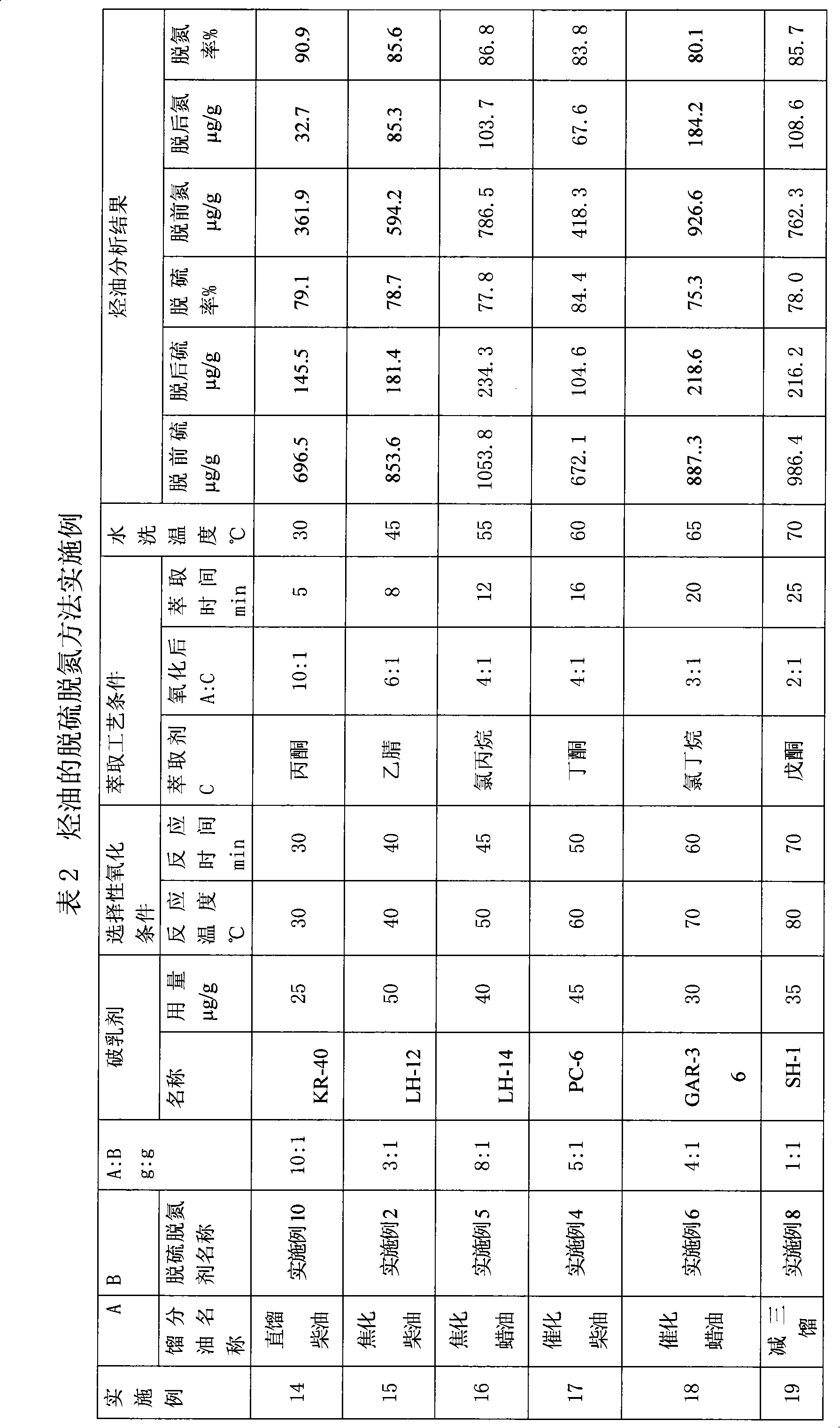

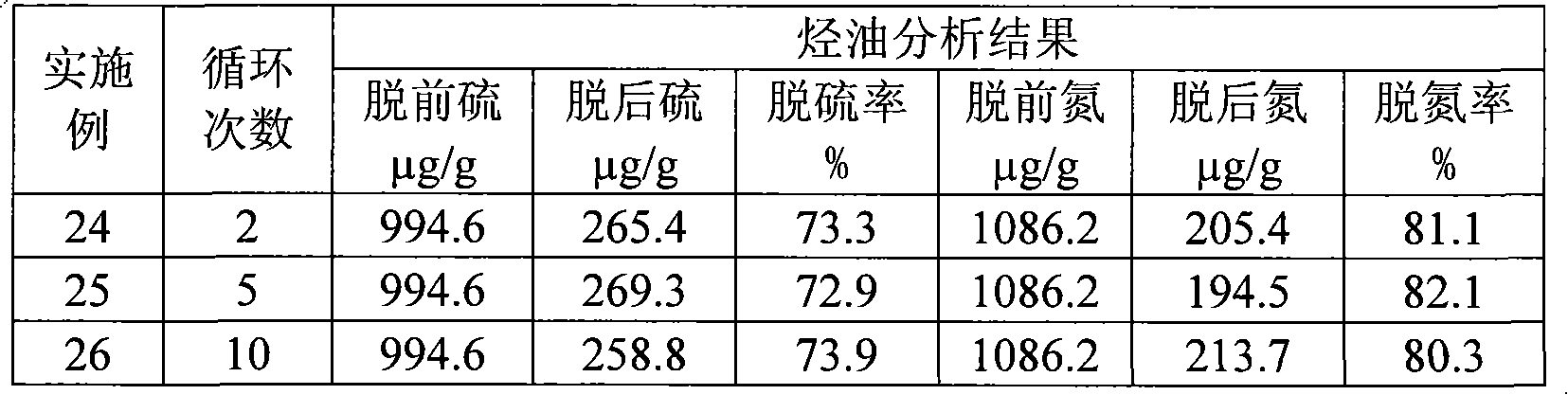

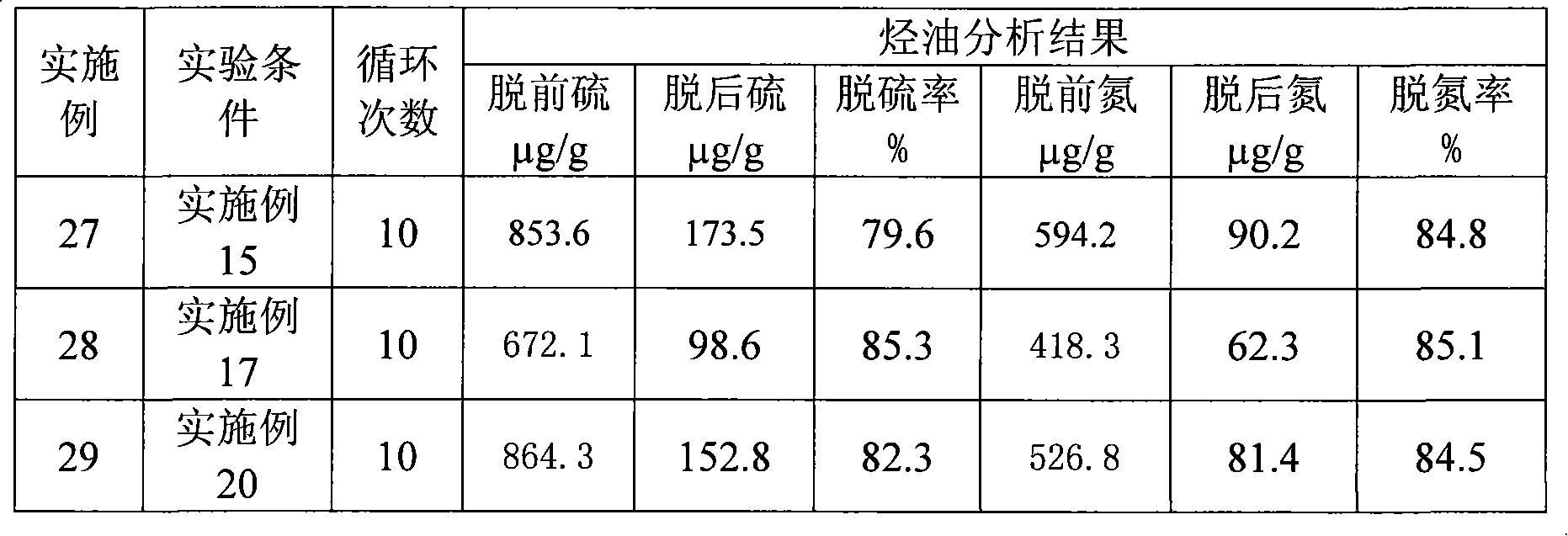

Hydrocarbon oil sulfur-nitrogen compound remover, preparation method thereof and application thereof

InactiveCN101638586AIncrease polarityReduce refining costsRefining with oxygen compoundsOrganic acidOrganic solvent

The invention relates to a hydrocarbon oil sulfur-nitrogen compound remover for selectively oxidizing and removing sulfide and nitride in hydrocarbon oil by using inorganic oxidant and organic acid, a preparation method thereof and application thereof. The remover consists of the inorganic oxidant and water soluble hydroxy acid according to a molar ratio of 1:1. A desulphurization and denitrification agent formed by the inorganic oxidant and the water soluble hydroxy acid is subjected to oxidation reaction with hydrocarbon oil fractions to convert the sulfide and the nitride in the hydrocarbon oil with weak polarity in the hydrocarbon oil into sulfur oxide and nitrogen oxide with strong polarity; and then the sulfur-nitrogen compounds with strong polarity in the oxidized sulfur oxide, thenitrogen oxide and the hydrocarbon oil are extracted from the hydrocarbon oil by using an organic solvent with strong polarity as an extracting agent so as to realize the separation of the sulfide, the nitride and the hydrocarbon oil. The method can remove the nitride at the same time of removing the sulfide in the hydrocarbon oil so as to improve the quality of the hydrocarbon oil; and the extracting agent can be recycled to reduce environment pollution.

Owner:PETROCHINA CO LTD +1

Method for converting carbonic acid type salt lake brine into chloride type brine

PendingCN111606334AImprove radiation efficiencyHigh yieldLithium halidesAlkali metal chloridesSulfate radicalsIon exchange

The invention discloses a method for converting carbonic acid type salt lake brine into chloride type brine. The method comprises the following steps that: enabling carbonic acid type salt lake brineto pass through ion exchange resin to remove trace calcium and magnesium ions in the brine and obtain softened brine; pumping softened brine into a first-stage nanofiltration membrane system, applyingpressure to the two sides of a first-stage nanofiltration membrane, to form a pressure difference; enabling parts of water, sodium ions, potassium ions, lithium ions and chloride ions in the softenedbrine to migrate to a low-pressure side from a high-pressure side through the first-stage nanofiltration membrane, enriching the high-valence anions on the high-pressure side to obtain brine rich inthe high-valence anions, pumping the brine rich in the high-valence anions back to the salt lake, wherein the high-valence anions comprise sulfate ions, carbonate ions and polyborate ions; and obtaining chloride type brine containing a small amount of high-valence anions on the low-pressure side.

Owner:BEIJING QINGYUAN POWERISE TECH CO LTD +1

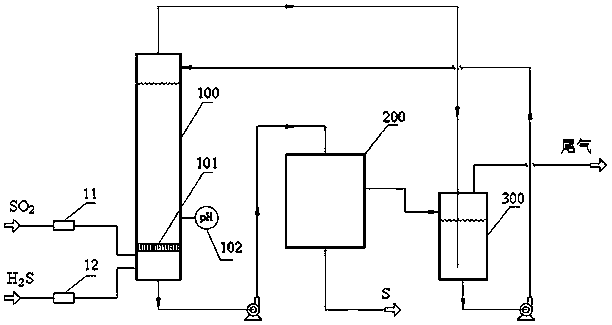

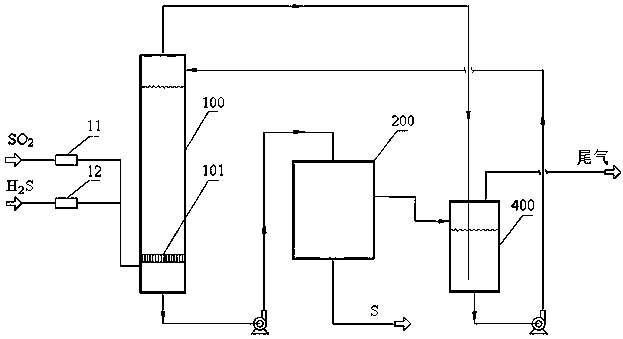

Process for desulfurization by reacting hydrogen sulfide with sulfur dioxide

ActiveCN109529567AIncrease acidityRapid responseGas treatmentDispersed particle separationAtmospheric pressureSafe operation

Disclosed is a process for desulfurization by reacting hydrogen sulfide with sulfur dioxide. The process includes the following steps: gas containing hydrogen sulfide and gas containing sulfur dioxideare introduced into a reactor, wherein the reactor is filled with a reaction solution, the reaction solution comprises water and at least one organic alkaline compound mutually soluble with water, and the organic alkaline compounds make the pH value of the solution greater than or equal to 7.2; and the hydrogen sulfide reacts with the sulfur dioxide to produce sulfur, the sulfur is removed in thereaction process, the reaction solution is replenished online, and liquid and solid in the reactor are separated after the reaction is completed to obtain the sulfur. The process of the invention utilizes the addition of the organic alkaline compounds in the reaction solution to greatly shorten the reaction time of H2S and SO2 in liquid phase, the reaction response time is less than 15 seconds, and the reaction can be carried out at normal temperature and atmospheric pressure for desulfurization. The high-purity sulfur can be obtained by simply liquid-solid separation without refinement. Theprocess of the invention has the advantages of mild reaction conditions required, simple and easy processing equipment, low investment and safe operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

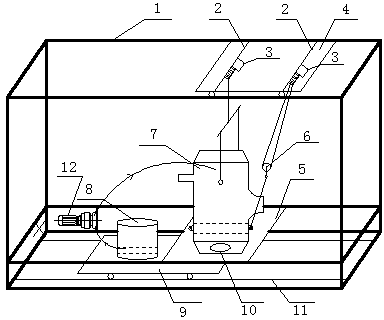

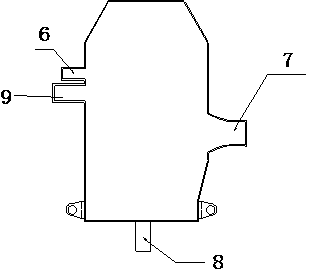

Test device for simulating smelting and tapping processes of rotary furnace

InactiveCN103866075AEfficient researchConvenient researchManufacturing convertersSteelmakingWater storage tank

The invention discloses a test device for simulating smelting and tapping processes of a rotary furnace. The test device comprises a test device frame, wherein a track is arranged at the bottom of the test device frame, a water storage tank trolley is placed on the track, and a water storage tank is placed on the water storage tank trolley; a test platform is arranged above the track, and a molten steel rotary furnace model is placed on the test platform; lifting equipment is arranged at the top of the test device frame and connected with the molten steel rotary furnace model and drives the molten steel rotary furnace model to move in horizontal and vertical directions and incline in the vertical direction; a water circulating pump is fixed on the test device frame, one pipe orifice of the water circulating pump is connected with a water storage tank, and the other pipe orifice of the water circulating pump is connected with the molten steel rotary furnace model. The test device disclosed by the invention can be used for efficiently, conveniently and fast researching the steelmaking process and tapping process of the rotary furnace in a laboratory and has great significance on the researching and developing the steelmaking process, reducing slagging quantity, reducing the refining cost, and the like.

Owner:武汉钢铁有限公司 +1

Method for refining molten iron containing chromium

InactiveUS20040245682A1Reduce forceMinimal damageCharge manipulationManufacturing convertersAtmospheric pressureMolten steel

A refining method and refining apparatus, able to shorten the time required for refining and reduce the refining costs in decarburization refining of a chromium-contained molten steel, which refining method for chromium-contained molten steel etc. performing decarburization refining by blowing a gas containing oxygen gas into a chromium-contained molten steel under a vacuum or atmospheric pressure and vacuum, said refining method for a chromium-contained molten steel etc. characterized by having a first step for blowing oxygen gas while making the inside of the vessel a pressure of a range of 400 Torr (53 kPa) to atmospheric pressure, a second step for blowing oxygen gas while evacuating the inside of the vessel to 250 to 400 Torr (33 to 53 kPa), and third step for blowing gas while evacuating the inside of the vessel to not more than 250 Torr (33 kPa). Further, a refining method and refining apparatus for an ultra-low carbon chrome melt characterized by performing a first vacuum refining until the third step, then restoring the pressure in the vessel to at least 400 Torr (53 kPa), then performing second vacuum refining while making the bottom blowing gas blow rate at least 0.4 Nm<3> / min per ton steel.

Owner:NIPPON STEEL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com