Single-dip-pipe vacuum refining device and using method thereof

A technology of vacuum refining and single dipping tube, which is applied in the field of molten steel refining outside the furnace, which can solve problems such as deviation, blockage of bottom blowing gas, interruption of refining process, etc., and achieve the effects of improving life, reducing erosion and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

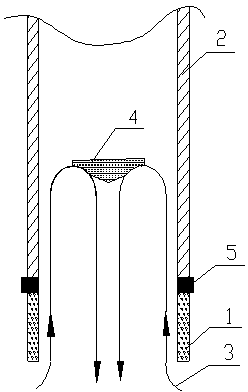

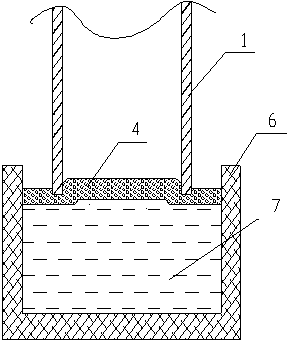

[0023]The single dipping tube vacuum refining device performs refining according to the following steps:

[0024] (1) When refining molten steel, first lift the ladle to the ladle car, and the ladle car drives into the treatment station of the single-dipping tube vacuum refining device, then insert the dipping tube into the ladle slag, vacuum the slag, and suck as much ladle slag as possible .

[0025] (2) Insert the dipping pipe into the molten steel to a depth of 400mm, open the nozzle valve on the circulation pipe of the dipping pipe, the blowing volume of each nozzle is equal, and the total blowing flow rate is controlled at 13NL / min per ton of steel.

[0026] (3) Vacuumize to reduce the vacuum degree to 73Pa after 3 minutes. Observe the top slag situation of the liquid steel surface in the vacuum chamber through the camera image of the vacuum chamber, and further adjust the total blowing flow rate of the nozzle to 18NL / min per ton of steel.

[0027] (4) After 10 min...

Embodiment 2

[0030] The single dipping tube vacuum refining device performs refining according to the following steps:

[0031] (1) When refining molten steel, first lift the ladle to the ladle car, and the ladle car drives into the treatment station of the single-dipping tube vacuum refining device, then insert the dipping tube into the ladle slag, vacuum the slag, and suck as much ladle slag as possible .

[0032] (2) Insert the dipping pipe into the molten steel to a depth of 400mm, open the nozzle valve on the circulation pipe of the dipping pipe, the blowing volume of each nozzle is equal, and the total blowing flow rate is controlled at 15NL / min per ton of steel.

[0033] (3) Vacuumize to reduce the vacuum degree to 70Pa after 3 minutes. Observe the top slag situation of the liquid steel surface in the vacuum chamber through the camera image of the vacuum chamber, and further adjust the total blowing flow rate of the nozzle to 20NL / min per ton of steel.

[0034] (4) After 11 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com