Hydrocarbon oil sulfur-nitrogen compound remover, preparation method thereof and application thereof

A compound and removing agent technology is applied in the field of hydrocarbon oil sulfur and nitrogen compound removing agents, which can solve the problems of excessive ionic liquid extraction, corrosion of downstream equipment, environmental hazards, etc., and achieves reduction of hydrocarbon oil refining costs, desulfurization The effect of increasing nitrogen rate and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

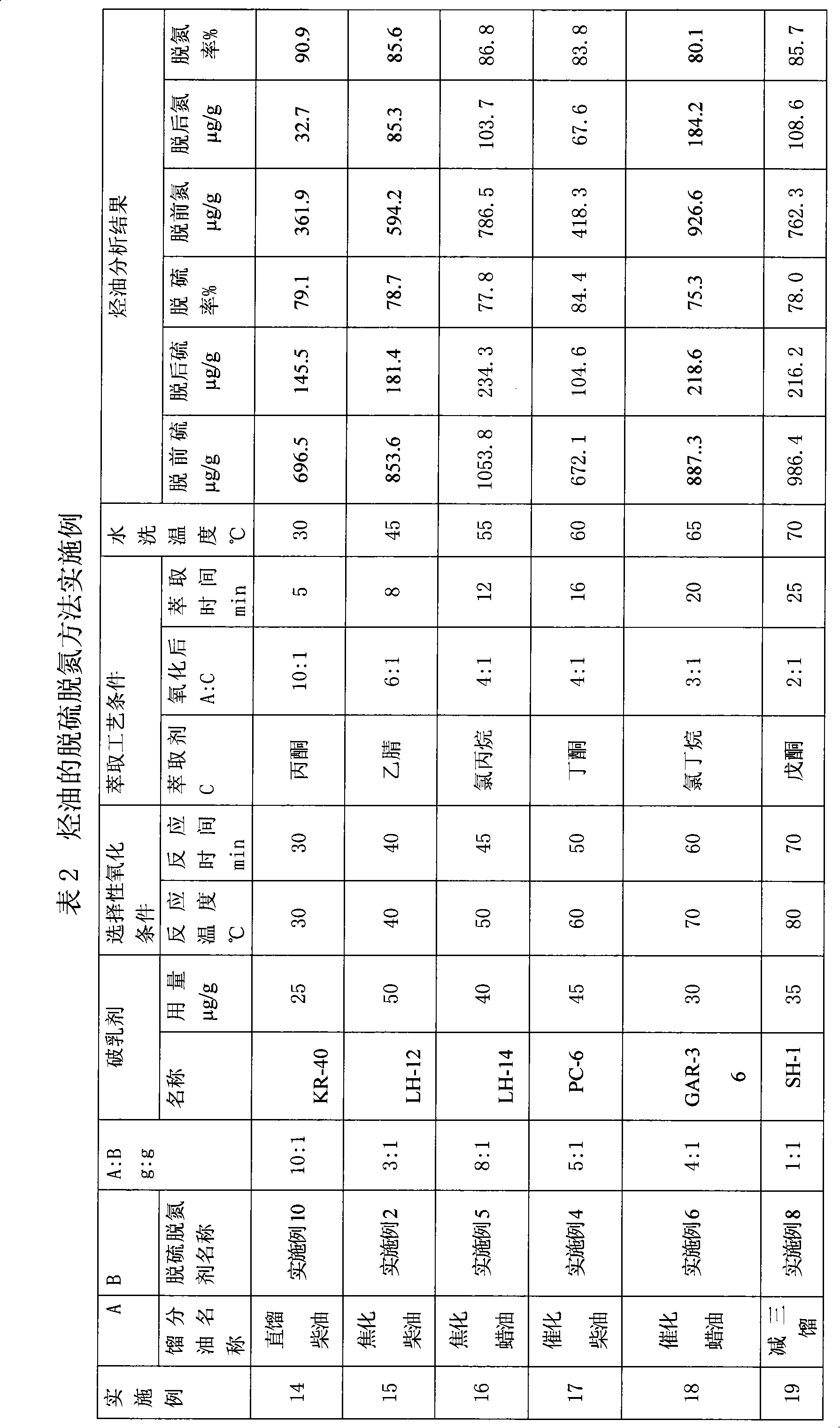

[0021] Examples 1-12 are preparation examples of desulfurization and denitrification agents, see Table 1 for details.

[0022] Table 1 Preparation Examples of Desulfurization and Denitrification Agents

[0023] Example

Embodiment 13

[0025] Add Karamay heavy oil to the second distillate oil: the hydrocarbon oil sulfur and nitrogen compound remover of Example 1 in a weight ratio of 7:1 into the reactor, and then add 50 μg / g demulsifier KR-41 accounting for the weight of the second distillate oil. The reaction temperature is 70±2°C, stirring and reacting for 60 minutes, fully standing at room temperature and stratifying, the obtained lower layer solution is stored for recycling, and the obtained upper layer oxidized distillate oil and acetonitrile extractant are calculated according to distillate oil: acetonitrile weight The ratio is 8:1 after extracting at room temperature for 10 minutes, then standing to separate layers, release the extracted distillate oil, save the solution containing acetonitrile extractant for later use, and then use 50 ℃ warm water to repeatedly distill the extracted distillate oil Washed with water until neutral, the oil sample was taken to measure and analyze the results: the sulfur ...

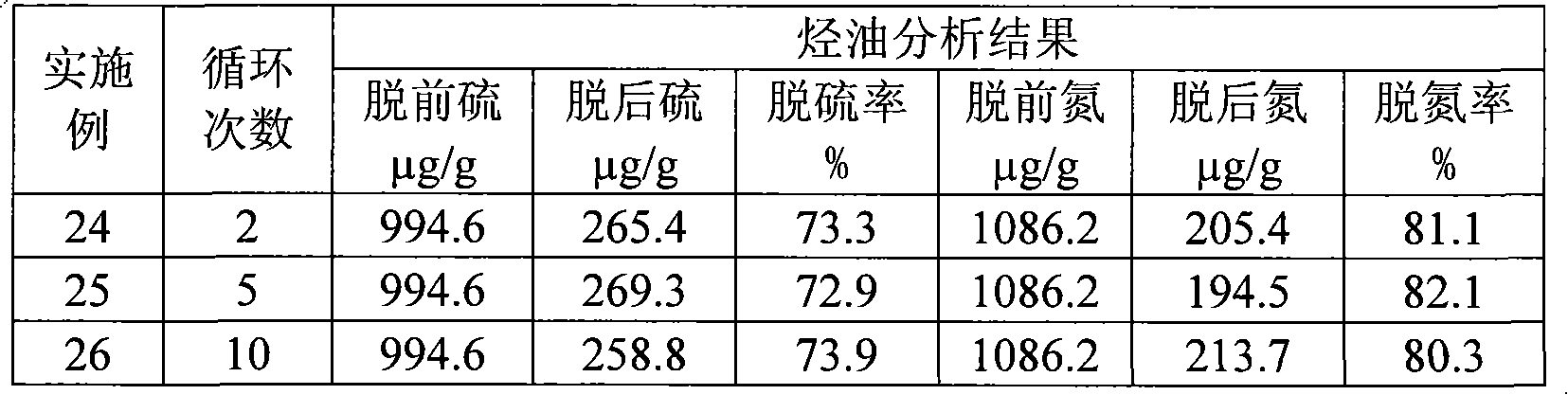

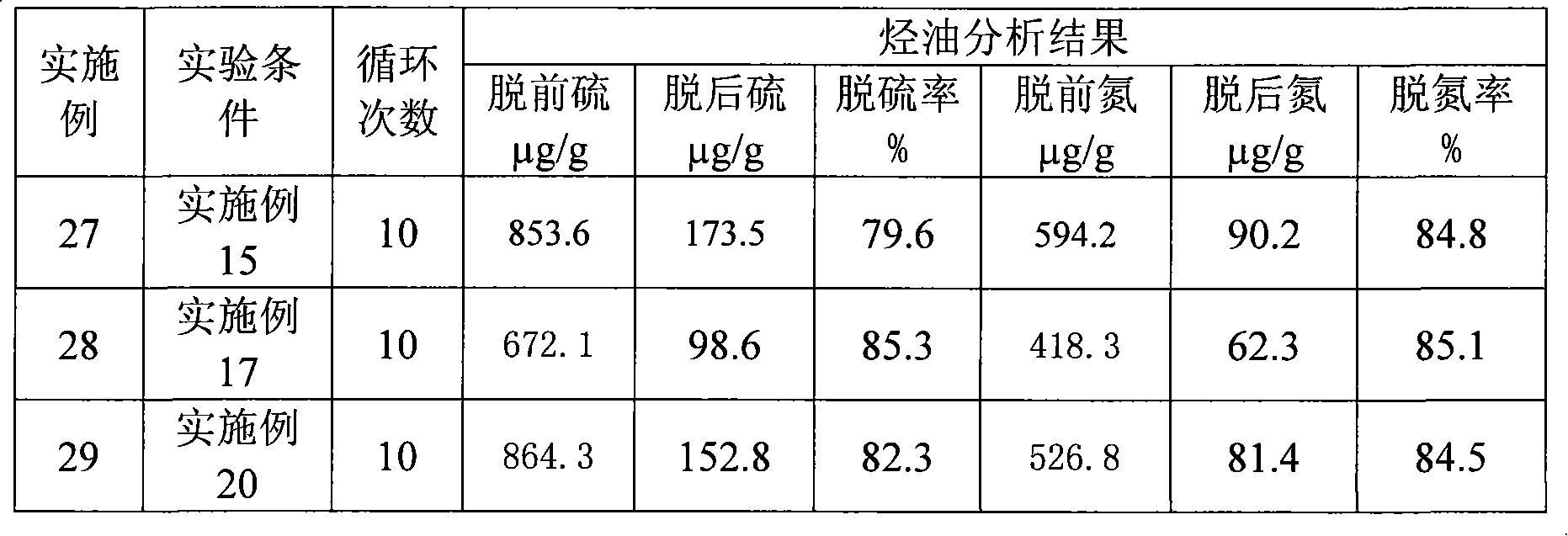

Embodiment 23

[0029] The solution obtained after filtering the isolated lower layer solution at room temperature after the selective oxidation reaction of Example 13 was titrated with 0.1mol / L sodium hydroxide solution to measure that glycolic acid was 4.5mol / L, according to The measured molar concentration of glycolic acid supplements the consumed H in a molar ratio of 1:1. 2 o 2 Inorganic oxidant, that is, reconstituted desulfurization and denitrification agent, stored at room temperature for 3 days.

[0030]The above-mentioned desulfurization and denitrification agent re-prepared according to the required amount is continued to carry out the recycling experiment according to the experimental process conditions of Example 13. When the desulfurization and denitrification agent is not enough for the distillate oil treatment capacity, an appropriate amount of fresh desulfurization and denitrification agent can be added. After the process steps of selective oxidation, solvent extraction, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com