High-strength water-based itaconic acid epoxide resin grouting material and preparation method thereof

A technology of itaconic acid epoxy resin and itaconic acid epoxy ester, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of low mechanical strength of the consolidated body, limited application, and low overall strength of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

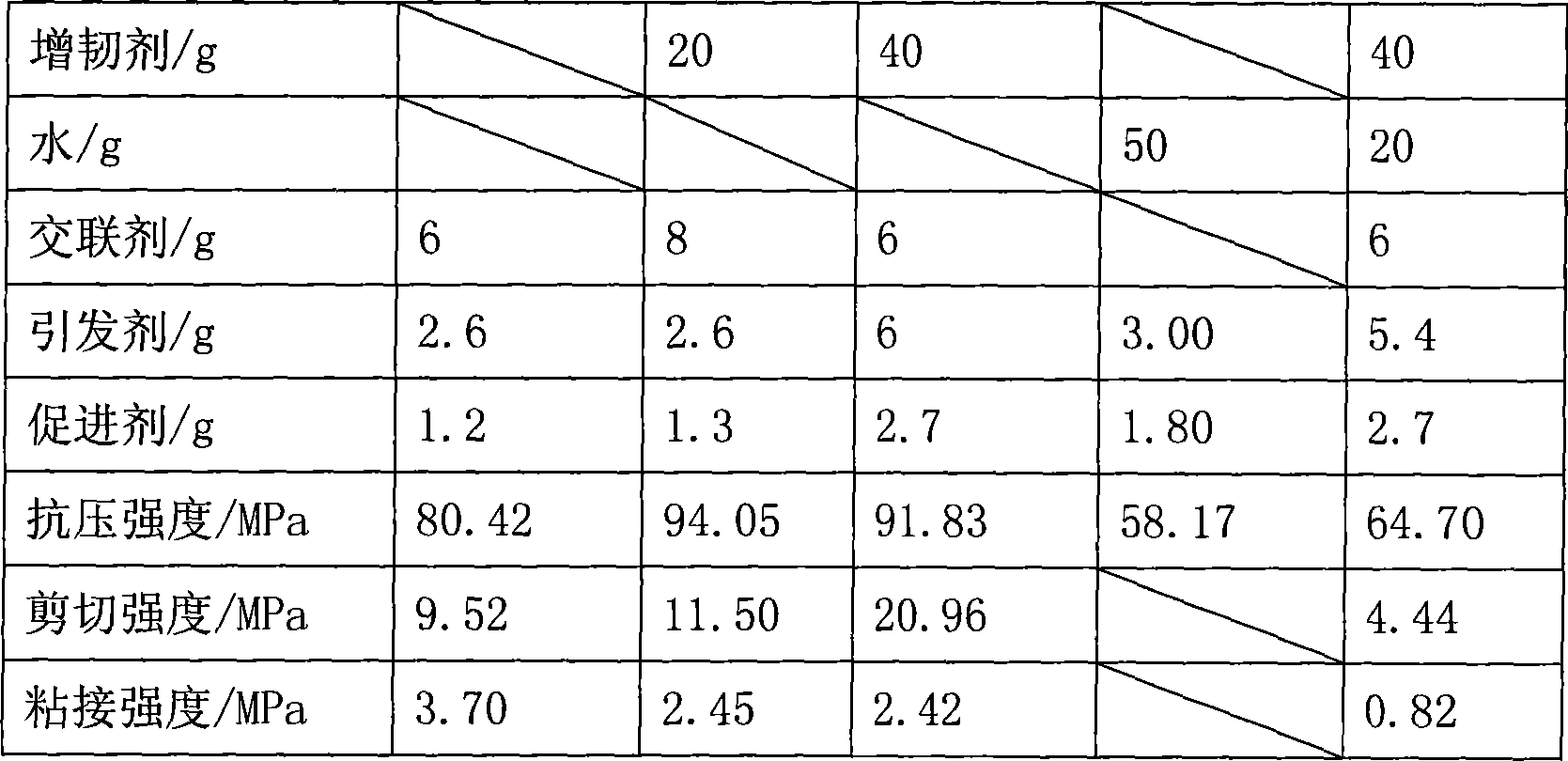

Examples

Embodiment 1

[0068] (1) Preparation of neutralized waterborne epoxy itaconate resin

[0069] In a 1000ml four-neck flask equipped with nitrogen, a stirring device and a thermometer, add 139.2g itaconic acid and 120g hydroxyethyl methacrylate, add 1.52g benzyl triethylammonium chloride and 0.42g hydroquinone, When heating up to 85°C, add 200g of E-51 epoxy resin in portions, keep the constant temperature at 110°C after adding, react for 2h, and stop the reaction when the measured acid value reaches 80 mg / g.

[0070] Lower the temperature to 60° C., add DMAM for neutralization, stir well, then add 200 g of methyl methacrylate for dilution, and stir well to obtain a water-based itaconic acid epoxy resin.

[0071] (2) Preparation of epoxy resin grouting material

[0072] Take 100g of the above resin, add 1.2g of cobalt isooctanoate, add 6g of tripropylene glycol dimethacrylate, add 2.6g of methyl ethyl ketone peroxide, and mix evenly to form the grouting material.

[0073] After the material w...

Embodiment 2

[0075] (1) Preparation of neutralized waterborne epoxy itaconate resin

[0076] In a 1000ml four-neck flask equipped with nitrogen, a stirring device and a thermometer, add 100g of itaconic acid and 50g of hydroxyethyl methacrylate, add 1.09g of benzyl triethylammonium chloride and 0.30g of hydroquinone, and heat When the temperature was raised to 85°C, 143.7g of E-51 epoxy resin was added in portions. After the addition, the constant temperature was maintained at 115°C, and the reaction was carried out for 3 hours. The reaction was stopped when the measured acid value reached 200 mg / g.

[0077] Lower the temperature to 60°C, add DMAM for neutralization, stir well, then add 140g MMA and 70g HEMA to dilute, then add 140g water and stir well to obtain a water-based itaconic acid epoxy resin.

[0078] (2) Preparation of epoxy resin grouting material

[0079] Take 100g of the above resin, add 1.8g of cobalt isooctanoate, add 6g of tripropylene glycol dimethacrylate, add 3.6g of m...

Embodiment 3

[0082] (1) Preparation of neutralized waterborne epoxy itaconate resin

[0083] In a 1000ml four-necked flask equipped with nitrogen, a stirring device and a thermometer, add 139.2g itaconic acid and 120g hydroxyethyl methacrylate, add 1.52g benzyl triethylammonium chloride and 0.42g hydroquinone, When heating up to 85°C, add 200g of E-51 epoxy resin in portions, keep the constant temperature at 112°C after adding, react for 2.5h, and stop the reaction when the measured acid value reaches 150 mg / g.

[0084] Lower the temperature to 60°C, add DMAM for neutralization, stir well, then add 220g of MMA to dilute, then add 63g of water and stir well to obtain a water-based itaconic acid epoxy resin.

[0085] (2) Synthesis of toughening agent

[0086] In a 500ml four-neck flask equipped with nitrogen, a stirring device and a thermometer, add 87g of TDI, dropwise add N204 polyether polyol at room temperature, heat up to 50°C for 3h after dropping, then add HEMA50g dropwise at 70°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com