High-performance binder for silicon materials for lithium ion batteries and preparation method thereof

A lithium-ion battery and binder technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of easy cyclization, alleviating volume expansion, and improving microscopic composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

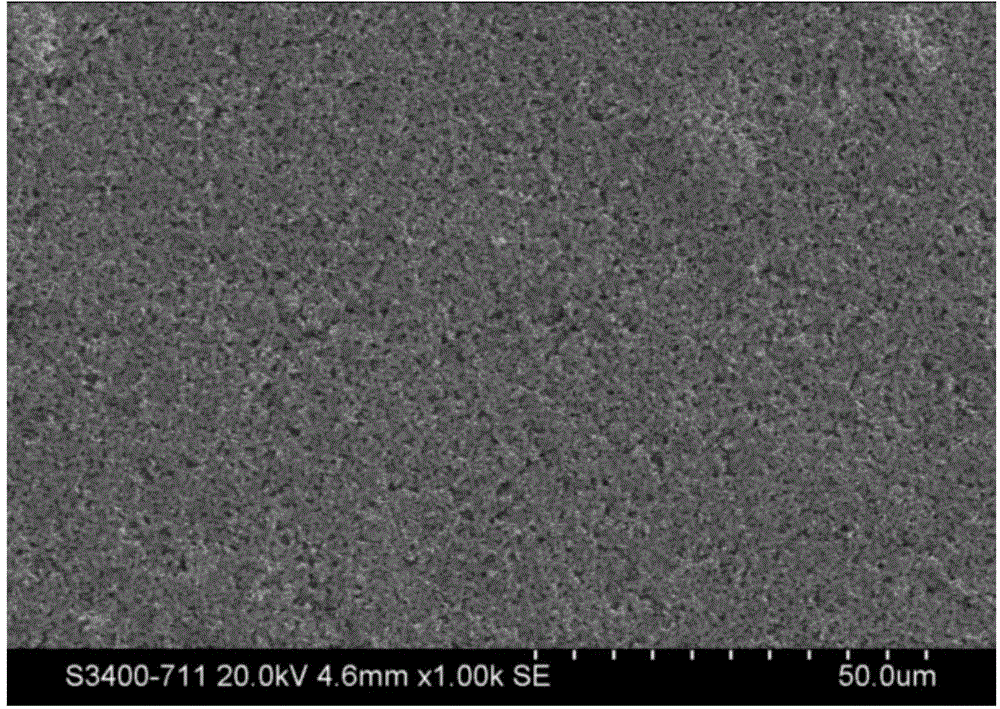

Image

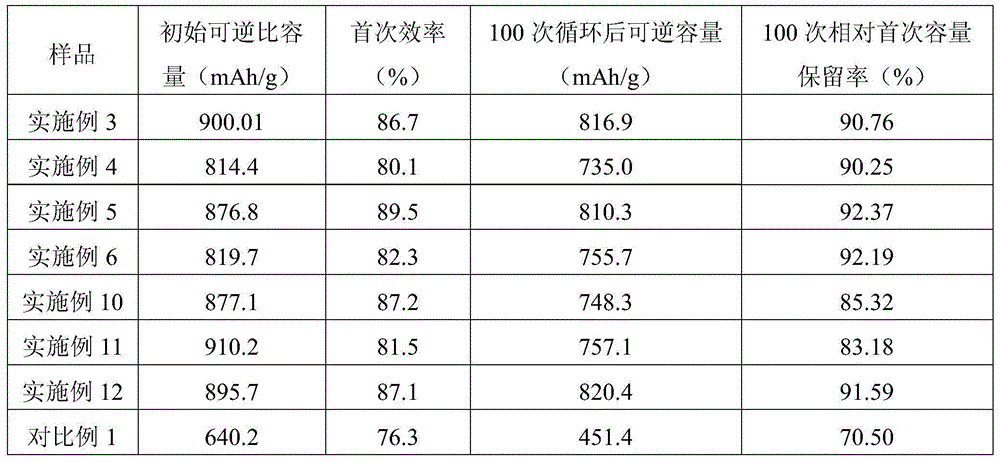

Examples

Embodiment 1

[0037] Prepare a kind of binder for lithium ion battery silicon material of the present invention, preparation method is as follows:

[0038] With a mechanical stirrer, N 2Add monobutyl itaconate (accounting for 5% of monomer mass), azoisobutyronitrile (accounting for 0.5% of monomer mass), n-butyl acrylate in different proportions to the 250mL four-necked flask with protective device and thermometer (accounting for 2% of the mass of acrylonitrile monomer), emulsifier OP10 (accounting for 0.5% of the mass of the monomer), acrylonitrile monomer and water (9 times the mass of the monomer), heated to 110 ° C, and took it out after 24 hours of reaction , after washing and filtering with deionized water several times, the polymer powder whose main component is polyacrylonitrile is obtained, which is used as the binder I for silicon materials of lithium-ion batteries, and its molecular weight is about 280,000.

Embodiment 2

[0040] Prepare a kind of binder for lithium ion battery silicon material of the present invention, preparation method is as follows:

[0041] With a mechanical stirrer, N 2 Add monobutyl itaconate (accounting for 8% of the monomer mass), azoisobutyronitrile (accounting for 0.5% of the monomer mass), n-butyl acrylate in different proportions in the 250mL four-necked flask with protective device and thermometer (2% of monomer mass), emulsifier OP10 (0.5% of monomer mass), acrylonitrile monomer (90% of monomer mass) and water (9 times of monomer mass), heated to Take it out after reacting for 24 hours at 85°C, wash and filter for many times to obtain a polymer powder whose main component is polyacrylonitrile, which is used as the binder II for silicon material of lithium ion battery, and its molecular weight is about 354,000.

Embodiment 3

[0043] In this embodiment, a high-purity crystalline silicon (Wt%=99.9%) material with a diameter of ~100nm and a particle size of ~1 μm Super P, 3 μm mesophase carbon microspheres, and MWCNTs are selected as the conductive agent (Super P: MCMB: MWCNTs w / w=60:35:5), using the binder I prepared in Example 1 as the binder material for preparing electrodes.

[0044] Follow the steps below to prepare high-purity crystalline silicon electrodes:

[0045] 1) Weighing 50% of the silicon-based active material and 20% of the carbon material conductive agent according to mass percentage and mixing and dispersing evenly;

[0046] 2) By mass percentage, take 30% of the binder I prepared in Example 1 as binder powder, dissolve it in an appropriate amount of NMP, disperse evenly, and stir into a transparent sol;

[0047] 3) Add the powder obtained in step 1) to the sol-like material obtained in step 2), control the solid content at 40%, stir vigorously, and form a slurry after stirring eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com