Method for preparing magnetic molecularly imprinted polymer through suspension polymerization

A technology of magnetic molecular imprinting and suspension polymerization, which is applied to alkali metal compounds, chemical instruments and methods, and other chemical processes, can solve the problems of lack of specific recognition ability and poor selectivity, and achieve good magnetic response performance and strong Adsorption performance and thermal stability performance, the effect of rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

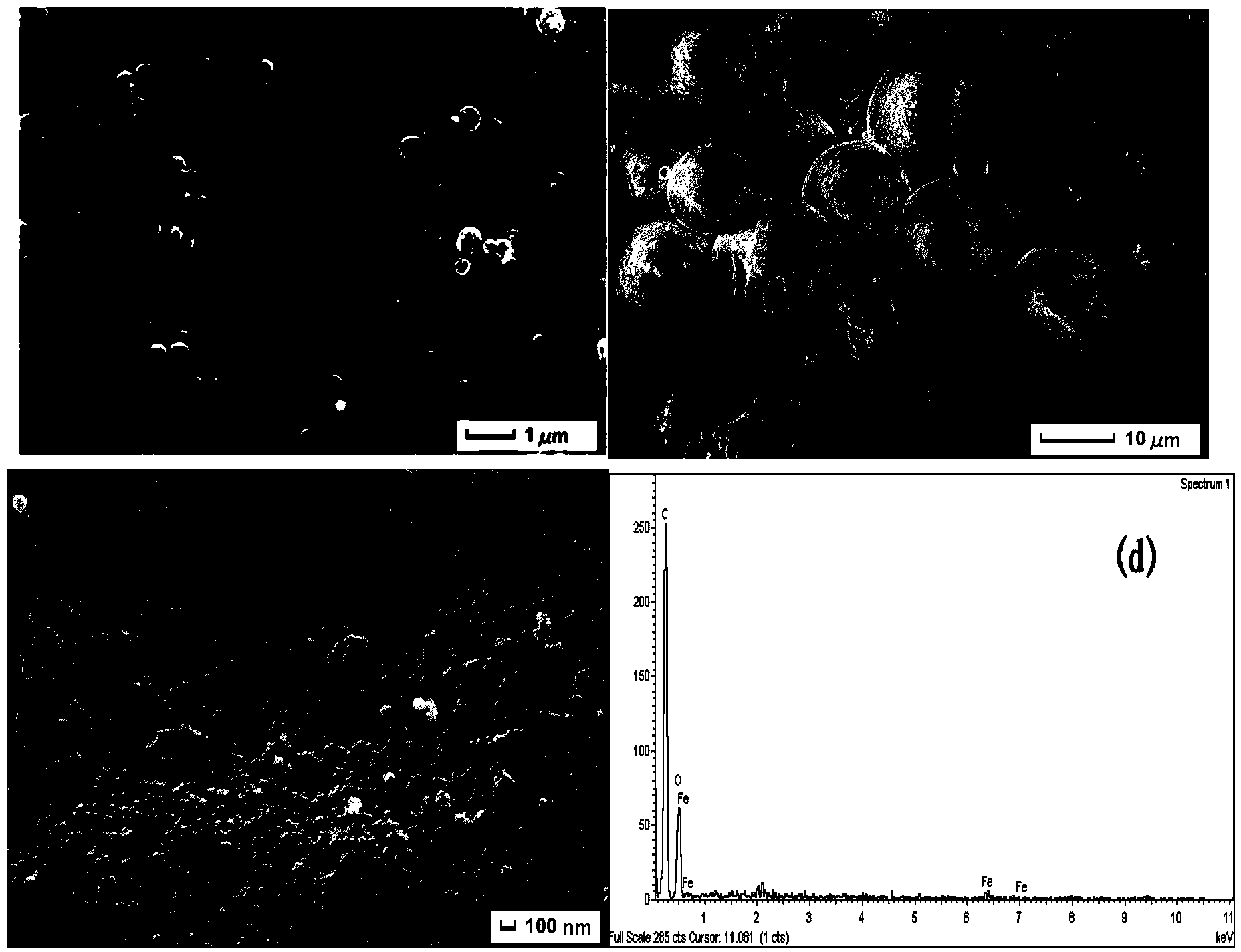

[0043] (1) Synthesis of ferroferric oxide (Fe 3 o 4 ) magnetic nanoparticles:

[0044] Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and anhydrous sodium acetate (NaAc) are dissolved in ethylene glycol solution, wherein control FeCl 3 ·6H 2 The ratio of O, NaAc and ethylene glycol is (1.3:7:40) (g / mL / mL). The mixed solution was stirred in a constant temperature water bath at 160°C at a speed of 800 rpm / min under the protection of nitrogen for 1 h, then the mixed solution was transferred to a 50ml reaction kettle, the temperature was controlled at 200°C, and the reaction time was 10 h. After cooling to room temperature, the suspension was washed three times with ethanol solution, and the obtained product was dried in a vacuum environment at 60° C., and finally pulverized and ground in a mortar.

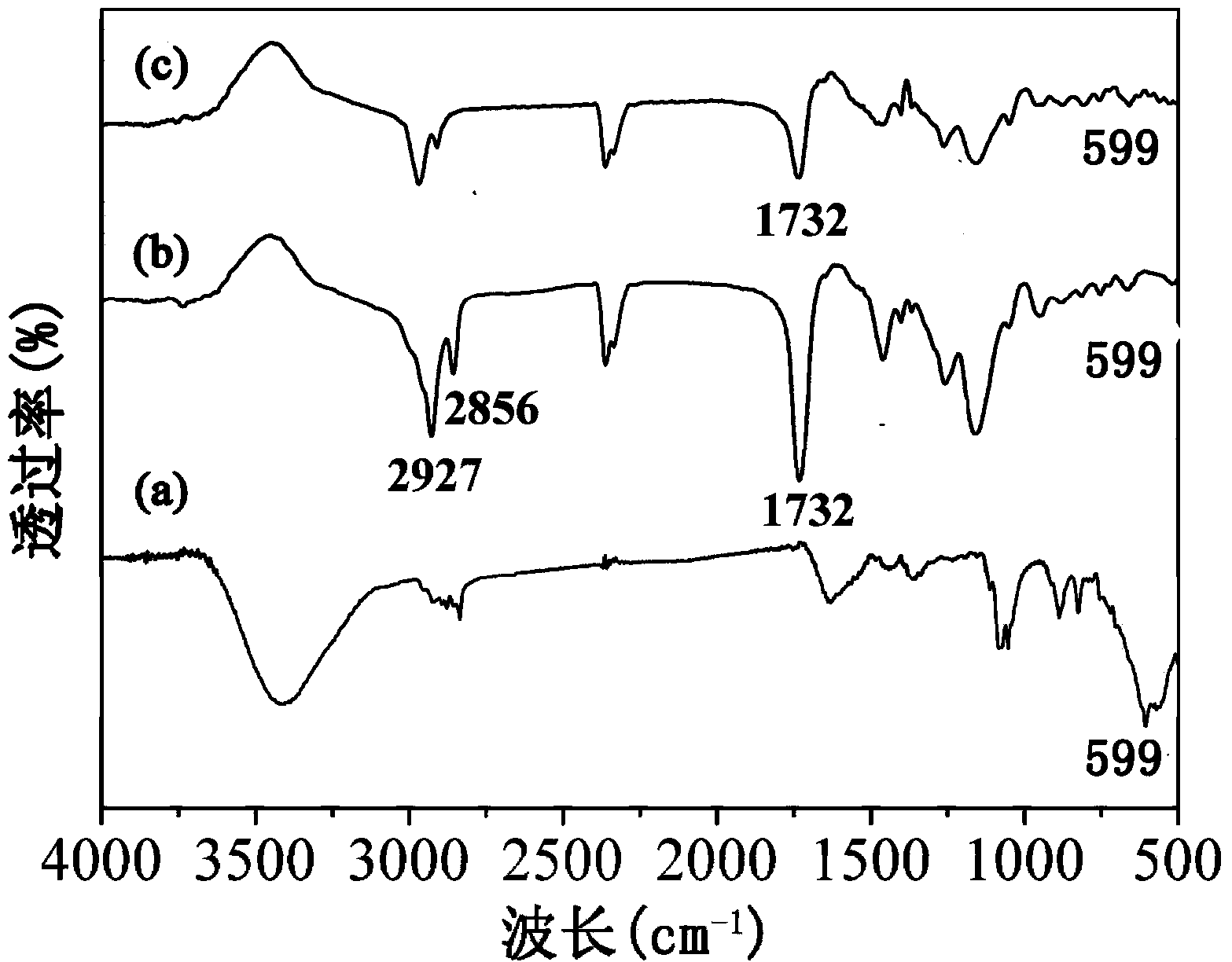

[0045] (2) Oleic acid on Fe 3 o 4 Magnetic nanoparticles for surface modification

[0046] The Fe prepared in step (1) 3 o 4 Nanoparticles were mixed with oleic acid and cont...

Embodiment 2

[0064] (1) Synthesis of ferric oxide (Fe 3 o 4 ) magnetic nanoparticles:

[0065] Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and anhydrous sodium acetate (NaAc) are dissolved in ethylene glycol solution, wherein control FeCl 3 ·6H 2 O, the ratio of NaAc and ethylene glycol is (1.4:8:50) (g / mL / mL). The mixed solution was stirred in a constant temperature water bath at 160 °C for 2 h at a speed of 800 rpm / min under the protection of nitrogen, and then the mixed solution was transferred to a 50 mL reactor, the temperature was controlled at 200 °C, and the reaction time was 10 h. After taking it out, it was cooled to room temperature, and the suspension was washed 5 times with ethanol solution, and the obtained product was dried in a vacuum environment at 60° C., and finally pulverized and ground in a mortar.

[0066] (2) Oleic acid on Fe 3 o 4 Magnetic nanoparticles for surface modification

[0067] The Fe prepared in step (1) 3 o 4 Nanoparticles were mixed with olei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com