Adhesive tape for bonding low-surface-energy material and preparation method thereof

A low surface energy and material technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of poor aging resistance, oxygen sensitivity, poor adhesion, etc., and achieve easy production and preparation Simple process, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a three-necked flask equipped with a reflux device, add 25 parts of isooctyl acrylate, 10 parts of methyl methacrylate, 52 parts of n-butyl acrylate, 5 parts of acrylic acid, 8 parts of hexafluorobutyl acrylate, and 140 parts of ethyl acetate And 0.2 parts of azobisisobutyronitrile, blow nitrogen, stir for half an hour, discharge oxygen, put in a water bath at 60°C and continue to react with nitrogen for 6 hours.

[0023] Add 0.5 parts of aluminum acetylacetonate to the obtained acrylate polymer solution and let it stand for degassing, then apply it on the release film, and dry it at 110°C for 3 minutes to ensure that the thickness of the dried film is 50um, and then match it with a thickness of 30um The corona-treated PET film was composited, placed at room temperature for 7 days and then tested for related properties.

Embodiment 2

[0025] In a three-necked flask equipped with a reflux device, add 35 parts of isooctyl acrylate, 12 parts of vinyl acetate, 41 parts of n-butyl acrylate, 2 parts of acrylic acid, 3 parts of (meth)hydroxyethyl acrylate, 7 parts of decaacrylate Difluoroheptyl ester, 140 parts of toluene and 0.2 part of benzoyl peroxide were fed with nitrogen, stirred for half an hour, and oxygen was discharged, put into a water bath at 75°C and continued to react with nitrogen for 6 hours.

[0026] Add 0.5 parts of Desmodur N75 to the obtained acrylate polymer solution and let it stand for degassing, then apply it on the release film, and dry it at 110°C for 3 minutes to ensure that the thickness of the dried film is 50um, and then mix with 30um thick The corona-treated PET film is composited, placed at room temperature for 7 days and then tested for related properties.

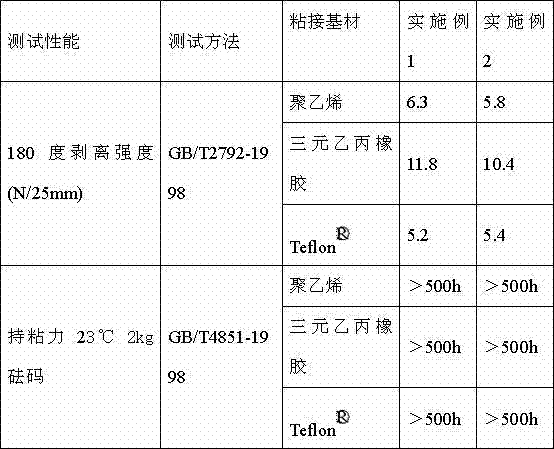

[0027] Table 1 lists the adhesive properties of the examples. The results show that the adhesive tape of the invention is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com