Ageing resistant wood plastic composite modified by titanium oxide fiber and lignin and preparation method thereof

A wood-plastic composite material and composite material technology, applied in the field of polymer processing, can solve the problems of material quality degradation, shortening service life, endangering human health, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

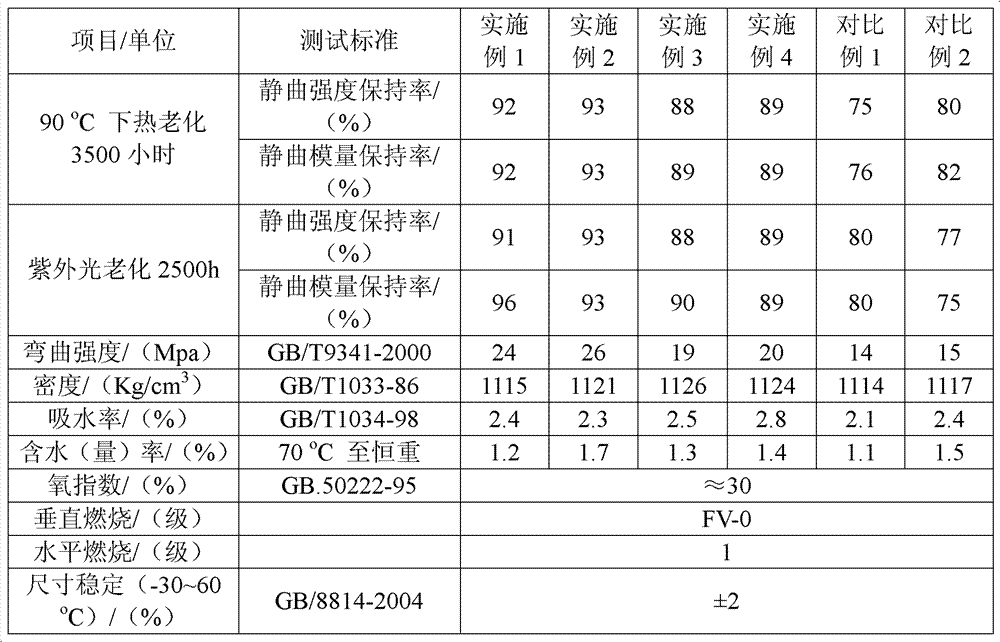

Examples

Embodiment 1

[0025] The raw material components are recorded as: 2 parts of titanium oxide fibers (10 nm in diameter, 1 μm in length, rutile type), 5 parts of alkali lignin, 28 parts of polyethylene, 50 parts of wood powder, and maleic anhydride grafted polyethylene 3 parts, 2 parts of zinc stearate, 1.5 parts of polyethylene wax, 7 parts of calcium carbonate, 0.5 part of iron red.

[0026] First, the above-mentioned raw materials are mixed evenly on a mixer, and the speed of the mixer is 3000 rpm, and then the mixed material is extruded and granulated in a twin-screw granulator. The head temperature is 180°C, the screw speed is 20r / min, and the feeder speed is 30r / min, and then the obtained pellets are sent into the twin-screw finished product extruder, and extruded and shaped through a die to obtain a wood-plastic composite product. The body temperature of the screw molding machine is 145°C-190°C, the die head temperature is 175°C, the screw speed is 40r / min, and the feeder speed is 30r / ...

Embodiment 2

[0028] The raw material components are recorded as follows by weight: 5 parts of titanium oxide fibers (1 μm in diameter, 10 μm in length, anatase type), 10 parts of acid lignin, 25 parts of polyvinyl chloride, 40 parts of wood powder, and 3 parts of phenolic resin , 4.5 parts of dibutyl phthalate, 12 parts of wollastonite, and 0.5 parts of carbon black.

[0029] First, the above-mentioned raw materials are mixed evenly on a mixer, and the speed of the mixer is 9000 rpm, and then the mixed material is extruded and granulated in a twin-screw granulator. The head temperature is 190°C, the screw speed is 30r / min, and the feeder speed is 40r / min, and then the obtained pellets are sent into the twin-screw finished product extruder, and extruded and shaped through a die to obtain a wood-plastic composite product. The body temperature of the screw molding machine is 145°C-190°C, the die temperature is 185°C, the screw speed is 50r / min, and the feeder speed is 40r / min.

Embodiment 3

[0031] The raw material components are recorded as follows by weight: 15 parts of titanium oxide fibers (5 μm in diameter, 50 μm in length, anatase type), 1 part of solvent lignin, 20 parts of polystyrene, 45 parts of wood powder, and maleic anhydride. 0.5 parts of branched polystyrene, 10 parts of ethylene bis-stearamide, and 8.5 parts of talc.

[0032] First, mix the above-mentioned raw materials evenly on a mixer, and the speed of the mixer is 5000 rpm, and then extrude and granulate the mixed material in a twin-screw granulator. The head temperature is 200°C, the screw speed is 40r / min, the feeder speed is 50r / min, and then the obtained pellets are sent into the twin-screw finished product extruder, and extruded through the die to set the shape to obtain a wood-plastic composite product. The body temperature of the screw molding machine is 145°C-190°C, the die temperature is 195°C, the screw speed is 60r / min, and the feeder speed is 50r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com