Inorganic bonding glaze and porcelain bushing bonding method for high-pressure porcelain sleeve

A technology of inorganic bonding and high-voltage porcelain, which is applied in the field of inorganic bonding glaze for high-voltage porcelain sleeves and bonding of porcelain sleeves, can solve problems such as poor aging resistance, and achieve the goal of improving strength, improving adaptability, and increasing self-strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] a. Preparation of bonding glaze

[0019] According to the composition of Table 1, four formulations of inorganic bonding glazes were prepared. After mixing clay, potassium feldspar, quartz, alumina, talc, calcite, fluorite, and pigments, the mixture was mixed with material: ball stone: water = 1: 1.8 : 1 ratio for ball milling, and the ball milling time was 48 hours. The ball-milled slurry is baked in an oven at 100°C until it becomes a paste-like viscous body. The pigment is a commercially available product of iron chromium manganese oxide, and the color is brown.

[0020] Table 1 Unit: Gram

[0021]

[0022] b. Bonding of porcelain bushings

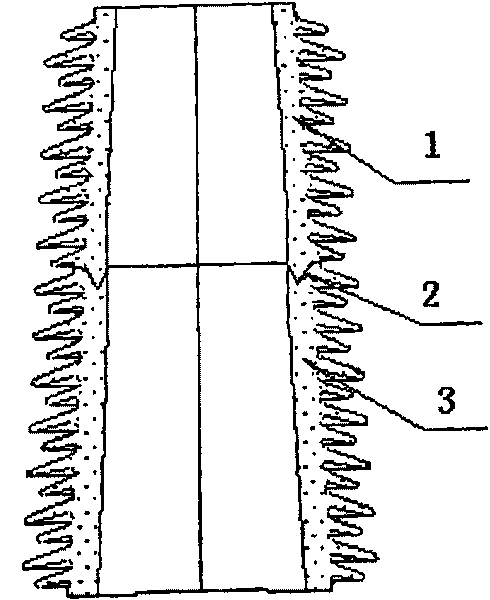

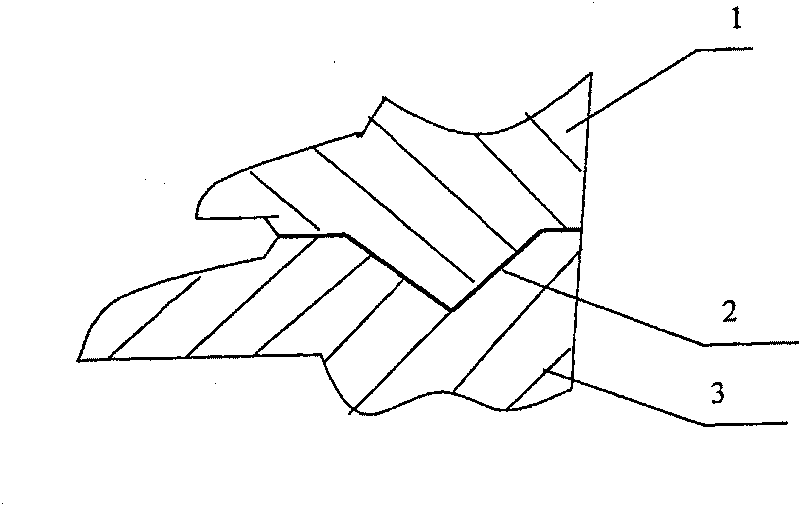

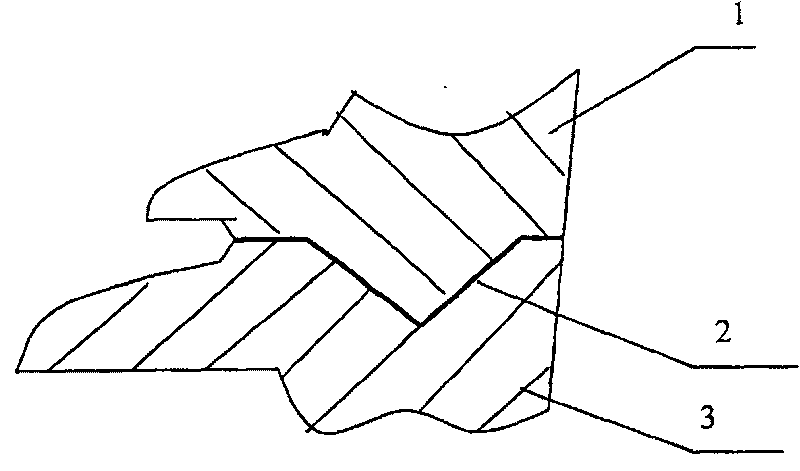

[0023] Such as figure 1 , figure 2 As shown, the connection end faces of the upper and lower ceramic sleeves 1 and 3 are respectively made into V-shaped convex and concave join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com