Steel wire bonding rubber composition with damp-heat aging resistance and steam aging resistance and application thereof

A rubber composition, a technology of resistance to heat and humidity, applied in the direction of adhesive types, natural rubber adhesives, aldehyde/ketone condensation polymer adhesives, etc., can solve problems such as accelerated rubber hydrocarbon aging, achieve good retention rate, The effect of good durability, improved service life and refurbishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

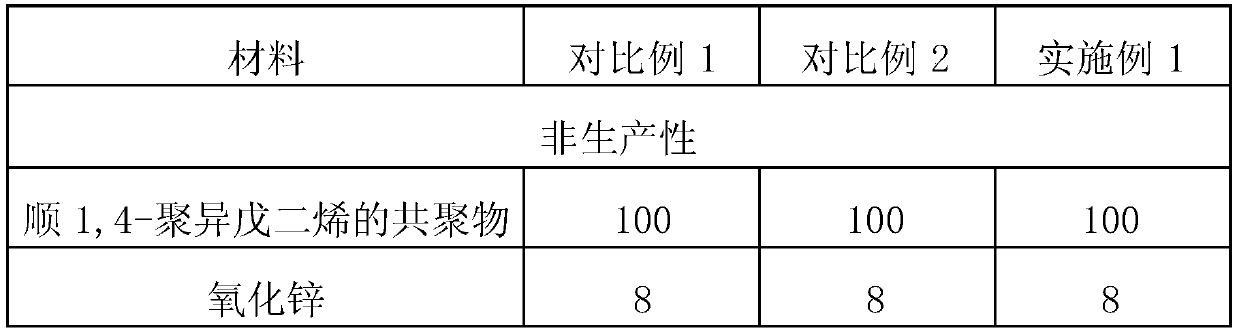

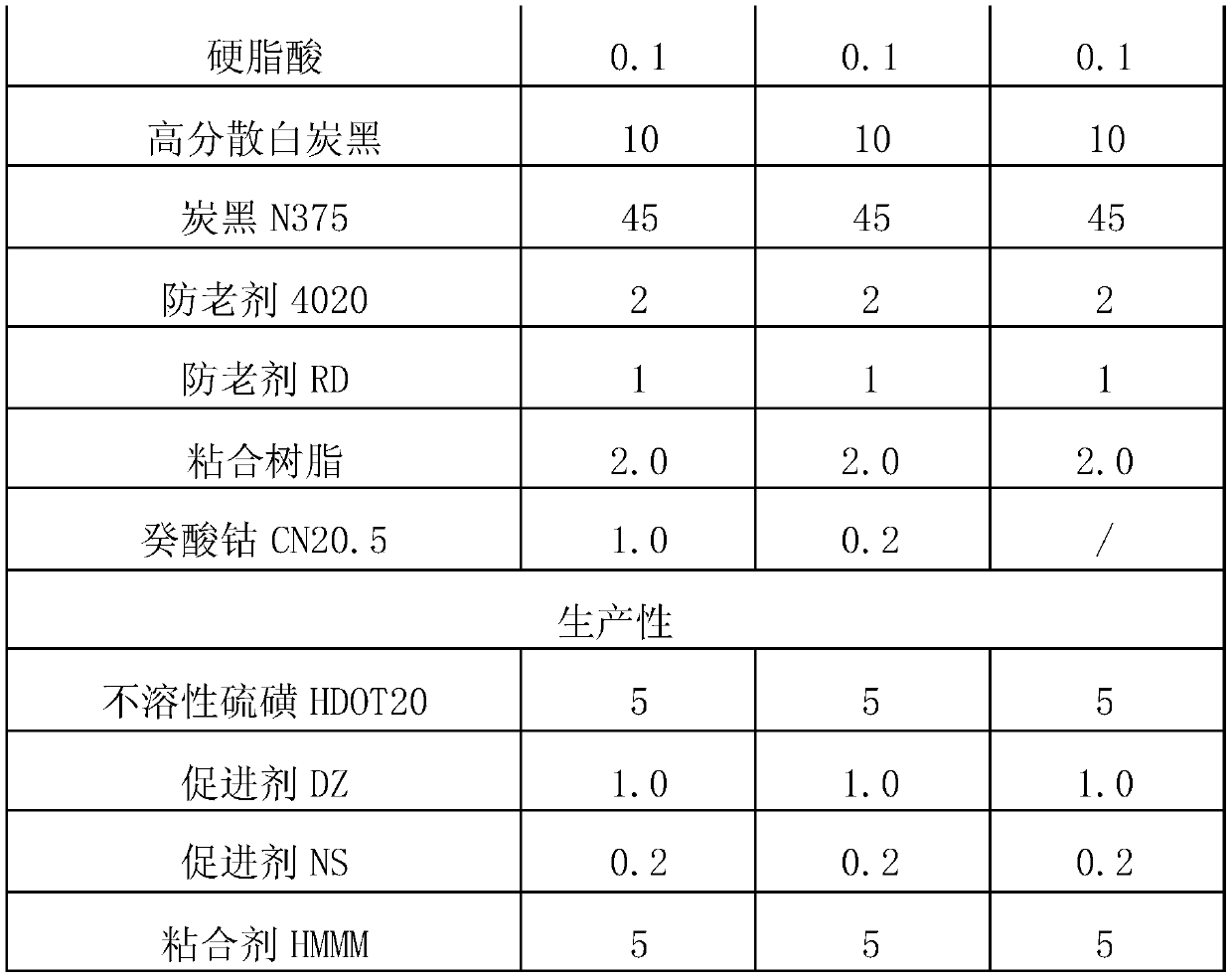

[0021] Rubber compositions of the composition specified in Table 1 were prepared in a BR Banbury internal mixer using four separate addition mixing stages, namely three non-productive mixing stages and one productive mixing stage. The three non-productive stages were mixed for about 1-3 minutes until the rubber temperature reached 160°C, which was completed; the productive stage was mixed for about 1-2.5 minutes until the rubber temperature reached 100°C.

[0022] The rubber compositions are referred to herein as Comparative Example 1, Comparative Example 2, and Example 1.

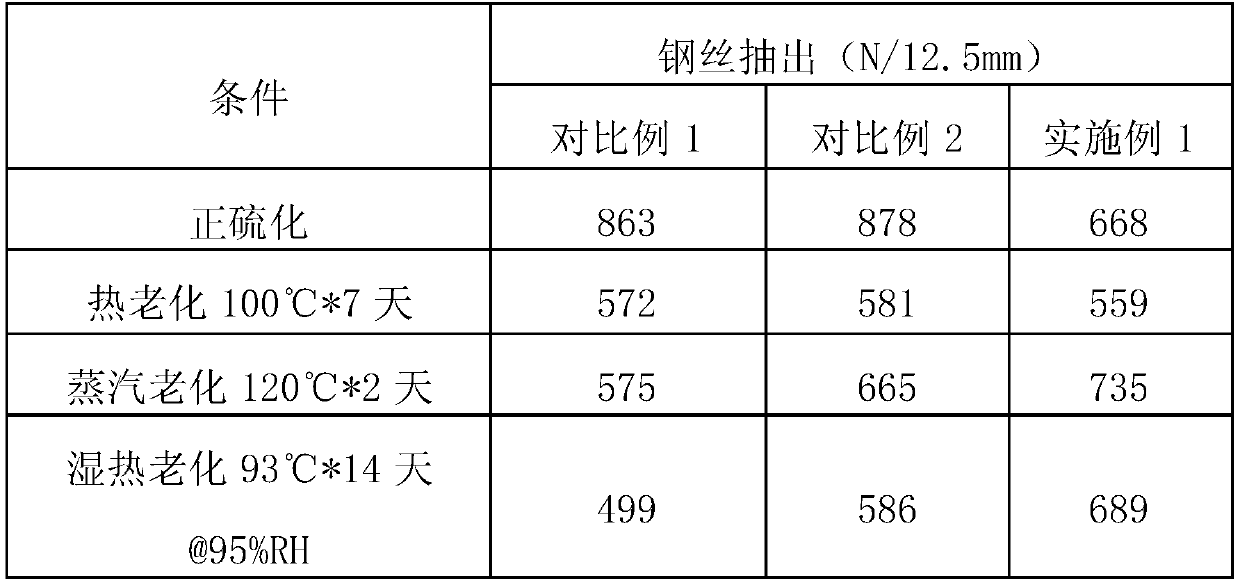

[0023] Table 2 shows the steel wire pulling performance of the vulcanized samples of Comparative Example 1, Comparative Example 2, and Example 1, and Table 3 shows the peeling force of the vulcanized samples of Comparative Example 1, Comparative Example 2, and Example 1.

[0024] Table 1 rubber composition raw material table

[0025]

[0026]

[0027] Table 2 Comparative Example 1, Comparative Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com