Resin composition

A technology of resin composition and thermoplastic resin, applied in fuel cells, conductive materials dispersed in non-conductive inorganic materials, electrochemical generators, etc., can solve problems such as insufficient conductivity, and achieve high conductivity and bending resistance Excellent foldability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 11 and comparative example 1~ comparative example 14

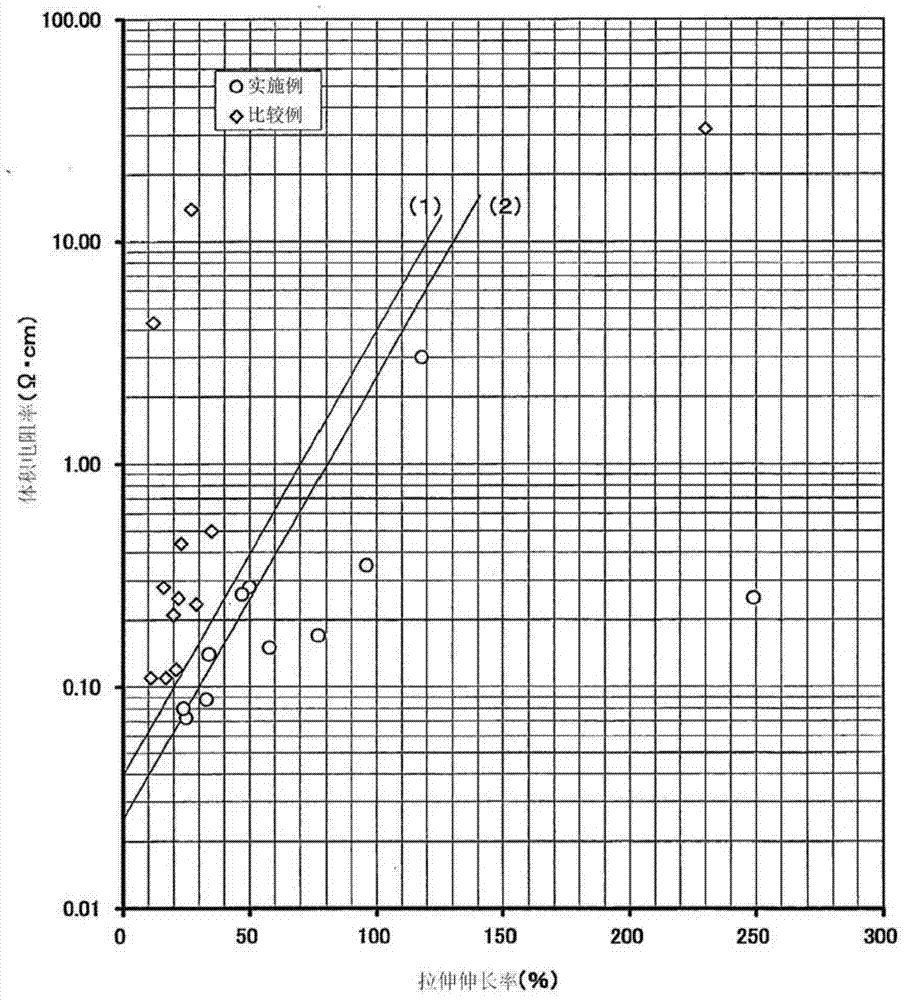

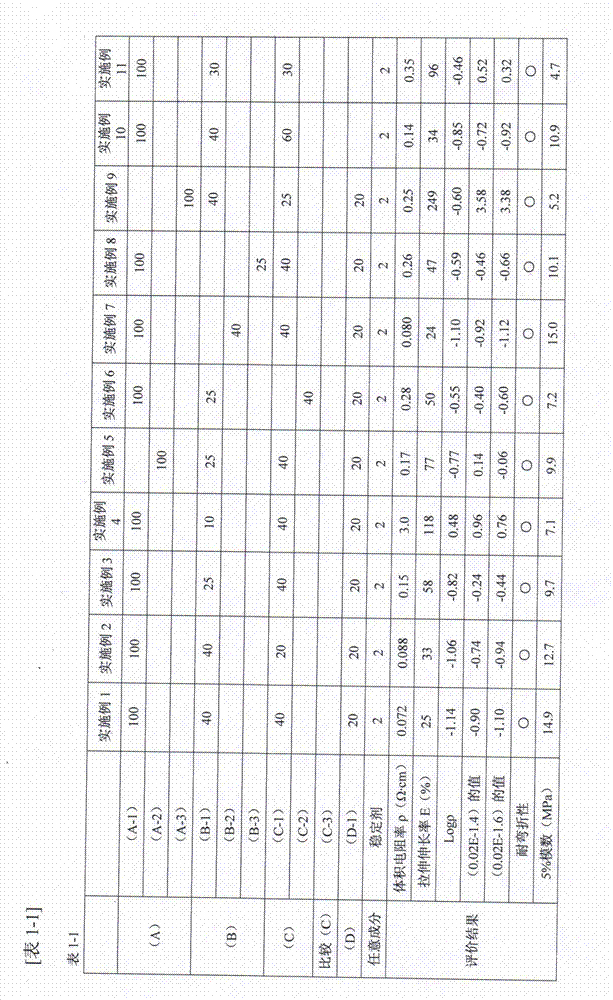

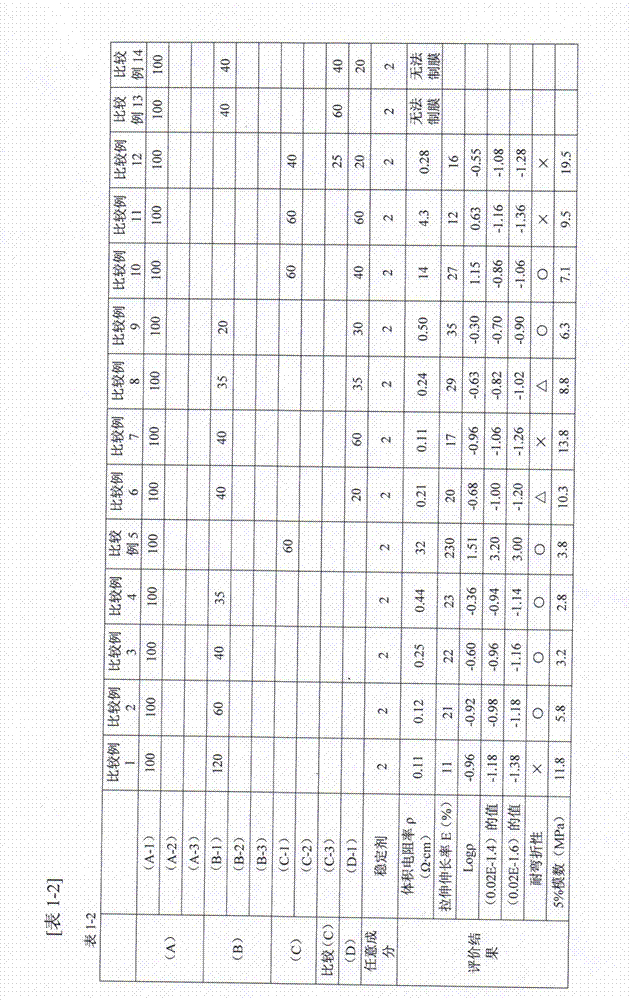

[0065] The formulations of the formulation ratios shown in Table 1 were melt-kneaded using a 5-liter intensive mixer of Nippon Roll MFG Co., Ltd. At this time, the discharge temperature was set at 190°C. Then, using the roll diameter of Japan Roll Manufacturing Co., Ltd., the roll diameter is 200mm, the roll width is 700mm reverse L word four calenders, and the film that obtains thickness is 300 μm (roll temperature according to the first roll / second roll / third roll / The sequence of the fourth roll is 205°C / 205°C / 185°C / 175°C, the drawing speed is 5 m / min). For the obtained film, the volume resistivity ρ and the tensile elongation E were determined, and tests for bending resistance and flexibility were performed according to the following methods. The results are shown in Table 1.

[0066] (c) Bending resistance

[0067]From the film that has been conditioned for more than 24 hours in a test room with a temperature of 23°C±2°C and a relative humidity of 50%±5%, a test pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com