Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Improve and improve performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

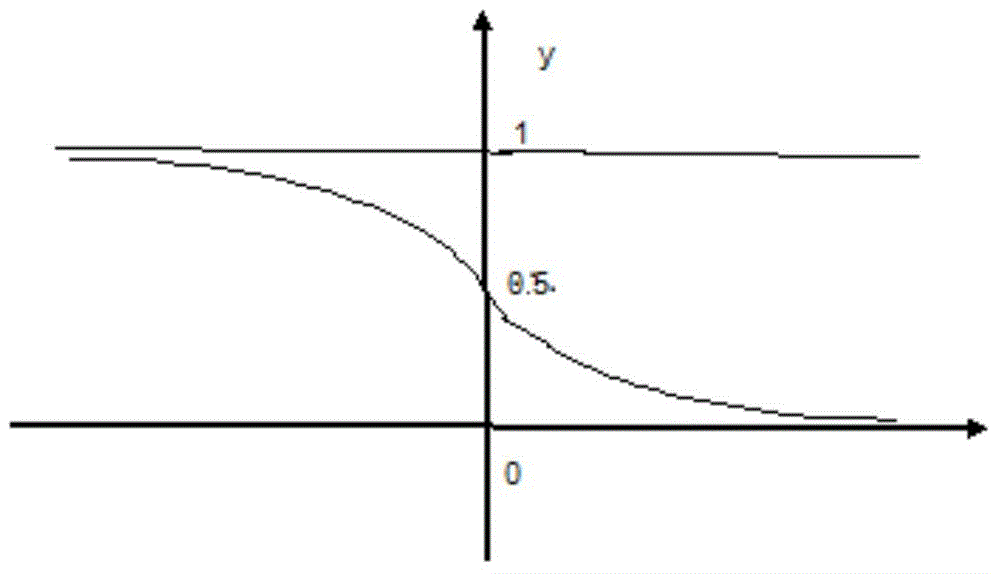

Personalized data searching method and device

ActiveCN104866474AImprove accuracyImprove and improve performanceSpecial data processing applicationsPersonalizationPreference vector

The application relates to a personalized data searching method and device. The device comprises the following steps: searching a data object according to a query word in a search request of a current user; determining a first behavior characteristic of a historic user in the search access process utilizing the query word according to a historic behavior log, and generating an intention vector of the query word; counting a second behavior characteristic of each user group to the data object according to a user attribute, and generating a preference vector of the user group; computing the similarity of the intention vector of the query word and the preference vector of each user group; using the user group corresponding to the condition that the similarity is greater than a set threshold value as a reference group for determining the intention preference of the current user; adjusting the sorting of the data objects searched by the current user through the query word through adoption of the historic behavior characteristics of the reference group. Thus the performance of a search platform is improved and promoted, the accuracy of a search result output to the user is improved, and the result, which is the most reasonable and the best for the search intention, is output for the user.

Owner:ALIBABA GRP HLDG LTD

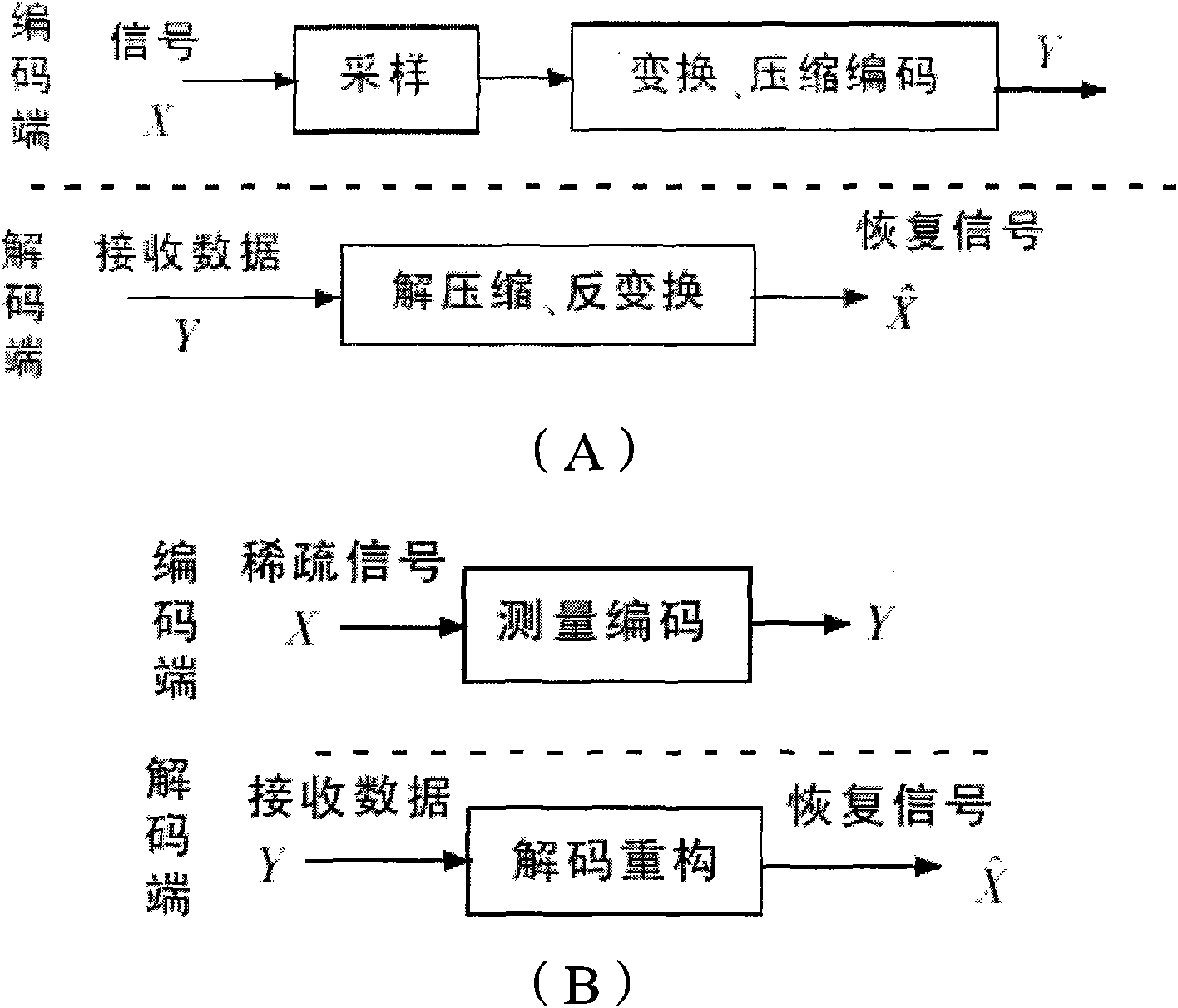

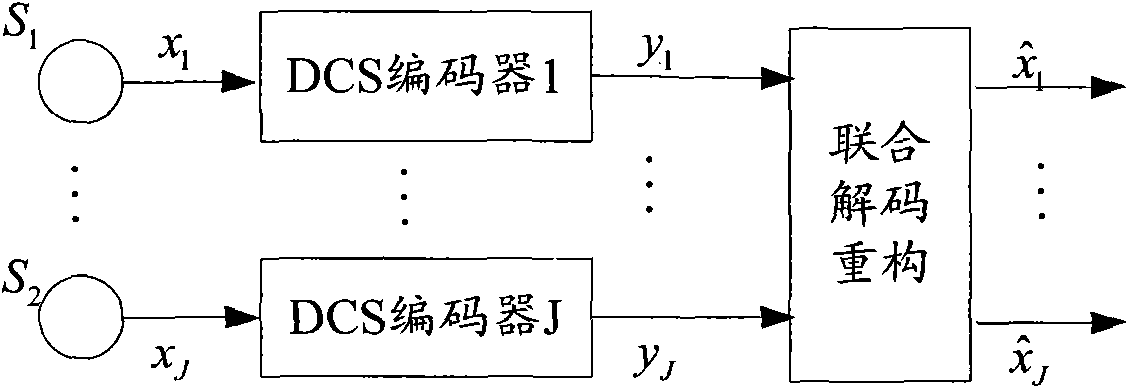

Signal source encoding method based on distributed compressive sensing technology

InactiveCN102123278AEasy to operateReduce computational complexityTelevision systemsDigital video signal modificationPattern recognitionHigh rate

The invention discloses a signal source encoding method based on a distributed compressive sensing (DCS) technology is characterized in that based on the sparseness of a video image data source and the characteristics of sparser differential signals, when a video image signal source is encoded, a low-rate sampling operation is performed on differential signals of data frames by using a CS (compressive sensing) technology so as to replace the high-rate data sampling and wavelet transform operations in the traditional signal source encoding; and in the process of decoding, based on the correlation between interframe data and intraframe data, the sparsity reconstruction algorithm of the DCS technology is used for replacing the inverse wavelet transform in the traditional signal source encoding so as to save the sampling resource consumption and reconstruct a video image resource by using less measurement data, thereby reducing the sampling rate and storage burden of a system, and enhancing the system performance so as to obtain a better image restoration effect after data transmission.

Owner:BEIJING UNIV OF POSTS & TELECOMM

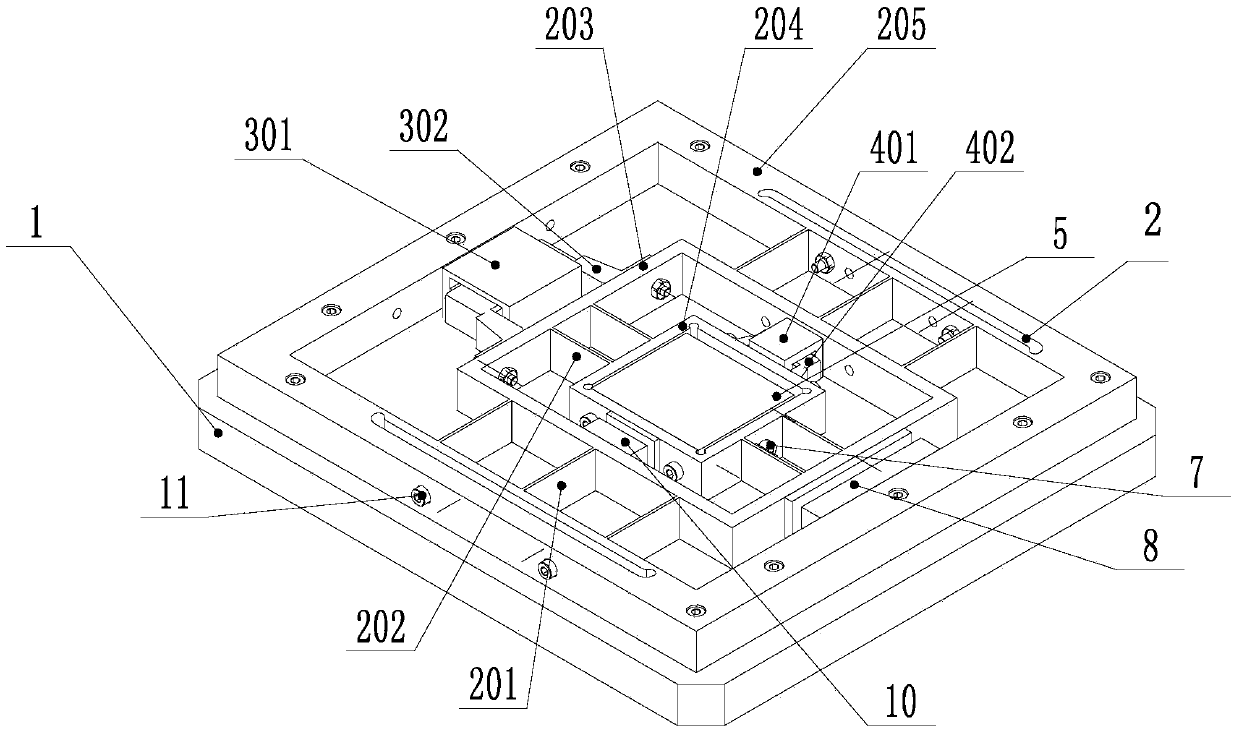

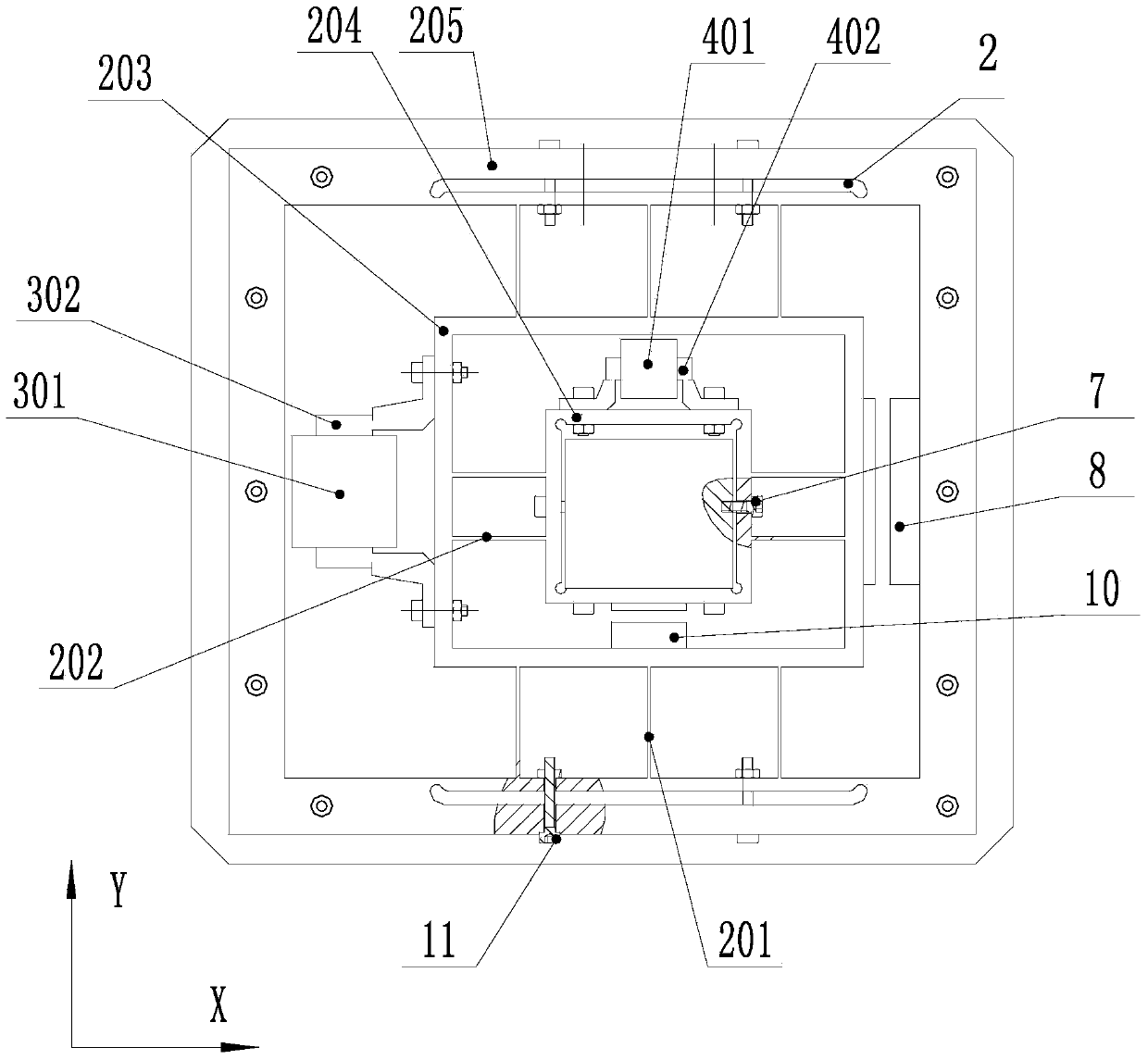

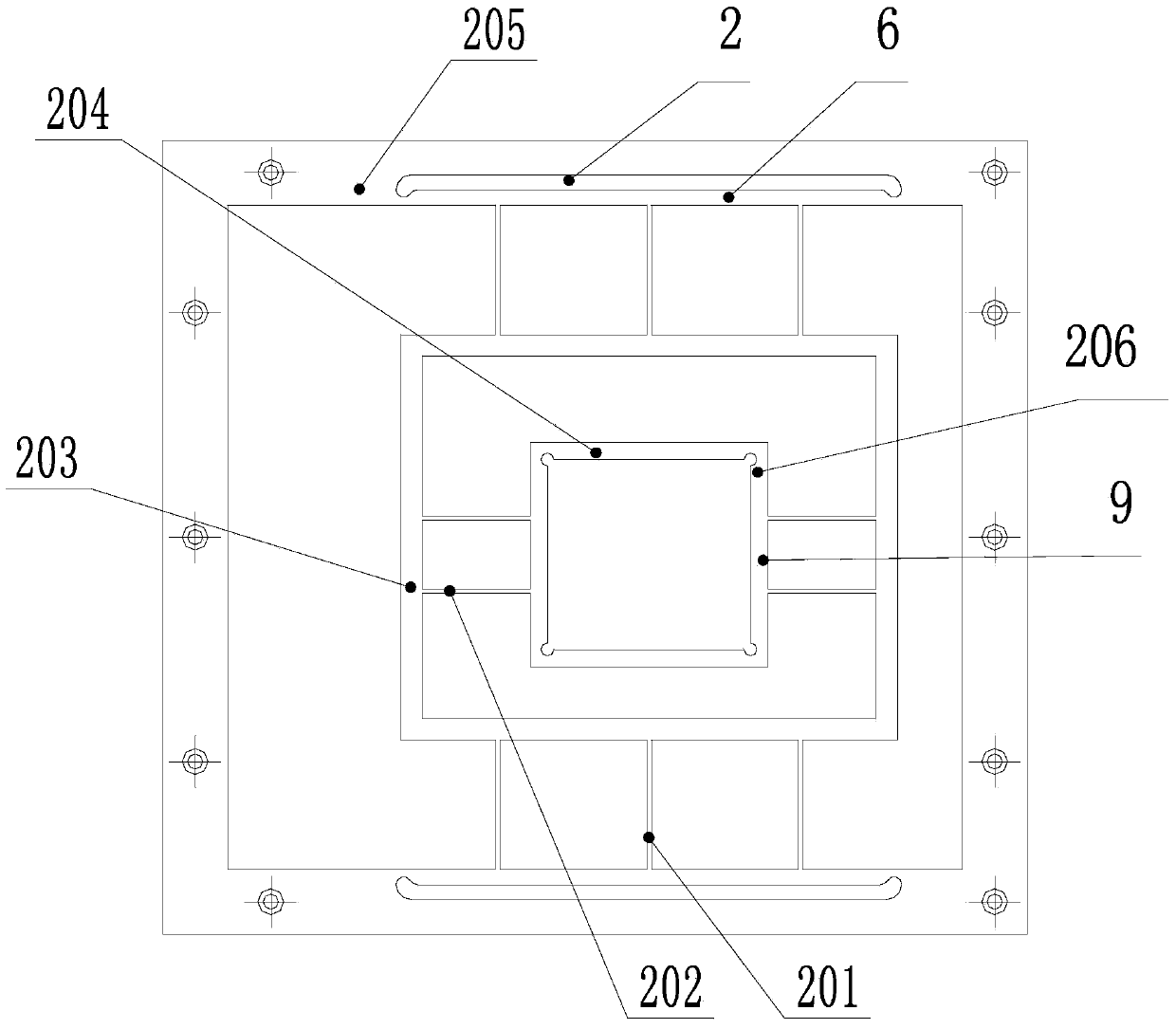

Stiffness frequency adjustable two-dimensional micro-motion platform based on stress stiffening principle

ActiveCN103990998AImprove performanceSmall inertiaMachine tool componentsFeeding apparatusEngineeringMechanical engineering

The invention relates to a precise two-dimensional motion occasion, can be used for precise displacement compensation of a general X-Y motion platform and particularly relates to a stiffness frequency adjustable two-dimensional micro-motion platform based on a stress stiffening principle. The stiffness frequency adjustable two-dimensional micro-motion platform based on the stress stiffening principle comprises X-direction and Y-direction motion sub-platforms, corresponding drivers and a micro-motion working platform, utilizes a film group for adjusting tensile force through screws as a flexible chain and achieves independent adjustment of vibrating frequency. By adopting the structure, the stiffness frequency adjustable two-dimensional micro-motion platform is based on prestress films, is adjustable in frequency and can adjust the inherent frequency of the micro-motion platform according to different working conditions and driving frequencies before working or in the working process, two feeding motion directions are orthogonal, and coupling of the micro-motion working table during two-dimensional motion is avoided.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

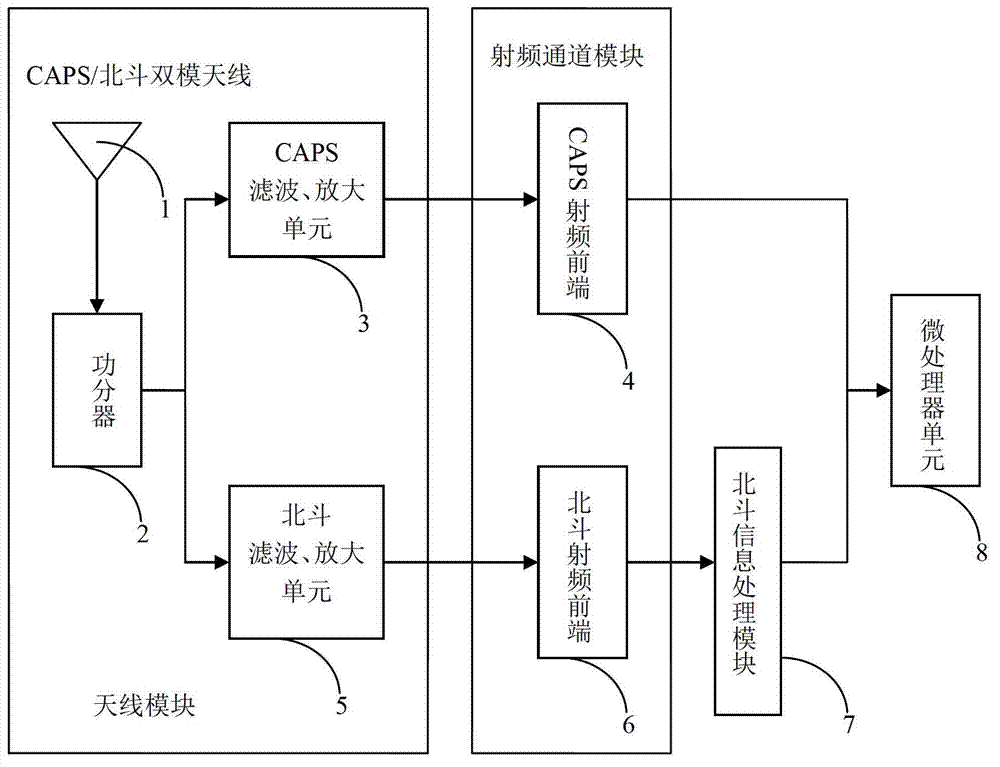

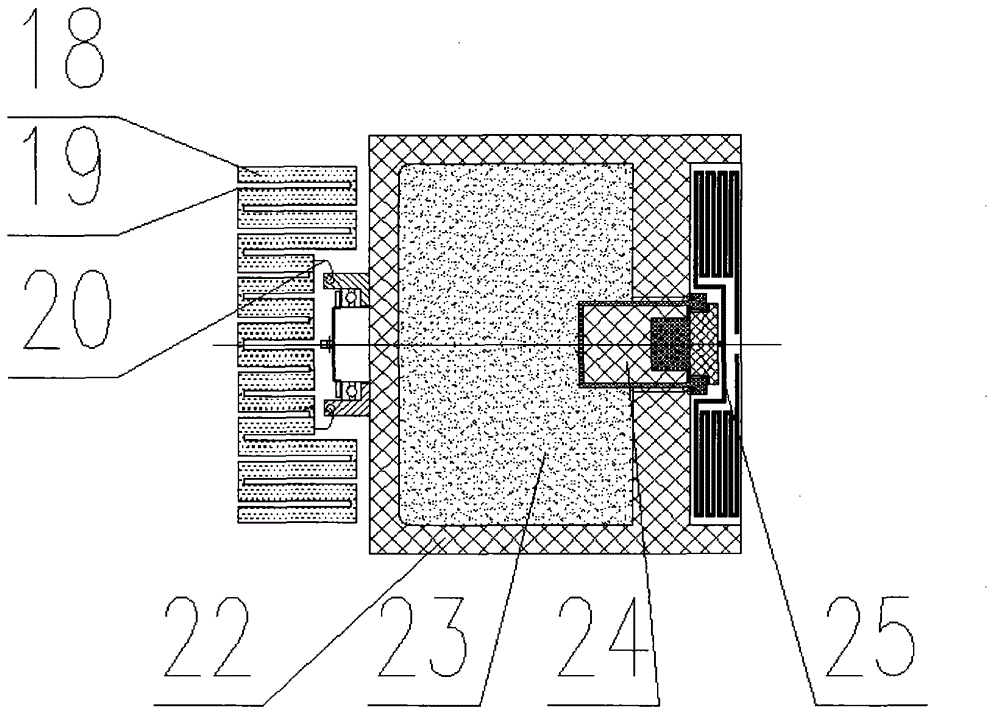

CAPS/Big Dipper bimodule receiver

InactiveCN102809751AGet rid of dependenceImprove and improve performanceSatellite radio beaconingInformation processingRF front end

The invention provides a CAPS (Chinese Area Positioning System) / Big Dipper bimodule receiver. A Big Dipper satellite signal and a CAPS satellite signal are respectively sent to a CAPS filtering and amplifying unit and a Big Dipper filtering and amplifying unit after being simultaneously received by a CAPS / Big Dipper bimodule antenna, and then the CAPS satellite signal is sent to a CAPS RF (Radio Frequency) front end to be processed into a mid-frequency digital signal which is sent to a microprocessor unit; the Big Dipper satellite signal is sent to a Big Dipper RF front end to be processed into a mid-frequency digital signal which is then sent to a Big Dipper information processing unit for catching, tracking, demodulating and decoding, and the decoded information is sent to the microprocessor unit; and the microprocessor unit outputs a position resolving result and a CAPS time pulse according to the CAPS satellite signal. The CAPS / Big Dipper bimodule receiver adopts redundant backup to achieve bimodule timing and positioning, and integrated navigation can greatly improve the system usability and completeness and can even improve the positioning accuracy.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

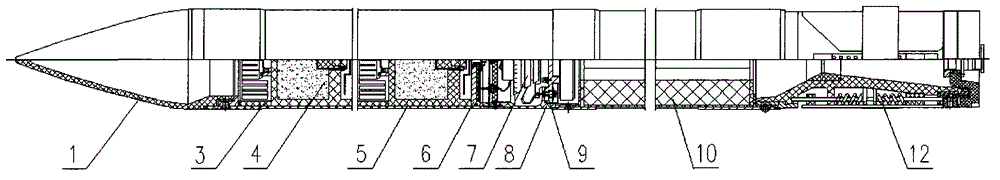

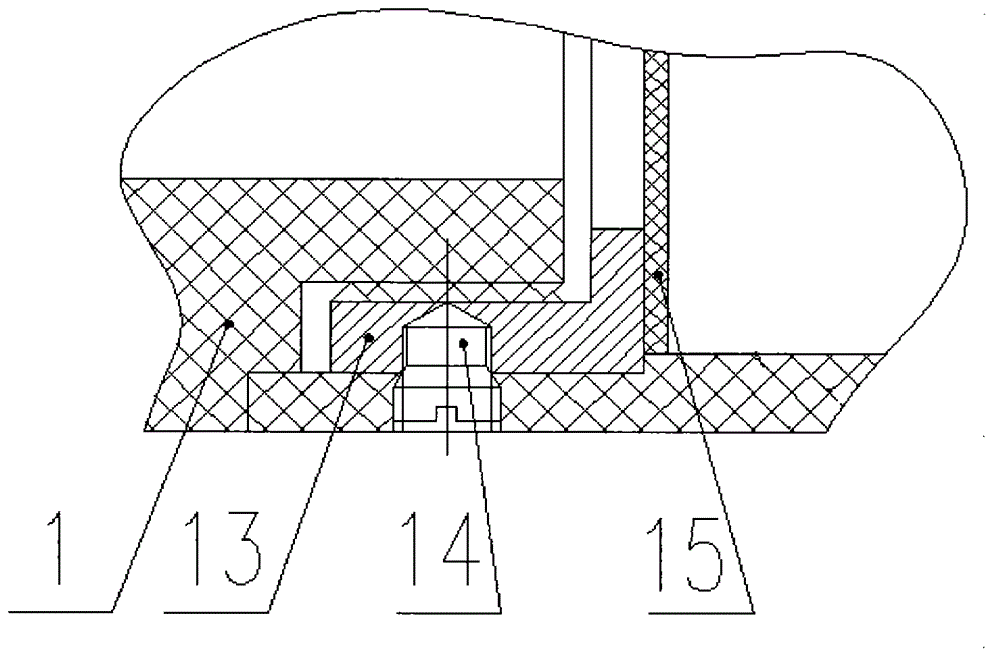

Extinguishment shrapnel type rocket bomb

InactiveCN102878870AGood effectSafe and reliable landingAmmunition projectilesFire rescueCombustionTime delays

The invention relates to an extinguishment rocket bomb and belong to the field of civil fire extinguishing bombs. The extinguishment bomb of is in a shrapnel filling form, thereby obviously strengthens the actual effect of long-distance fire field extinguishment operation. The extinguishment bomb carries a drag parachute, is used for air or ground extinguishment in a flame covering region, and can definitely land safely and reliably from the high altitude; the extinguishment bomb carries a time delay self-destroying fuse by oneself, thereby improving the use security of the extinguishment bomb; wiring terminal switchover is adopted to replace the traditional manner of direct drilling holes for wiring, and effectively meeting the requirement on sealing and heat-shielding performance; the major part of the tail of the bomb is made of a non-metal material in a die forming manner, ground dry humus layer in a forest can be prevented from secondary combustion, the weight of the extinguishment rocket bomb is light, and the product burden is reduced; and an empennage piece which is particularly a roll camber empennage can be folded, a rocket gun barrel firomg requirement is realized, and the extinguishment accuracy is high.

Owner:JINXI IND GRP

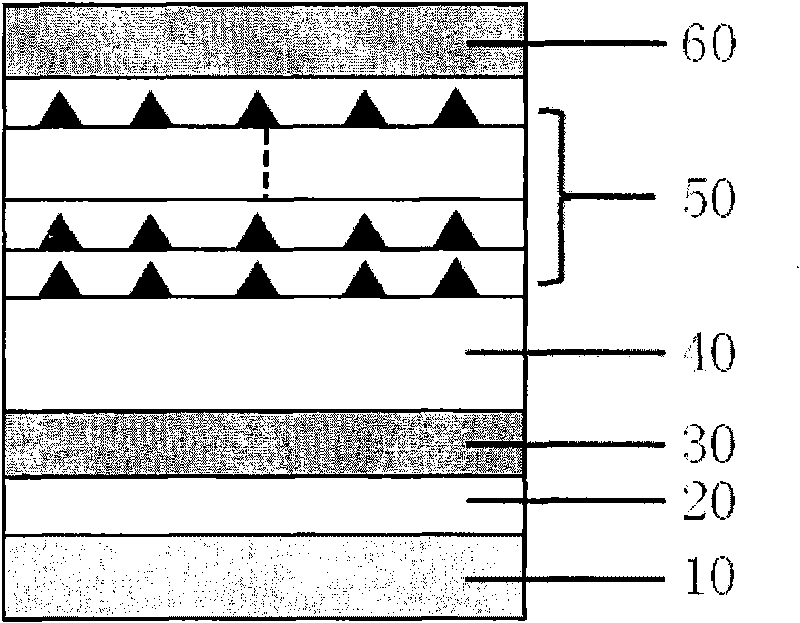

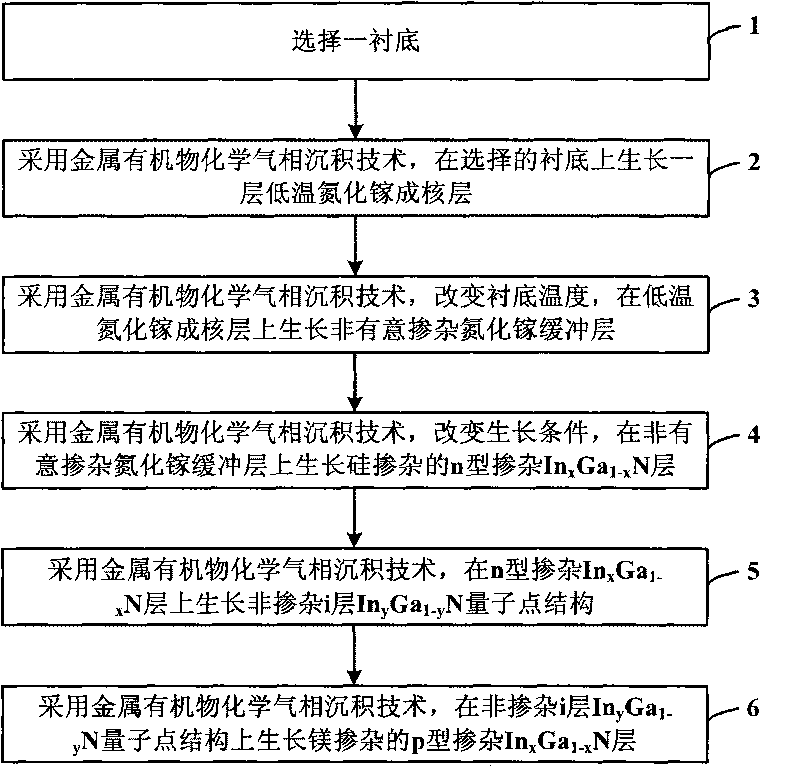

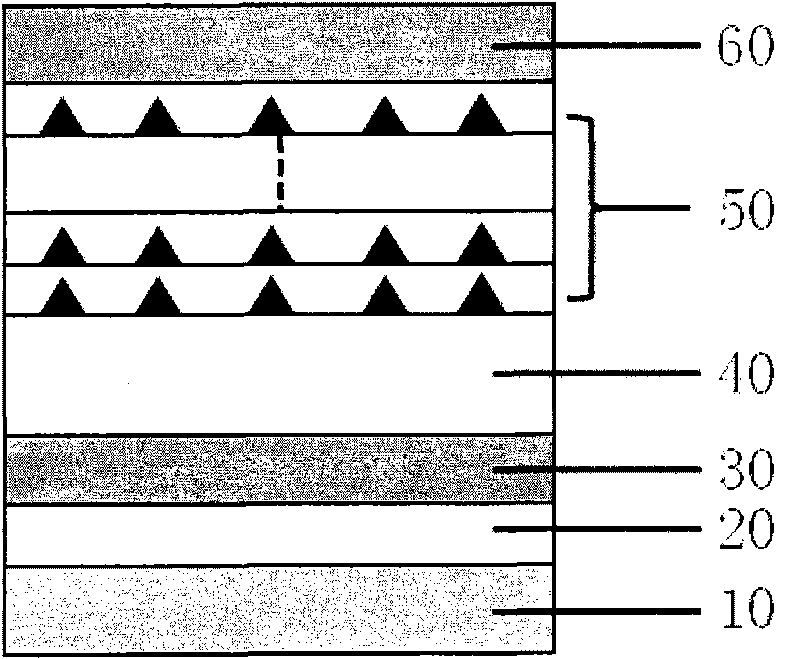

p-i-n type InGaN quantum dot solar battery structure and manufacture method thereof

InactiveCN101752444AQuality improvementImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationQuantum dotNon doped

The invention relates to the technical field of inorganic photoelectric technology, and discloses a p-i-n type InGaN quantum dot solar battery structure and a manufacture method thereof. The p-i-n type InGaN quantum dot solar battery structure comprises a substrate, a low-temperature gallium nitride nucleation layer, a non-intentionally doped gallium nitride buffer layer, an n-type doped InxGal-xN layer, a non-doped i layer InyGal-yN quantum dot structure and a p type doped InxGal-xN layer. By adopting an InGal-xN ternary alloy material and a quantum dot structure, using the advantage of the adjustability of alloy bandwidth, combining the advantage of a quantum dot superlattice structure and strictly controlling the growth condition, the p-i-n structural material with an InyGal-yN quantum dot as an i layer and the InGal-Xn as a barrier layer can be obtained with high quality, thereby achieving 63 percent of limit conversion efficiency in theory.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

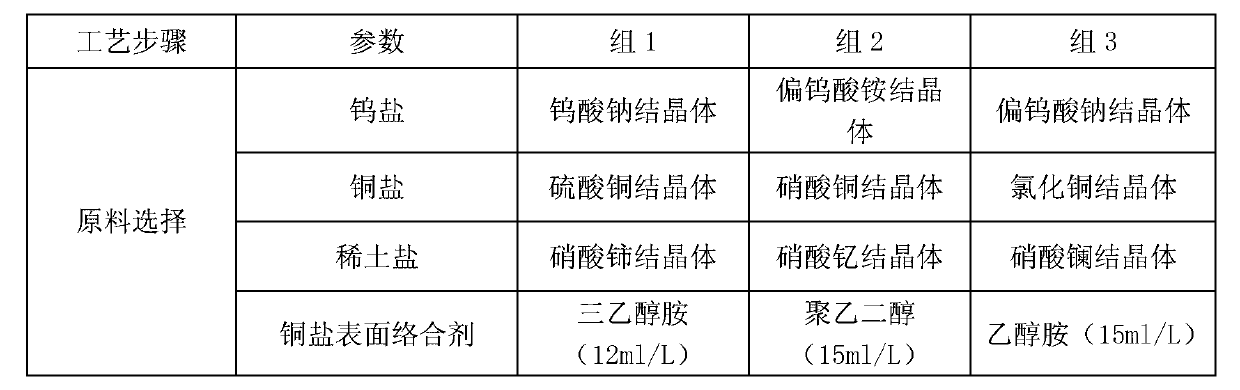

Rare-earth-oxide-doped W-Cu composite material and preparation method thereof

The invention provides a W-Cu composite material which is characterized by comprising the following components in percentage by mass: 5-30 wt% of Cu, 0.5-2 wt% of rare-earth oxide and the balance of W. The invention also provides a preparation method of the W-Cu composite material. The density of the composite material is up to 99.2%, the density uniformized coefficient of different positions is less than 5%, the room temperature tensile strength is greater than 900 MPa, the elongation percentage is greater than 10%, and the fracture toughness K1C is greater than 28 MPa.m<1 / 2>; and thus, the composite material satisfies the performance requirements of electric contact materials and liner materials for complete density, structure uniformity, ablation resistance and the like of the W-Cu alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

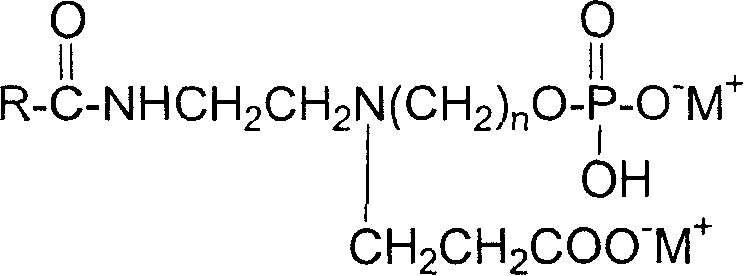

Imidazoline amophoteric surface active agent and its synthesis technology

InactiveCN1911938ALess irritatingExcellent cleaning and descaling performanceGroup 5/15 element organic compoundsPhosphateSURFACTANT BLEND

The present invention is amphoteric imidazoline surfactant in the structure as shown and its synthesis. The amphoteric imidazoline surfactant of the present invention contains phosphate ester radical and carboxyethyl radical and has improved product performance.

Owner:CHINA RES INST OF DAILY CHEM IND

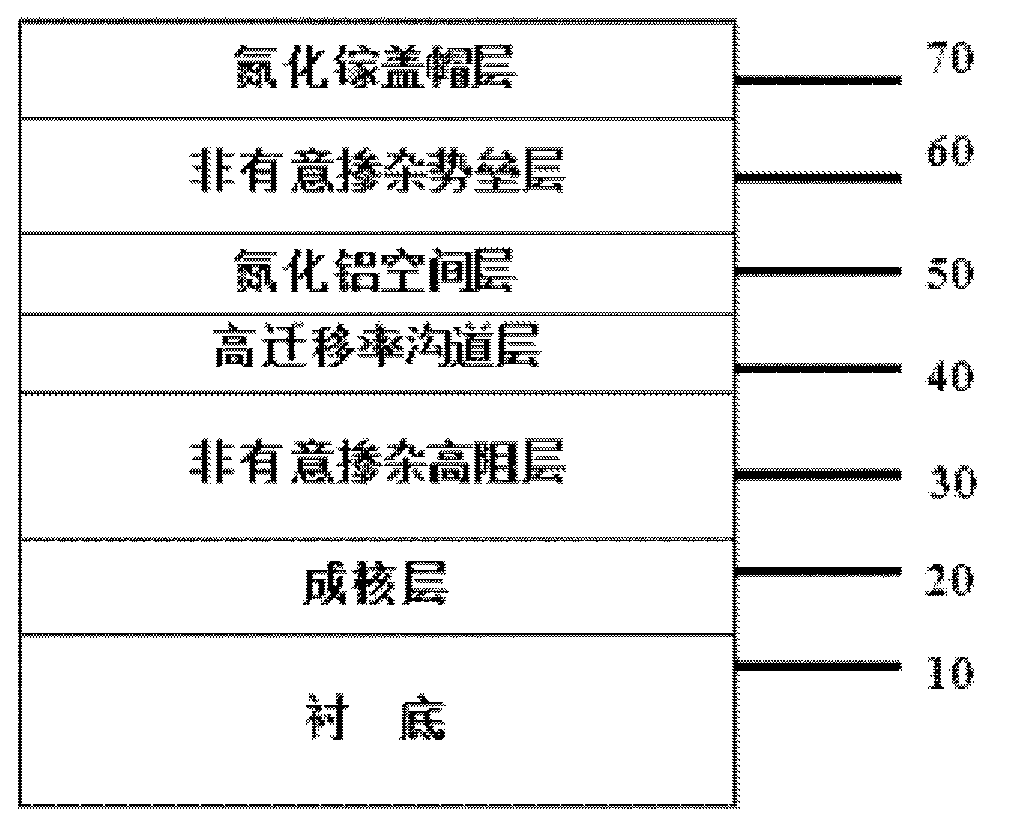

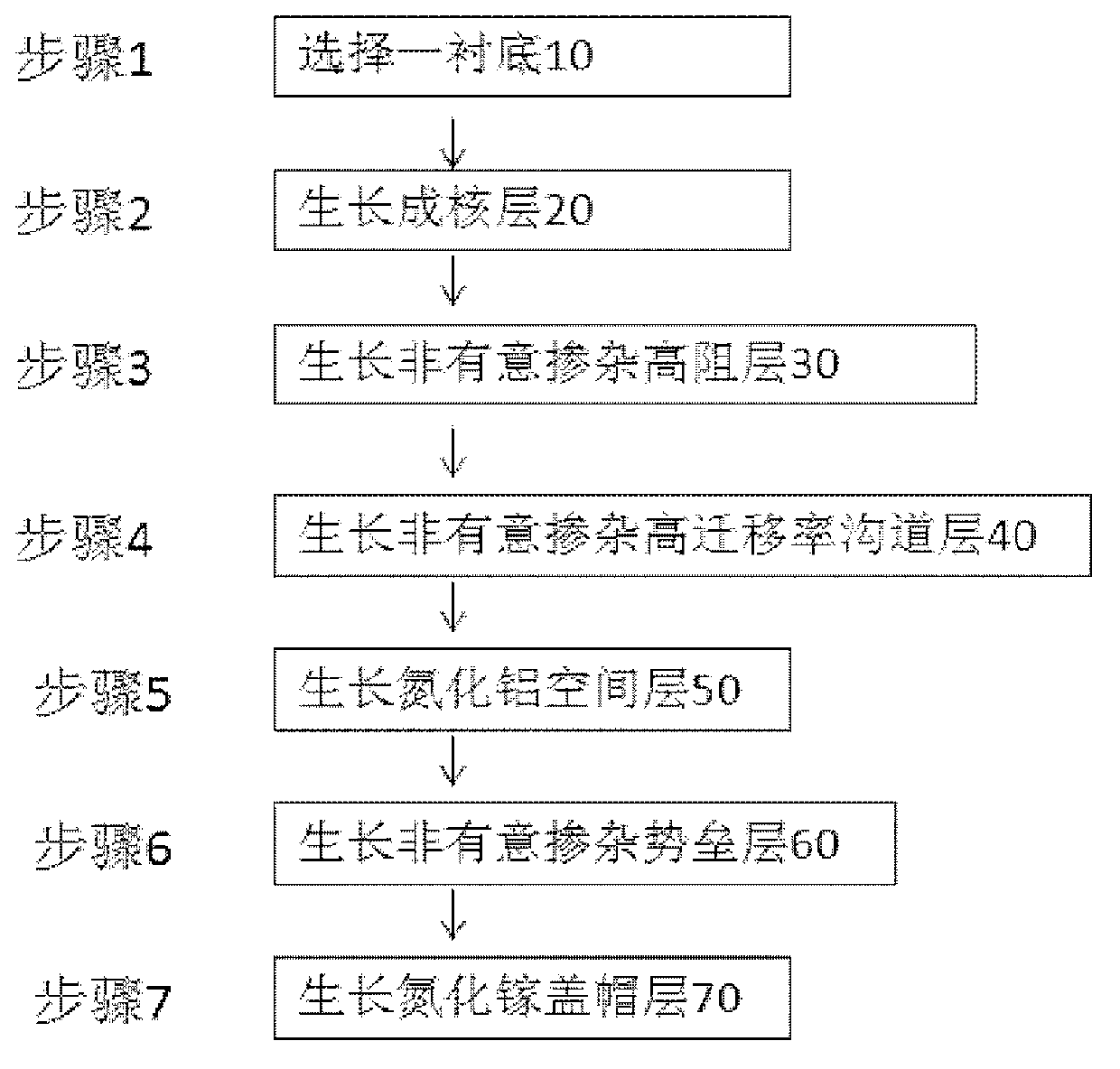

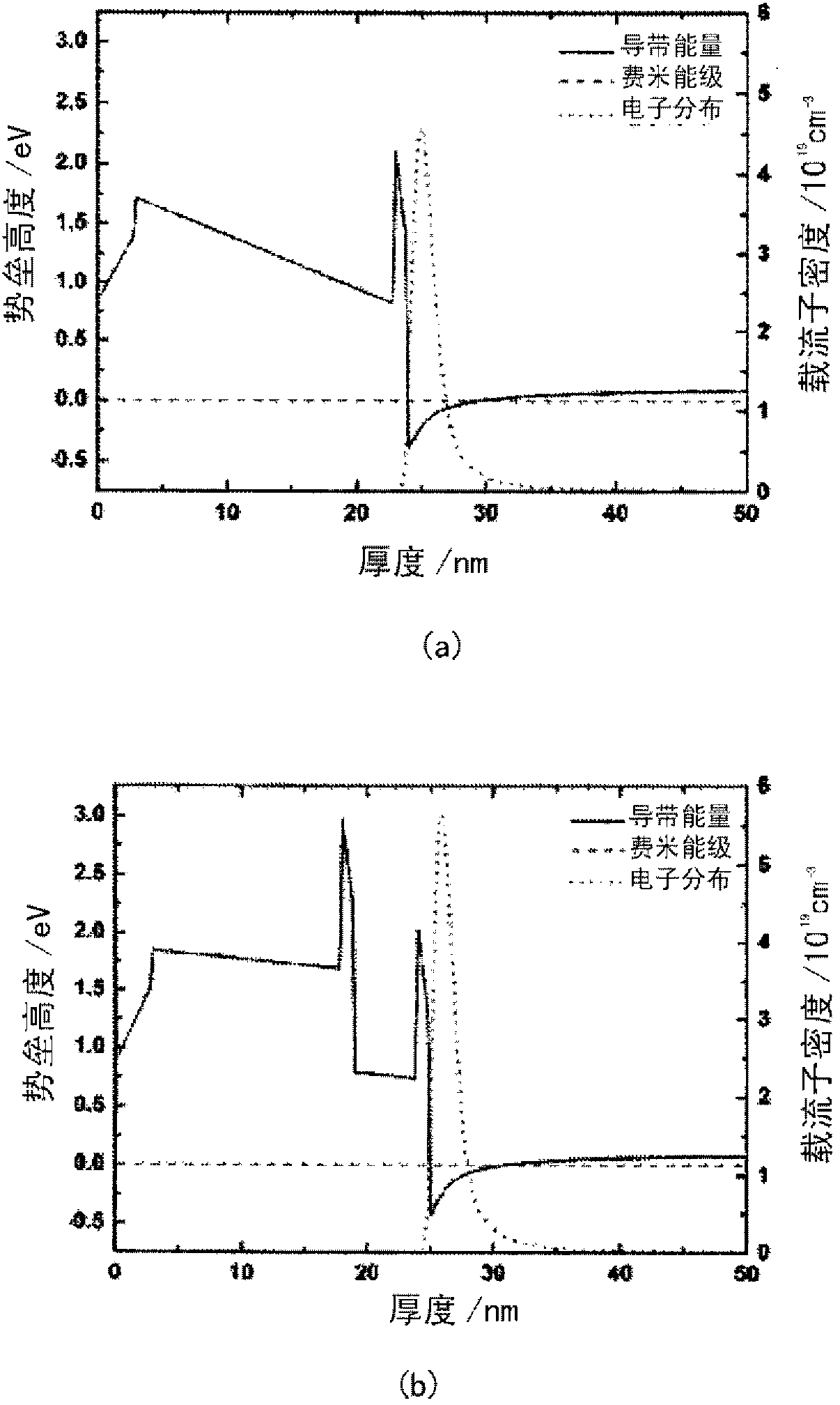

Gallium-nitride-based high electronic mobility transistor structure with barrier layer and manufacture method thereof

ActiveCN103123934AReduce process difficultyReduce process stepsSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideHigh-electron-mobility transistor

A gallium-nitride-based high electronic mobility transistor structure with a barrier layer comprises a substrate, a nucleating layer manufactured on the substrate, an unintentionally doped high resistance layer manufactured on the nucleating layer, an unintentionally doped high mobility channel layer manufactured on the unintentionally doped high resistance layer, an unintentionally doped aluminum nitride space layer manufactured on the unintentionally doped high mobility channel layer, an unintentionally doped barrier layer manufactured on the unintentionally doped aluminum nitride space layer and an unintentionally doped gallium nitride cap layer manufactured on the unintentionally doped barrier layer. The gallium-nitride-based high electronic mobility transistor structure can improve a limiting effect on channel two-dimensional electron gas and increase output power of a developed device, and simultaneously grate current of the device is reduced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Novel pumping rod

InactiveCN102839332AReasonable formulation of ingredientsStrong enoughDrilling rodsDrilling casingsUltimate tensile strengthThermal treatment

The invention discloses a novel pumping rod which is made of a high-performance alloy steel material. The high-performance alloy steel material comprises the following main components: 0.12-0.18% of C, 0.45-0.85% of Si, 2.2-3.2% of Mn, 1.0-1.4% of Cr, 0.1-0.3% of Ni, 0.12-0.3% of Al, 0.06-0.12% of Co, 0.001-0.004% of B and the balance of Fe. The novel pumping rod disclosed by the invention is reasonable in the preparation of the components; the prepared pumping rod has sufficient strength, rigidity, toughness and cutting performance and excellent corrosion resistance and oxidation resistance; the service performance of the material can be improved and increased through thermal treatment.

Owner:常熟市石油固井工具有限公司

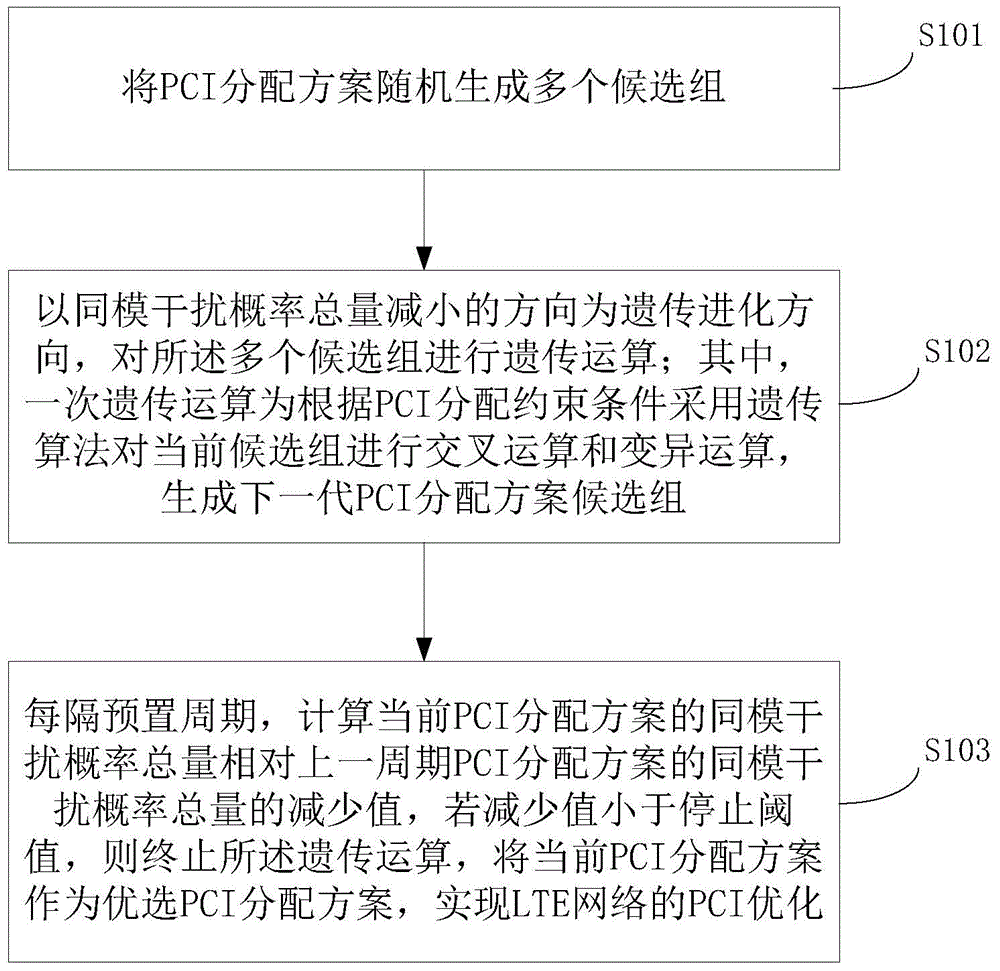

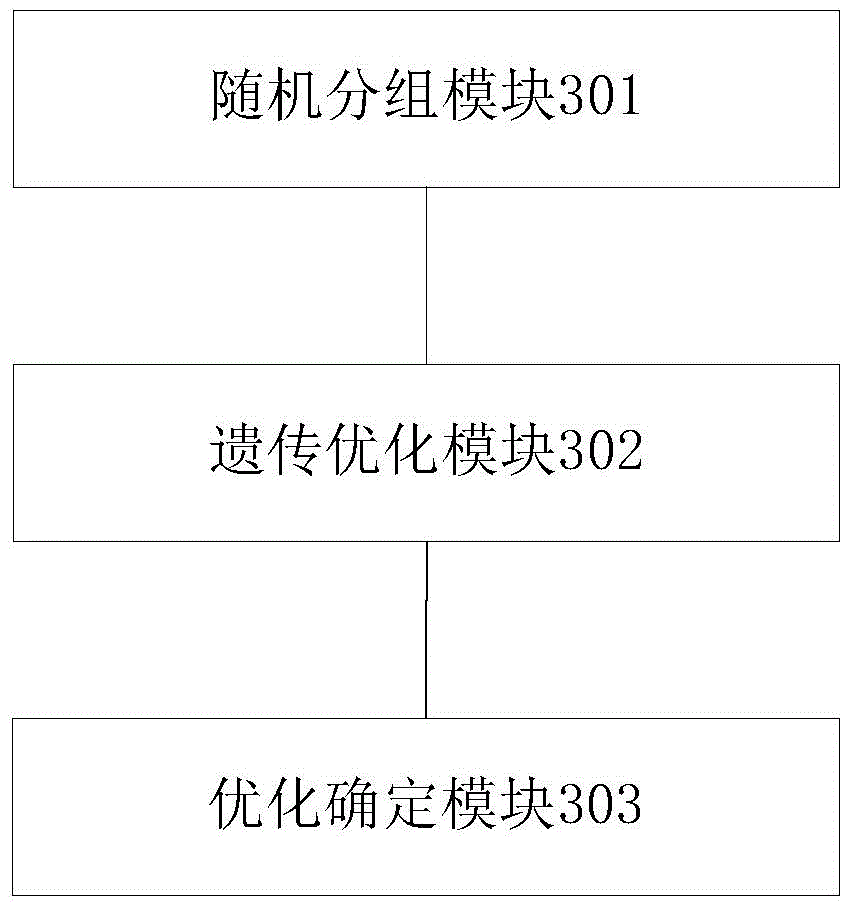

A physical layer cell identification PCI optimization method in LTE network and system

ActiveCN105208580AAccurate and reasonable allocation analysisEasy to adjustWireless communicationAlgorithmGenetic algorithm

The invention discloses a PCI optimization method in an LTE long-term evolution network and a system and relates to the mobile communication technology field. In an embodiment of the invention, a genetic algorithm is used to optimize a PCI distribution scheme; relative to a traditional optimization mode, in the genetic algorithm, evolution search calculating is performed from a string set; a coverage area is large, which is good for global prioritizing; PCI signal optimization analysis is accurate and reasonable; accurate and reasonable planning and adjustment can be performed on a wireless network signal and integral performance of an LTE wireless network is radically improved and increased. Crossover operation and mutation operation are firstly performed on an auxiliary synchronization signal SSS of each PCI group in a current candidate group. And then the crossover operation and the mutation operation are performed on a main synchronization signal PSS in each PCI group so that a condition that a same PSS is distributed in a same station during PCI distribution can be avoided and a severe same-mode interference condition of a model 3, a model 6 and the like can be greatly reduced.

Owner:ULTRAPOWER SOFTWARE

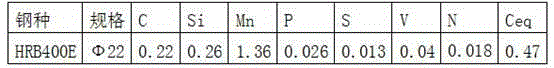

Method for increasing nitrogen content in vanadium-containing steel bar

ActiveCN104673971AReduce the amount addedImprove and improve performanceProcess efficiency improvementSlagVanadium nitride

The invention discloses a method for increasing the nitrogen content in a vanadium-containing steel bar. The method comprises the following steps: performing ladle bottom nitrogen blowing stirring in the converter tapping process, adding a deoxidant in the steel ladle in the tapping process to control the oxygen activity of the molten steel to below 30 ppm, and adding the converter vanadium-containing slag to perform vanadium alloying so that the nitrogen content of the molten steel is 70-90 ppm before LF refining; in the LF converter refining process, adding ferrovanadium nitride to adjust the vanadium content in the molten steel, simultaneously stirring the molten steel by adopting the ladle bottom nitrogen blowing to substitute the bottom argon blowing to finally control the nitrogen content in the molten steel to 130-220 ppm. The nitrogen content is increased in the converter tapping-LF refining process so that the nitrogen content in the steel is controlled to 130-220 ppm; the vanadium alloying is performed by the converter vanadium-containing slag so that separation out of vanadium nitride from the steel is promoted. The steel performance is obviously increased, the alloy adding amount is reduced and simultaneously the production cost of the vanadium-containing steel bar is reduced.

Owner:HEBEI IRON AND STEEL

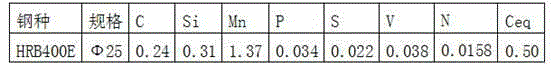

Method and system for processing interference signals

ActiveCN103442374AAccurate reflection of frequency reuse statusReduce distractionsWireless communicationFrequency reuseComputer science

The invention discloses a method and system for processing interference signals and relates to the field of mobile communication technologies. The method includes the steps that boundaries and central points of all time slots of all frame periods are determined; aiming at one frequency point, service free time slots in the frequency point are calculated; the average background noise of all the service free time slots in the frequency point is calculated; according to the average background noise, whether background noise interference signals exist or not is judged, and if yes, frequency is adjusted. In comparison with the mode that in the prior art, whether the background noise exists or not is evaluated according to experience, the method and system can accurately calculate a value of the average background noise, so that frequency reuse conditions of all frequency points is accurately reflected, and reasonable adjustment is accurately performed on parts with high frequency reuse density, therefore, network optimization is achieved, and the overall performance of a cellular wireless network is fundamentally improved.

Owner:ULTRAPOWER SOFTWARE

Food-grade polypropylene composite material and preparation method and application thereof

The invention relates to a food-grade polypropylene composite material, a preparation method and an application thereof. The composite material is composed of the following components in mass percentage: 48-78wt% of polypropylene, 20-50wt% of food-grade additive calcium carbonate; 0.5-2wt% of food-grade processing aid and 0-1.0wt% of food-grade coloring agent, wherein the food-level standard is as follows: the content is 98.0-100% calculated by dry basis, the loss on drying is less than or equal to 2.0%, the content of acid insoluble matter is less than or equal to 0.2%, the content of fluoride is less than or equal to 0.005%, the content of alkali metals and magnesium salt is less than or equal to 1.0%, the content of arsenic metals is less than or equal to 3.0mg / kg, and the content of lead metals is less than or equal to 3.0mg / kg. The food-grade polypropylene composite material and the prepared tableware in the invention have favorable mechanical property and lower cost; and compared with the traditional tableware, the tableware filled with food-grade additive calcium carbonate are more in accordance with the hygienic standard and are easily degraded.

Owner:富岭科技股份有限公司

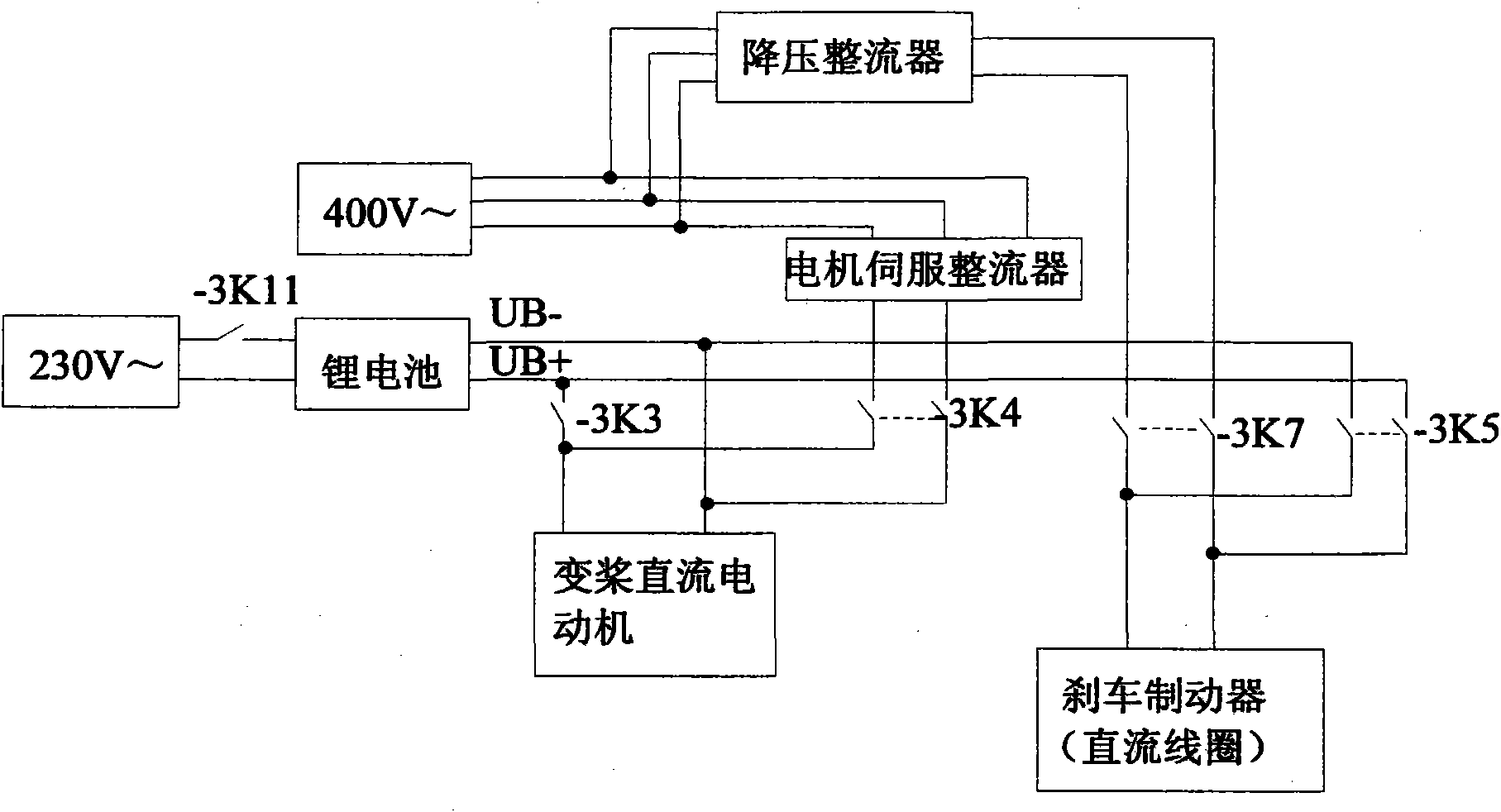

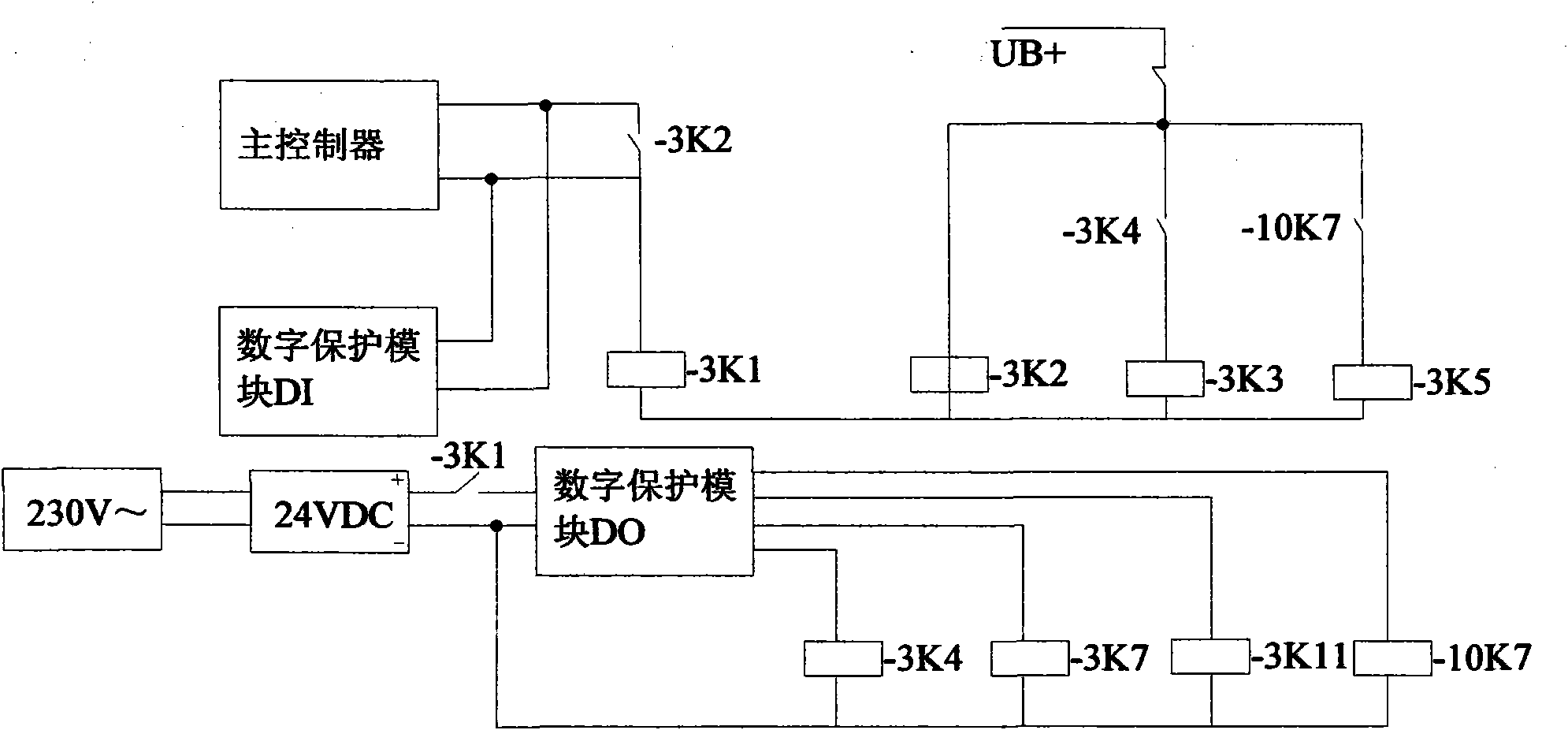

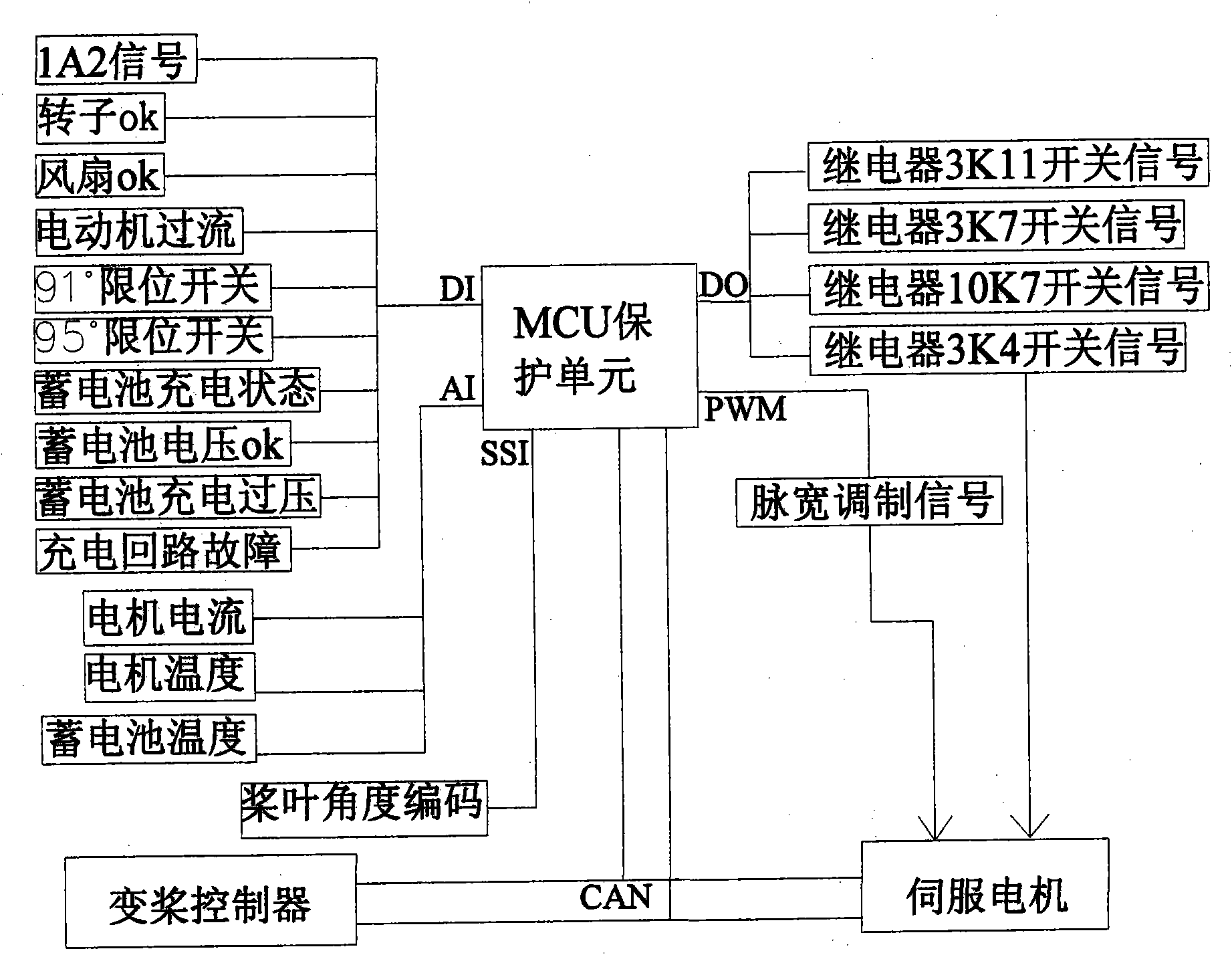

Relay protection device of variable pitch blade system of wind driven generator

ActiveCN101964539AImprove and enhance featuresImprove and improve performanceBatteries circuit arrangementsWind motor controlWind forceElectric generator

The invention provides a relay protection device of a variable pitch blade system of a wind driven generator. The device comprises a power source, a variable pitch blade motor relay, a brake relay, a relay control circuit and a control power source, wherein the power source is used for supplying power to the variable pitch blade motor and a brake thereof; the variable pitch blade motor relay is used for controlling power-on or power-down of the variable pitch blade motor; the brake relay is used for controlling the power-on or power-down of the brake; the relay control circuit is used for controlling the power-on or power-down of the variable pitch blade motor relay and the brake relay; the control power source is used for supplying power for the relay control circuit; and the relay control circuit is a digital circuit. The device has the advantages of realizing digital protection of a single blade, improving the action feature and the performance of the relay protection, occupying small space and volume of a shaft control cabinet and greatly reducing the power consumption, along with high correctness, stability, reliability and self-examination and polling capacity, friendly man-machine interface, superior technical structural conditions, remarkable economic benefit and obvious technical improvement, and is flexible and convenient to use, and easy to use on a large scale and popularize.

Owner:DONGFANG ELECTRIC AUTOMATIC CONTROL ENG CO LTD

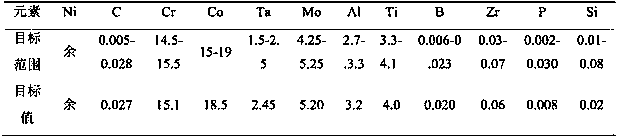

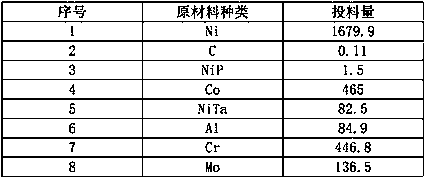

Novel powder high-temperature alloy and preparing method thereof

The invention relates to novel powder high-temperature alloy and preparing method thereof. The novel powder high-temperature alloy comprises, by weight percent, 14.00 to 15.00% of Cr, 14.50 to 19.50%of Co, 4.5 to 5.5% of Mo, 3.25 to 4.10% of Ti, 2.50 to 3.10% of Al, 1.45 to 2.50% of Ta, 0.55 to 1.55% of Hf, 0.045 to 0.068% of Zr, 0.005 to 0.030% of C, 0.006 to 0.023% of B, 0.002 to 0.030% of P, 0.01 to 2.0% of Re, 0.1 to 2.0% of W, 0.1 to 1.0% of Nb, smaller than 0.5% of Y, smaller than 0.3% of V, smaller than 0.5% of Fe, smaller than 0.15% of Si, smaller than 0.12% of Mn, and the balance Ni.The gamma' phase content in the l powder high-temperature alloy is about 40 to 50%. The novel powder high-temperature alloy prepared through the preparing method has the good room temperature strength, high temperature strength and high temperature creep properties, and the use temperature is up to 750 DEG C.

Owner:西部超导材料科技股份有限公司

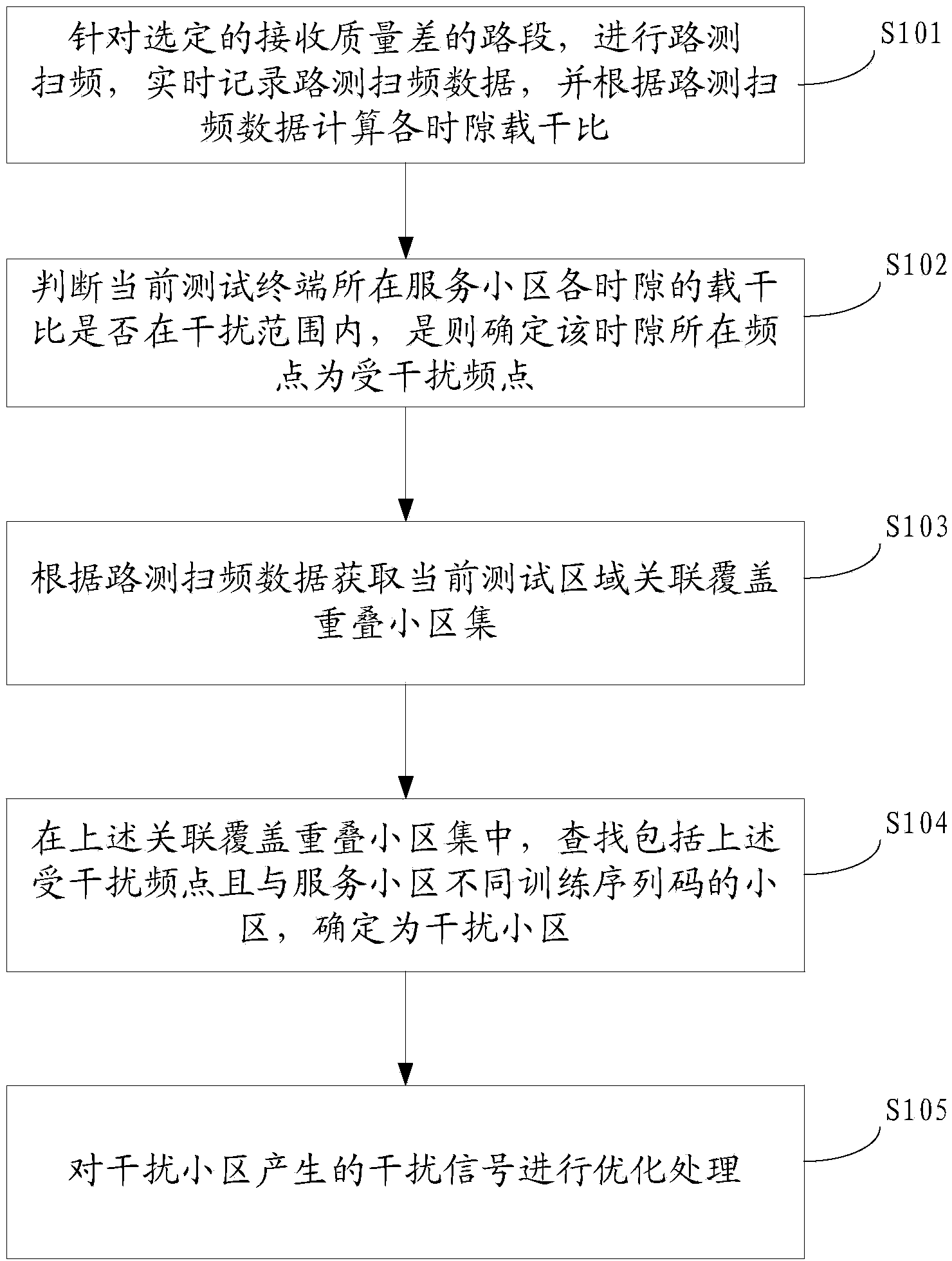

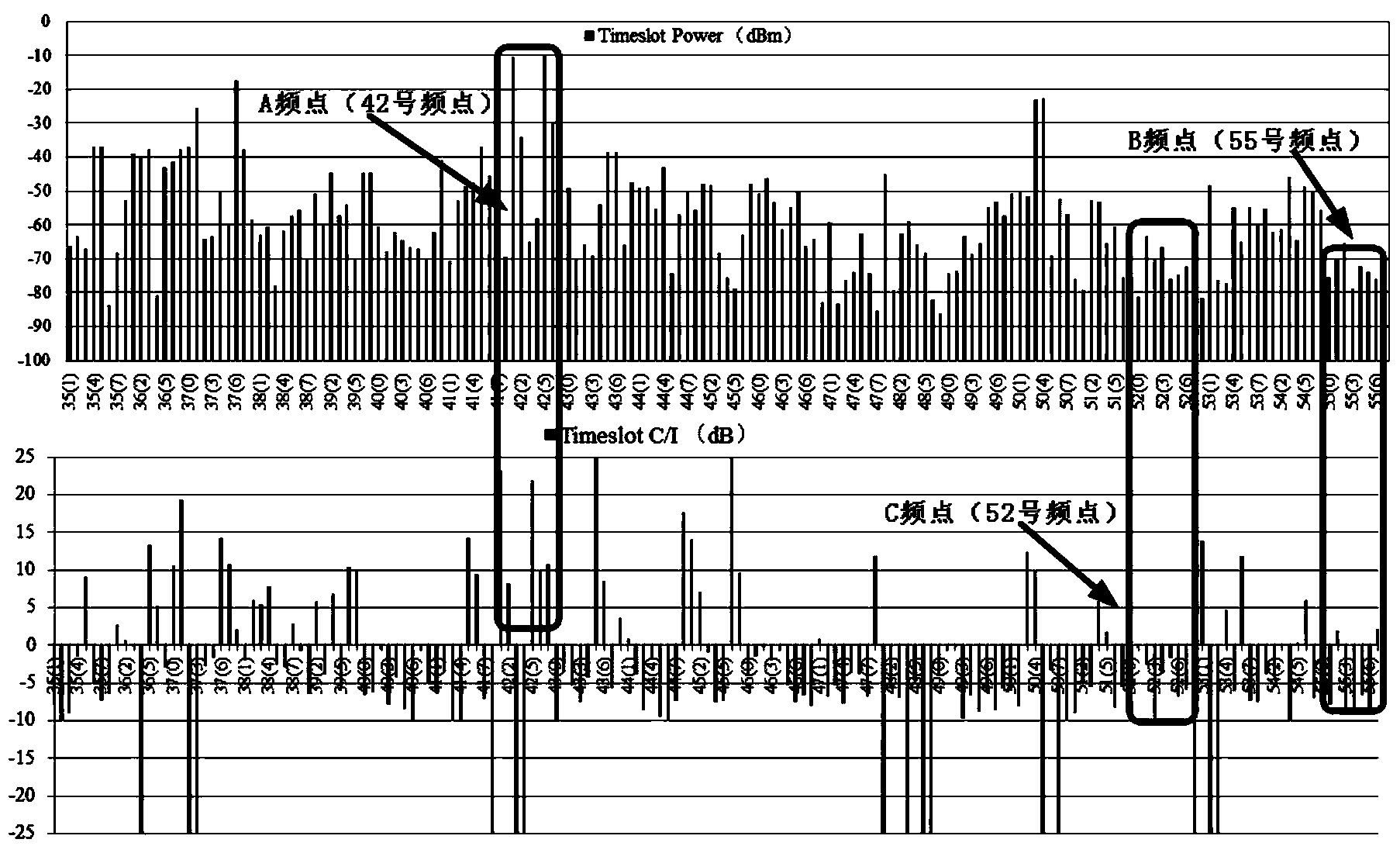

Method and system for positioning and processing interference

ActiveCN103442384APrecise positioningImprove and improve performanceNetwork planningInterference ratioEngineering

The invention discloses a method and system for positioning and processing interference and relates to the field of mobile communication technologies. According to the method and system, a novel signal optimization technology is provided, high-precision service channel time slot frequency sweep data are obtained through precise calculation, electrical levels and carrier-to-interference ratios (C-to-I) of all time slots of all carrier frequency of all cells of problematic router sections so that the interference can be accurately positioned, detailed causes are analyzed according to the positioning of the interference, optimization adjustment is performed, and therefore the overall performance of a cellular wireless network is fundamentally improved. Furthermore, according to the method and system, values of the C / I can be combined for judging the degree of the interference more accurately, and effective reference is provided for signal analyzing and adjusting.

Owner:ULTRAPOWER SOFTWARE

Slide plate refractory with silicon nitride added and production method thereof

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powder and a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

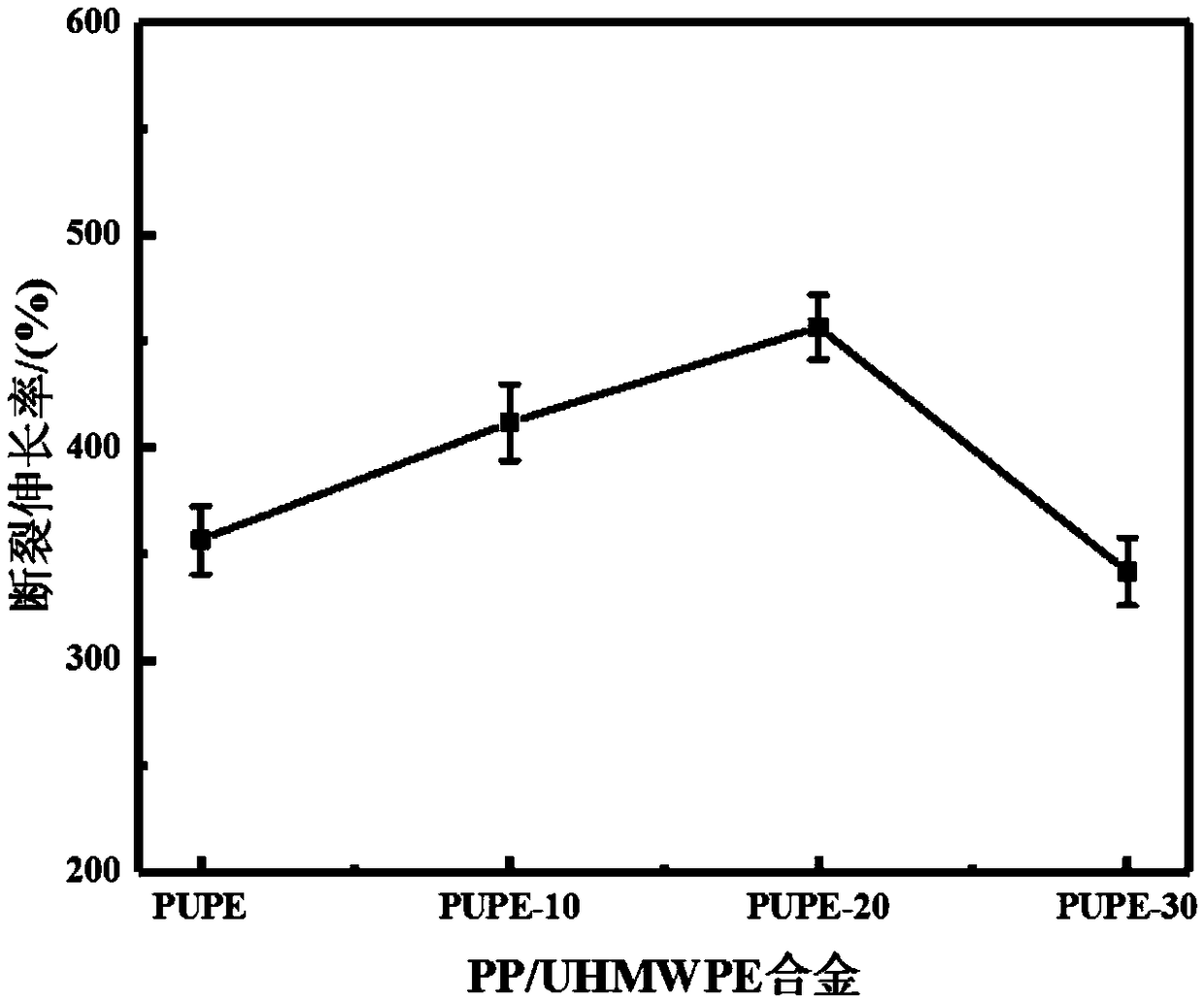

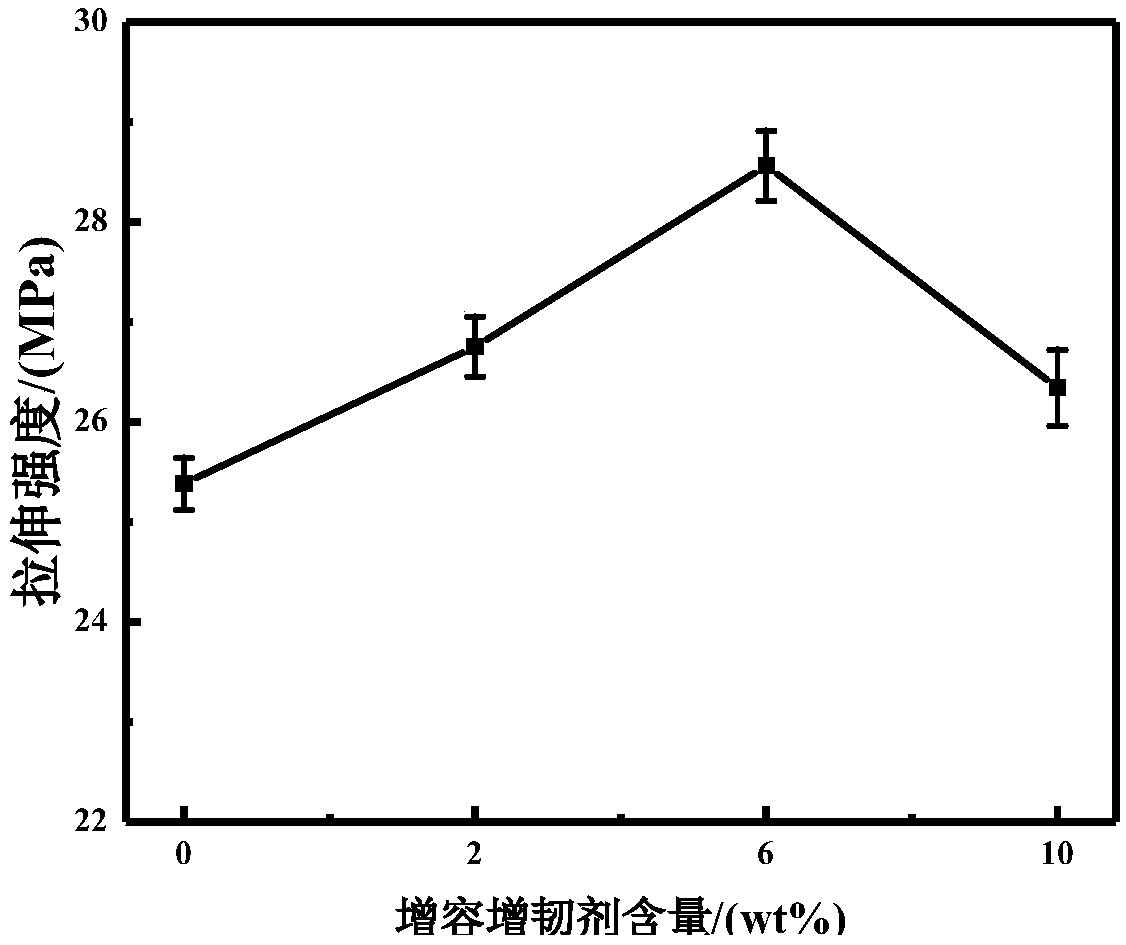

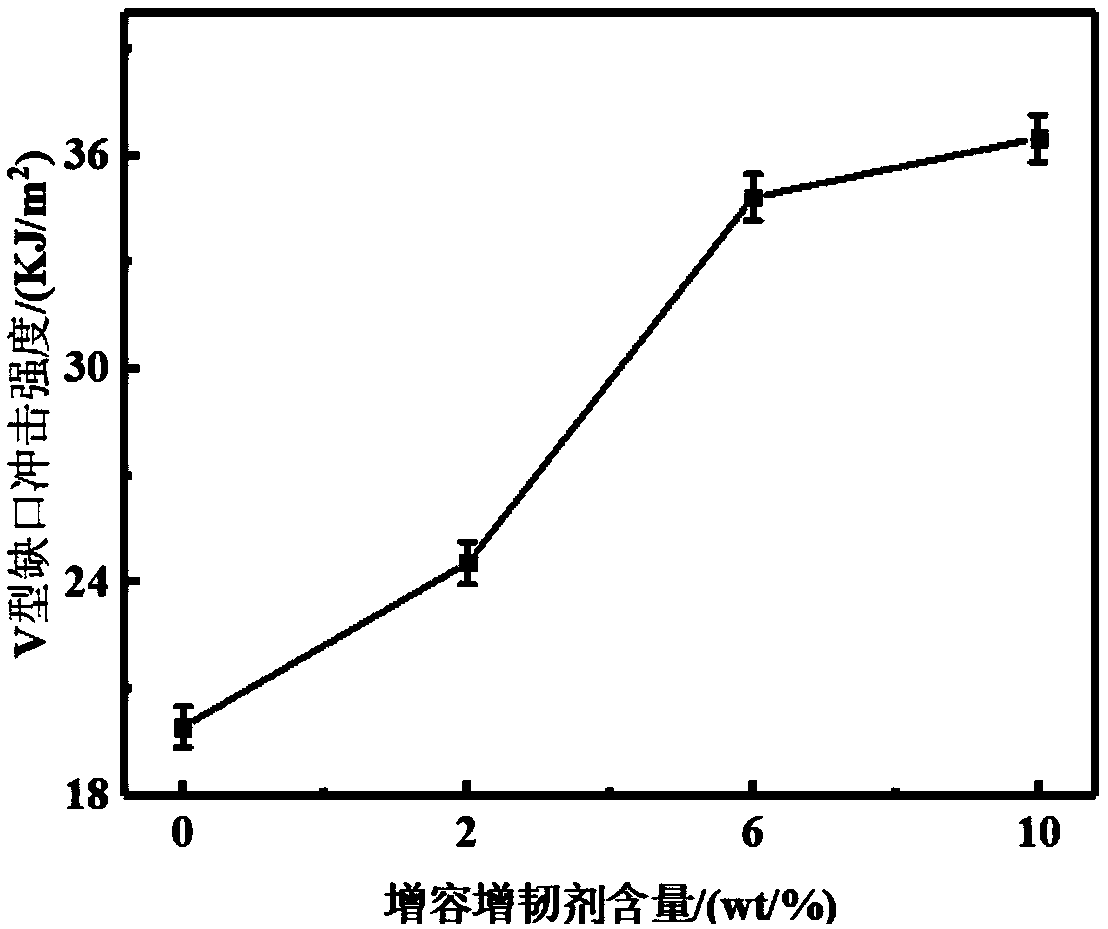

Special material for UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and preparation method of special material

The invention discloses a special material for an UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and a preparation method of the special material. The special material comprises, by weight, 60-85 parts of block co-polypropylene granules, 5-10 parts of fillers, 5-30 parts of capacity increasing and toughening agents and 1-5 parts of flowability modifiers. The corrugated pipe produced by the special material has the advantages of good mechanical properties, better low-temperature impact resistance, high heat distortion temperature, high heat conductivity coefficient, good flame resistance, good surface glossiness, good production stability and the like.

Owner:FUJIAN NORMAL UNIV

High-temperature organic heat carrier and production technology thereof

InactiveCN104178092ASolution to short lifeSave resourcesHeat-exchange elementsDibenzyltolueneHeat carrier

A high-temperature organic heat carrier comprises the following compositions (in percent by weight): A, 50%-70% of biphenyl and diphenyl oxide; B, 8%-20% of dibenzyltoluene; C, 10%-35% of hydrogenated terphenyl; D, 0.2%-0.4% of a cleaning agent; E, 0.2%-0.4% of an anti-oxidation anti-corrosion agent; and F, 0.4%-0.8% of an antirust agent. The production steps comprise: 1, adding A biphenyl and diphenyl oxide, B dibenzyltoluene, C hydrogenated terphenyl, D a cleaning agent, E an anti-oxidation anti-corrosion agent and F an anti-rust agent into a reaction kettle, heating to 80-82 DEG C, and mixing with stirring for reaction; 2, dewatering the mixed reaction raw materials in the step 1 by a dewatering tank by utilizing position difference and specific gravity difference; 3, adding an isomerization catalyst, concretely pumping the dewatered raw materials into a raw-material tank for buffering, and sending into an isomerization catalysis reactor by a metering pump to perform isomerization catalytic reaction, so as to combining the sheet-shaped structure into a needle-shaped structure and further to increase the fluidity of the product and reduce condensation point, and performing flash evaporation in a distillation tower to remove unideal compositions; 4, cooling; 5, filtering; and 6, subpackaging.

Owner:山东恒利热载体工程技术有限公司

Method for manufacturing superior weather- and highvoltage-resistant special high polymer rubber belt substrate material

The invention relates the method for preparation of super high pressure and special high polymer rubber belt base material. The raw material comprises K polyvinyl chloride resin, high K polyvinyl chloride resin, C11 nanometer active carbonate, pasty polyvinyl chloride resin, polyester plasticity agent, DINCH plasticity agent, epoxy plasticity agent, anti-oxidant, UV absorbing agent, fire retardant, PVC processing auxiliary agent, MS nanometer rare earth stabilizing agent, calcium and zinc stabilizing agent, J710 flowable agent, lubricating agent, and pigment. The method comprises the following steps: adjusting the metering system according to product formula, then using low-speed hot agitator, cold agitator, extrusion machine, tow-roll mill, filter and calendar, and getting resin rubber belt base material, then stretching, cooling, embossing, batching, checking, and getting the product.

Owner:上海益鑫塑料制品厂

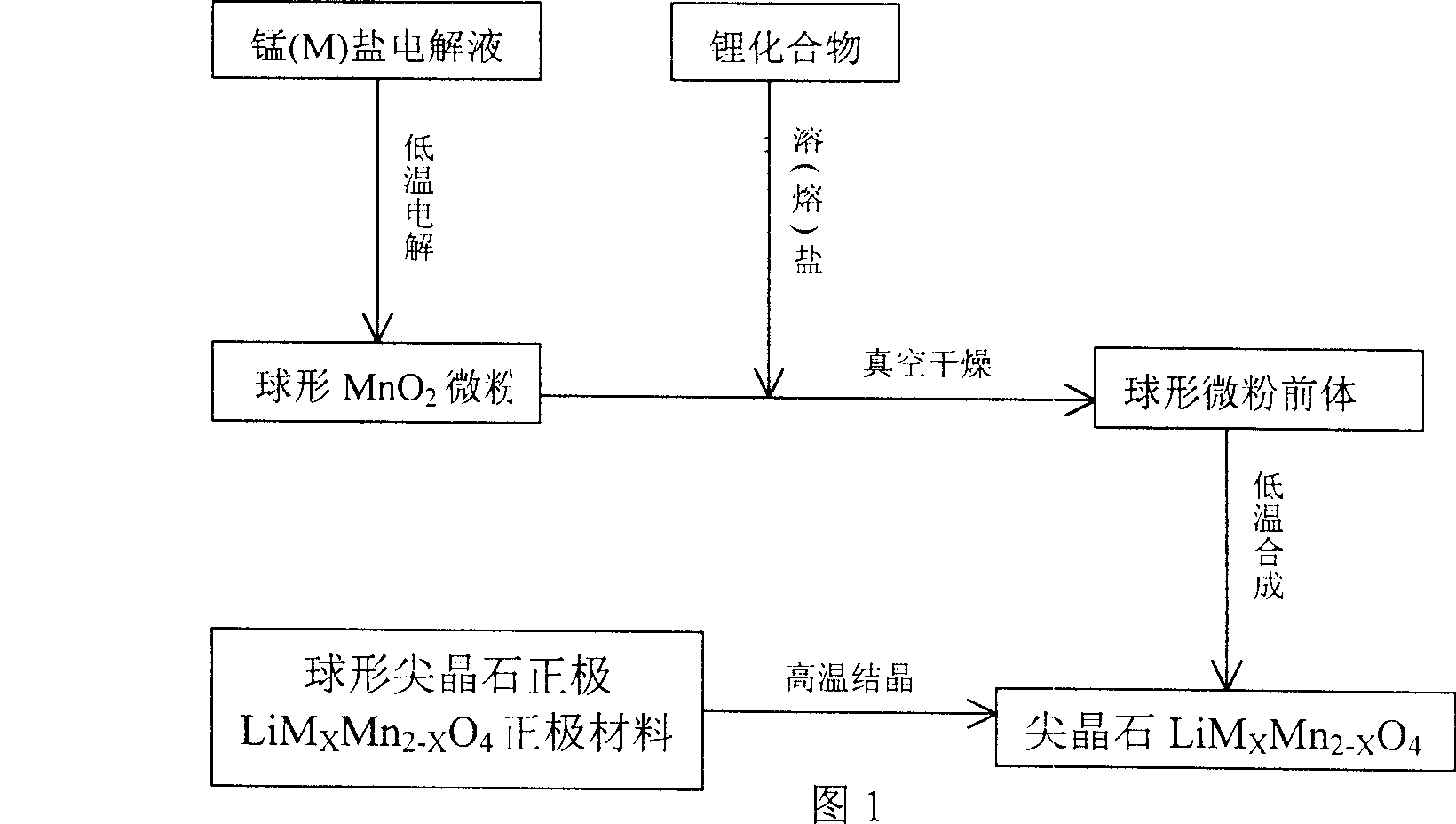

Method for preparnig spherical spinel Li-Mn-oxide lithium ion cell anode material

InactiveCN1744353ASmall surface areaEliminate protrusionsElectrode manufacturing processesLithium oxides/hydroxidesElectrolysisDecomposition

First, using special electrolytic technology in low temperature, the method prepares spherical MnO2 fine grain of pure or composite M metallic oxide. Then, through diffusion process of dissolution (melt), lithium ion is led in; and through thermal reaction, anode material of spinel LiMxMn2-xO4 is obtained. Spherical Li-Mn-Oxide anode material of lithium ion cell prepared by the invention is different from material of polyhedral columnar material prepared by traditional solid phase method, combustion method, coprecipitation method, sol-gel method, and hydrothermal method etc. Spherical form possesses minimal external surface per unit volume. Thus, Spherical form can reduce surface area exposed in electrolyte solution so as to avoid point active effect and restrain Mn2+ from dissolution and running out as well as decomposition of electrolyte. The invention raises performance of anode material LiMn2O4 and improves allover properties of pole pieces.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

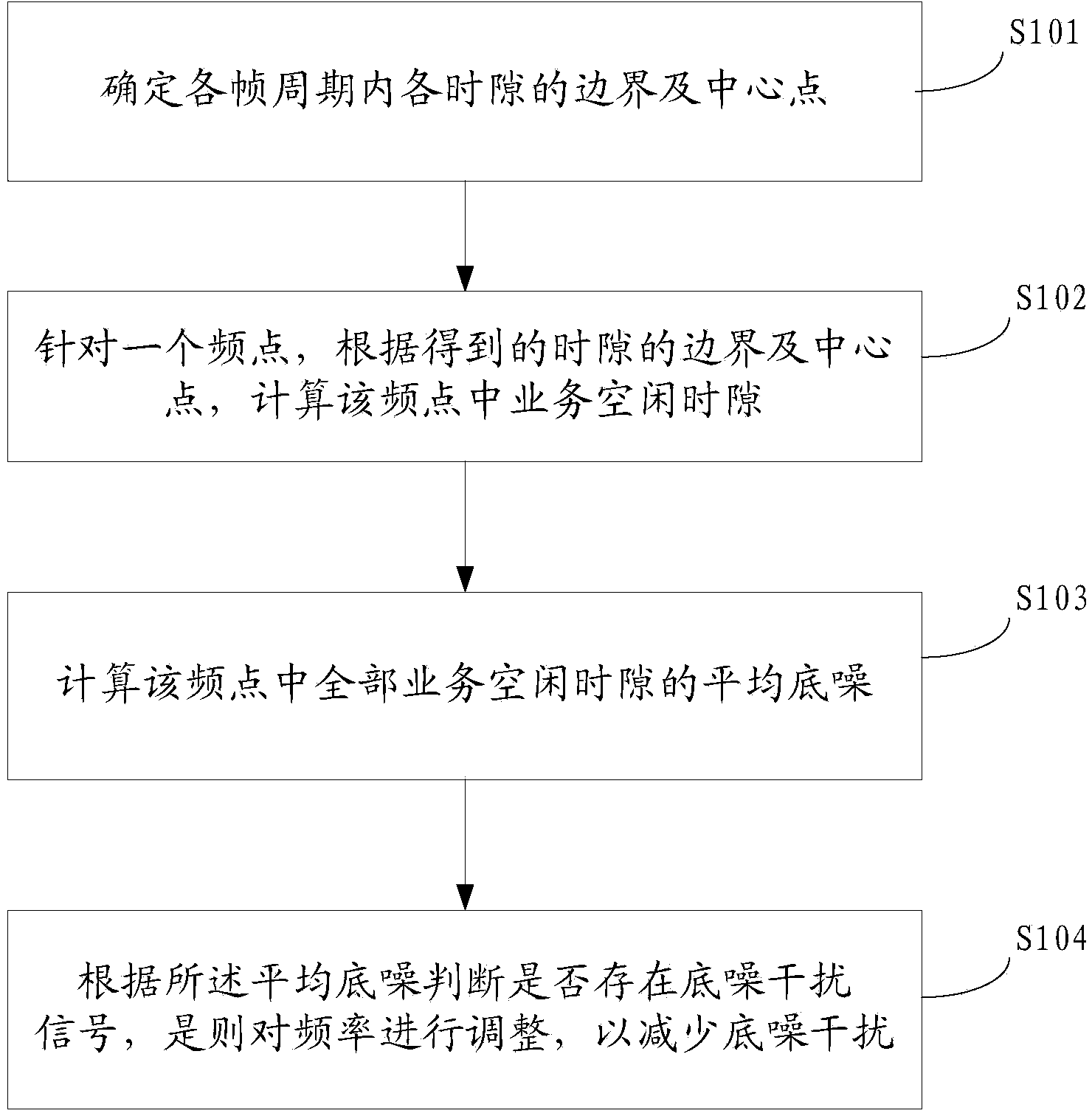

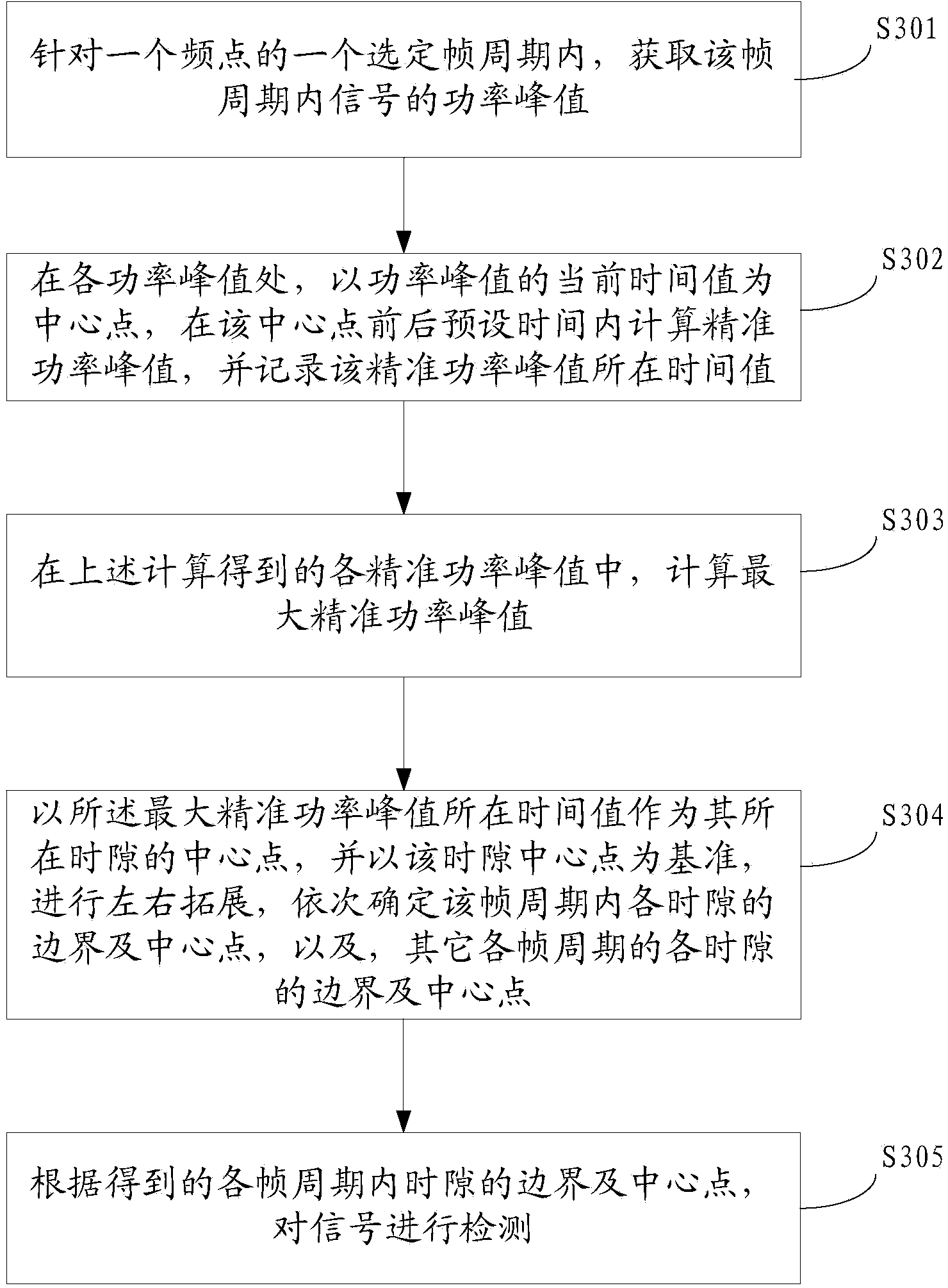

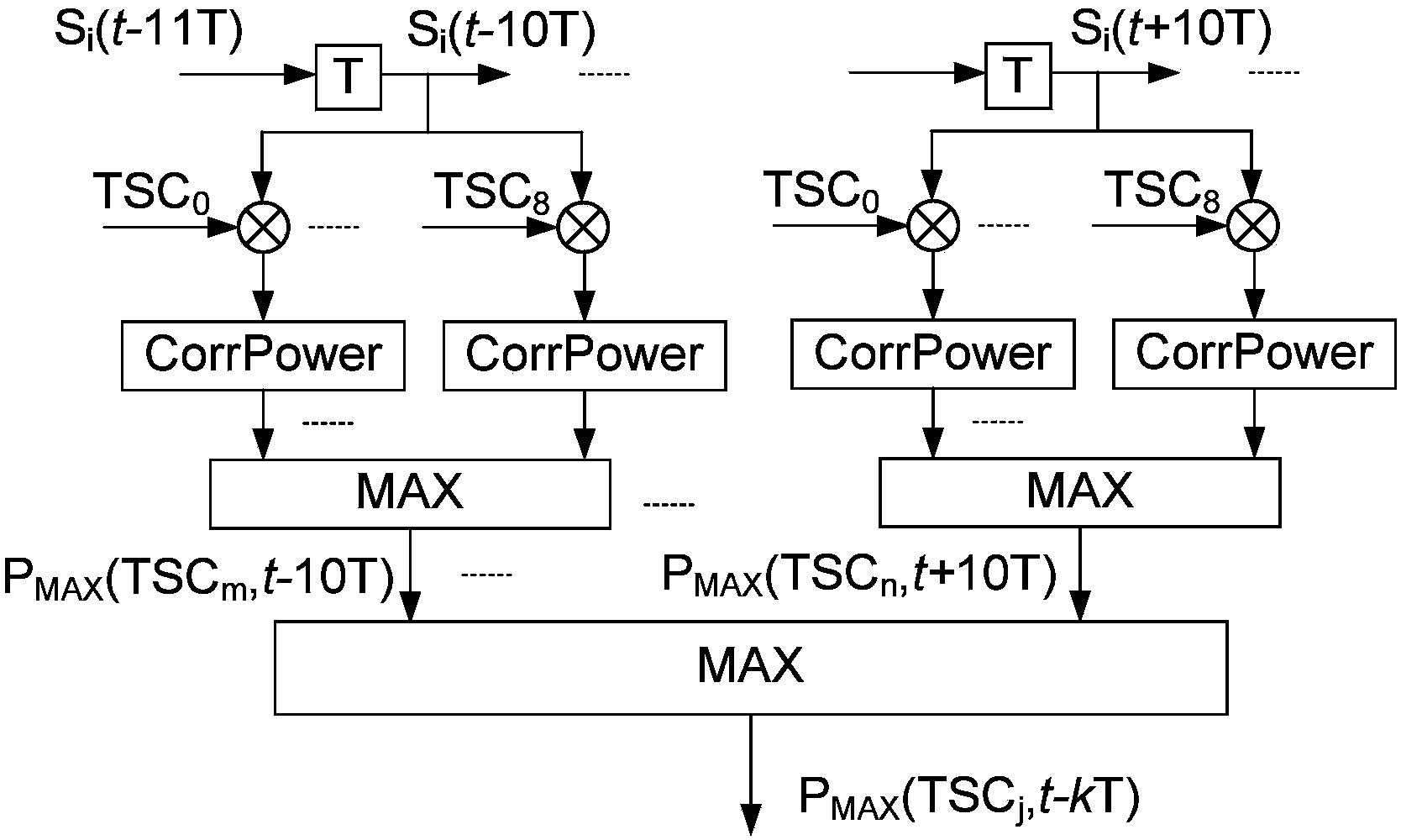

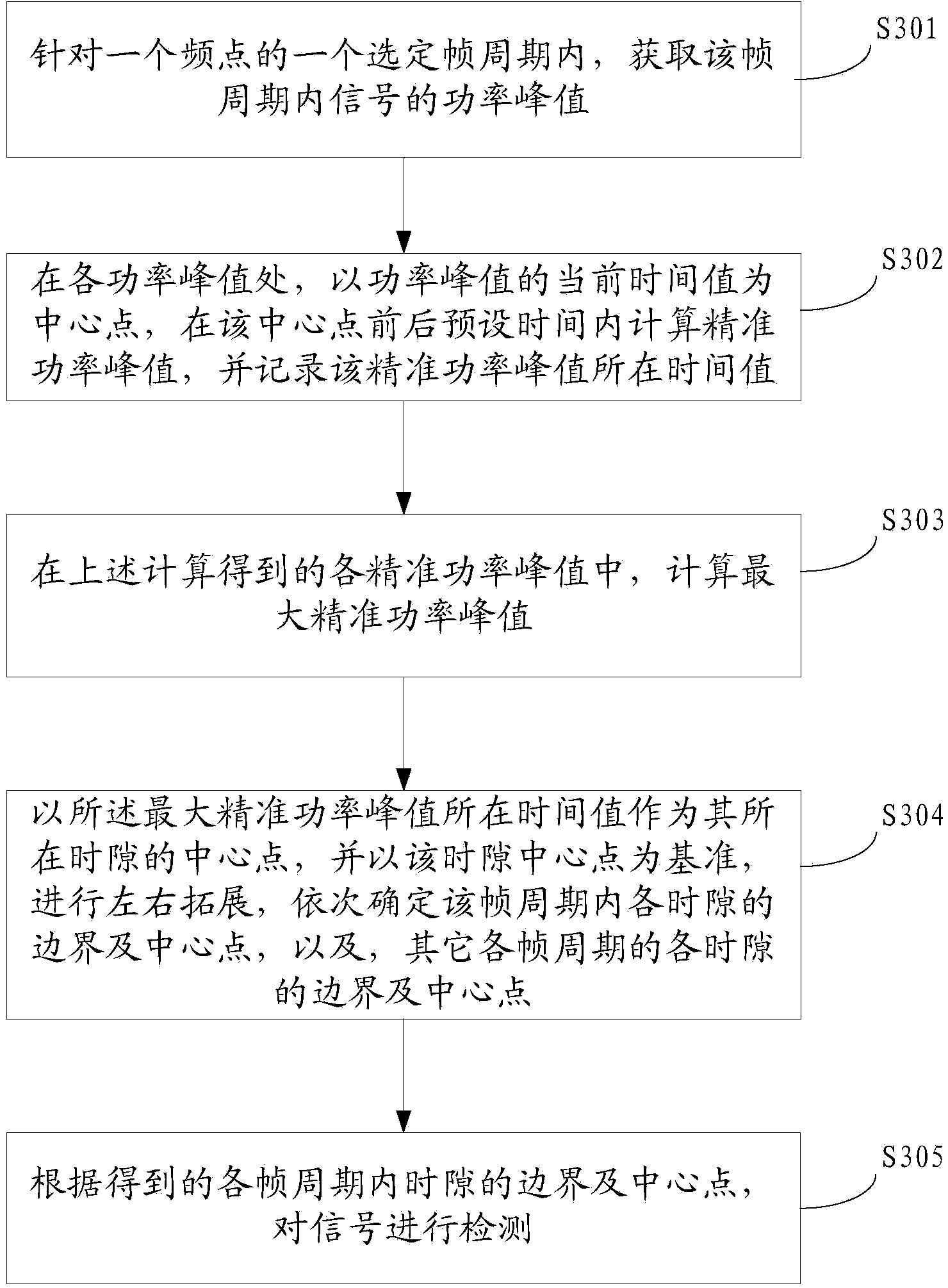

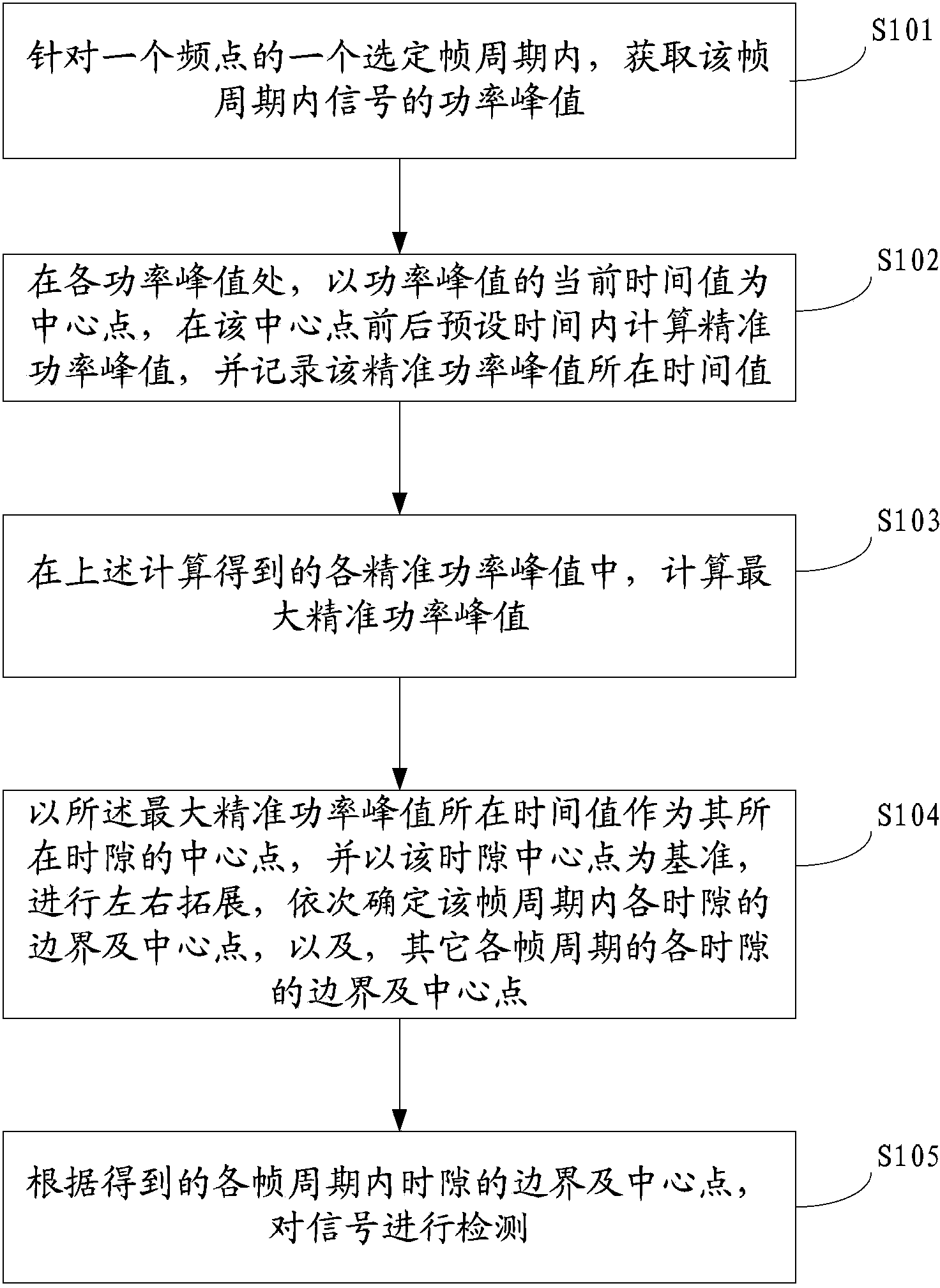

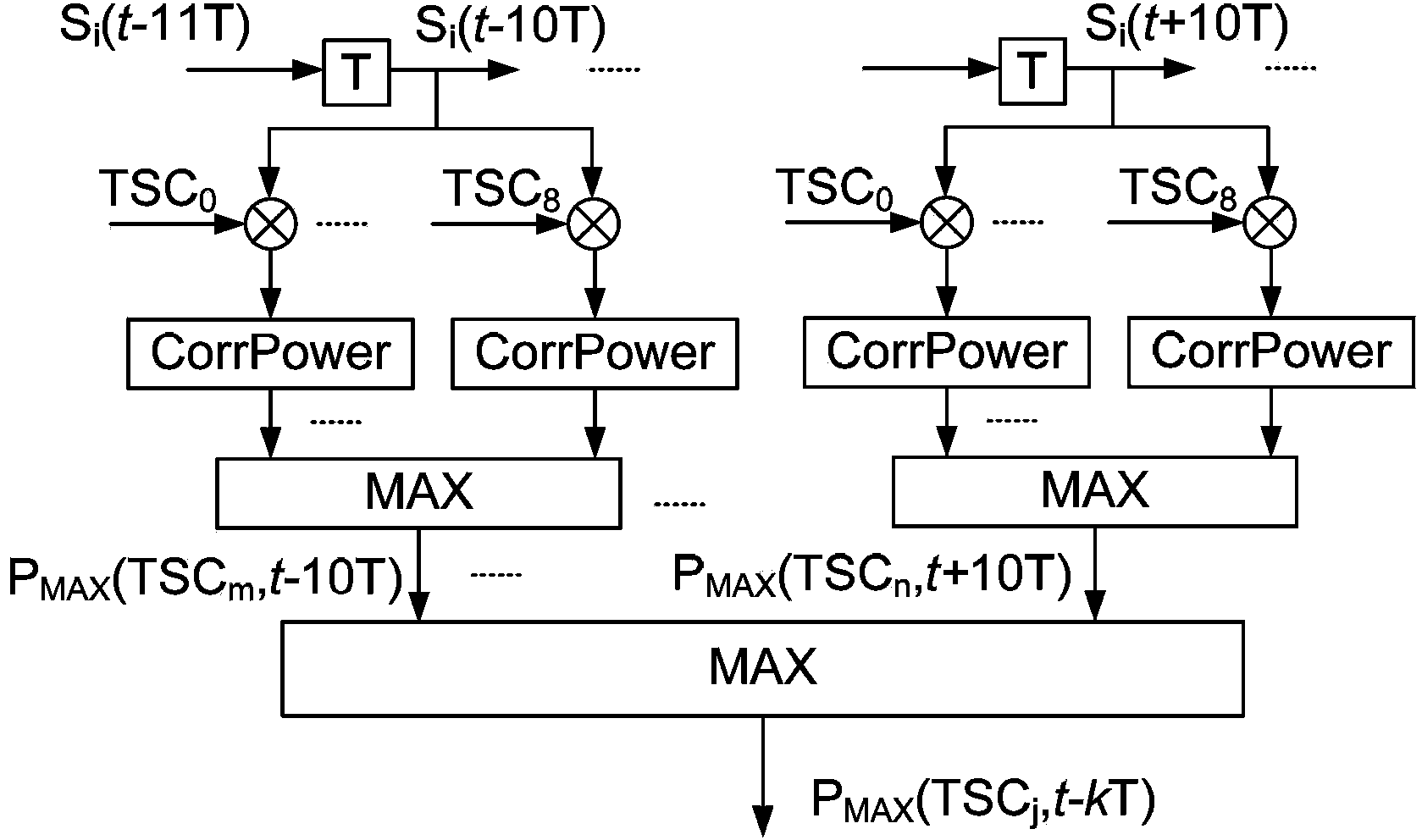

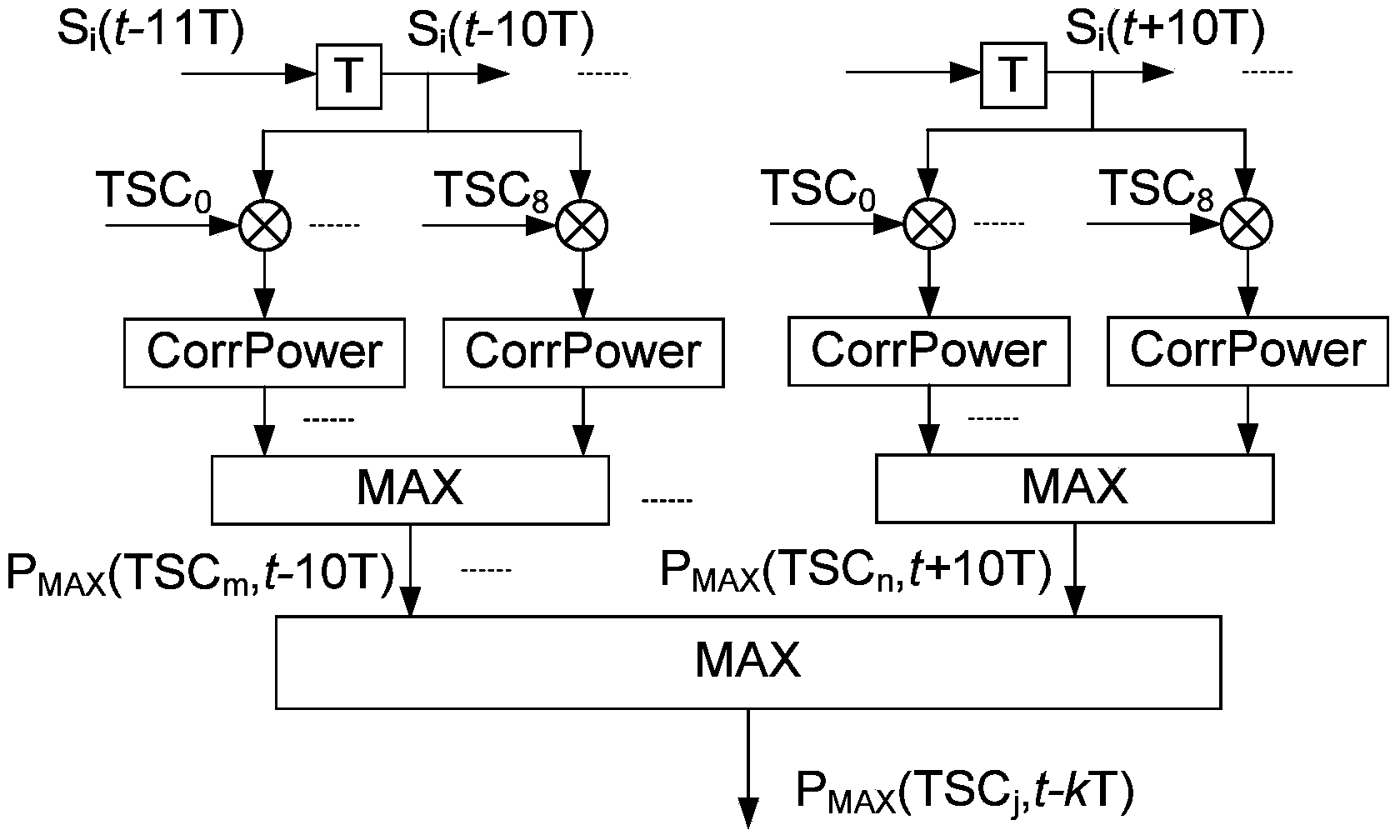

Signal detection method and system

The invention discloses a signal detection method and system and relates to the field of mobile communication technologies. The method includes the steps of step 1, obtaining power peak values of signals in a frame period, step 2, computing accurate power peak values and recording time values when the accurate power peak values are located in preset time before and after a center point, wherein the current time value of the power peak values serves as the center point in all power peak values, step 3, computing the maximum accurate power peak value in all the obtained accurate power peak values through computation, step 4, carrying out expansion left and right on a time slot central point to determine boundaries and central points in the frame period and other frame periods, wherein the time value when the maximum accurate power peak value is located serves as the central point of the time slot when the maximum accurate power peak value is located , and step 5, carrying out signal detection according to the boundaries and central points in each frame period. The signal detection method and system provide basis for deeper scientific and accurate qualitative analysis, furthermore, provide more accurate optimized schemes for signal direction, and improve the whole performance of honeycomb wireless networks fundamentally.

Owner:ULTRAPOWER SOFTWARE

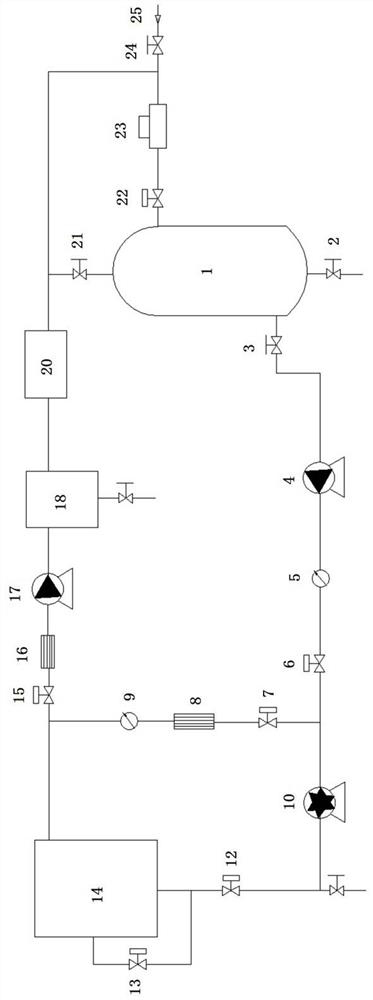

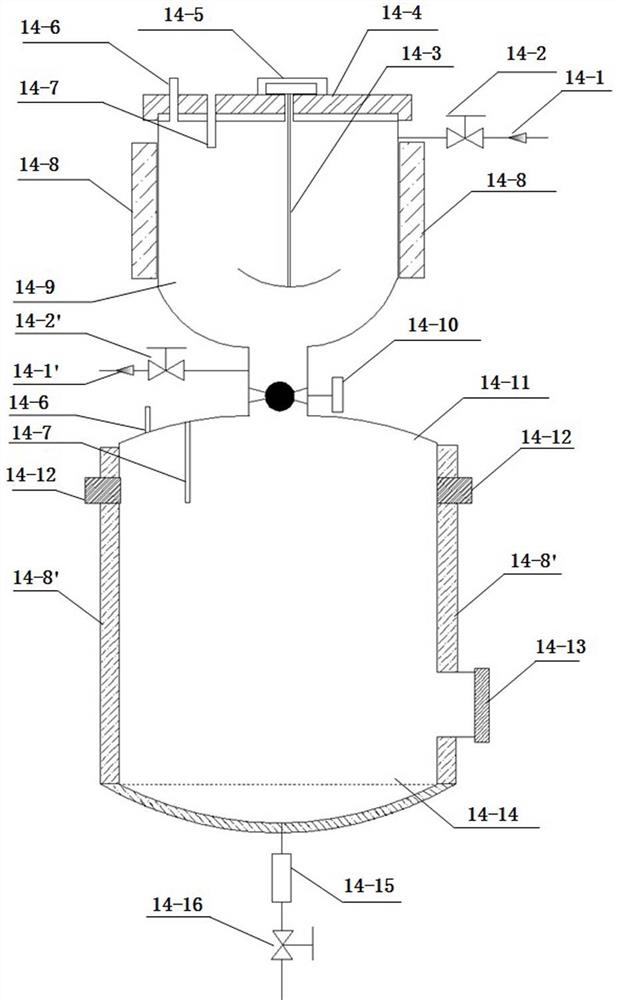

Supercritical carbon dioxide fluid flash explosion machine

PendingCN111676627AExpand the scope of applicationEnhanced Efficient Flash Explosion TreatmentSolvent treatment with solvent recoveryTextile/flexible product manufactureChemistryProcess engineering

The invention discloses a supercritical carbon dioxide fluid flash explosion machine. The supercritical carbon dioxide fluid flash explosion machine comprises a high-temperature and high-pressure fluid flash explosion system, a carbon dioxide medium pressurization system, a circulation treatment system and a carbon dioxide separation and recovery system. A high-temperature and high-pressure fluidtreatment area and a fluid flash explosion area are arranged in the high-temperature and high-pressure fluid flash explosion system and communicate through a quick-opening valve, the quick-opening valve can conveniently and rapidly achieve adjustment of different opening degrees and opening rates according to requirements, the requirements for different temperatures and pressures in the final treatment state can be effectively met, and flash explosion machining of materials under different working conditions is achieved. A magnetic stirring system and an external fluid circulation system are arranged in the high-temperature and high-pressure fluid treatment area, and the treatment uniformity of the treated materials is greatly improved. The fluid flash explosion area can achieve anhydrousdry-state machining of the materials, the technological process is shortened, the obvious ecological and environment-friendly characteristics are achieved, and efficient flash explosion treatment of compact type materials difficult to permeate is achieved and improved.

Owner:SUZHOU UNIV

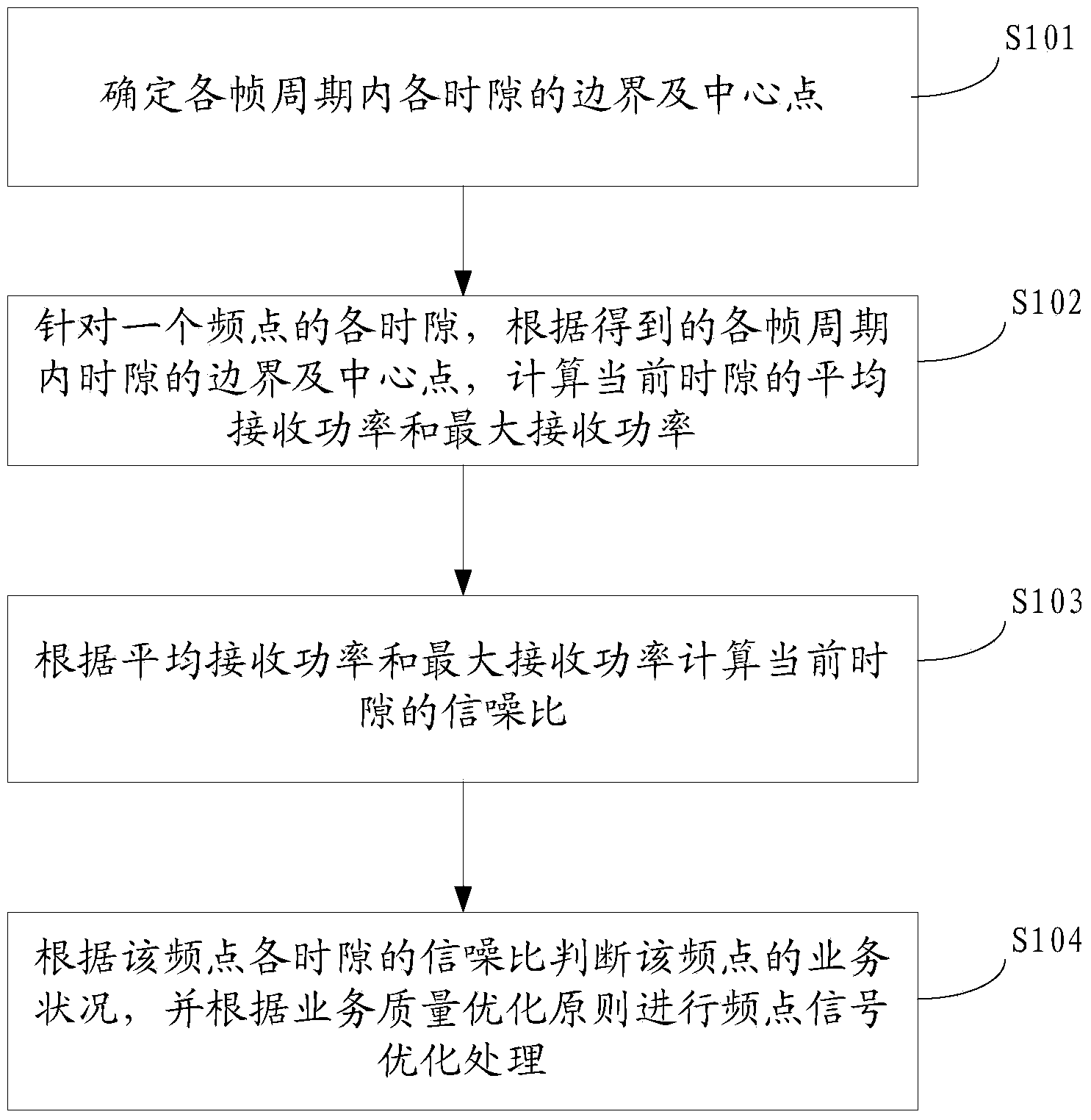

Method and system for carrying out signal optimization based on carrier-to-interference ratio (C/I)

ActiveCN103442373AAchieve load optimizationImprove and improve performanceNetwork traffic/resource managementSignal qualityInterference ratio

The invention discloses a method and system for carrying out signal optimization based on carrier-to-interference ratio (C / I), and relates to the field of mobile communication technologies. The method includes the steps that boundaries and center points of all time slots of all frame periods are determined; aiming at all the time slots of a frequency point, average received power and the maximum received power of a current time slot are calculated according to the boundaries and center points of the time slots; then the carrier-to-interference ratio of the current time slot is calculated; according to the carrier-to-interference ratios of all the time slots of the frequency point, the service state of the frequency point is judged, and signal quality optimization processing is carried out according to the service quality optimization principle. According to the carrier-to-interference ratio C / I values, the serves states of all the time slots can be reflected accurately, the frequency point containing much disturbed time slots is adjusted to be a frequency point containing much free time slots, moreover, the maximum received power is smaller than preset power, and therefore the signal optimization is achieved. Signals can be optimized reasonably according to the service states, network load optimization is achieved, and overall performance of a honeycomb wireless network is improved and promoted fundamentally.

Owner:ULTRAPOWER SOFTWARE

Level-variable turbocharging system and engine with same

ActiveCN103615308AImprove machine efficiencyGood acceleration and responsivenessInternal combustion piston enginesTurbochargerEngineering

An engine with a level-variable turbocharging system comprises an engine body (1) and the level-variable turbocharging system, wherein the engine body (1) comprises an engine mechanical assembly and an engine electric control unit; the level-variable turbocharging system comprises a large turbocharger (21), a middle turbocharger (22) and a small turbocharger (23) which are different in flow, each of the turbochargers comprises a turbine and an air compressor which form a network with an air pipe through a tee joint (312), a tee joint (322), a tee joint (331), a tee joint (342), a tee joint (381), a tee joint (412), a tee joint (422), a tee joint (441), a tee joint (451), a three-way valve (311), a three-way valve (321), a three-way valve (341), a three-way valve (351), a three-way valve (411), a three-way valve (421) and a three-way valve (461), and connected with the engine body (1).

Owner:HUNAN TYEN MACHINERY

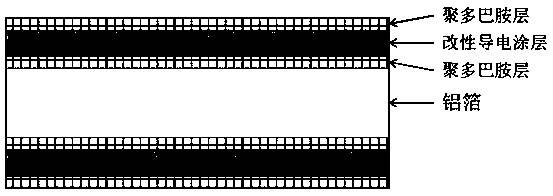

Carbon-coated aluminum foil used for lithium battery and manufacturing method thereof

ActiveCN110676462AImprove and improve performanceImprove corrosion resistanceElectrode thermal treatmentElectrode carriers/collectorsLithium-ion batteryElectronic conductivity

The invention discloses a carbon-coated aluminum foil used for a lithium battery and a manufacturing method thereof. The carbon-coated aluminum foil successively comprises a polydopamine layer, a modified conductive coating, the polydopamine layer and an aluminum foil from outside to inside, and the modified conductive coating is made of a cyclized polyacrylonitrile (C-PAN) modified conductive carbon material which is taken as a raw material. A pi bond in a C-PAN chain can be used to improve an electronic conductivity characteristic of a conductive carbon material and conductivity of the carbon-coated aluminum foil is improved. The polydopamine layer formed through coating on a surface of the aluminum foil has good corrosion resistance, thermal conductivity and cohesiveness performance sothat the corrosion resistance and heat dissipation of the carbon-coated aluminum foil are improved, and the cohesiveness of the conductive coating with active substances and the aluminum foil can beincreased. Therefore, the manufactured carbon-coated aluminum foil has good conductivity, corrosion resistance, heat dissipation performance and cohesiveness performance, and can be widely applied tothe lithium ion battery field.

Owner:福建巨电新能源股份有限公司

High-performance functionalized alloy modified polypropylene corrugated pipe special-use material and preparation method thereof

ActiveCN109401045AImprove low temperature toughnessHigh surface glossHeat deflection temperatureAntioxidant

The invention discloses a high-performance functionalized alloy modified polypropylene corrugated pipe special-use material and a preparation method thereof. The special-use material includes, by weight, 40-70 parts of homo-polypropylene powder, 15-25 parts of block-copolymerized polypropylene powder, 3-15 parts of filler, 2-10 parts of a compatibilizing and toughening agent, 1-5 parts of a flowability modifier, 1-5 parts of a flame retardant, 0.1-1.2 parts of an antioxidant, and 0.05-0.5 parts of an ultraviolet absorber. The corrugated pipe manufactured from the special-use material has goodmechanical performance and low-temperature anti-impact effect, is high in thermal-deformation temperature and heat-conductivity, and has good flame retarding effect, excellent surface glossiness and production stability.

Owner:FUJIAN NORMAL UNIV

Method for preparing multifunctional polymer-based nanometer ZnO composite tanning agent

InactiveCN103074455AEasy to prepareImprove stabilityTanning treatmentZinc Acetate DihydratePolymer chemistry

A method for preparing a multifunctional polymer-based nanometer ZnO composite tanning agent is characterized by comprising the following steps: preparing modified ZnO soils by taking zinc acetate as a nanometer particle precursor and diallyldimethylammonium chloride as a modifying agent, and preparing a polymer-based nanometer ZnO composite tanning agent for a leather retanning procedure through a soil-in-situ polymerization method. Through adoption of the method, nanometer ZnO is uniformly dispersed in a polymeric matrix, so that the stability of the polymer-based nanometer ZnO composite tanning agent is improved. When the method is applied to the leather retanning procedure, the dyeing depth of the leather can be greatly increased so that the K / S value of the dyed leather is increased by 98.26 %, the fullness of the leather is improved so that the tanned leather is thickened by 20.88 %, and the leather is endowed with good antibacterial property and aging resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com