Extinguishment shrapnel type rocket bomb

A technology of sub-unit bombs and fire-extinguishing mines, applied in warheads, ammunition, fire rescue, etc., can solve the problems of ineffective forest fire treatment, fire-extinguishing bombs do not have self-destruction function, weak anti-interference ability, etc., to improve the safety of use, The effect of light weight and high fire extinguishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

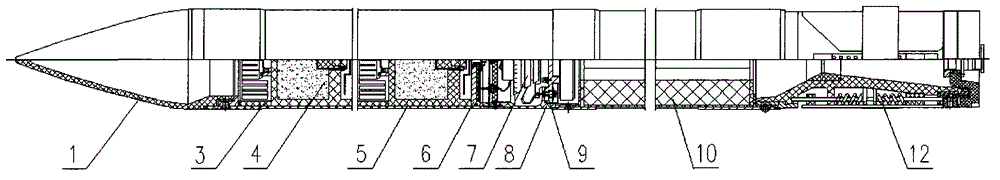

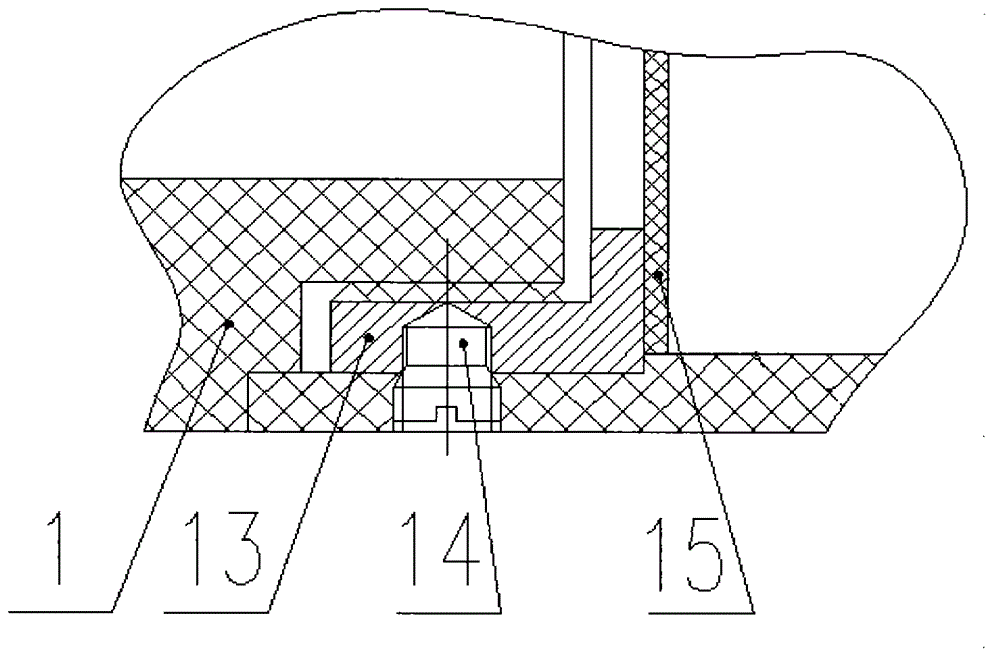

[0040] A kind of fire extinguishing submunition of the present invention, as figure 1 As shown, it includes wind cap 1, fire extinguishing mine cabin body 5 and its internal fire extinguishing mine 4, annular retainer 3 and push plate assembly 6, control cabin shell 8 and its internal propellant fuze 7, propellant box, propellant Igniter and sealed heat insulation conductive mechanism 9, rocket motor 10, rocket tail 12;

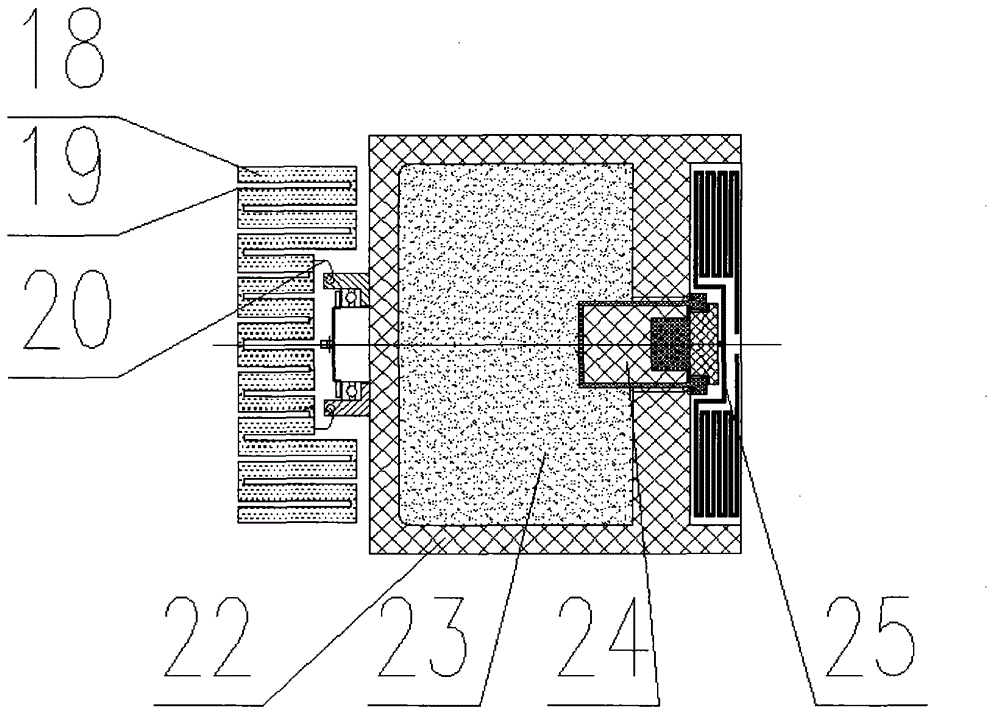

[0041] Among them, fire mine 4, such as image 3 As shown, including drogue parachute 18, umbrella cover 19, umbrella rope 20, fire extinguishing mine shell 22, fire extinguishing agent 23, thermal trigger fuze 24;

[0042] Fire extinguishing mine shell 22 is filled with fire extinguishing agent 23, and the lower end of fire extinguishing mine shell 22 is threadedly connected with heat-sensitive trigger fuze 24, so that the front-end ignition device of heat-sensitive trigger fuze 24 is located inside fire extinguishing mine shell 22 and is in contact with fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com