Carbon-coated aluminum foil used for lithium battery and manufacturing method thereof

A lithium battery and aluminum foil technology, which is applied in the field of lithium-ion batteries, can solve the problems of no obvious improvement in the conductivity of carbon-coated aluminum foil, graphene modification, and no obvious improvement in the adhesion between the carbon-coated layer and the positive active material. Achieve the effects of improving multiple properties, improving electronic conductivity, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

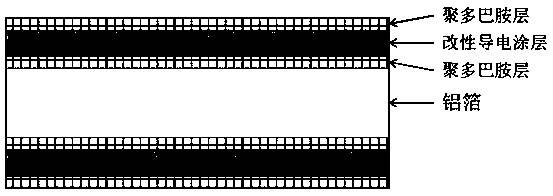

[0023] Embodiment 1: Preparation of carbon-coated aluminum foil for lithium batteries

[0024] (1) Aluminum foil surface coated with polydopamine layer: prepare 10 mmol / L Tris-HCl buffer solution, use 0.1 mol / L hydrochloric acid to adjust the pH of the buffer solution to 7.5, and then dissolve dopamine monomer in Tris-HCl buffer solution , dopamine solution; rinse the aluminum foil with deionized water for 10 min, put the aluminum foil into the prepared dopamine solution, place the solution in a constant temperature (25°C) shaker for 24 h, take out the aluminum foil and wash it with deionized water Rinse with water for 5 minutes, ultrasonically clean for 5 minutes, and dry to obtain an aluminum foil with a polydopamine layer formed on the surface;

[0025] (2) Preparation of cyclized polyacrylonitrile modified conductive carbon material: mix polyacrylonitrile (PAN) and graphene in DMF at a mass ratio of 2:8, and place the mixed material in a quartz tube , sintered at 240 °C f...

Embodiment 2

[0028] Embodiment 2: Preparation of carbon-coated aluminum foil for lithium batteries

[0029] (1) Aluminum foil surface coated with polydopamine layer: Prepare 15 mmol / L Tris-HCl buffer solution, use 0.1 mol / L hydrochloric acid to adjust the pH of the buffer solution to 8, and then dissolve dopamine monomer in Tris-HCl buffer solution , dopamine solution; rinse the aluminum foil with deionized water for 15 min, put the aluminum foil into the prepared dopamine solution, place the solution in a constant temperature (25°C) shaker for 30 h, take out the aluminum foil and wash it with deionized water Rinse with water for 7.5 minutes, ultrasonically clean for 7.5 minutes, and dry to obtain an aluminum foil with a polydopamine layer formed on the surface;

[0030] (2) Preparation of cyclized polyacrylonitrile modified conductive carbon material: mix polyacrylonitrile (PAN) and graphite in DMF at a mass ratio of 2.5:7.5, and place the mixed material in a quartz tube. Sinter at 260°C...

Embodiment 3

[0033] Embodiment 3: Preparation of carbon-coated aluminum foil for lithium batteries

[0034] (1) Aluminum foil surface coated with polydopamine layer: Prepare 20 mmol / L Tris-HCl buffer solution, use 0.1 mol / L hydrochloric acid to adjust the pH of the buffer solution to 8.5, and then dissolve dopamine monomer in Tris-HCl buffer solution , dopamine solution; rinse the aluminum foil with deionized water for 20 min, put the aluminum foil into the prepared dopamine solution, place the solution in a constant temperature (25°C) shaker for 36 h, take out the aluminum foil and wash it with deionized water Rinse with water for 10 minutes, ultrasonically clean for 10 minutes, and dry to obtain an aluminum foil with a polydopamine layer formed on the surface;

[0035] (2) Preparation of cyclized polyacrylonitrile modified conductive carbon material: mix polyacrylonitrile (PAN) and carbon nanotubes in DMF with a mass ratio of 3:7, and place the mixed material in a quartz tube , sintered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com