Special material for UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and preparation method of special material

A technology of toughening and modifying polypropylene, applied in the special material for UHMWPE alloy compatibilizing and toughening modified polypropylene corrugated pipe and its preparation field, can solve the problems of poor processability, decreased impact performance, flammability, etc., and improve the surface gloss. Smoothness and smoothness, improved dispersibility and lubricity, weight reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A special material for UHMWPE alloy expansion and toughening modified polypropylene bellows consists of: 80 parts of block copolymerized polypropylene powder, 8 parts of filler, 10 parts of UHMWPE alloy expansion and toughening agent, and 2 parts of fluidity modifier.

[0033] The preparation method is carried out according to the following steps:

[0034] (1) Add 6 kg of hollow glass microspheres, 2 kg of nano-calcium carbonate and 1 wt% of silane coupling agent KH560 into the high mixer, keep the rotating speed at 2000 rpm, and stir at high speed for 20 minutes to obtain the filler according to the present invention;

[0035] (2) The UHMWPE alloy compatibilizing and toughening agent of the present invention is an alloy prepared by melting and blending LLDPE, UHMWPE and organic silicon impact modifier S-2001 according to a certain quality formula, and its preparation method is:

[0036] A. Drying: Dry UHMWPE, LLDPE and silicone impact modifier S-2001 in a drying oven a...

Embodiment 2

[0045] A special material for UHMWPE alloy expansion and toughening modified polypropylene bellows consists of: 60 parts of block copolymerized polypropylene powder, 8 parts of filler, 30 parts of UHMWPE alloy expansion and toughening agent, and 2 parts of fluidity modifier.

[0046] The preparation method is carried out according to the following steps:

[0047] (1) Mix 6 kg of hollow glass microspheres, 2 kg of nano-calcium carbonate and 1 wt% of silane coupling agent KH550

[0048] Add it together to the high mixer, keep the rotating speed at 2000 rpm, and stir at a high speed for 20 minutes to obtain the filler according to the present invention;

[0049] (2) The UHMWPE alloy compatibilizing and toughening agent of the present invention is an alloy prepared by melting and blending LLDPE, UHMWPE and organic silicon impact modifier S-2001 according to a certain quality formula, and its preparation method is:

[0050] A. Drying: Dry UHMWPE, LLDPE and silicone impact modifier...

Embodiment 3

[0058] (1) LLDPE, UHMWPE and silicone impact modifier S-2001 were melt blended at a certain mass ratio to prepare a UHMWPE alloy compatibilizer and toughener. The preparation method is as follows:

[0059] A. Drying: Dry UHMWPE, LLDPE and silicone impact modifier in a drying oven at 80°C for 4 h;

[0060] B. Weighing: Weigh the dried UHMWPE, LLDPE and silicone impact modifier S-2001 according to the weight percentage of 75 / 25 / 10;

[0061] C. Blending: each component weighed is placed in a high-speed kneader and mixed at a high speed for 10 min, and the rotating speed of the high-speed mixer is 2000 rpm;

[0062] D. Extrusion granulation: Put the above-mentioned fully mixed and uniform raw materials into the screw extruder, heat at a high temperature of 195~205 °C, melt and plasticize in the high-temperature screw melting cavity, and extrude the raw materials at a speed of 200 rpm; The raw material extruded by the screw is cooled and sent to the pelletizer to be cut into UHMW...

PUM

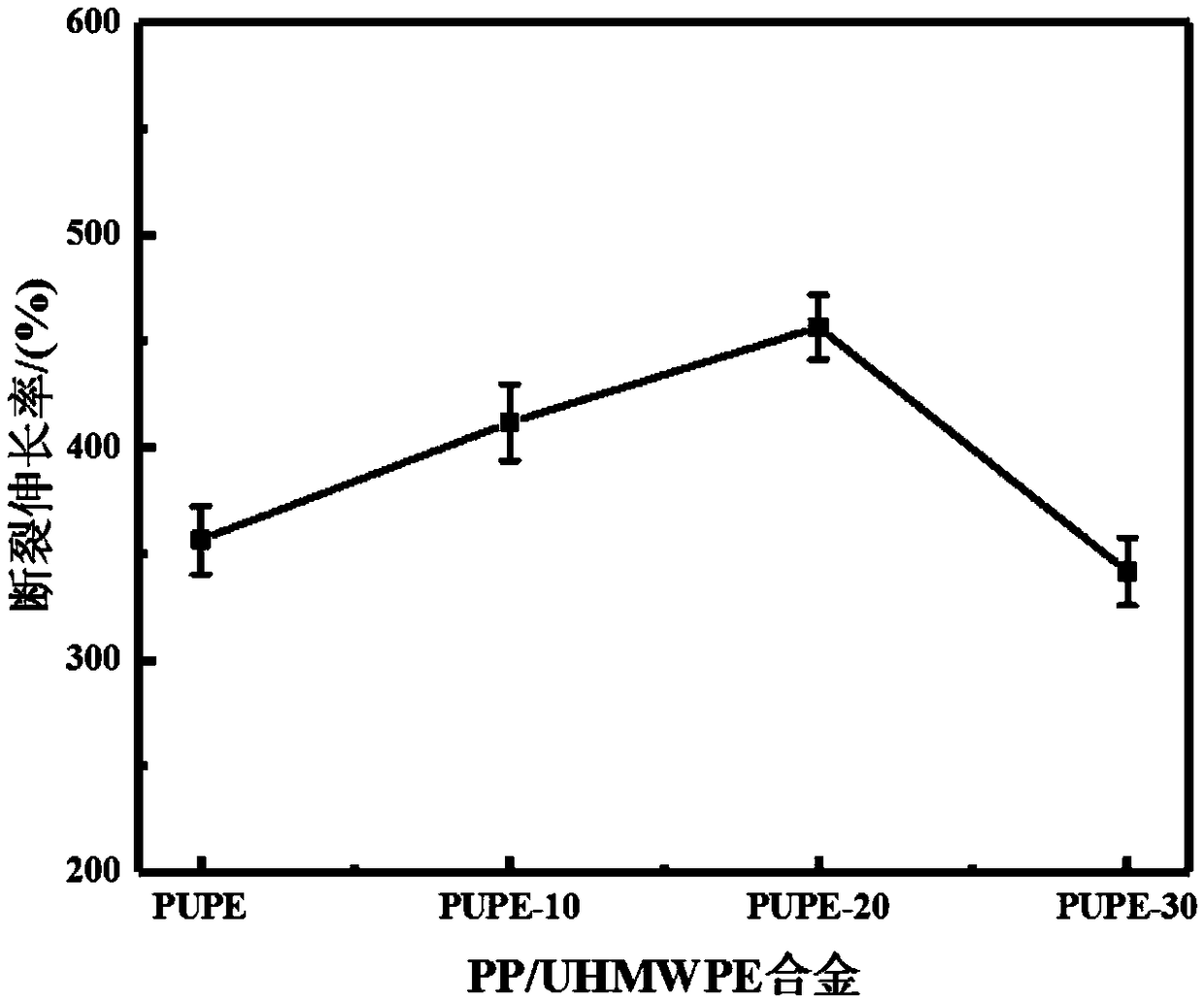

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com