Polycarbonate-Based Resin Composition for Carrier Tape Having Excellent Electric Conductivity

A technology of polycarbonate resin and composition, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, transportation and packaging, packaging, etc., which can solve the problems of polycarbonate resin conductivity difficulties and achieve excellent conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

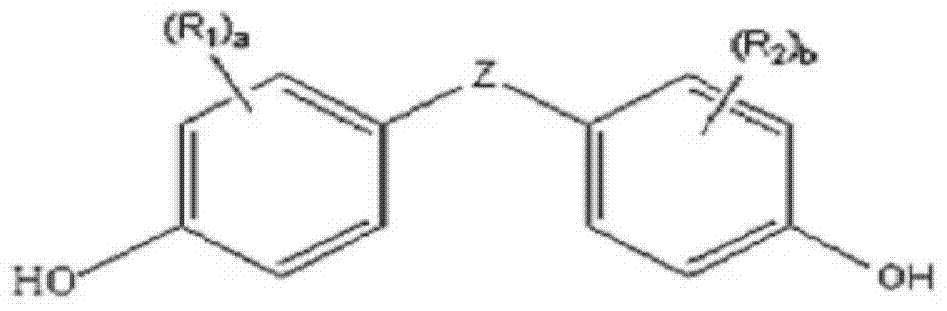

[0139] The details of each component used in the examples and comparative examples of the present invention are as follows:

[0140] (A) polycarbonate resin

[0141] PANLITE L1225WX manufactured by TEIJIN CHEMICALS LTD was used.

[0142] (B1) Rubber-modified aromatic vinyl resin

[0143] (b1) ABS resin

[0144] CHTS manufactured by Cheil Industries Inc was used.

[0145] (b2) SEBS resin

[0146] KRATON G1651, SHELL

[0147] (B2) Semi-crystalline polymer resin

[0148] (b3) Polybutylene terephthalate (PBT)

[0149] Shinite K001 manufactured by SHINKONG is used.

[0150] (b4) Ethylene vinyl acetate (EVA)

[0151] Use manufactured by Dupont 150.

[0152] (C) carbon nanotubes

[0153] Multi-walled carbon nanotubes having an aspect ratio of 500 to 2,000 are used.

[0154](D) Additives

[0155] Wax: Licowax PED191, Clariant

[0156] Antioxidants: IRGANOX1076, CIBA

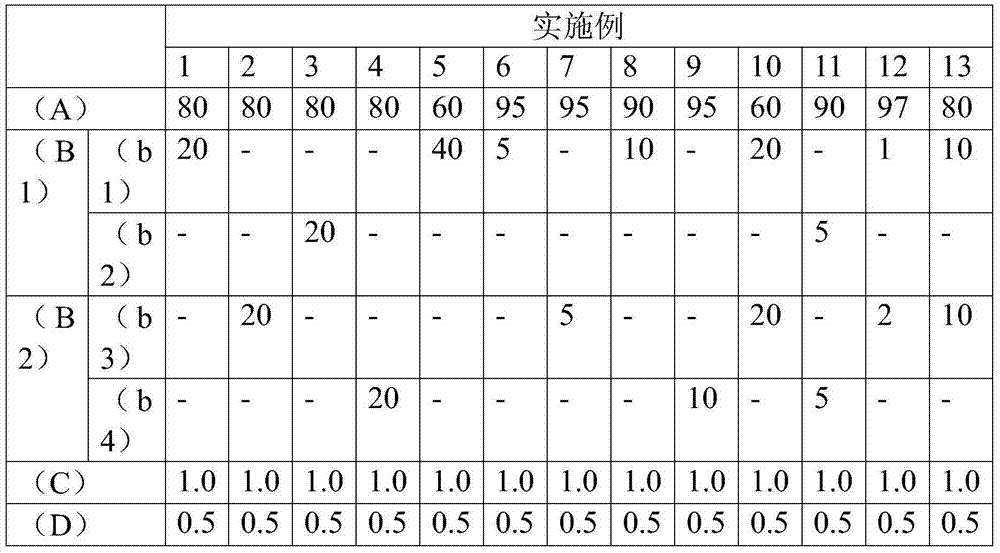

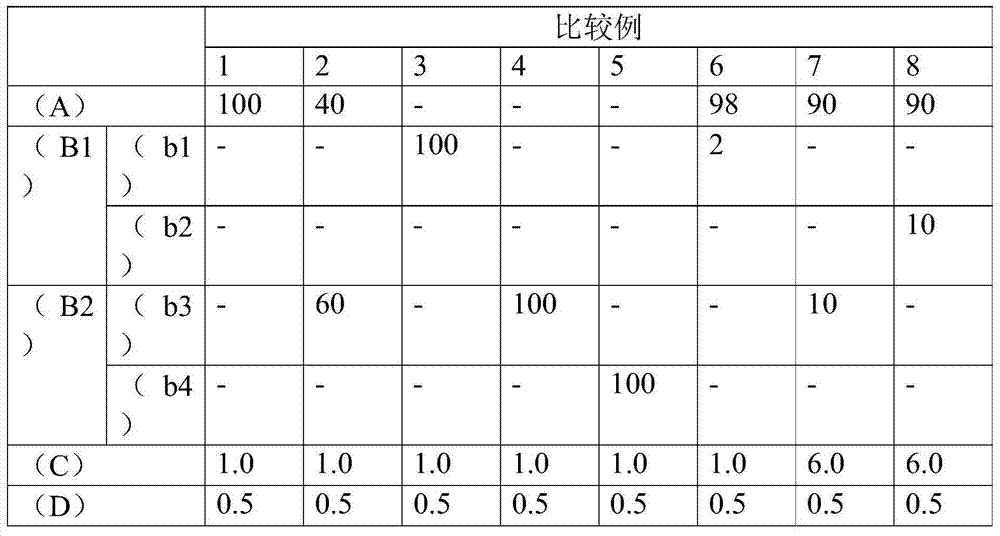

example 1-13 and comparative example 1-8

[0158] Each ingredient was dry-blended in the amount shown in Table 1 and Table 2, and then the mixture was extruded using a twin-screw extruder (L / D=35, Φ=45 mm) to prepare an extruded mixture as pellets. The prepared pellets were injected at 280° C. using a 10 oz injection machine to prepare test samples for measuring various physical properties.

[0159] In Table 1 and Table 2, the mixing ratio of (A), (B) and (C) is expressed in % by weight of each ingredient, based on 100% by weight of (A) and (B), and ( C) is expressed in parts by weight based on 100 parts by weight of (A)+(B).

[0160] [Table 1]

[0161]

[0162] [Table 2]

[0163]

[0164] The physical properties of the prepared test samples were measured by the following methods, and the results are shown in Tables 3 and 4 below.

[0165] Methods used to measure physical properties

[0166] (1) Surface resistance (Ω / □) Measured according to ASTM D257 using SRM-100 manufactured by Wolfgang Warmbier GmbH & C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com