High-strength three-layer co-extrusion durable shed film and preparation method thereof

A high-strength, shed film technology, applied in the field of agricultural shed film, can solve the problems of difficult to obtain comprehensive performance agricultural shed film, reduce the tensile and tear properties of the shed film, affect the comprehensive performance of the shed film, etc., and achieve enhanced photosynthesis. efficiency, increase crop yield, and the effect of superior cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second aspect of the present invention provides a method for preparing the above-mentioned high-strength greenhouse film, comprising the following steps:

[0044] (1) Mix various raw materials according to the ratio of outer, middle and inner layers of 1:1:1, and stir for 15 minutes to ensure that the various raw materials are mixed evenly;

[0045] (2) Put the mixed raw materials into the hoppers of the outer, middle and inner layer three hosts respectively; the three hosts are continuously extruded into the composite die head with the outer, middle and inner three-layer spiral flow channels, and the molten resin Flow out according to their respective spirals and converge at the die mouth to form a three-layer composite tube blank;

[0046] (3) The stretched tube blank is blown to the required bubble diameter by the air supply of the high-pressure fan; then it is cooled and shaped by the blowing of the outer layer, and the shaped film bubble reaches V through the f...

Embodiment 1

[0051] Embodiment 1 provides a high-strength greenhouse film, the high-strength greenhouse film is a three-layer composite structure made by a co-extrusion blown film machine, including an inner layer, a middle layer and an outer layer; the inner layer, the middle layer The total weight ratio of the preparation raw material and the outer layer is 1:1:1; the preparation raw material of each layer of the three-layer composite structure contains polyethylene-based high-performance polymer.

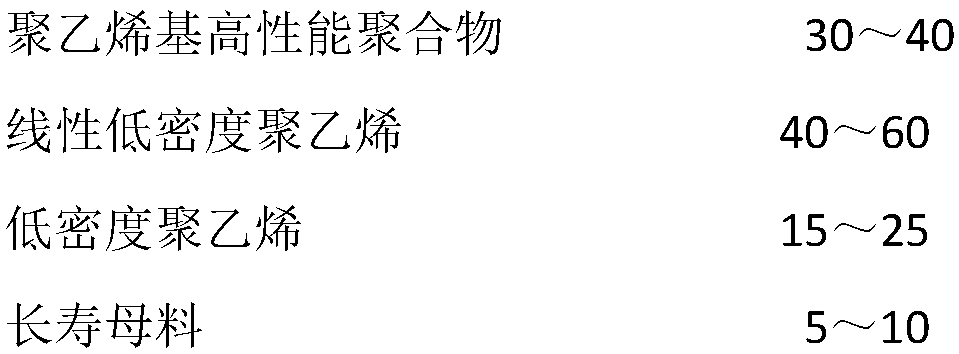

[0052] The raw materials for preparing the outer layer, in parts by weight, include

[0053]

[0054] The raw materials for preparing the inner layer are the same as those for the outer layer.

[0055] Described polyethylene-based high-performance polymer is the polyethylene (density of 0.916g / m2) that Exxon Mobil brand is XP6026ML 3 , melt index is 0.2g / 10min); said linear low density polyethylene is Exxon Mobil brand is LL1001 (density is 0.918g / m 3 , melt index is 1.0g / 10min); the low...

Embodiment 2

[0065] Embodiment 2 provides a high-strength greenhouse film, the high-strength greenhouse film is a three-layer composite structure made by a co-extrusion blown film machine, including an inner layer, a middle layer and an outer layer; the inner layer, the middle layer The total weight ratio of the preparation raw material and the outer layer is 1:1:1; the preparation raw material of each layer of the three-layer composite structure contains polyethylene-based high-performance polymer.

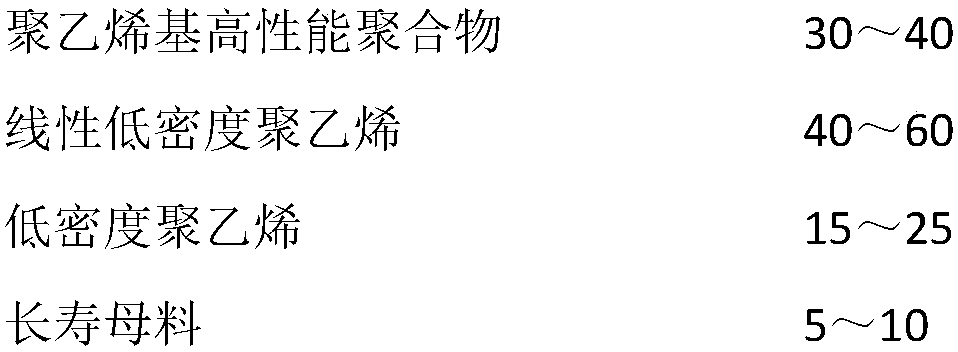

[0066] The raw materials for preparing the outer layer, in parts by weight, include

[0067]

[0068] The raw materials for preparing the inner layer are the same as those for the outer layer.

[0069] Described polyvinyl high-performance polymer is the polyethylene-based high-performance polymer-based high-performance polymer of XP6026ML model (density is 0.916g / m 3 , melt index is 0.2g / 10min); said linear low density polyethylene is Exxon Mobil brand is LL1001 (density is 0.918g / m 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com