Fertilizer prepared by hydrolysis of bulk propellant powder and/or explosives and preparation method thereof

A technology for propellants and explosives, which is applied in the field of energetic material processing, and can solve the problems of limited disposal of waste explosives, large investment in equipment, complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

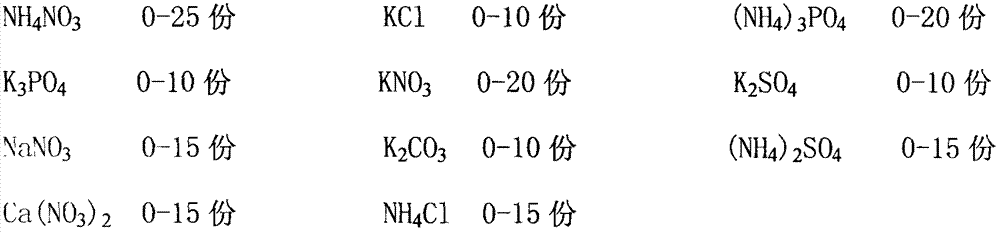

Image

Examples

Embodiment 1

[0055] A method for preparing fertilizer by hydrolyzing bulk propellants and / or explosives, comprising the following steps:

[0056] a. Prepare solution: prepare KOH with a mass concentration of 5-45% or NH with a mass concentration of 5-30% 4 OH or 5-40% NaOH, 1-10% potassium humate or 1-10% sodium humate; the concentration is 20-40% H 2 o 2 ;

[0057] b. Raw material pretreatment: crush bulk propellant and / or explosives to a fineness of 10-40 mesh, and use circulating water humidification method during crushing, so that the moisture content of bulk propellant and explosive is 4-6%; Add water 2-8 times the weight of the material to the pulverized raw material bulk propellant and / or explosives, and then add microorganisms for degradation. At least one of mildew, Penicillium parvum, Penicillium specificum, Penicillium fungus, Penicillium decumbens, Aspergillus niger, Aspergillus terreus, Rhizopus niger, Spot mold, Spot mold verruca, Spot mold black globus , adjust the pH va...

Embodiment 2

[0062] Its specific preparation method of the hydrolyzate fertilizer obtained by the hydrolysis of single-base propellants is as follows:

[0063] a. Prepare solution: prepare NaOH with a mass concentration of 10-30%, 1-10% potassium humate / sodium humate; concentration of 20-40% H 2 o 2 ;

[0064] b. Raw material pretreatment: crush the single-base propellant until its fineness is 10-40 mesh, and adopt circulating water humidification method during pulverization, so that the moisture content of the single-base propellant is 4-6%; Add water 2-8 times the weight of the material into the propellant, and then add microorganisms to degrade it. The microorganisms are: at least one of Trichoderma reesei, Aspergillus terreus, Rhizopus niger, and Spot mold. Adjust the pH value to 6-8. The degradation temperature is 40°C-50°C, and the degradation stops after 24-36 hours;

[0065] c. Reaction: Send the single-base propellant after microbial degradation into the reactor for reaction, c...

Embodiment 3

[0068] The specific preparation method of the fertilizer that the double-base propellants are hydrolyzed to remove the hydrolyzate that can be obtained is as follows:

[0069] a. Prepare solution: prepare NaOH with a mass concentration of 10-35%, potassium humate / sodium humate with a concentration of 1-10%; H with a concentration of 20-40% 2 o 2 ;

[0070] b. Raw material pretreatment: pulverize the double-base propellant until its fineness is 10-40 mesh, adopt circulating water humidification method during pulverization, make the water content of the double-base propellant be at 4-6%; Add water to the propellant according to the ratio of 2-8 times the weight of the material, adjust the pH value, and then add microorganisms to degrade. Adjust the pH value to 7-8, the degradation temperature is 30°C-40°C, and the degradation stops after 30-42h;

[0071] c. Reaction: Send the double-base propellant after microbial degradation into the reactor for reaction, control the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com