Formaldehyde-free plywood and fabrication method thereof

A plywood and formaldehyde technology, applied in chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve problems such as poisoning, achieve good water resistance, excellent physical and mechanical properties, and solve environmental pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

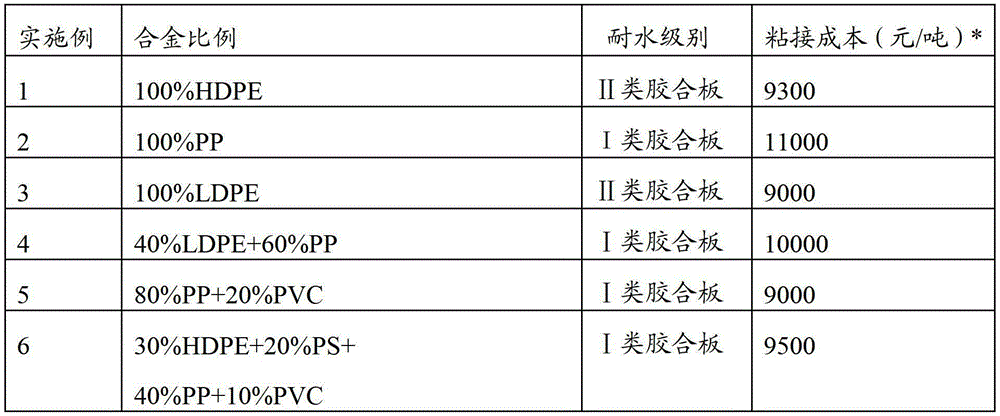

Examples

Embodiment 1

[0053] The present invention utilizes film blowing equipment to prepare high-density polyethylene (HDPE) waste plastic films, and uses them as bonding materials to prepare 5-layer formaldehyde-free birch plywood (thickness 5 mm), using the following steps:

[0054] 1. Recycling high-density polyethylene (HDPE) waste plastics;

[0055] 2. Clean, pulverize and dry recycled high-density polyethylene (HDPE) waste plastics through a circulating water plastic cleaning pulverizer;

[0056] 3. Mix and granulate high-density polyethylene (HDPE) pulverized materials, lubricants, compatibilizers and fillers according to a certain ratio, and the formed plastic alloy particles are then passed through film blowing equipment to prepare a certain format of plastic alloy film.

[0057] 4. The dried birch veneer (thickness 1.2 mm) is repaired and assembled, and formed with plastic alloy film to form a 5-layer birch plywood blank. Plastic alloy films with the same format;

[0058] 5. After the...

Embodiment 2

[0066] A polypropylene (PP) waste plastic film was prepared and used as an adhesive material to prepare 5 layers of formaldehyde-free poplar plywood (thickness 5 mm), the steps were the same as in Example 1.

[0067] Among them, waste plastics are mixed: the lubricant is polyvinylidene fluoride, and the addition amount is 6% of the total amount of plastic; the compatibilizer is maleic anhydride modified polypropylene, and the addition amount is 4%; the filler is light calcium carbonate, The addition amount is 20%.

[0068] The thickness of the alloy is 0.2 mm, and the blown film processing temperature is 170-240°C;

[0069] Hot pressing: the hot pressing temperature is 190°C, the board surface pressure is 2 MPa, and the hot pressing time is 6 minutes.

[0070] Cold pressing: the cold pressing temperature is 20°C, the plate surface pressure is 1.5 MPa, and the cold pressing time is 5 minutes.

Embodiment 3

[0072] Prepare low-density polyethylene (LDPE) waste plastic film, and use it as bonding material to prepare 5 layers of formaldehyde-free poplar plywood (thickness 5 mm), the steps are the same as in Example 1.

[0073] Among them, waste plastics are mixed: the lubricant is polyethylene wax, and the addition amount is 8% of the total amount of plastic; the compatibilizer is hard fatty acid, and the addition amount is 6%; the filler is diatomaceous earth, and the addition amount is 25%.

[0074] The thickness of the alloy is 0.2mm, and the film blowing processing temperature is 150-180°C.

[0075] Hot pressing: the hot pressing temperature is 160°C, the board surface pressure is 2 MPa, and the hot pressing time is 6 minutes.

[0076] Cold pressing: the cold pressing temperature is 20°C, the plate surface pressure is 1.5 MPa, and the cold pressing time is 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com