PHC pipe pile concrete and preparation method thereof

A PHC pipe pile and concrete technology, applied in the field of concrete, can solve the problems of shortage of natural sand resources, pollution of the environment, waste of low-grade machine-made sand resources, etc., and achieve the effects of saving natural sand resources, improving economic benefits, and solving pollution and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

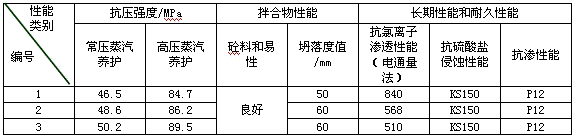

[0016] Embodiment: Test according to the design mix ratio numbers 1, 2, and 3, and trial-manufacture 3 trays of PHC pipe pile concrete. See the attached table for the trial mix ratio and trial compressive strength. The concrete test blocks produced by the trial mix are made by sampling from the pipe pile production and distribution process. The finished test blocks are cured according to the curing process system. The quality of the raw materials for trial production and the technical requirements related to the production process are shown in the following appendix:

[0017] Table 1 PHC pipe pile concrete quality requirements index

[0018]

[0019] Table 2 PHC pipe pile concrete design mix ratio (Kg / m 3 )

[0020]

[0021] Table 3 Main performance indicators of Zhonglian brand P.O52.5 grade cement

[0022]

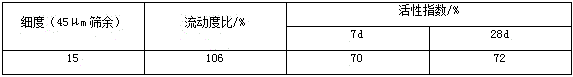

[0023] Table 4 Main performance indicators of Rizhao S95 mineral powder

[0024]

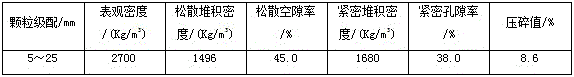

[0025] Table 5 Main performance indicators of Class II fly ash

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com