Plant acid corrosion organic fertilizer

A plant acid and organic fertilizer technology, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of soil micro-ecological balance damage, affecting the quality of agricultural products, endangering life safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Embodiment 1: the present invention is by weight: 350 parts of plant acid, 500 parts of compound amino acid, 35 parts of polyamide, 900 parts of plant straw, 200 parts of urea, 160 parts of potassium feldspar, 260 parts of phosphate rock and epoxy It is made of 60 parts of propane. When preparing, firstly crush and mix plant acid, compound amino acid and plant straw evenly, add propylene oxide and stir, and react for 2 hours at 25°C. When the reaction is complete and gas is released, then Add urea, potassium feldspar and phosphate rock in turn and stir for 2 hours, and finally add polyamide and stir for 2 hours to obtain a finished product with a pH of 5.8.

Embodiment 2

[0007] Embodiment 2: the present invention is made of plant acid 350kg, compound amino acid 500kg, polyamide 35kg, plant straw: 900kg, urea 200kg, potassium feldspar 160kg, phosphate rock 260kg and propylene oxide 60kg, when preparing, first Plant acid, compound amino acid and plant straw are pulverized and mixed evenly, add propylene oxide and stir, and react at 30°C for 1.5 hours. When the reaction is complete and gas is released, then add urea, potassium feldspar and phosphate rock in turn and stir thoroughly. React for 1.5 hours, and finally add polyamide and stir for 1.5 hours to obtain a finished product with a pH value of 6.3.

Embodiment 3

[0008] Embodiment 3: the present invention is by weight percent: plant acid 14%, compound amino acid 20%, polyamide 1%, plant straw 37%, urea 8%, potassium feldspar 7%, phosphate rock 11% and ring It is made of 2% propylene oxide. When preparing, firstly crush and mix plant acid and compound amino acid plant stalks evenly, add propylene oxide and stir, and react for 2.5 hours at 18°C. When the reaction is complete and gas is released, then Add urea, potassium feldspar and phosphate rock in turn and stir for 2.5 hours, and finally add polyamide and stir for 2.5 hours to obtain a finished product with a pH of 6.7.

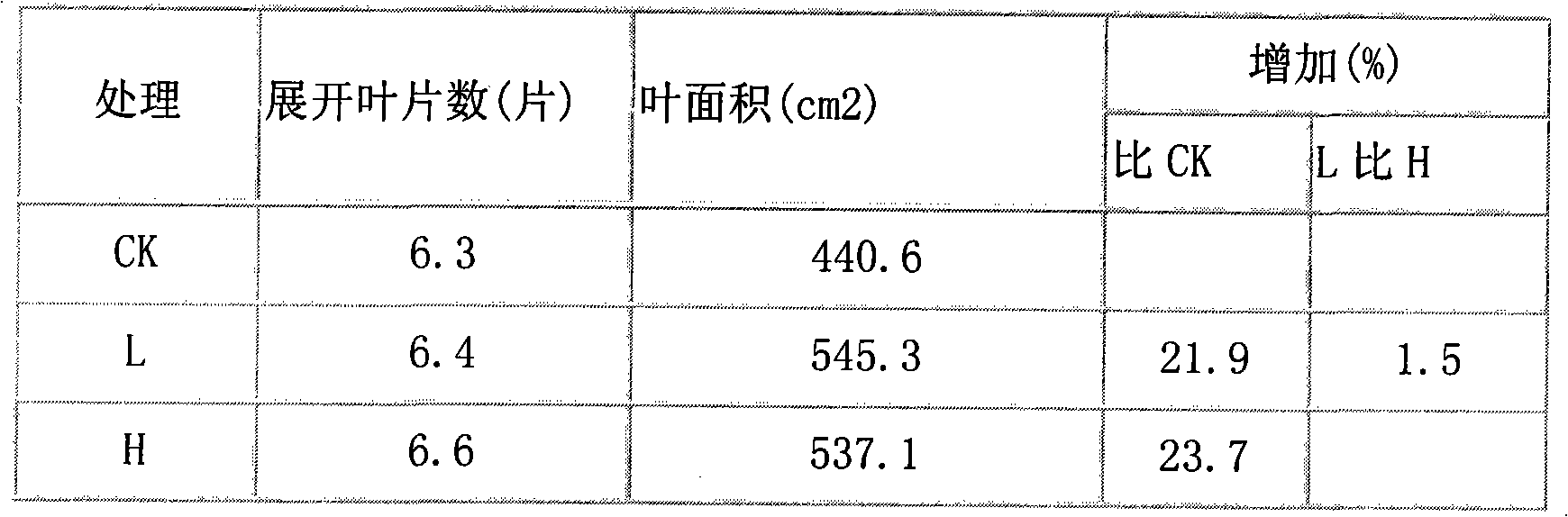

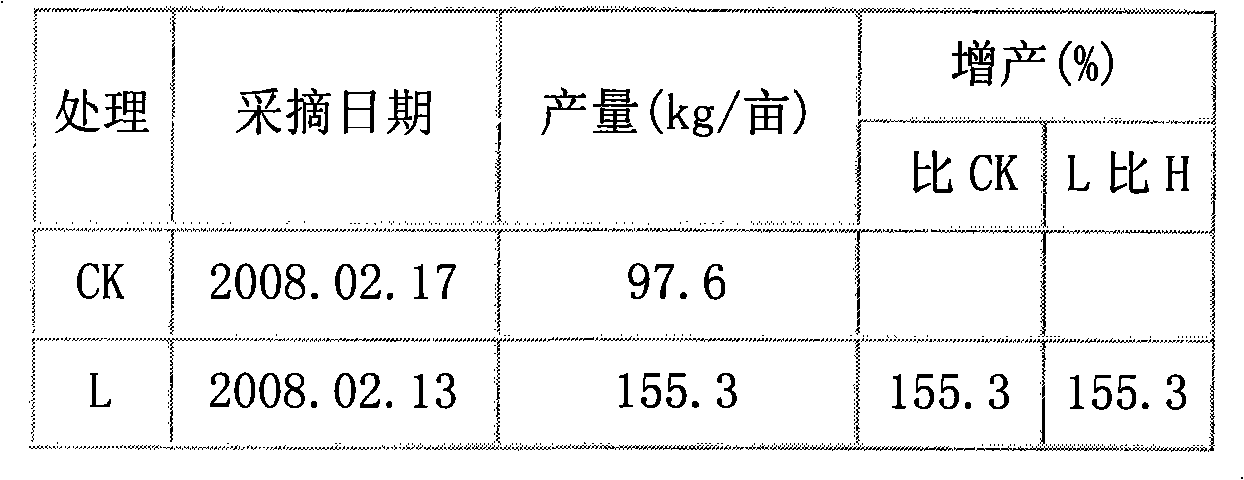

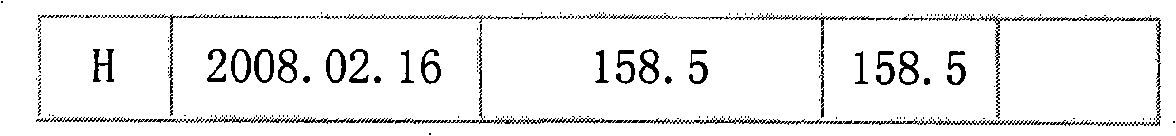

[0009] The composition of the invention is reasonable, easy to produce, and has good application effect. After trial, the product has the following prominent functions:

[0010] The invention is a high-efficiency and environment-friendly fertilizer, which contains three beneficial microorganisms that fix nitrogen, decompose phosphorus, and decompose potassium, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com