Granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and preparation method thereof

A micro-electrolysis, dual-purpose technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc. problems, to achieve the effect of slowing down consumption, increasing service life, and reducing electron transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

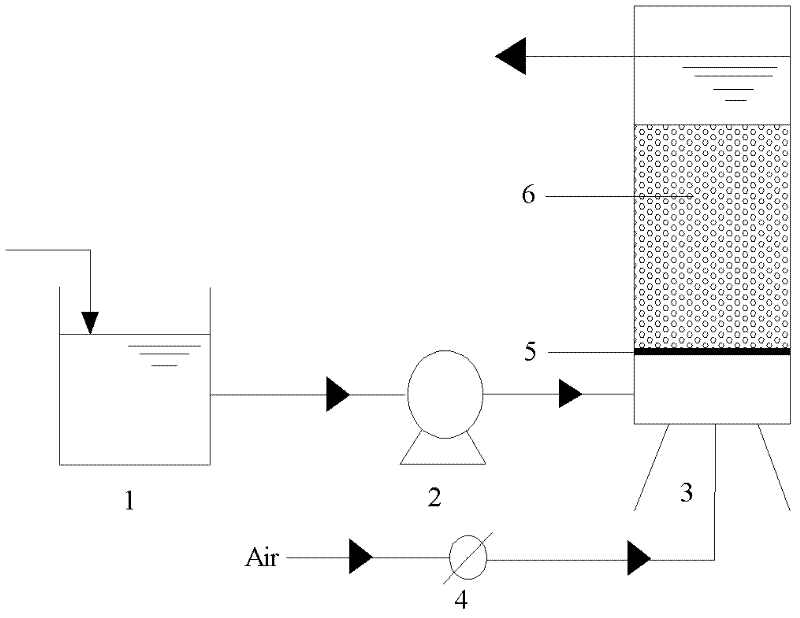

Image

Examples

Embodiment 1

[0035] In parts by weight, weigh 50 parts of Fe powder, 50 parts of Al powder, and 10 parts of graphite powder, dry them in vacuum, mix them completely in a mixer, place them in a granulator, and add 15 parts of the mass prepared by sodium silicate. Concentration of 5% sodium silicate solution, rolled into a ball. Place the prepared raw meal balls in a tube furnace protected by a nitrogen atmosphere, raise the temperature to about 150°C at a rate of 3°C / min, and keep warm for 30 minutes, then continue to heat up to 700°C at a rate of 3°C / min, and keep warm for 2 hours . Cool down to 60°C at a rate of 3°C / min, take out the pellets, and keep them sealed.

[0036] The performance parameters of the obtained Fe-Al-C ternary micro-electrolytic filler are as follows:

[0037] Particle size: 3mm; Bulk density: 1100kg / m 3 ;Particle density: 2105kg / m 3;Water Absorption: 12%.

Embodiment 2

[0039] In parts by weight, weigh 40 parts of Fe powder, 45 parts of Al powder, and 15 parts of graphite powder, dry in vacuum, mix completely in a mixer, place in a granulator, add 18 parts of binder (1%wt poly Vinyl alcohol+2%wt carboxymethylcellulose sodium mixed liquor) solution, rolled into balls. Put the prepared raw meal balls in a tube furnace protected by a nitrogen atmosphere, raise the temperature to about 120°C at a rate of 2°C / min, keep warm for 20 minutes, continue to raise the temperature to 650°C at a rate of 2°C / min, and keep warm for 1.5 hours . Cool down to 80°C at a rate of 2°C / min, take out the pellets, and keep them sealed. Take out the ball and keep it sealed.

[0040] The performance parameters of the obtained Fe-Al-C ternary micro-electrolytic filler are: particle size: 2.5mm; bulk density: 1053kg / m 3 ;Particle density: 2030kg / m 3 ;Water Absorption: 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com