Na2O-CaO-SiO2 opaque glass and preparation method thereof

A 1.na2o-cao-sio2, opaque glass technology, applied in the field of building materials, can solve the problems of large crystallization tendency, easy precipitation of large particles, poor process control, etc., to improve glass hardness, opacity, etc. The effect of improved performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of Na 2 O-CaO-SiO 2 The preparation method of opal glass comprises the following steps:

[0029] 1), ingredients:

[0030] SiO 2 64.0 parts, CaO 7.0 parts, Na 2 CO 3 27.36 parts, Al 2 o 3 2.0 copies, K 2 CO 3 2.93 parts, MgO 3.0 parts, P 2 o 5 5 parts and ZrO 2 1 serving.

[0031] Namely: Na 2 CO 3 27.36 parts replaced Na 2 O16.0 parts, K 2 CO 3 2.93 copies replaced K 2 O 2 parts.

[0032] 2), fully mix all the ingredients in step 1), then place in a furnace and heat to 1450°C to melt and keep warm for 3 hours to obtain a clear and uniform molten glass;

[0033] 3) Pour the molten glass obtained in step 2) into a mold for molding and allow it to cool naturally and slowly to room temperature to finally obtain uniform milky white opalescent glass.

Embodiment 2

[0034]Embodiment 2, a kind of Na 2 O-CaO-SiO 2 The preparation method of opal glass comprises the following steps:

[0035] 1), ingredients:

[0036] SiO 2 69.0 parts, CaO 6.0 parts, Na 2 CO 3 27.36 parts, Al 2 o 3 1.0 copies, K 2 CO 3 0.73 parts, MgO 1.5 parts, P 2 o 5 4 parts and ZrO 2 2 servings.

[0037] Namely: Na 2 CO 3 27.36 parts replaced Na 2 O16.0 parts, K 2 CO 3 0.73 parts replaced K 2 O 0.5 parts.

[0038] 2), fully mix all the ingredients in step 1), then place in a furnace and heat to 1450°C to melt and keep warm for 3 hours to obtain a clear and uniform molten glass;

[0039] 3) Pour the molten glass obtained in step 2) into a mold for molding and allow it to cool naturally and slowly to room temperature to finally obtain uniform milky white opalescent glass.

Embodiment 3

[0040] Embodiment 3, a kind of Na 2 O-CaO-SiO 2 The preparation method of opal glass comprises the following steps:

[0041] 1), ingredients:

[0042] SiO 2 59.0 parts, CaO 8.0 parts, Na 2 CO 3 34.20 parts, Al 2 o 3 2 copies, K 2 CO 3 2.93 parts, MgO 3.0 parts, P 2 o 5 1.0 parts and ZrO 2 5 servings.

[0043] Namely: Na 2 CO 3 34.20 parts instead of Na 2 O 20.0 parts, K 2 CO 3 2.93 instead of 2.

[0044] 2), fully mix all the ingredients in step 1), then place in a furnace and heat to 1450°C to melt and keep warm for 3 hours to obtain a clear and uniform molten glass;

[0045] 3) Pour the molten glass obtained in step 2) into a mold for molding and allow it to cool naturally and slowly to room temperature to finally obtain uniform milky white opalescent glass.

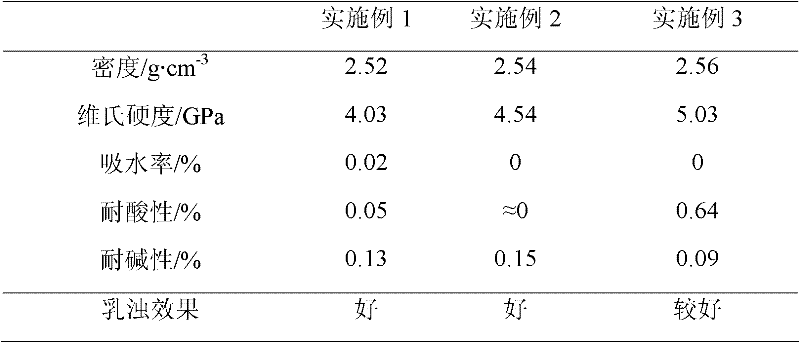

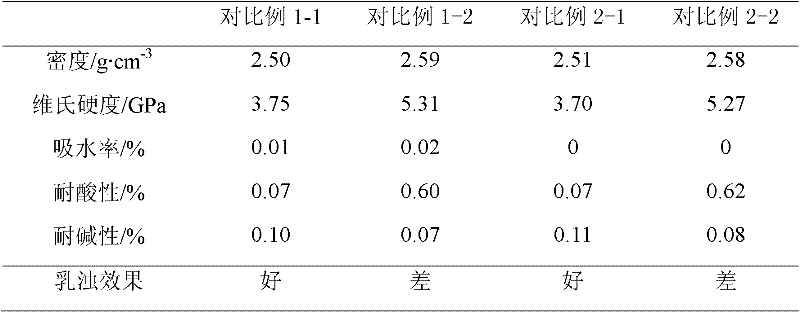

[0046] The performance corresponding to each embodiment of table 1

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com