Silicon-carbon alloy cathode material for lithium ion batteries and preparation method thereof

A lithium-ion battery, alloy negative electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of electrode material pulverized electrode performance, poor battery cycle performance, deterioration, etc., to achieve easy operation, low cost, and high preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

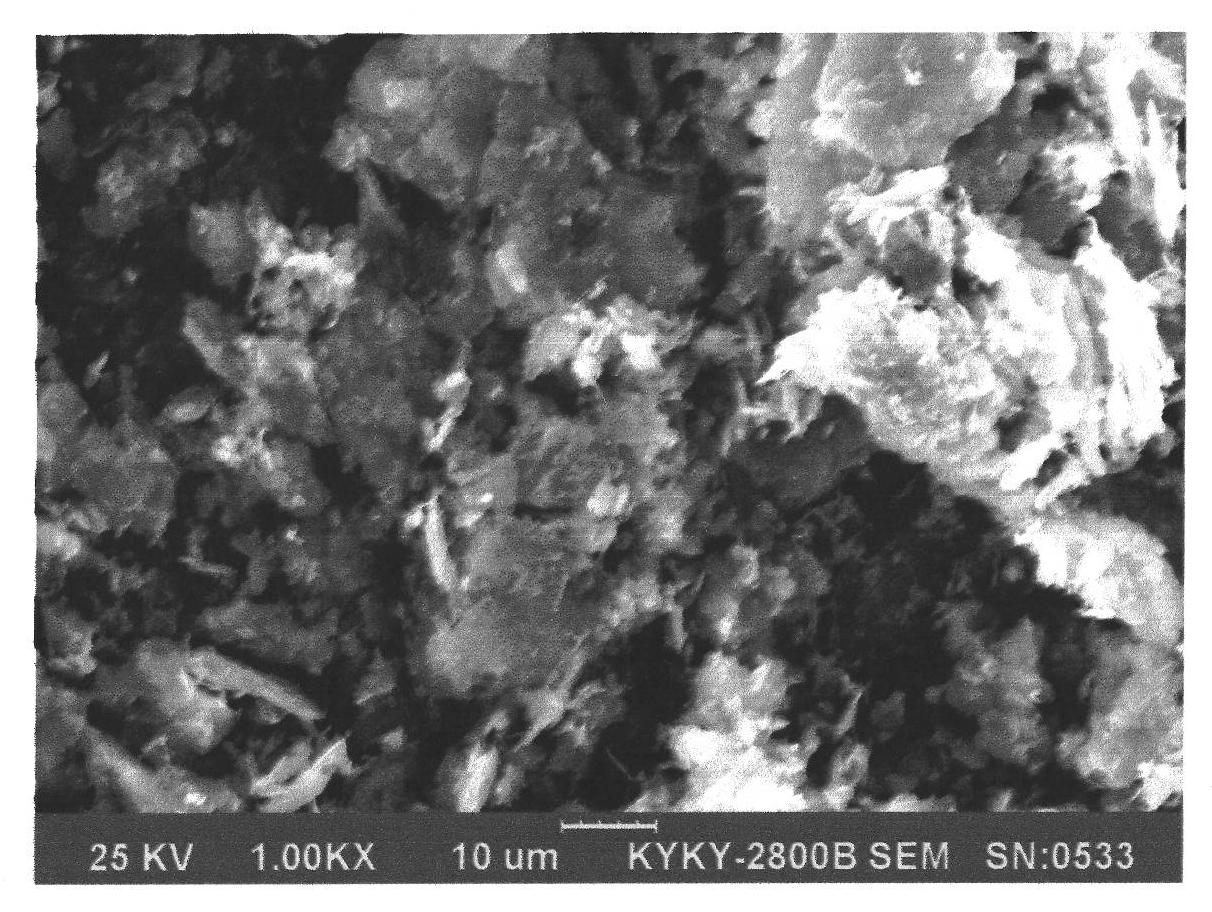

[0019] The preparation method of the lithium-ion battery silicon-carbon alloy negative electrode material of the present invention adopts general-purpose equipment, first alloys aluminum-silicon and then composites it with graphite powder, then adopts asphalt coating treatment, and finally drys and burns to obtain the required silicon-carbon alloy negative electrode Material. Include the following steps:

[0020] 1. Add additives accounting for 3-6% of the total weight of the lithium-ion silicon-carbon alloy negative electrode material, pitch accounting for 25-30% of the total weight of the material, and 4-8 μm elemental silicon powder accounting for 7-15% of the total weight of the material (vacuum packaging, After unpacking, put it into a glove box for storage), add absolute ethanol, the amount is to soak all the above-mentioned materials, after mixing, add it to a ball mill and stir the wet ball mill at a speed of 200-600rpm, preferably 400rpm, for 10-15h, and then mix the ...

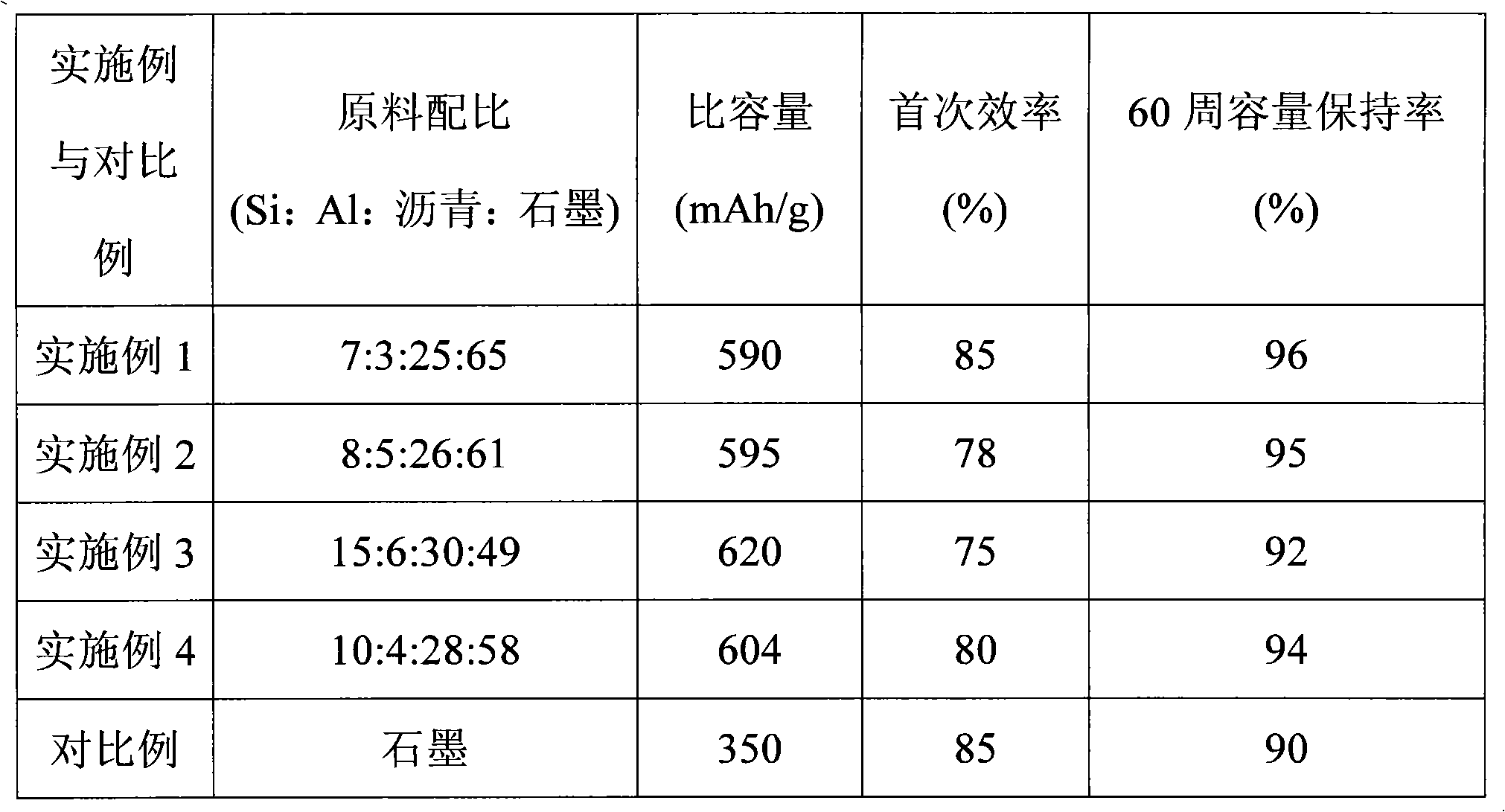

Embodiment 1

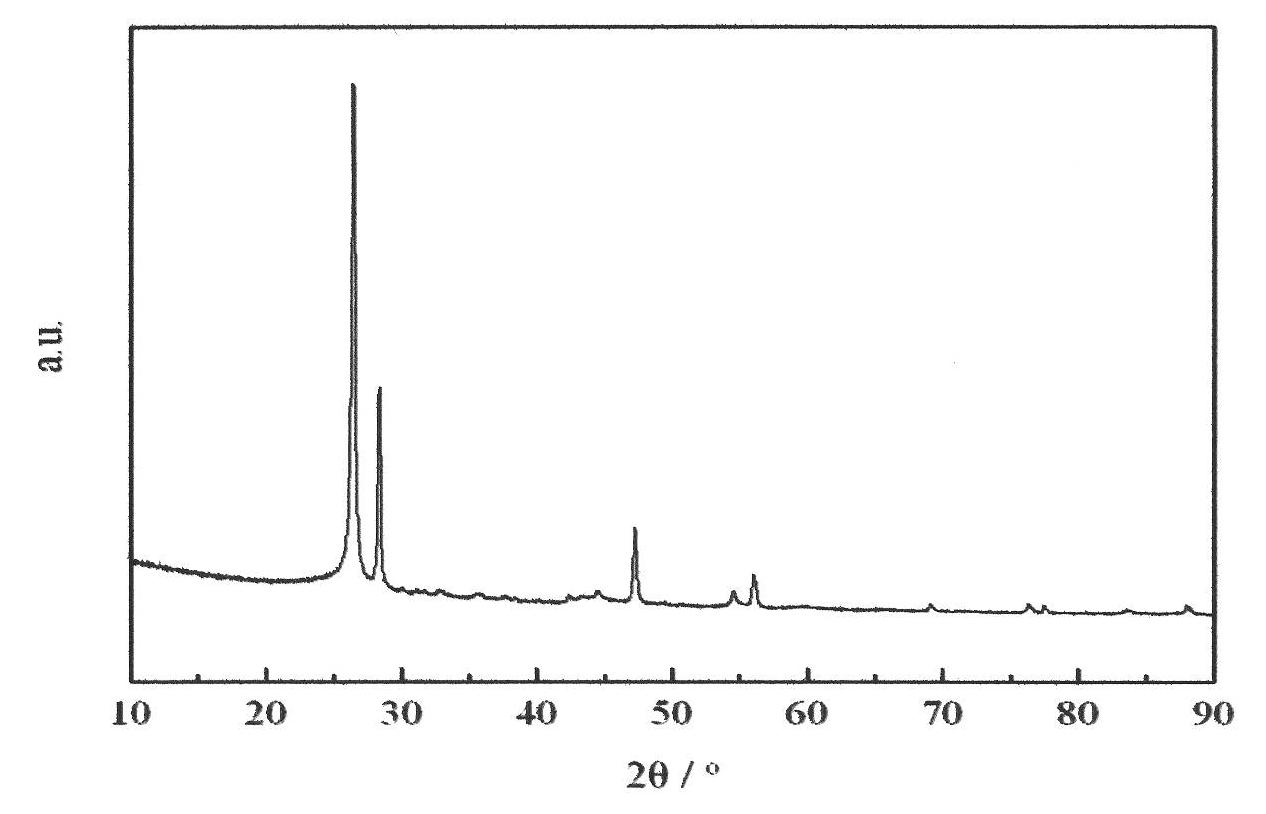

[0024] Embodiment 1, weigh the silicon powder whose weight is 7% of the total weight of the lithium-ion silicon-carbon alloy negative electrode material, the average particle diameter 4~8 μ m, the aluminum powder whose weight is 3% of the total weight of the material, the average particle diameter 5~10 μ m, 25% of the total weight of the material asphalt for industrial use is poured into the high-energy ball mill tank, and then absolute ethanol is added in the high-energy ball mill tank. Soak ingredients well. Mix with wet ball mill at 400rpm for 10 hours, then weigh 65% of the total weight of spherical natural graphite and add it to the ball mill tank, add absolute ethanol, soak all ingredients, mix with high-speed ball mill for 1 hour, and then stir at 250rpm at low speed 1.5h. Take out suction filtration and carry out vacuum drying, and its vacuum degree is 10 -2 Pa, the drying temperature is 80°C, the drying time is 10h, and then it is lowered to room temperature, and a ...

Embodiment 2

[0027]Embodiment 2, weigh the silicon powder whose weight is 8% of the total weight of the lithium-ion silicon-carbon alloy negative electrode material, the average particle diameter 4~8 μ m, the aluminum powder whose weight is 5% of the total weight of the material, the average particle diameter 5~10 μ m, The industrial asphalt whose weight is 26% of the total weight of the material is poured into a high-energy ball mill tank, and absolute ethanol is added to fully soak the ingredients in the absolute ethanol. 200rpm rotating speed wet ball mill mixed 15h, then weighed spherical natural graphite and artificial graphite (mass ratio 1: 1) that weighed 61% of the total weight of the pole material, joined in the ball mill jar, and added absolute ethanol, soaked all ingredients, Then high-speed ball milling and mixing for 1.5 h, and then stirring at a low speed of 150 rpm for 3 h. Take out suction filtration and carry out vacuum drying, and its vacuum degree is 10 -2 Pa, the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com