Taper pipe for concrete pumping device and manufacturing method thereof

A technology for concrete pumps and conical pipes, which is applied in the direction of mechanical equipment, pipes, conveyors, etc., can solve the problems of complex and difficult-to-control surfacing welding process, large flow channel resistance, etc., and achieve raw material saving, strong hardening ability, and impact resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

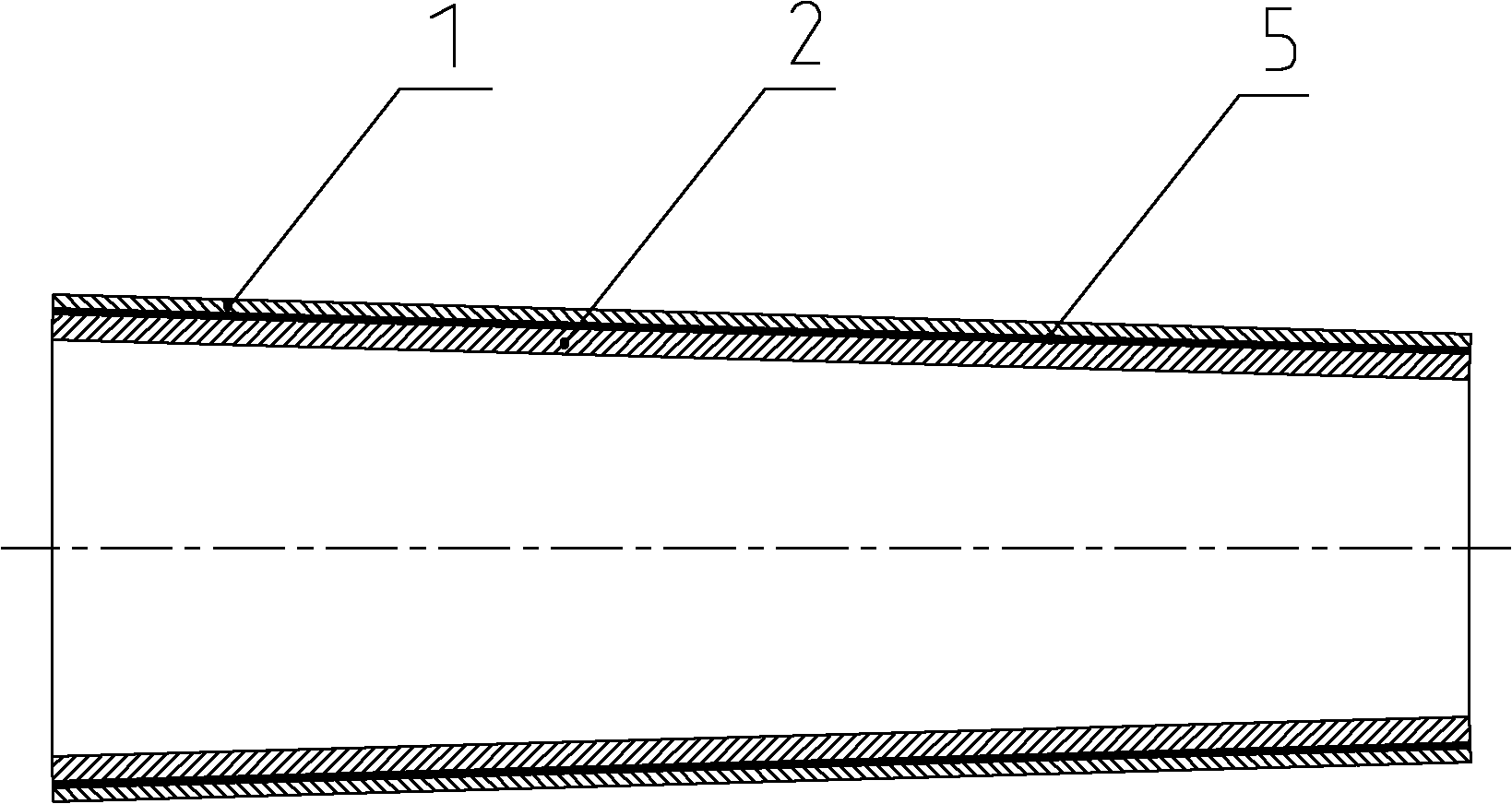

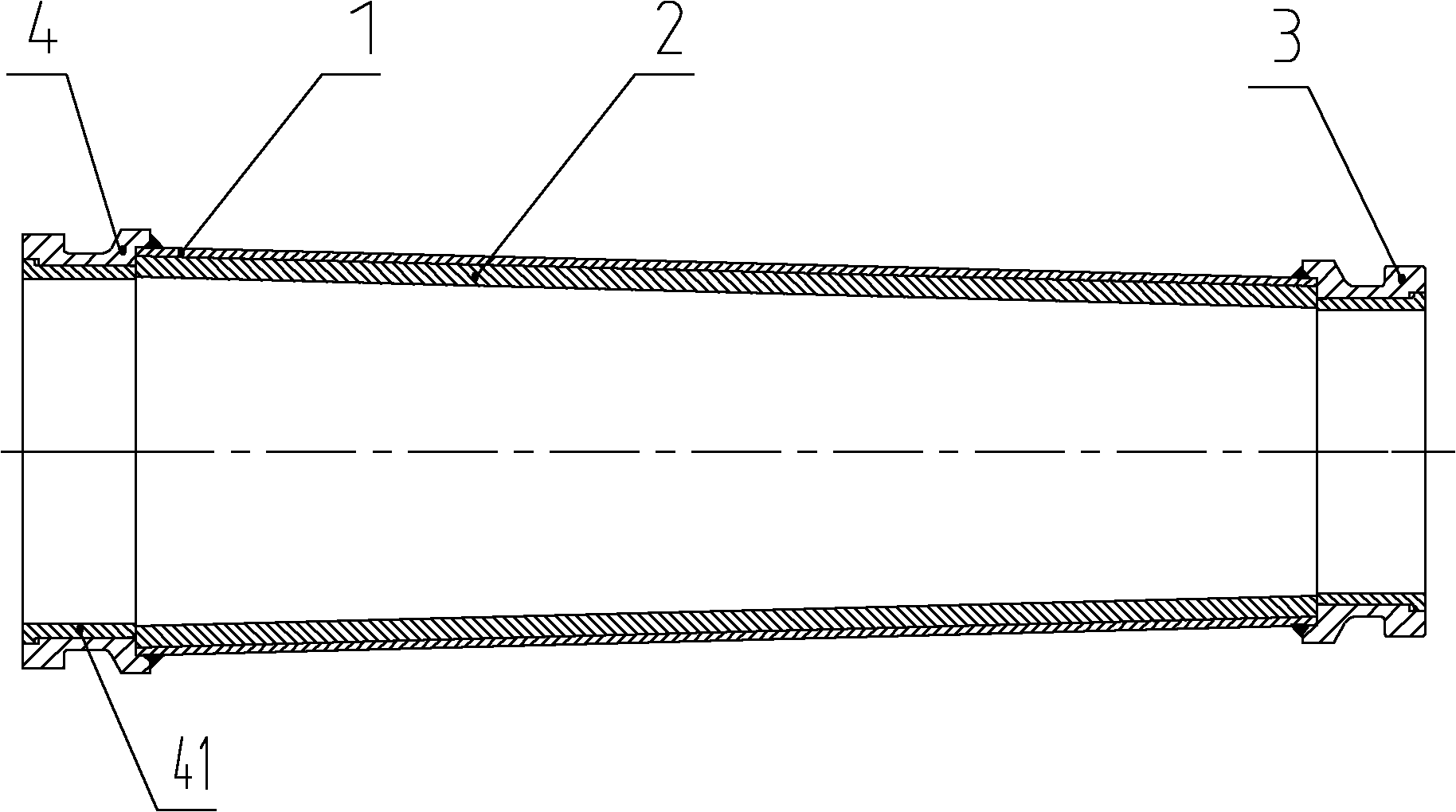

[0027] Such as figure 1 As shown, the inner pipe 2 is made of medium-carbon low-alloy steel, and the outer pipe 1 is made of ordinary low-carbon steel. First, two steel pipes that meet the design requirements are drawn and compounded to obtain a double-layer composite steel pipe, and then the composite pipe is passed through a taper pipe machine Induction heating molding, to obtain the required taper, and to achieve a tight combination of the inner and outer layers of the tapered tube without gaps. The double-layer composite tapered tube has unequal wall thickness, the big end is thin and the small end is thick. Finally, the product is quenched as a whole to make the inner tube with better hardenability form martensite and bainite structure to obtain higher hardness and wear resistance, while the outer tube with weak hardenability is pearlite and ferrite Body structure, low hardness, good toughness, and strong impact resistance.

Embodiment 2

[0029] The inner tube is made of wear-resistant cast iron and wear-resistant cast steel with a thickness greater than 5mm, and cast into a cone shape; the outer tube is made of 20 steel and molded; then the inner tube is pressed into the outer tube to form a double-layer composite tapered tube. Limited by the casting process, the inner tube must be thicker than 5mm, because too thin will cause the metal liquid to condense without flowing to the bottom of the model during casting, resulting in various casting defects, and the required size of the workpiece cannot be obtained. The total thickness is 10 Between -16mm.

Embodiment 3

[0031] The outer tube is made of 20 steel and molded into a single-layer tapered tube with a thickness of 2-6mm. The obtained outer tube is placed into the cavity, and the inner tube material is cast with wear-resistant cast iron or cast steel to form a local metallurgical bond, and then quenched after compounding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com