A welding repair method for anti-sulfur wellhead valve body

A welding repair and valve body technology, applied in welding equipment, welding medium, welding equipment, etc., can solve problems such as structural failure, welding joint strength, welding seam composition difficult to meet relevant requirements, and difficult repair, etc., to achieve high load bearing ability, avoid repeated repair welding rework, and avoid softening problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

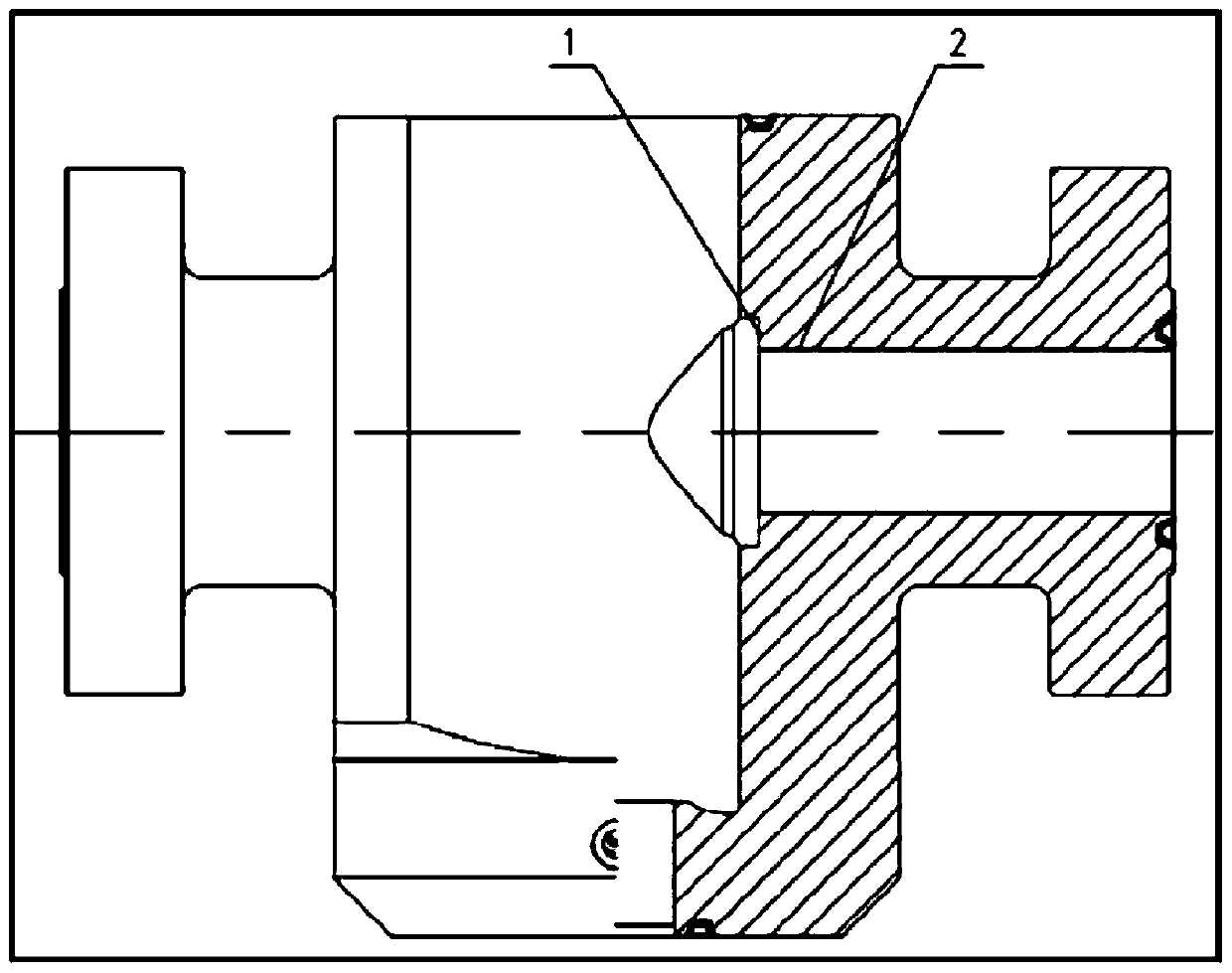

Image

Examples

Embodiment 1

[0032] 1. Clean the product to be repaired, process one damaged sealing surface side, and remove 1.5mm on one side;

[0033] 2. The 2 erosion pits need to be polished to repair the welding pit and the surface of the surrounding 20-30mm to remove rust and oil stains, revealing the metallic luster, and clean the polished surface with absolute ethanol or acetone;

[0034] 3. The workpiece is preheated to 130°C as a whole before welding;

[0035] 4. Using Ar+CO 2 The mixed gas shielded welding fills the 2 pits with 655MPa high-toughness welding wire. The chemical composition of the deposited metal is: C≤0.11%, Si 0.5%-0.9%, Mn 1.4%-1.8%, Cu ≤0.5%, Cr 0.20%~0.6%, Ti≤0.17%, S≤0.025%, P≤0.025%, the balance is Fe; Ar and CO 2 The gas volume ratio is 80%:20%, and the welding parameters are: filler wire diameter 1.2mm, welding voltage 22-26V, welding current 200-260A, shielding gas flow rate 15-22L / min.

[0036] 5. Then repair welding on the processed surface of one sealing surface, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com