Method for manufacturing foamed aluminum sandwich plate

A sandwich panel and aluminum foam technology, which is applied in the field of foam aluminum sandwich panel preparation, can solve the problems of large powder loss, low powder density at the edge, poor high temperature resistance and corrosion resistance, and achieve high thickness accuracy and plate shape. The effect of high precision and uniform foam structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

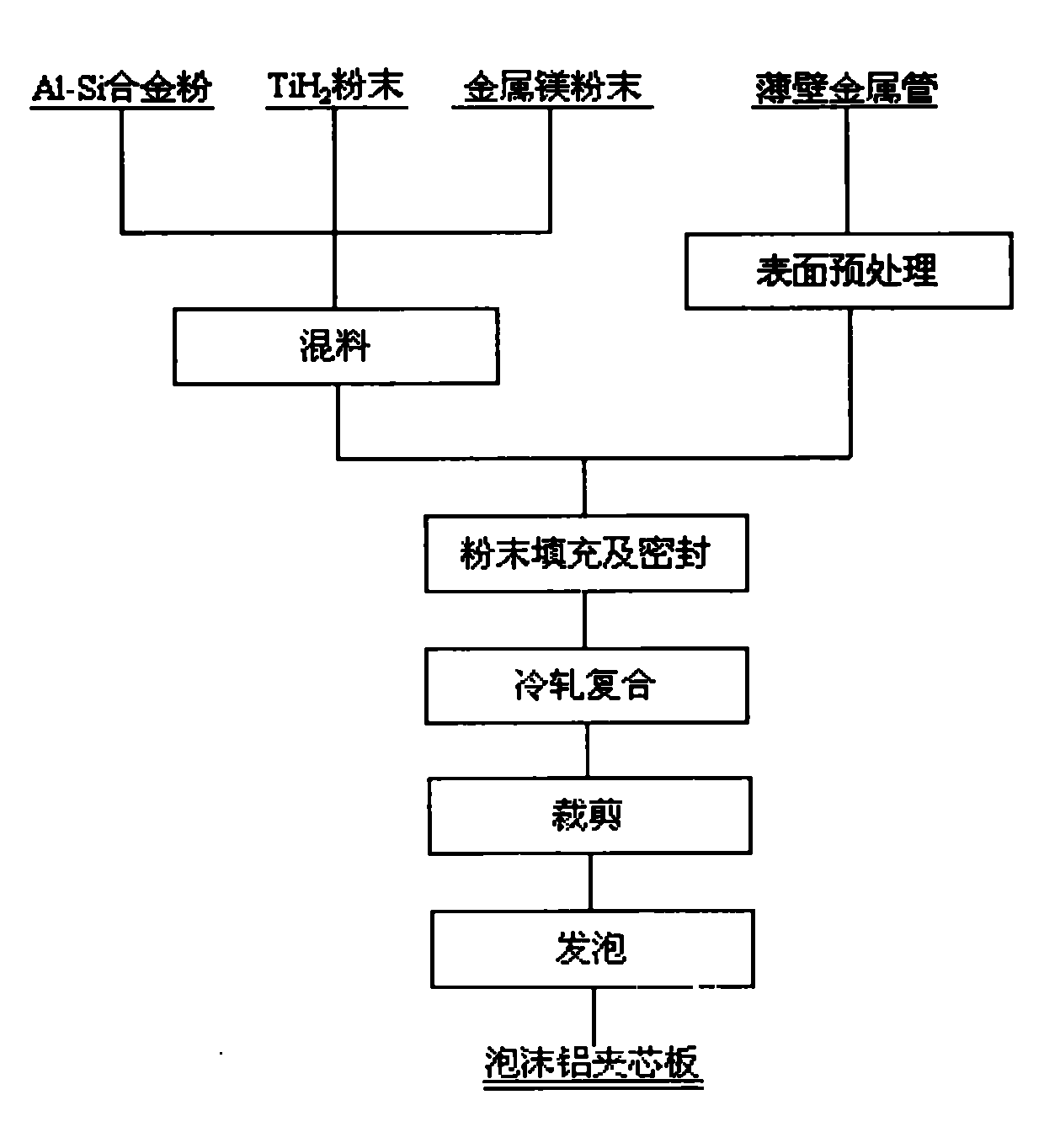

Image

Examples

Embodiment 1

[0038] Select: 295.5g of aluminum-silicon alloy powder (containing 12.5% of silicon) (with a particle size of 200 mesh), 1.5g of foaming agent titanium hydride (with a particle size of 50 mesh), and 3g of metal magnesium powder (with a particle size of 100 mesh). The powder is put into a ball mill tank containing diamond balls, the ball / material ratio is 1:3, the ball mill tank is placed on a high-energy ball mill for mixing, the speed is 2000r / min, and the mixing time is 1h, using duralumin LY12 thin-walled Rectangular tube is used as cladding material, the tube wall thickness is 1mm, the rectangular section length is 50mm, the width is 10mm, and the rectangular tube is 100mm long. The rectangular tube is soaked in 10% NaOH solution for 10min, rinsed with clean water and dried, and then cleaned with a wire brush. The inner wall of the tube is mechanically polished, and one end of the polished rectangular tube is flattened and closed on a press, and the mixed powder is filled...

Embodiment 2

[0040]Select: aluminum-silicon alloy powder (containing 7% silicon) 292.5g (particle size is 300 mesh), foaming agent titanium hydride 3g (particle size is 100 mesh), metal magnesium powder 4.5g (particle size is 150 mesh), the above The powder is put into a ball mill tank containing diamond balls, the ball / material ratio is 1:3, the ball mill tank is placed on a high-energy ball mill for mixing, the speed is 2500r / min, and the mixing time is 1.5h. Industrial pure aluminum 1100 Thin-walled rectangular tube is used as the cladding material, the tube wall thickness is 1.5 mm, the rectangular section is 60 mm long, 8 mm wide, and the rectangular tube is 100 mm long. Soak the rectangular tube in 10% NaOH solution for 15 minutes, rinse it with clean water and dry it, then use The steel wire brush mechanically grinds the inner wall of the tube. One end of the polished rectangular tube is flattened and closed on a press, and the mixed powder is filled from the open end of the rectangu...

Embodiment 3

[0042] Selection: 288g of aluminum-silicon alloy powder (containing 3% silicon) (400 mesh in particle size), 6g of titanium hydride foaming agent (150 mesh in particle size), 6g of magnesium metal powder (200 mesh in particle size), the above various powders Put it into a ball mill tank containing diamond balls, the ball / material ratio is 1:3, put the ball mill tank on a high-energy ball mill for mixing, the speed is 3000r / min, and the mixing time is 2h. , low-carbon steel Q235A thin-walled rectangular tube is used as the cladding material, the tube wall thickness is 1.5 mm, the rectangular section is 60 mm long, 8 mm wide, and the rectangular tube is 100 mm long. Electroless nickel plating is carried out on the steel pipe, and the specific process conditions are that the composition of the plating solution is NiSO 4 ·6H 2 O 250g / L, NiCl 2 ·6H 2 o

[0043] 60g / L, H 3 BO 3 40g / L, CH 3 (CH 2 ) 11 · SO 4 Na 0.1g / L, C 7 h 5 NO 3 S 1.0g / L, C 4 h 6 o 2 0.1g / L, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com