Lithium sulfur battery provided with adsorption layer

A lithium-sulfur battery and adsorption layer technology, which is applied to battery electrodes, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as cycle performance degradation and battery capacity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

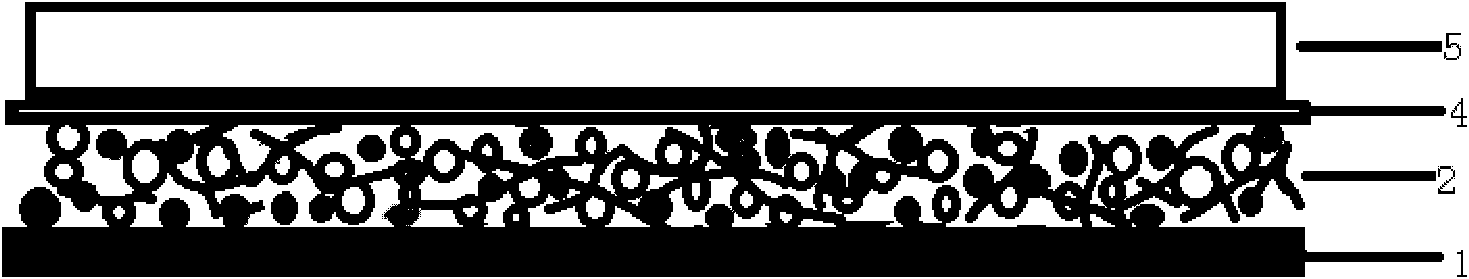

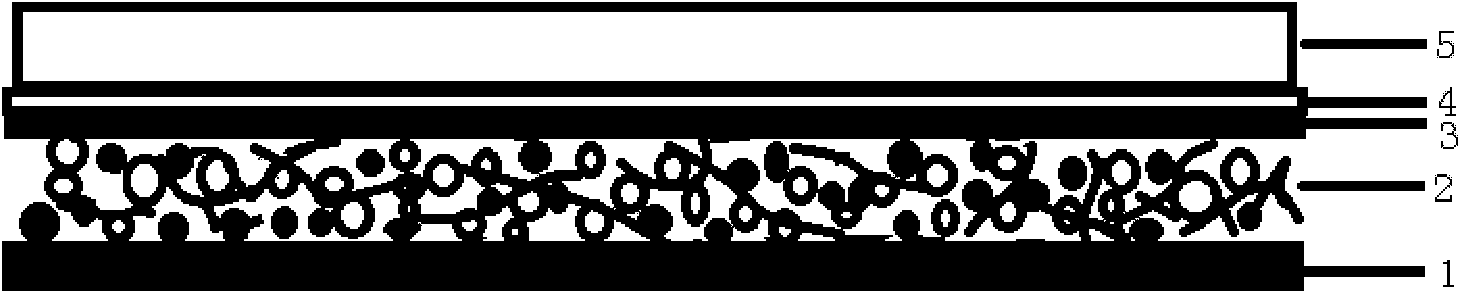

Method used

Image

Examples

Embodiment 1

[0023] Select carbon nanotube and sulfur composite material as positive electrode active material, acetylene black as conductive agent, 5wt% polyvinylidene fluoride solution (solution solvent is N-methylpyrrolidone) as binding agent to prepare positive electrode slurry, wherein positive electrode active material , The mass ratio of the conductive agent and the binder is 80%: 15%: 5%. Then, the slurry is coated on the nickel foam to form a sheet, and dried to form a positive electrode sheet with a thickness of 45-55um.

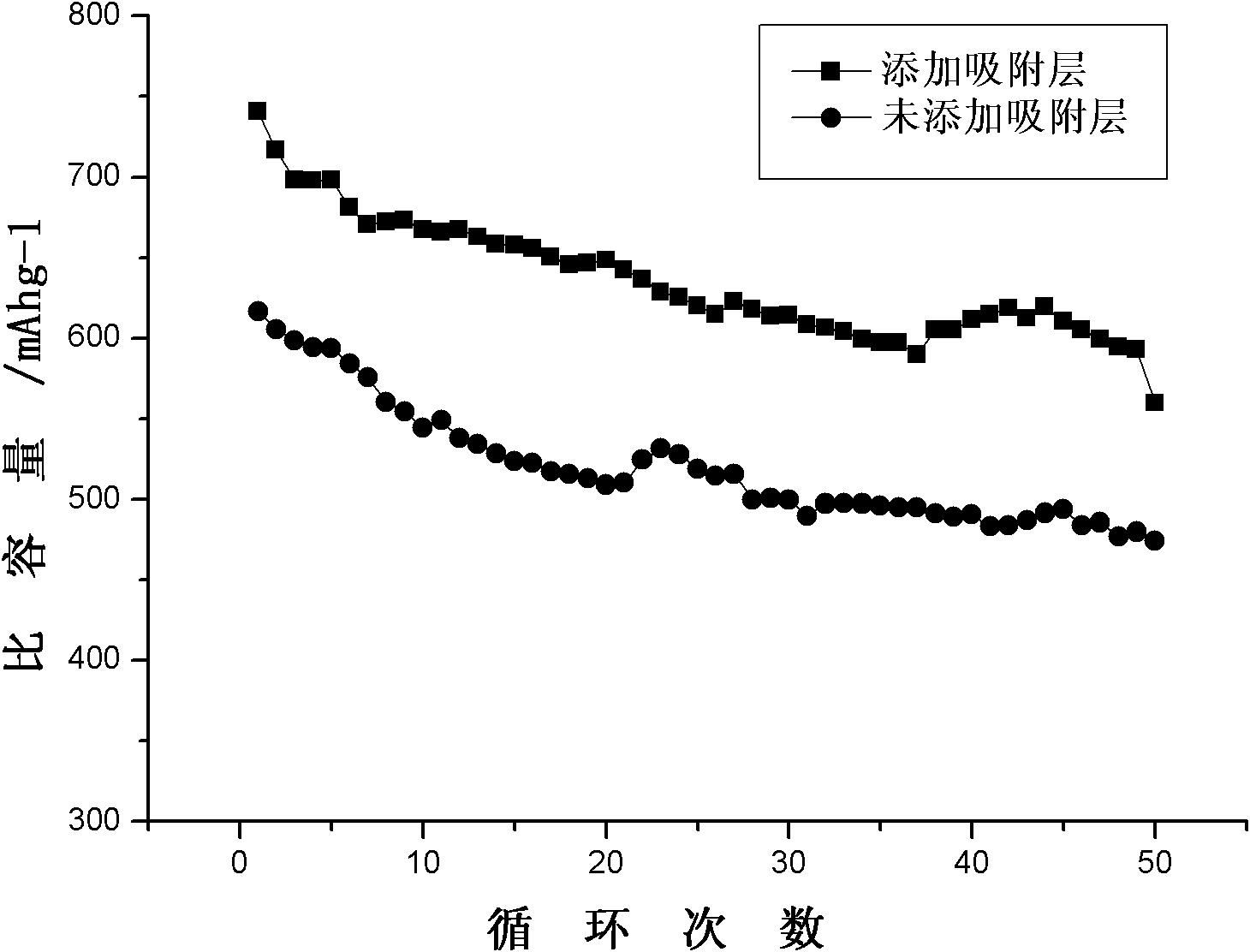

[0024] The selected specific surface area is 1000m 2 Activated carbon per g is used as the adsorption material of the adsorption layer, and the adsorption material activated carbon is prepared as an adsorption layer on the surface of the porous diaphragm, and the porous diaphragm is prepared into a CR2025 button battery with a Celgard2400 film, wherein the electrolyte is 1mol / L LiPF6 / EC:DMC : EMC (1:1:1 volume ratio, EC: ethylene carbonate, DMC: dimethyl carbo...

Embodiment 2

[0027] Select carbon nanotube and sulfur composite material as positive electrode active material, acetylene black as conductive agent, 5wt% polyvinylidene fluoride solution (solution solvent is N-methylpyrrolidone) as binding agent to prepare positive electrode slurry, wherein positive electrode active material The mass ratio of the conductive agent and the binding agent is 80%: 15%: 5%, and the porous carbon microspheres are used as the adsorption material of the adsorption layer to prepare the positive electrode sheet. The same method as in Example 1 was used to prepare the positive electrode sheet and assemble the battery.

[0028] The battery charge and discharge test results show that the first charge and discharge specific capacity of the material is 780.3mAh / g, and the specific capacity remains at 587.2mAh / g after 50 cycles, showing good battery performance.

Embodiment 3

[0030]Select carbide-derived carbon and sulfur composite material (wherein the pore size distribution of carbide-derived carbon is 0.5 ~ 5nm) as the positive electrode active material, acetylene black as the conductive agent, and the binder is the same as in Example 1 to prepare the positive electrode sheet, the positive electrode The mass ratio of active material, conductive agent and binder in the sheet is 80%:12%:8%. Mesoporous carbon was used as the material of the adsorption layer to prepare the adsorption layer, and the same method as in Example 1 was used to prepare the positive electrode sheet and assemble the battery.

[0031] The charge-discharge test results show that the first charge-discharge specific capacity of the material is 753.7mAh / g, and the specific capacity remains at 548.1mAh / g after 50 cycles, showing good battery performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com