Method for preparing lithium ion battery

A lithium-ion battery and lithium chip technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, etc., can solve the problems affecting the actual performance of batteries, harsh experimental conditions, difficult operation and control, etc., and reduce irreversible capacity loss. , the method is simple, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

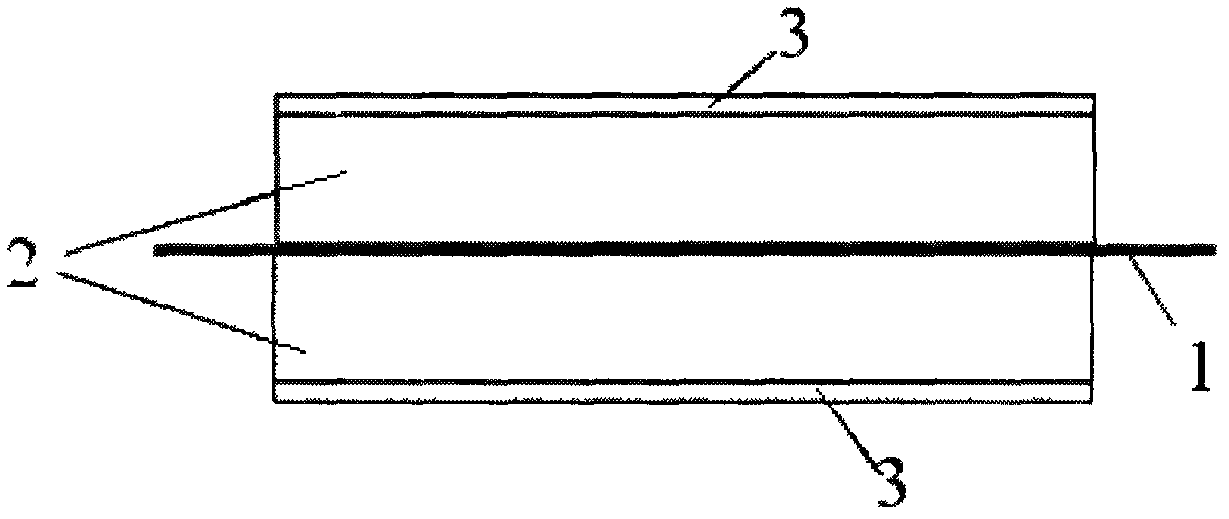

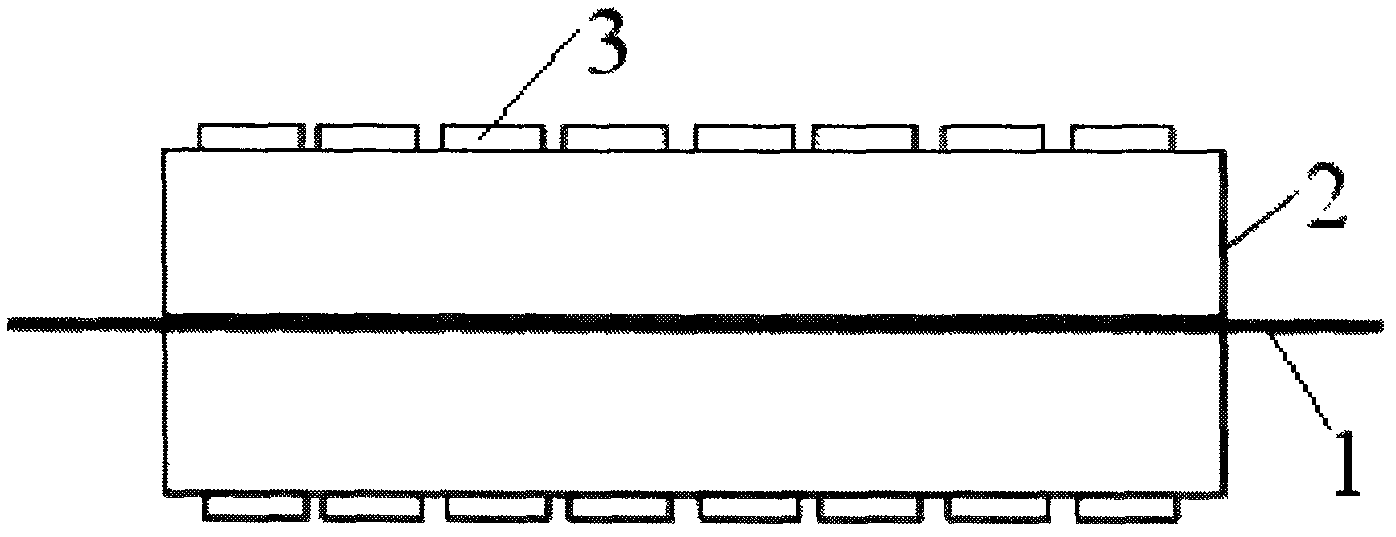

[0044] Add graphite, conductive carbon, sodium carboxymethyl cellulose, and styrene-butadiene rubber into the solvent water according to the mass ratio of 94.5:1.5:1.5:2.5, mix and stir evenly to make a stable slurry, and then use metal copper foil as the current collector. The slurry is coated on the copper current collector to form a film. A negative electrode sheet with a diameter of about 20.3 mm was prepared with a die-cutting cutter.

[0045] Add lithium cobaltate, conductive carbon, and polyvinylidene fluoride into the solvent N-methylpyrrolidone (NMP) according to the mass ratio of 95.5:2.2:2.3, mix and stir evenly to make a stable slurry, and then use metal aluminum foil as a current collector, The slurry was coated on an aluminum current collector. A positive electrode sheet with a diameter of about 14.3 mm was prepared with a die-cutting tool

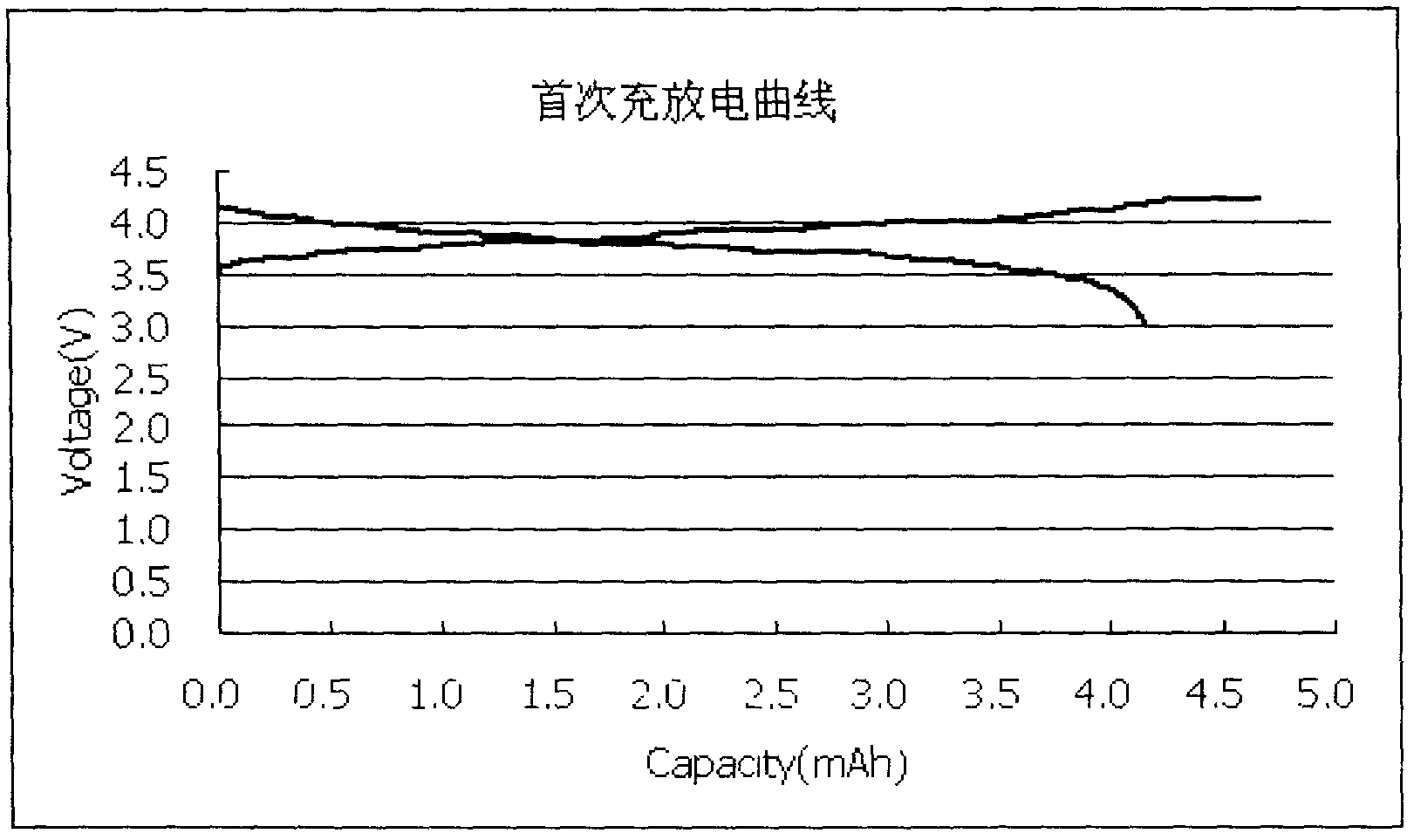

[0046] LiPF 6 Dissolved in a mixed solvent containing ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl ...

Embodiment 2

[0052] Add Si alloy material, graphite carbon material, conductive carbon, sodium carboxymethyl cellulose, and styrene-butadiene rubber into solvent water according to the mass ratio of 68:23:3:1.5:3.5:1, mix and stir evenly to make a stable slurry, Then the metal copper foil is used as the current collector, and the slurry is coated on the copper current collector to form a membrane. A negative electrode sheet with a diameter of about 20.3 mm was prepared with a die-cutting cutter.

[0053] Add lithium cobaltate, conductive carbon, and adhesive to NMP solvent in a mass ratio of 95.5:2.2:2.3, mix and stir evenly to make a stable slurry, and then use metal aluminum foil as a current collector to coat the slurry on the aluminum collector. fluid on. A positive electrode sheet with a diameter of about 14.3 mm was prepared with a die-cutting cutter.

[0054] LiPF 6 Dissolved in a solvent containing EC, DEC and EMC (the volume ratio of the three is 1:1:1), making LiPF 6 The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com