Gel polymer electrolyte power battery

A gel polymer, power battery technology, used in secondary batteries, circuits, electrical components, etc., can solve problems such as electrochemical performance and safety need to be further improved, achieve excellent safety performance, reduce losses, and suppress side effects. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

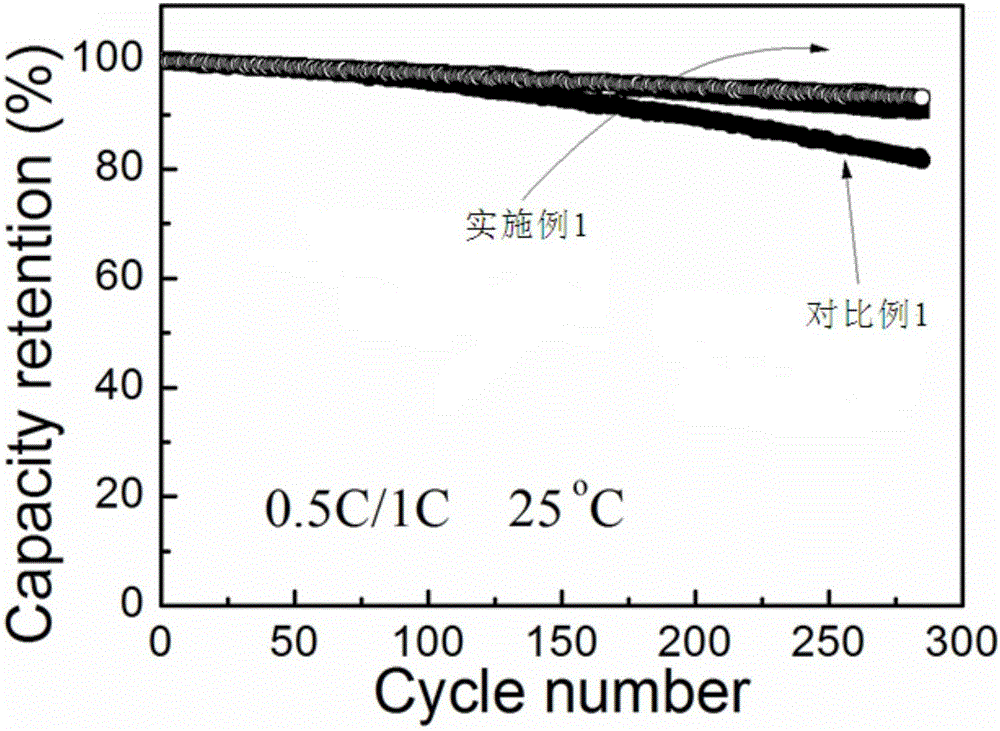

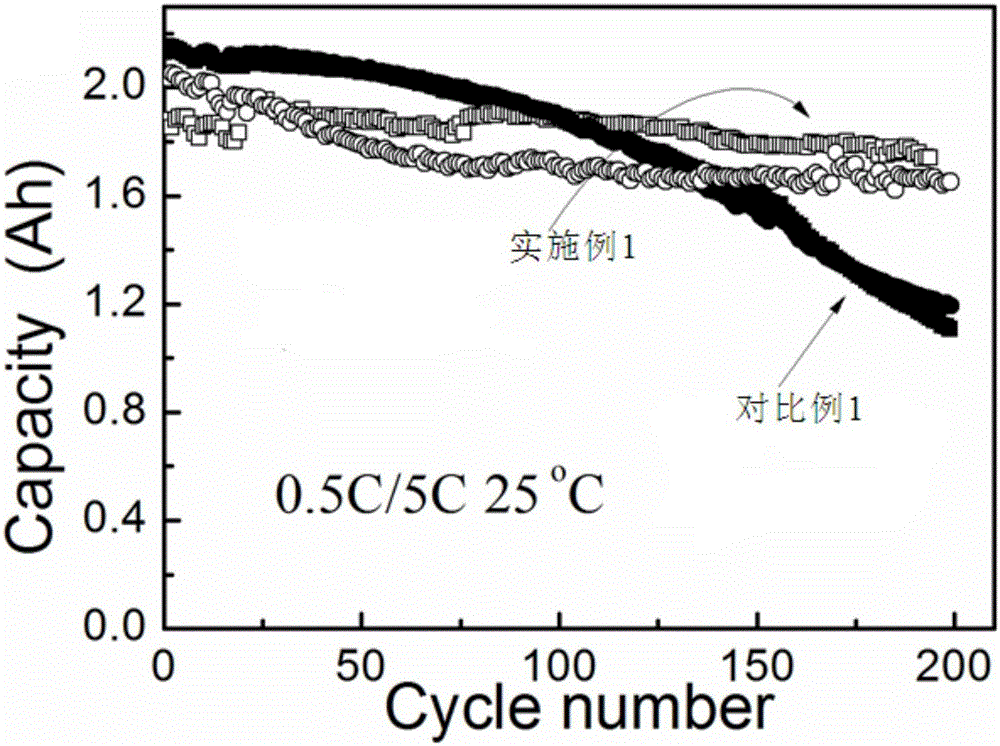

Embodiment 1

[0040] This embodiment provides a gel polymer electrolyte power battery, including a negative electrode, a positive electrode, a gel polymer electrolyte and a diaphragm, the positive electrode includes a positive electrode current collector and a positive electrode active material layer coated on the surface of the positive electrode current collector, and the negative electrode includes a negative electrode The current collector and the negative electrode active material layer coated on the surface of the negative electrode current collector, the negative electrode active material layer includes graphite and silicon carbon materials dispersed in the gaps of graphite, the specific gravity of graphite is 50%, and the particle size of graphite is 0.5 μm-100 μm The silicon carbon material is a silicon material coated with a porous carbon layer, the thickness of the porous carbon layer is 5 μm-90 μm, the mass ratio of the porous carbon layer to the silicon carbon material is 30%, an...

Embodiment 2

[0052] The difference with embodiment 1 is:

[0053] The negative electrode active material layer includes graphite and silicon-carbon material dispersed in the gaps of graphite. The proportion of graphite is 60%. The mass ratio of the layer to the silicon-carbon material is 20%, and the porosity of the porous carbon layer is 60%.

[0054] The positive active material layer includes nickel-cobalt-manganese ternary material LiNi 0.6 co 0.2 mn 0.2 o 2 .

[0055]The gel polymer electrolyte includes liquid electrolyte, polymer monomer and initiator, and the mass ratio of liquid electrolyte, polymer monomer and initiator is 97.8:2:0.2, and the polymer monomer is tripropylene glycol Diacrylate (TPGDA), the initiator is azobisisobutyronitrile (AIBN).

[0056] The composition of the SEI-like film coating layer is: 70% amorphous carbon, 10% lithium carbonate, 10% alkyl lithium carbonate, 9.3% lithium fluoride and 0.7% binder styrene-butadiene rubber, SEI-like The thickness of th...

Embodiment 3

[0059] The difference with embodiment 1 is:

[0060] The negative electrode active material layer includes graphite and silicon-carbon material dispersed in the gaps of graphite, the proportion of graphite is 80%; the silicon-carbon material is a silicon material coated with a porous carbon layer, and the thickness of the porous carbon layer is 5 μm-90 μm. The mass ratio of the layer to the silicon-carbon material is 25%, and the porosity of the porous carbon layer is 30%.

[0061] The positive active material layer includes nickel-cobalt-aluminum ternary material LiNi 0.7 co 0.2 al 0.1 o 2 .

[0062] The gel polymer electrolyte includes liquid electrolyte, polymer monomer and initiator, and the mass ratio of liquid electrolyte, polymer monomer and initiator is 86.95:13:0.05, and the polymer monomer is tripropylene glycol Diacrylate (TPGDA), the initiator is benzoyl peroxide (BPO), the additive is 1% ethylene carbonate and 2% vinylene carbonate. The lithium salt is lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com