Carbon-coated silicon nanosheet, silicon-based composite and preparation methods of carbon-coated silicon nanosheet and silicon-based composite

A silicon-based composite material, silicon nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of carbon-coated silicon nanosheets:

[0034] Step 1: Add 0.1 g of sucrose to 5 mL of water, fully stir and ultrasonically disperse for 10 min; add 0.1 g of silica powder with a D50 particle size of 10 nm, and ultrasonically disperse for 10 min;

[0035] Step 2: The mixture obtained in step 1 is subjected to a hydrothermal reaction in a closed container, the reaction temperature is 100 ° C, and the reaction time is 10 hours;

[0036] Step 3: the hydrothermal reaction product is centrifuged, and the obtained solid matter is vacuum-dried at 60°C;

[0037] Step 4: grinding and calcining the dried solid. During calcination, the heating rate is 10°C / min, the calcination temperature is 500°C, and the calcination time is 5 hours to obtain carbon-coated silicon nanosheets.

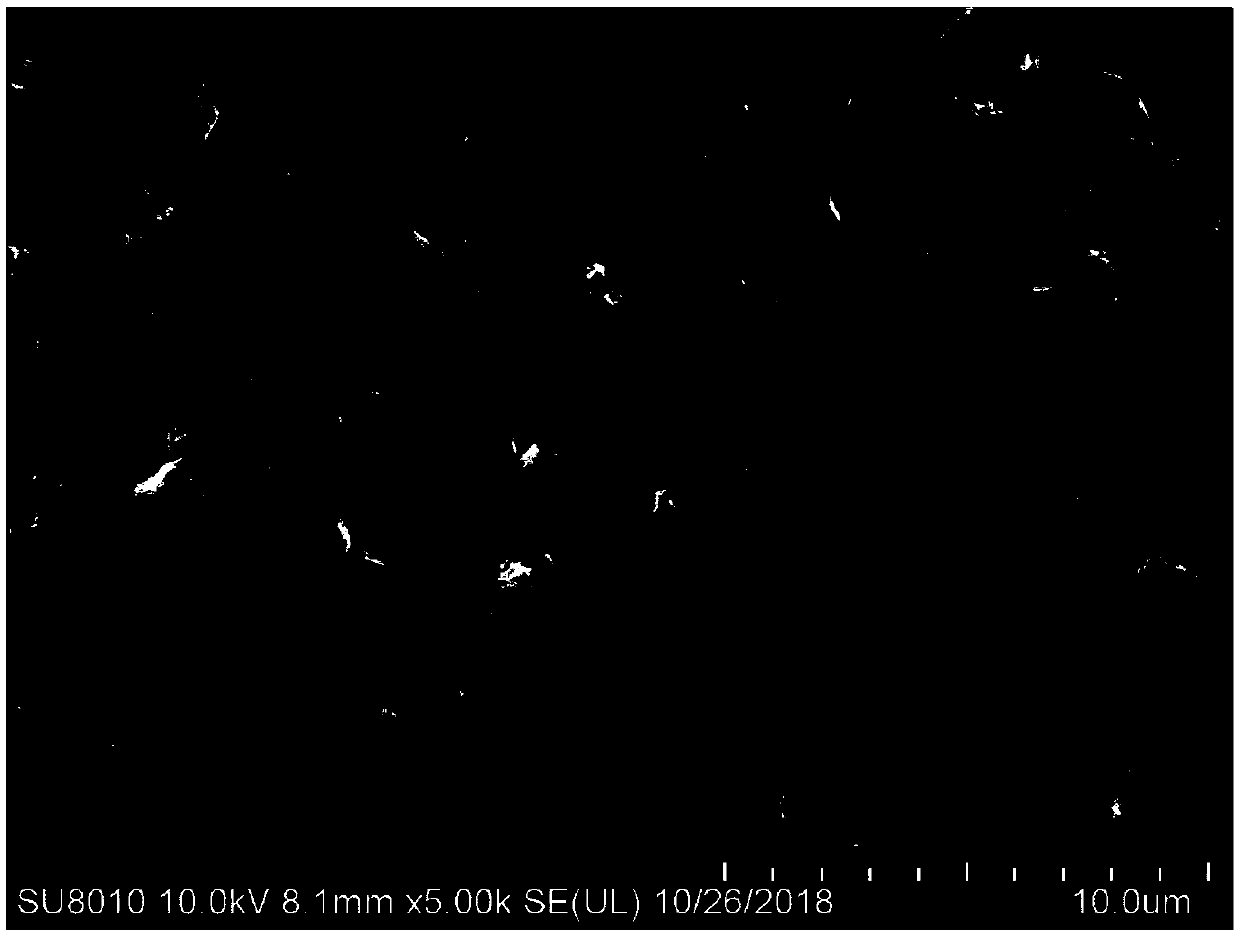

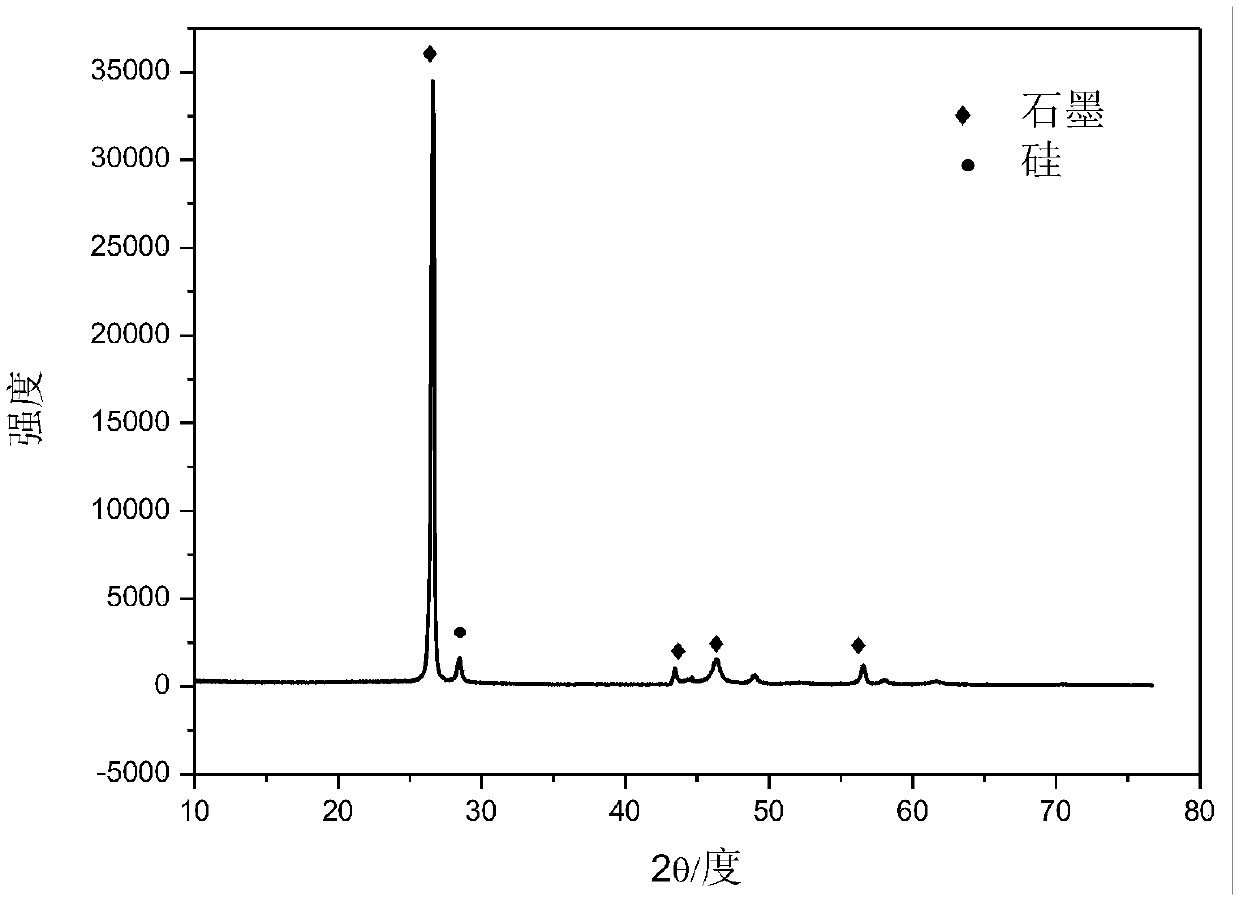

[0038] figure 1 The XRD patterns of the carbon-coated silicon nanosheets prepared in this example are obtained from figure 1 The XRD results can confirm that the main component of the prepare...

Embodiment 2

[0046] Preparation of carbon-coated silicon nanosheets:

[0047] Step 1: Add 0.5g of asphalt to 15mL of water, fully stir and ultrasonically disperse for 20min; add 0.5g of silica fume with a D50 particle size of 50nm, and ultrasonically disperse for 20min;

[0048] Step 2: The mixture obtained in step 1 is subjected to a hydrothermal reaction in a closed container, the reaction temperature is 150 ° C, and the reaction time is 16 hours;

[0049] Step 3: the hydrothermal reaction product is centrifuged, and the obtained solid matter is vacuum-dried at 40°C;

[0050] Step 4: Grinding and calcining the dried solid, the heating rate during calcination is 5°C / min, the calcination temperature is 750°C, and the calcination time is 8 hours to obtain carbon-coated silicon nanosheets.

[0051] Preparation of silicon matrix composites:

[0052] Step 1: The carbon-coated silicon nanosheets prepared above, graphite with a D50 particle size of 40 μm, and polyaniline are mixed in a mass rati...

Embodiment 3

[0055] Preparation of carbon-coated silicon nanosheets:

[0056] Step 1: Add 1g of glucose into 20mL of water, stir well and disperse ultrasonically for 30min; add 1g of silicon powder with a D50 particle size of 200nm, and disperse ultrasonically for 30min;

[0057] Step 2: The mixture obtained in step 1 is subjected to a hydrothermal reaction in a closed container, the reaction temperature is 200 ° C, and the reaction time is 24 hours;

[0058] Step 3: Centrifuge the hydrothermal reaction product, and vacuum dry the obtained solid matter at 80°C;

[0059] Step 4: Grinding and calcining the dried solid, the heating rate during calcination is 3°C / min, the calcination temperature is 1000°C, and the calcination time is 8 hours to obtain carbon-coated silicon nanosheets.

[0060] Preparation of Silicon Matrix Composites::

[0061] Step 1: Mix the carbon-coated silicon nanosheets prepared above, hard carbon with a D50 particle size of 1 μm, and pitch according to a mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com