Multifunctional high speed automatic punch machine for pattern card

An automatic punching and multi-functional technology, which is used in the punching device of cardboard, textile, textile and paper making, etc. It can solve the problem of whether the punching is correct or not, cannot guarantee the punching quality of the cardboard, and cannot determine the accuracy of punching. and other problems, to achieve the effect of high degree of automation, good punching quality and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

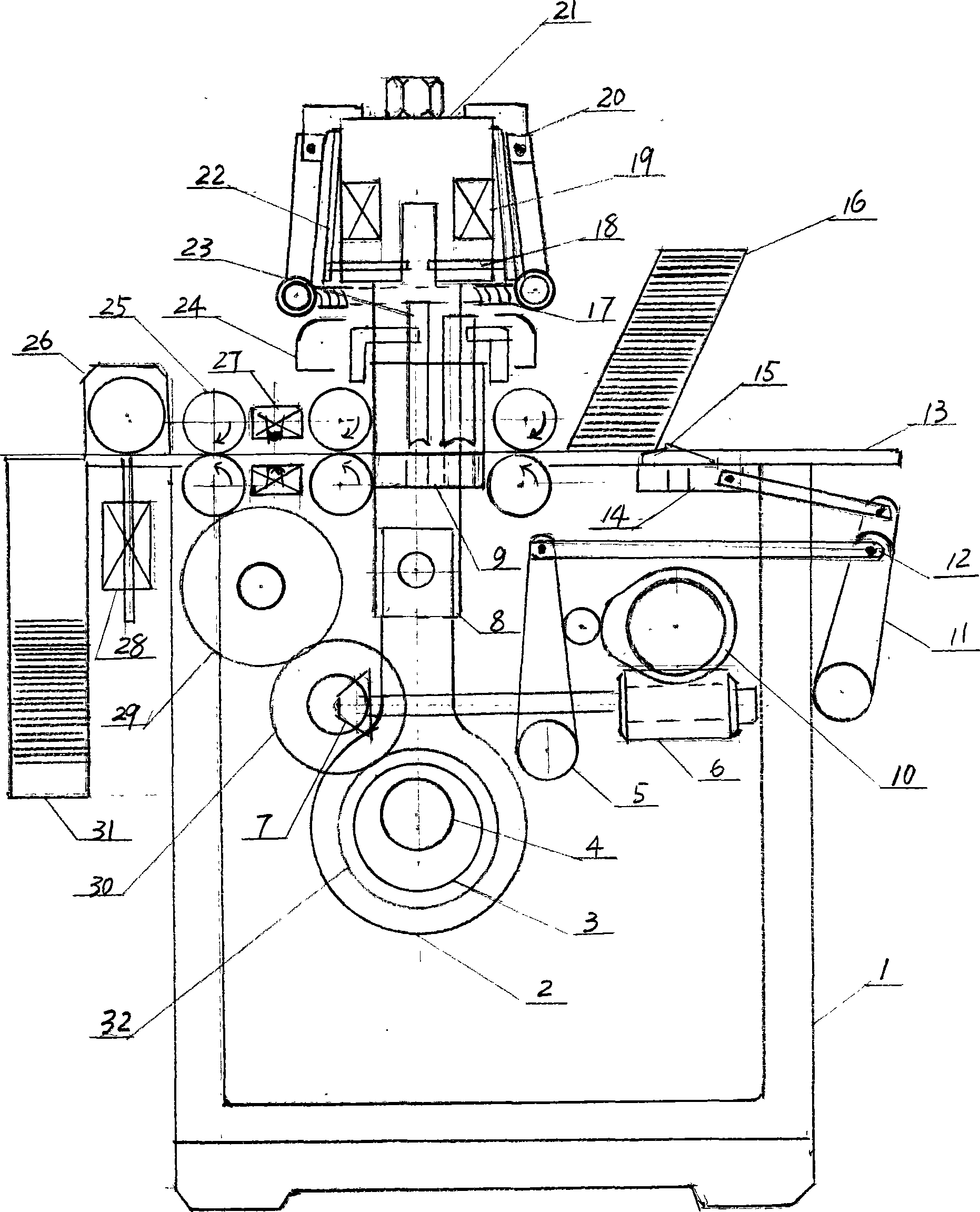

[0009] Combine below figure 1 The implementation process clearly proposed by the present invention is further described: (1) installation process: main shaft 4, platen 13, die 9 are installed on the frame 1 successively from bottom to top, eccentric wheel 3, eccentric wheel connecting rod 2, lifting shaft 18. The machine head 21 is assembled above the main shaft 4 in order from bottom to top. The horizontal needle 18, the electromagnet 19, the suction aid mechanism 20, the armature 22, and the tension spring 17 are installed on both sides of the machine head 21. When the machine head 21 rises, the tension spring 17 Tighten the suction aid 20 and attach the armature 22 to the electromagnet 19. The impact block 24 is installed under the suction aid 20. When the machine head rushes down, the suction aid 20 collides with the impact block 24, and the punching needle 23 is installed on the die 9. Shaft 25, cardboard stepping mechanism 29, and bridge gear 30 are sequentially connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com