Device for hooking between elements of a shed forming device, method for manufacturing and using the same

A component and shed technology, which is applied to the device for hooking components in the shed forming equipment, the field of manufacture and use of the device, can solve the problems of brittle end piece, complicated installation operation, inaccurate control of the heald, etc., and achieve sliding Stable resistance, reduced friction, improved accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

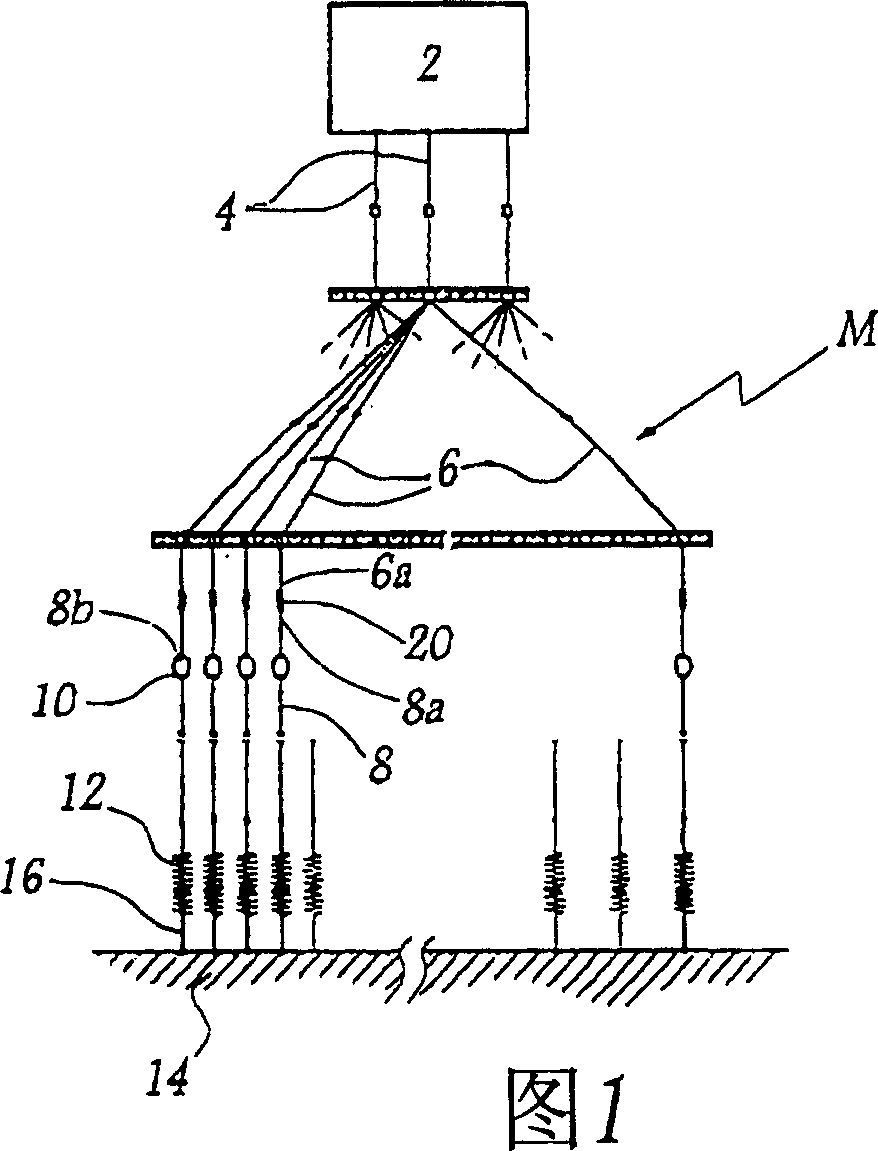

[0038] The weaving machine M shown in Figure 1 is equipped with a Jacquard mechanism 2 which controls a plurality of threads 4, only one of which is shown and whose lower end is connected to a plurality of cords 6, the combination of which forms said The heald H of the loom. The lower end 6a of each cord 6 is connected to the upper end 8a of a heald 8 each provided with an eye 8b for the passage of warp threads 10 and subjected to the action of a return spring 12 fixed to the frame 14 of the loom by means of rods 16 .

[0039] The healds 8 can also be controlled individually by the mechanism 2, in which case each rope 6 is moved individually by means of this mechanism.

[0040] In the meaning of this specification, the adjective "upper" refers to the part or element of the device which is directed upwards in the normal configuration of use of the loom M, i.e. upwards in Fig. 1, while the adjective "lower" refers to the part or element which is directed downwards in this config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com