Chain jacquard

A jacquard and chain technology, applied in jacquard, textile, textile and paper making, etc., can solve the problems of increased component failure points and failure rate, complicated equipment maintenance, limited space structure, etc., and achieve component failure points and failure rate. The effect of reduction, smooth operation of equipment and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

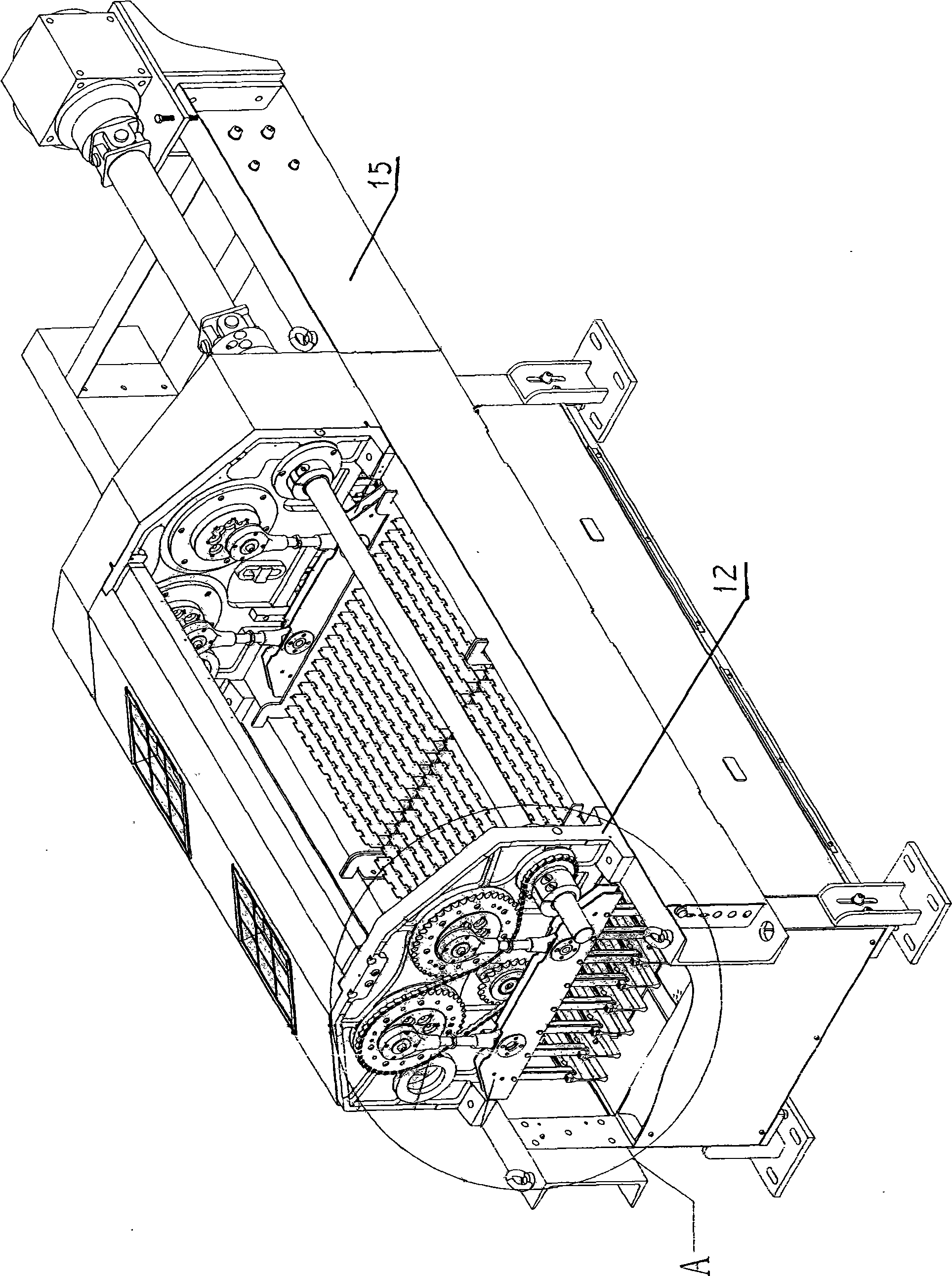

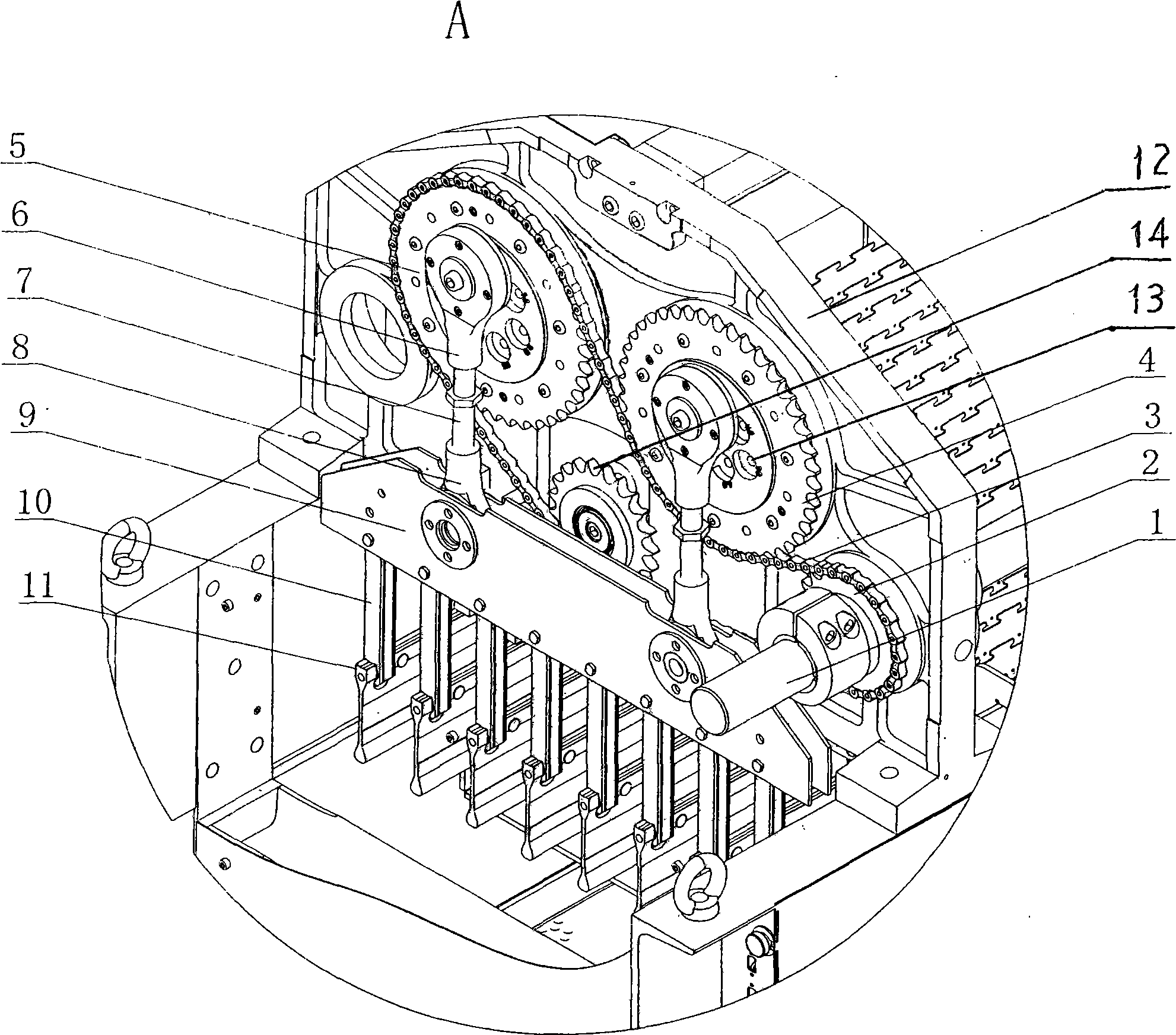

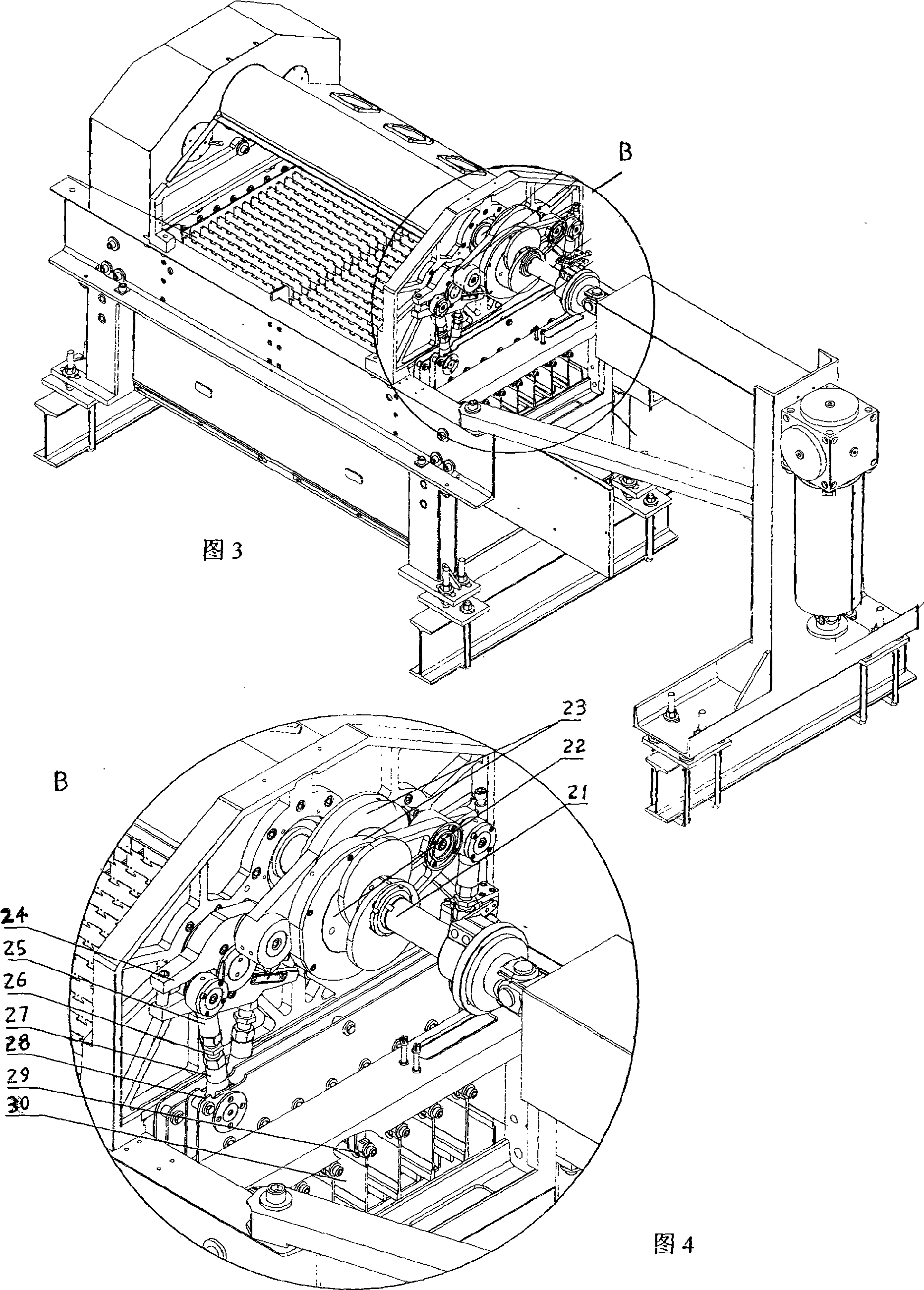

[0016] refer to figure 1 and figure 2 , The chain jacquard machine of the present invention has left and right wall panels 12 arranged on the frame 15 . Left and right wallboards 12 are equipped with transmission shaft 1 and symmetrically arranged left and right broach mechanisms, and a transmission mechanism is respectively installed symmetrically between the transmission shaft 1 and the left and right broach mechanisms.

[0017] The left and right broach mechanisms respectively include a pair of symmetrically arranged adjusting screw rods 7, a pair of lower seats 8, a broaching tool holder plate 9, several small pull rods 10 and broaches 11 respectively connected thereto. Seat 8 is hinged on the broach frame plate 9.

[0018] Transmission mechanism comprises transmission shaft 1, driving sprocket 2, chain 3, first shed adjustment sprocket 4, second shed adjustment sprocket 5, upper seat 6, adjustment screw rod 7, lower seat 8 and tension sprocket 14. Wherein, the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com