Textile having an integral underlying layer of hook and loop fabric

a technology of hook and loop fabric and textile, applied in the field of textiles, can solve the problems of separating layers from one another, affecting the quality of textiles,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

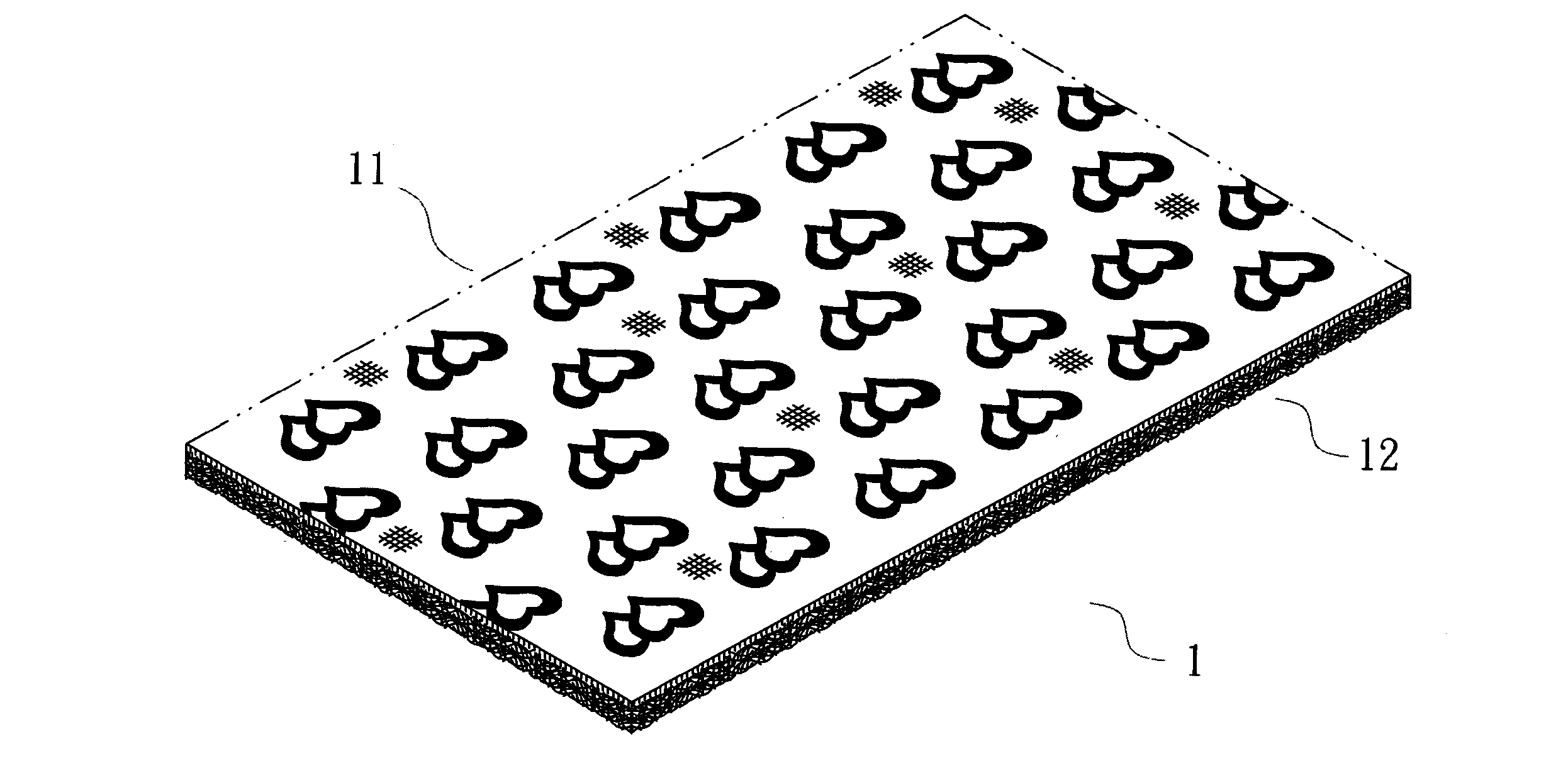

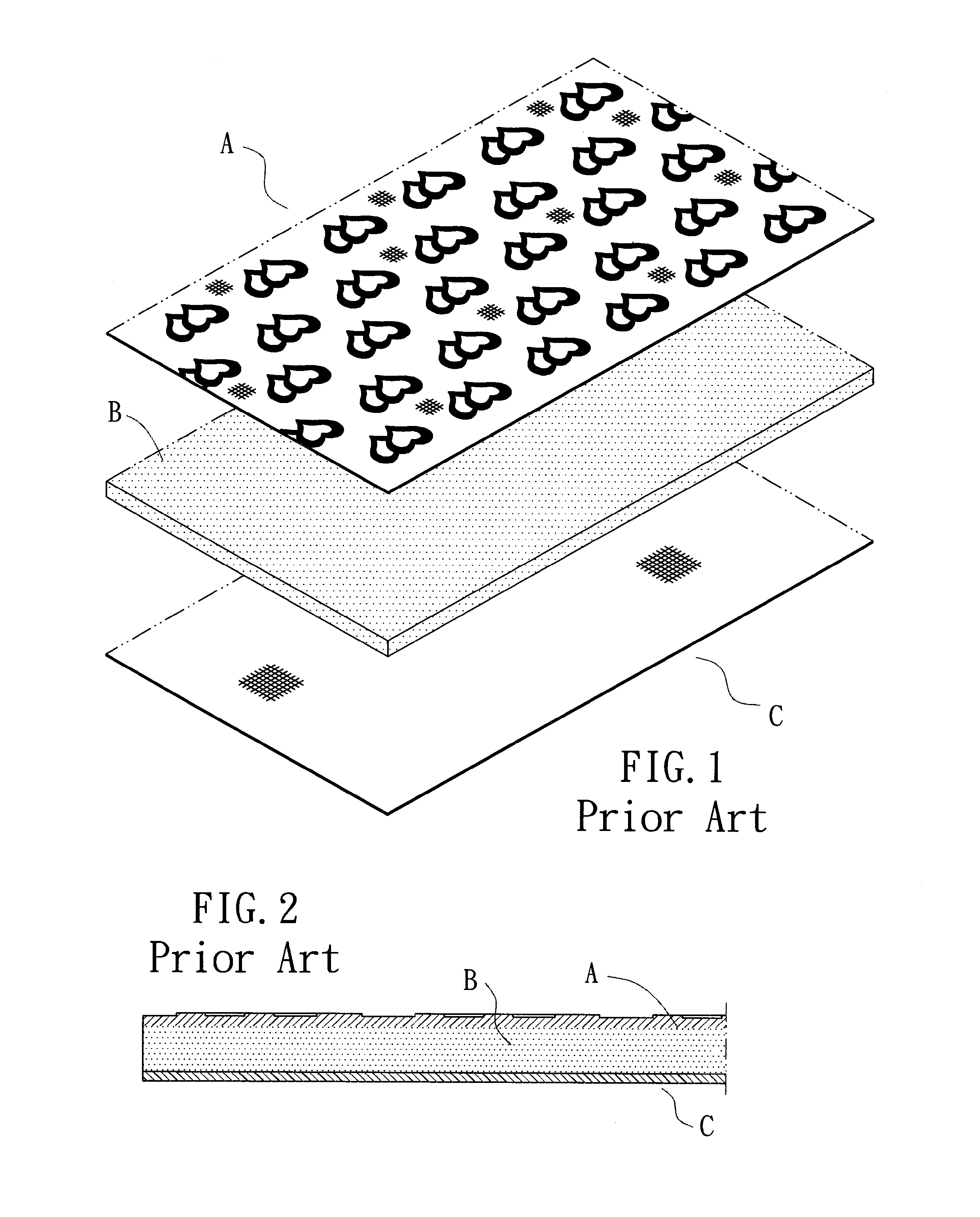

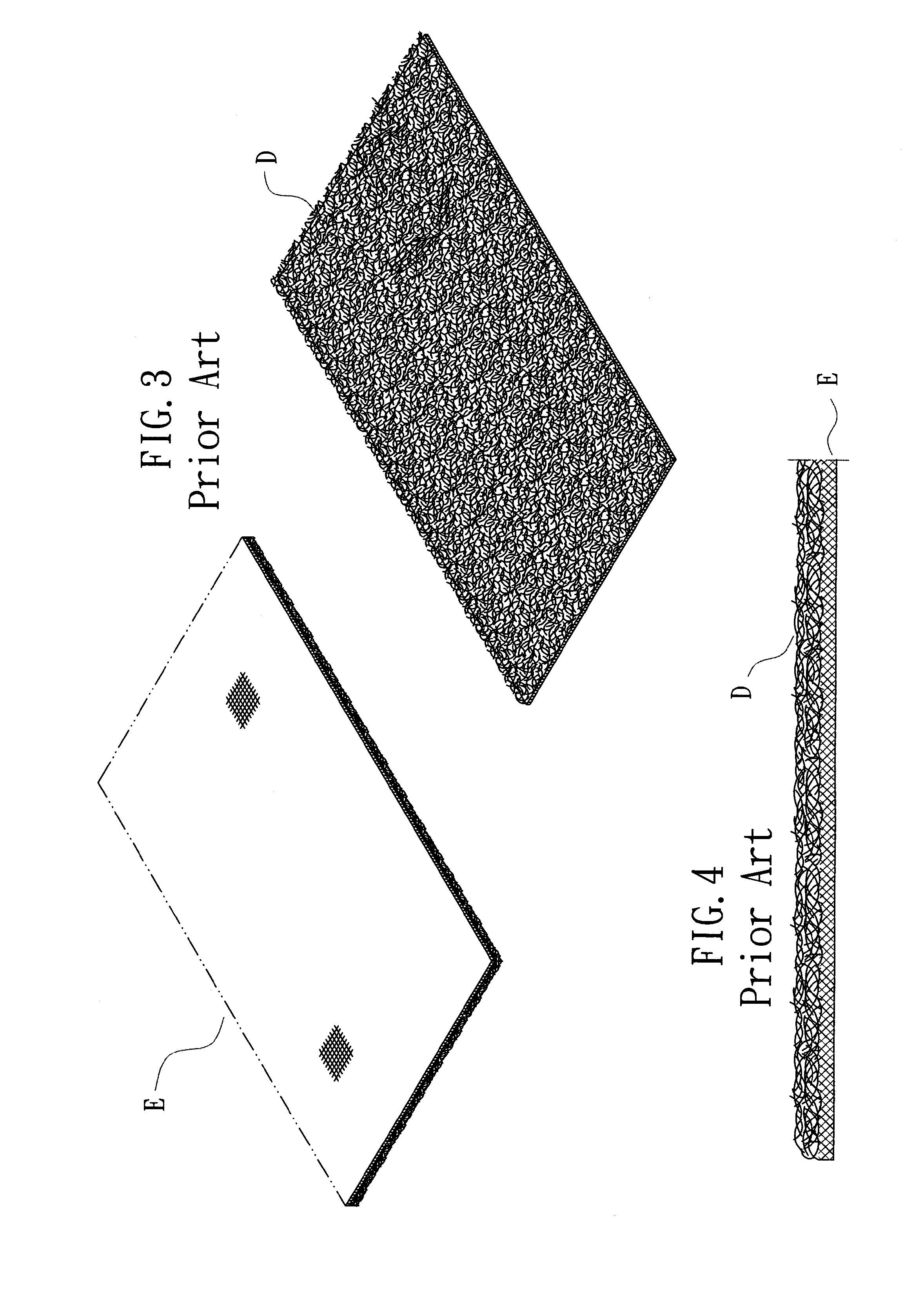

[0022]Referring to FIGS. 7 to 9, a textile 1 in accordance with the invention comprises an underlying layer of hook and loop fabric 12 and a jacquard surface layer 11 formed integrally therewith in the manufacturing processes.

[0023]It is envisaged by the invention that no adhesive is used in the manufacturing processes so as to minimize impact to the environment.

[0024]Referring to FIG. 10, the textile 1 can be used as a material for the manufacturing of a soft, thick, inner liner of a helmet.

[0025]Referring to FIGS. 11 and 12, the textile 1 can be used as a material for the manufacturing of vamps of two athletic shoes respectively.

[0026]Referring to FIGS. 13, 14, and 15, there are shown three configurations of the textile 1 having different designs of decoration implemented on the jacquard surface layer 11 respectively.

[0027]Although the invention has been described in detail, it is to be understood that this is done by way of illustration only and is not to be taken by way of limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com