Novel electronic jacquard machine

An electronic jacquard, a new type of technology, used in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of large use space, high use cost, long installation period, etc., to achieve large space occupation, high use cost and long installation period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings.

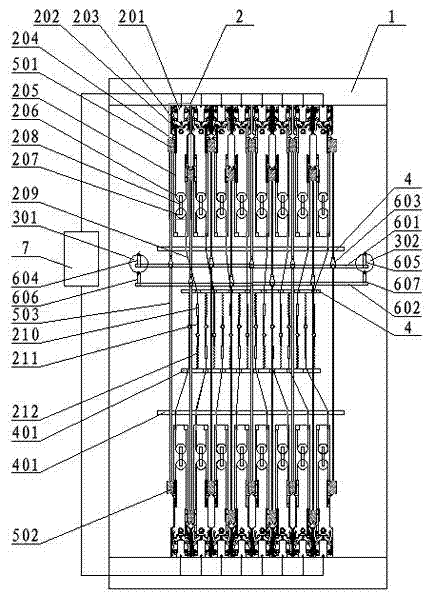

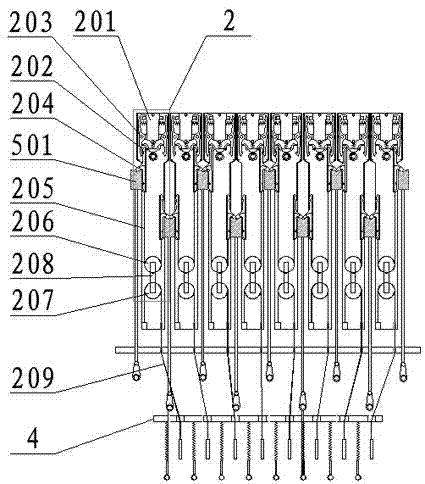

[0015] figure 1 , 2 As shown, a new electronic jacquard machine includes a frame 1, an electromagnetic selection actuator 2, an upper fixed plate 4, a lower fixed plate 401, an upper lifting knife 501, a lower lifting knife 502, a connecting rod 503, and a first lifting and pressing arm 601. , the second lifting arm 602, reciprocating link 603, link 604, 605, 606, 607, left synchronous eccentric rotary wheel 301, right synchronous eccentric rotary wheel 302 and control electric box 7. A plurality of electromagnetic selection assemblies 2 are arranged side by side to form an upper electromagnetic selection assembly, and a plurality of electromagnetic selection assemblies 2 are arranged in parallel to form a lower electromagnetic selection assembly. On the upper part or both sides of the upper electromagnetic selection assembly, the lifting and pressing arms 601, 602...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com