Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Factory floor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Factory Floor's debut self-titled album was released on 9 September 2013 featuring new versions of their previous singles "Two Different Ways" and "Fall Back", after which Dominic Butler departed the group. Their second album 25 25 was released on 19 August 2016, to positive reviews.

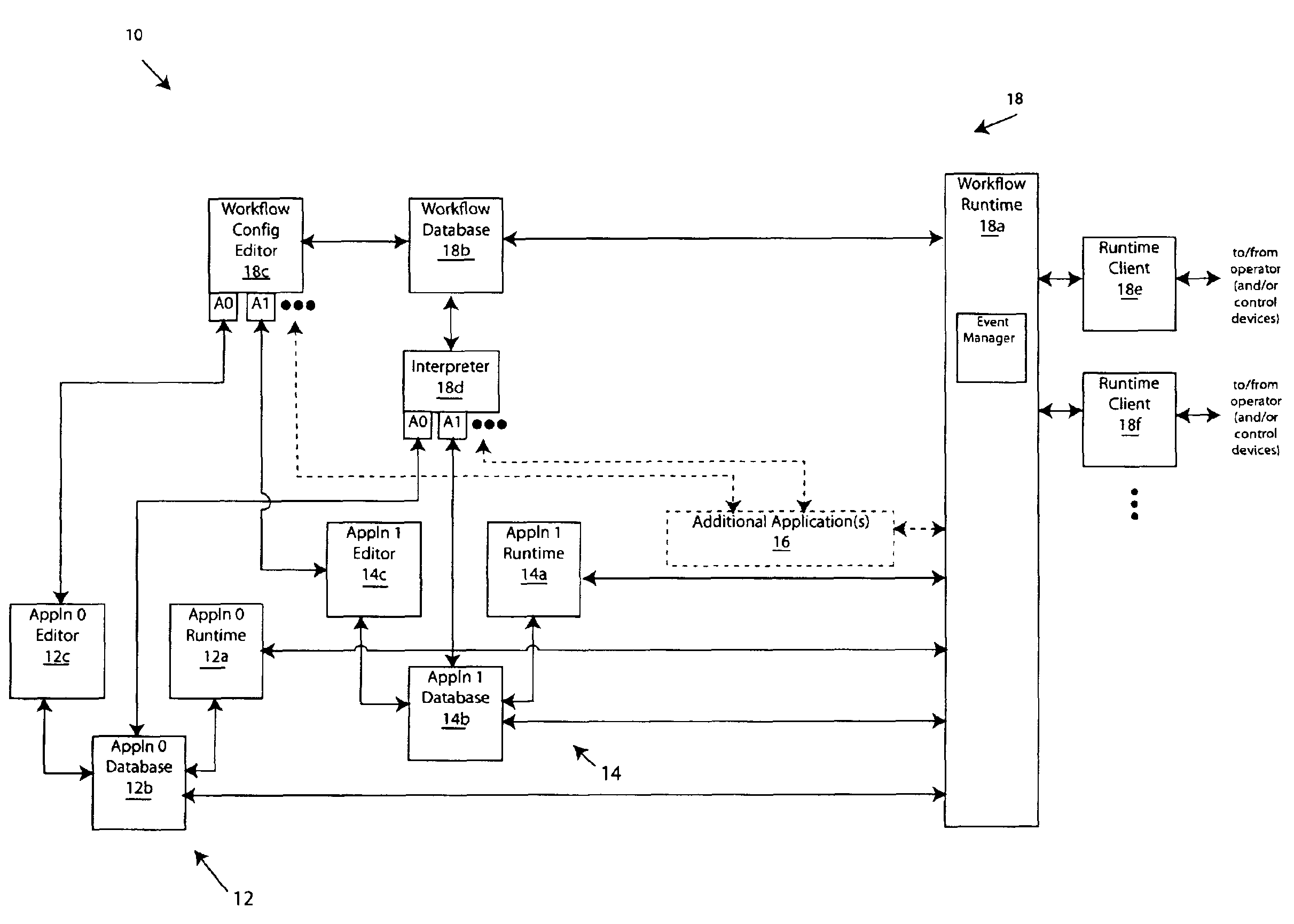

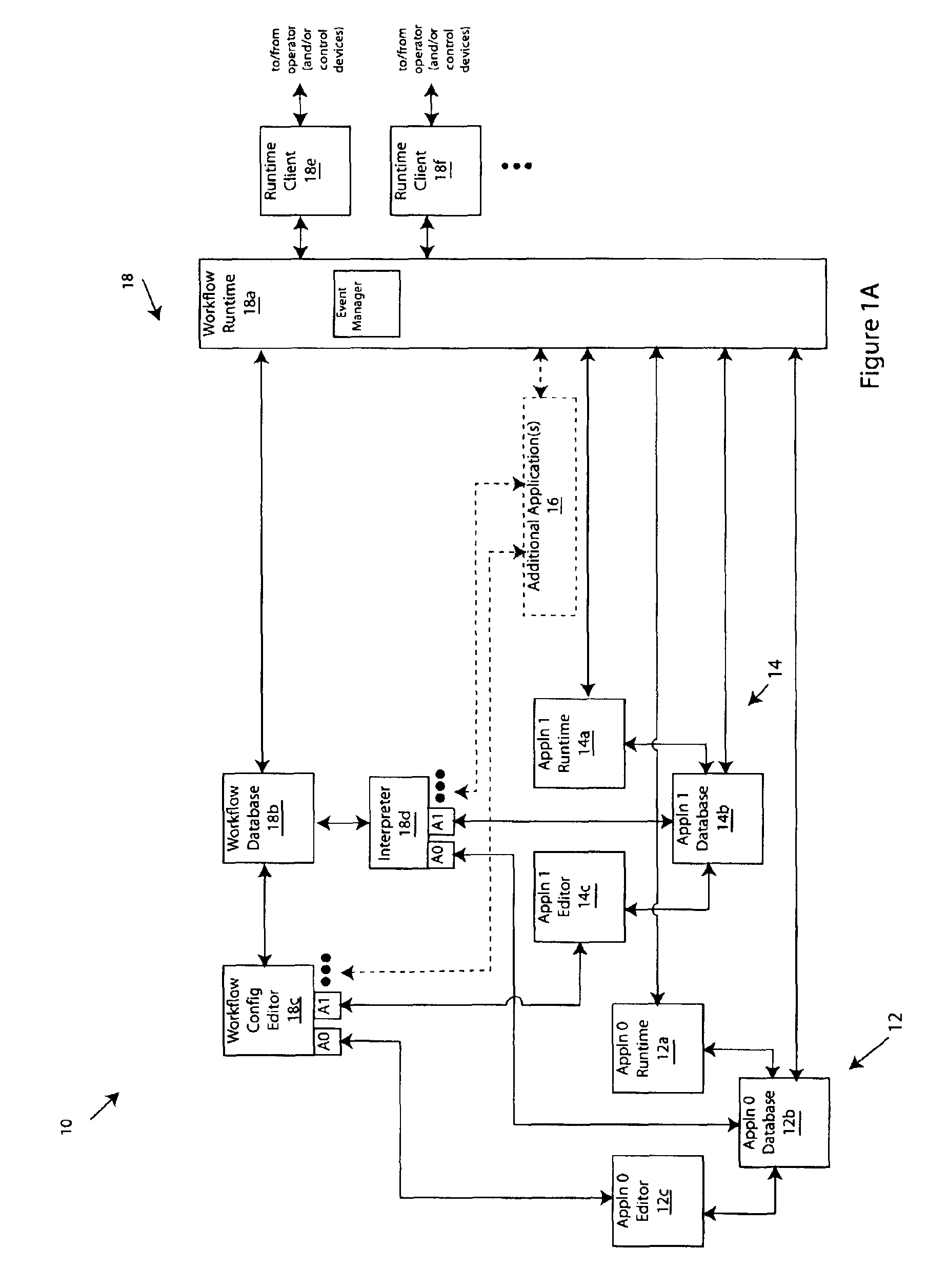

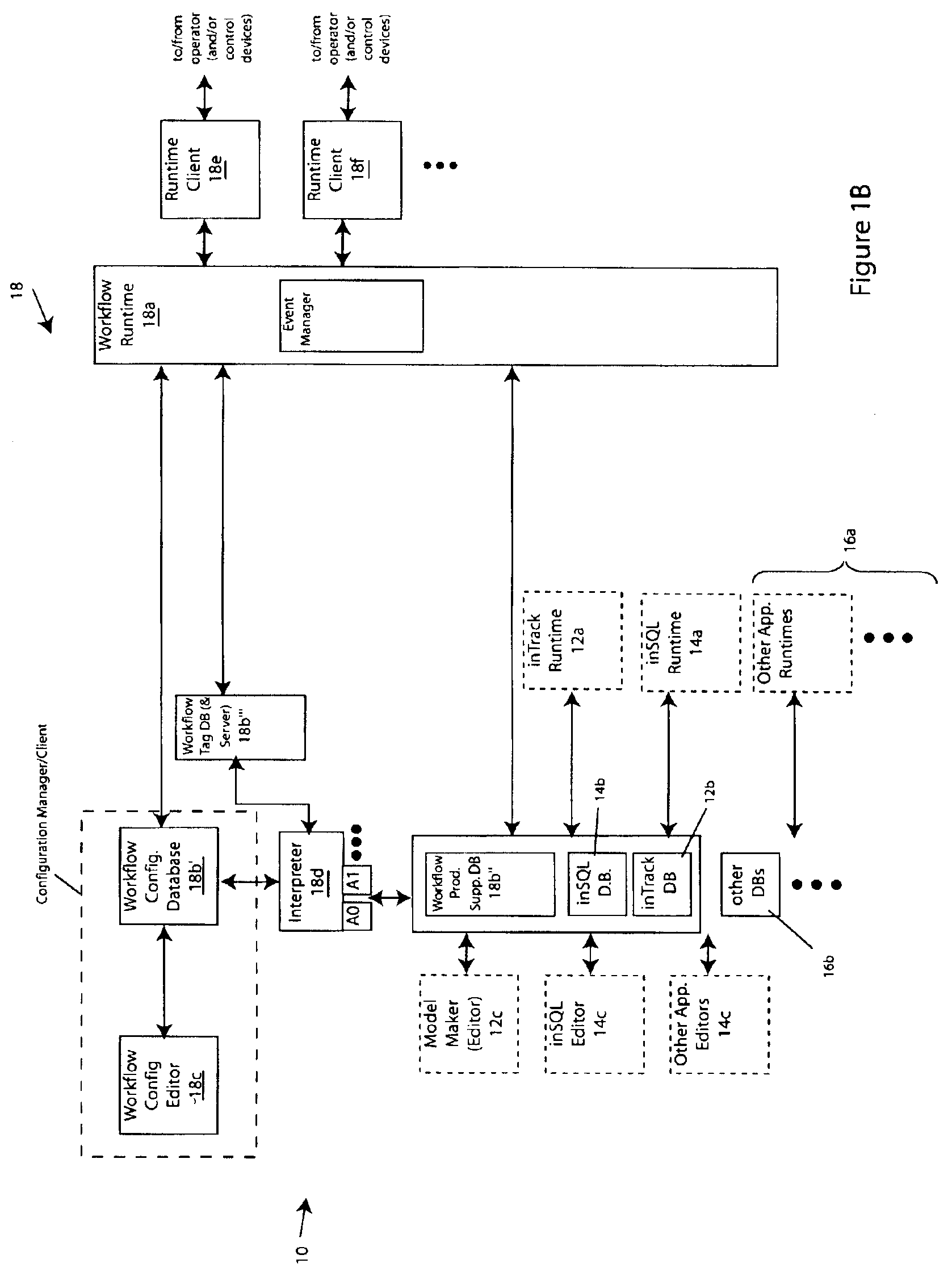

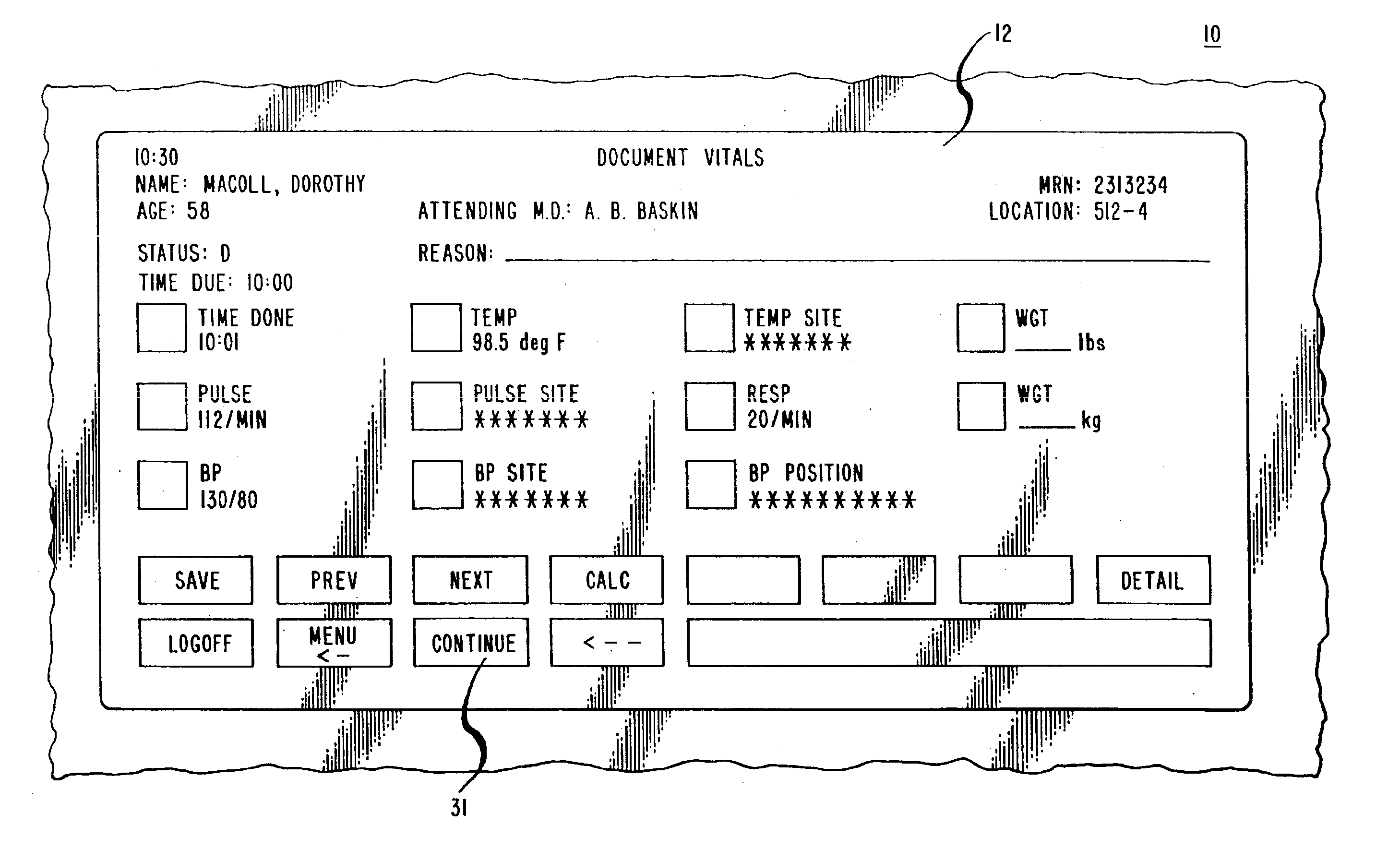

Methods and apparatus for process, factory-floor, environmental, computer aided manufacturing-based or other control system with unified messaging interface

InactiveUS6975914B2Enhanced informationFacilitate communicationComputer controlDigital data processing detailsProgram planningControl system

The invention provides improved methods and apparatus for workflow editing. Such methods and apparatus permit, for example, user-defined and / or other tasks to be combined in any combination or combinations to specify a workflow. The tasks can be linked for direct, serial processing and / or for conditional processing that includes branching and / or looping. The invention also improved methods and apparatus of workflow definition and processing with extensible actions. The invention provides, further, improved methods and apparatus for workflow definition and processing which utilize workflow variables for communication of data and control information among tasks within a workflow. The invention provides, still further, improved methods and apparatus of workflow definition and processing with enhanced messaging. The invention provides, still yet further, improved methods and apparatus for workflow definition and processing which permit definition of hierarchically enumerated data types and for for definition of “plans” to collect, e.g., for storage, data such as the aforementioned hierarchical data types.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

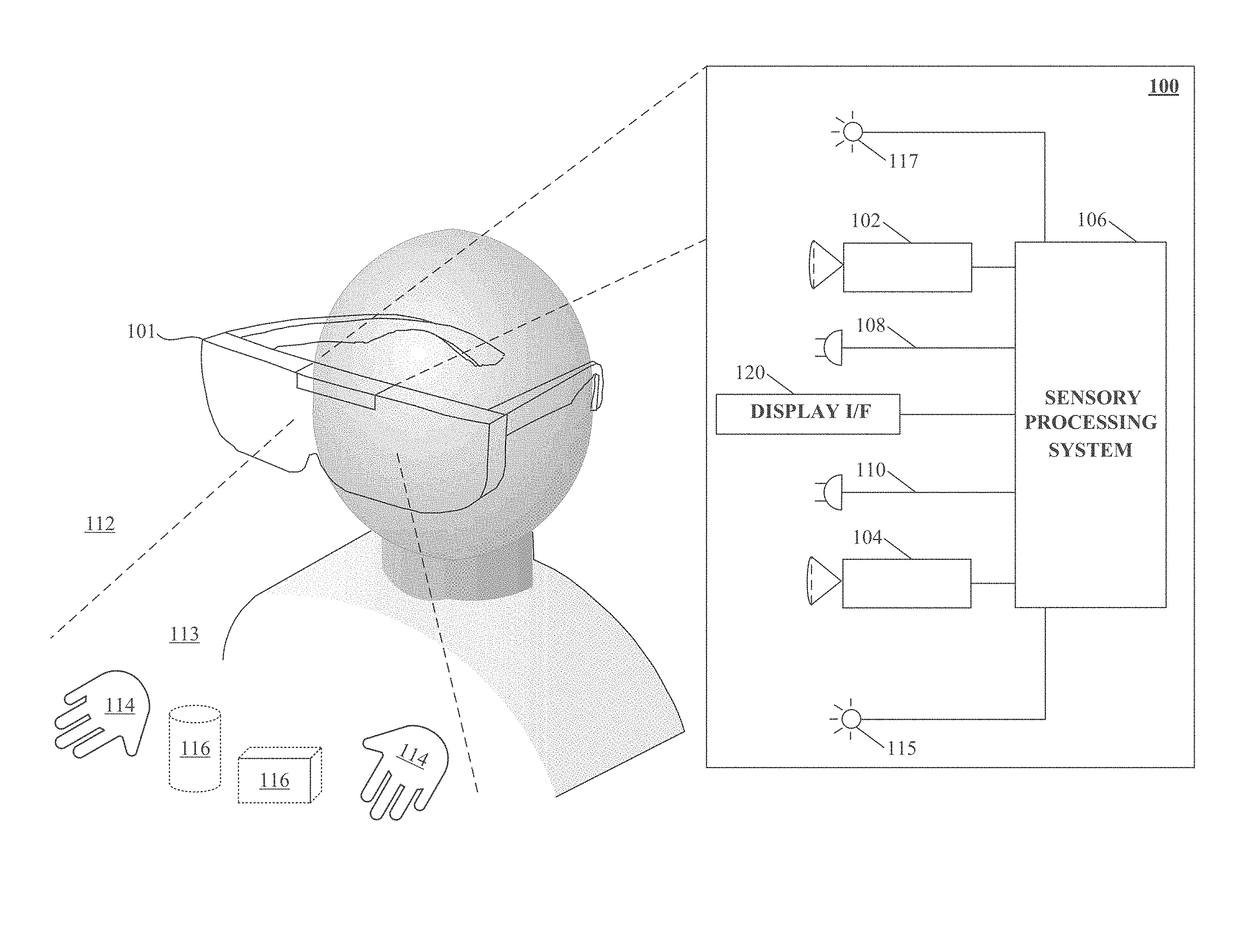

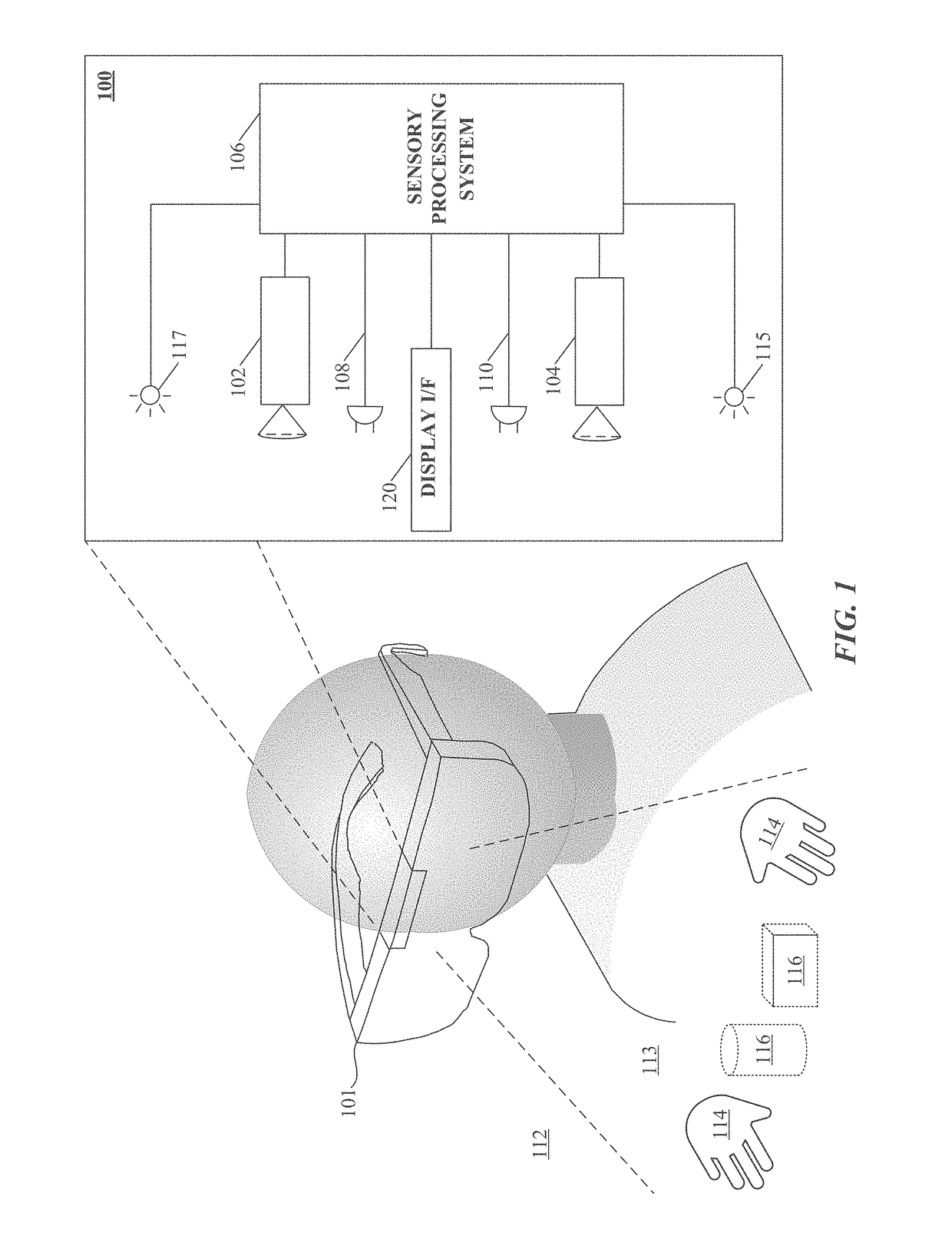

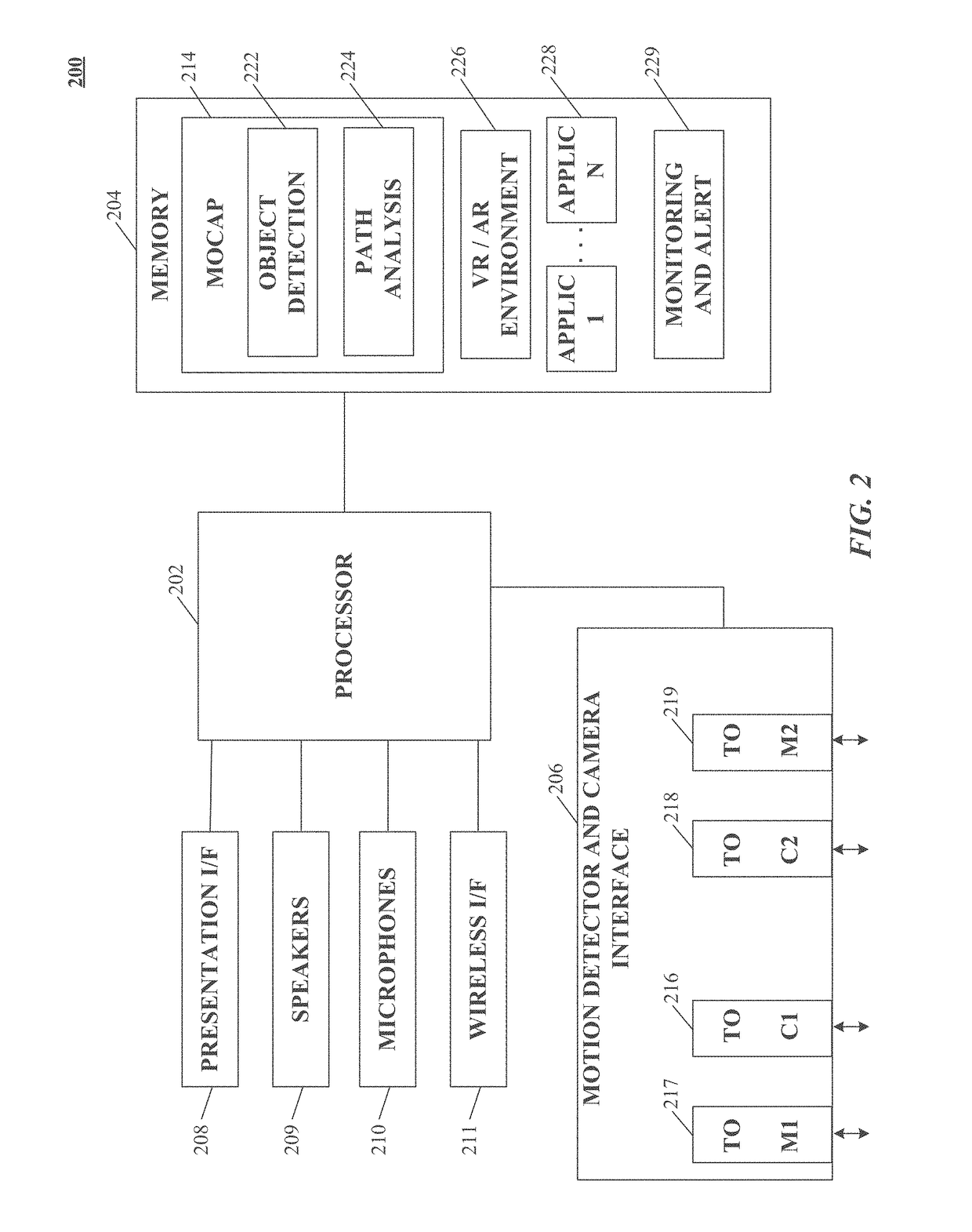

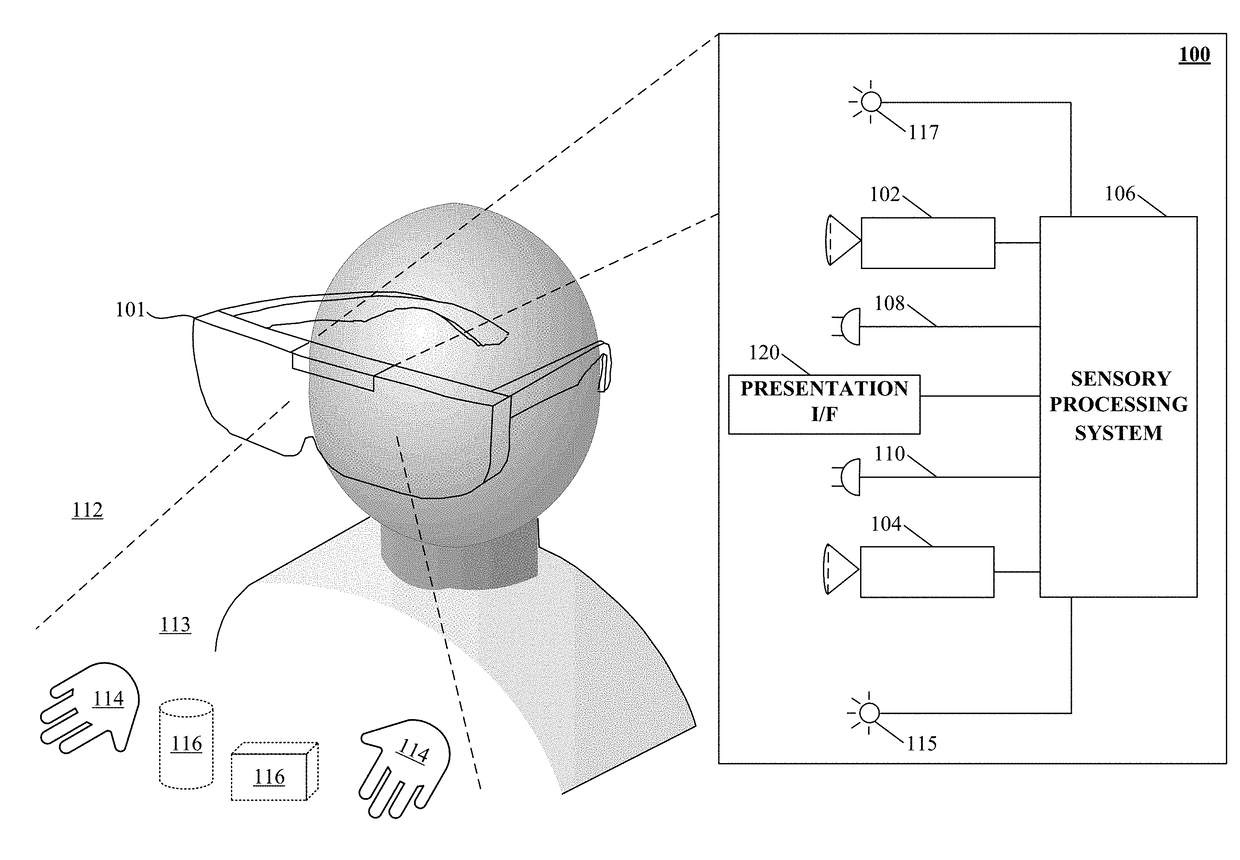

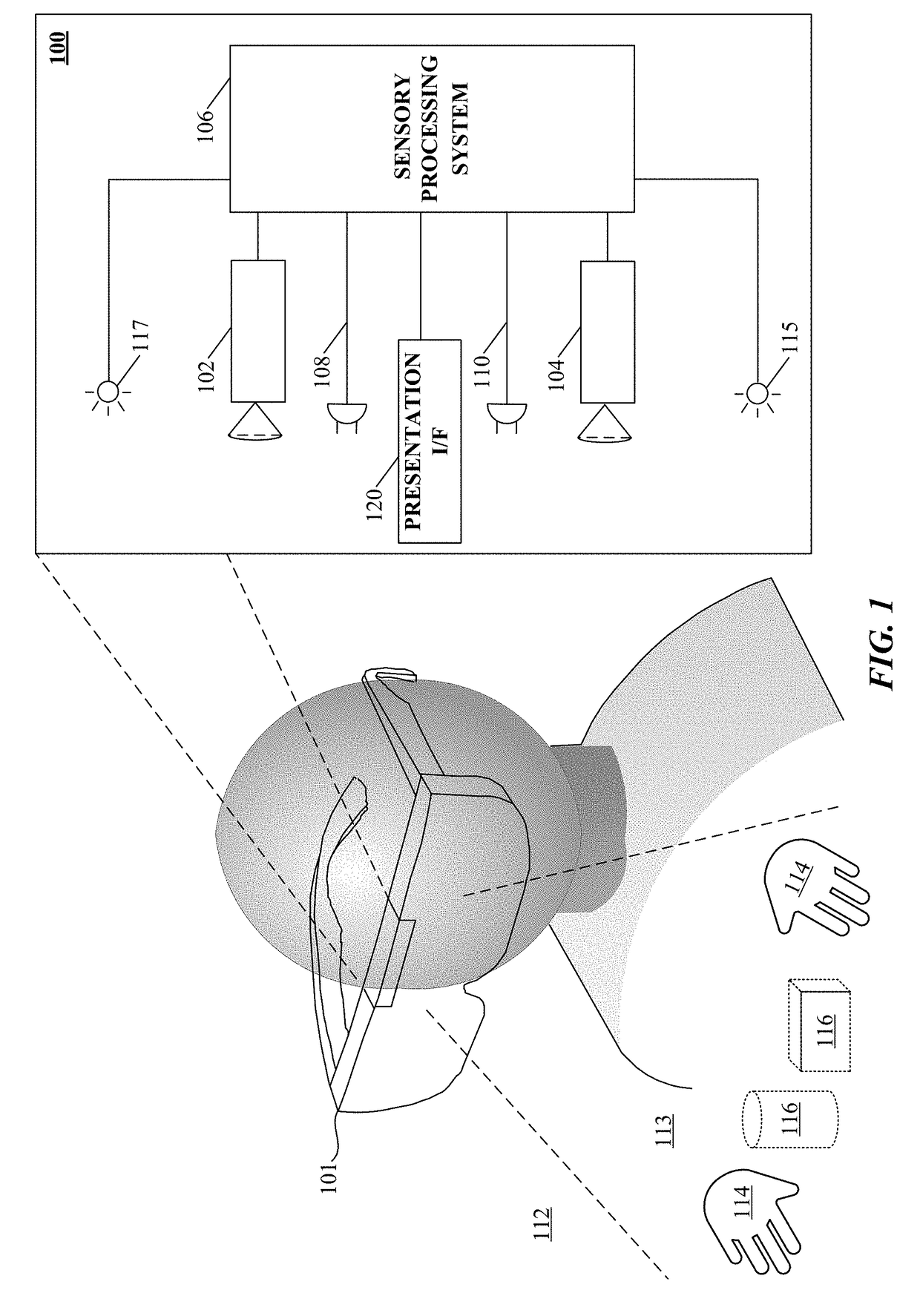

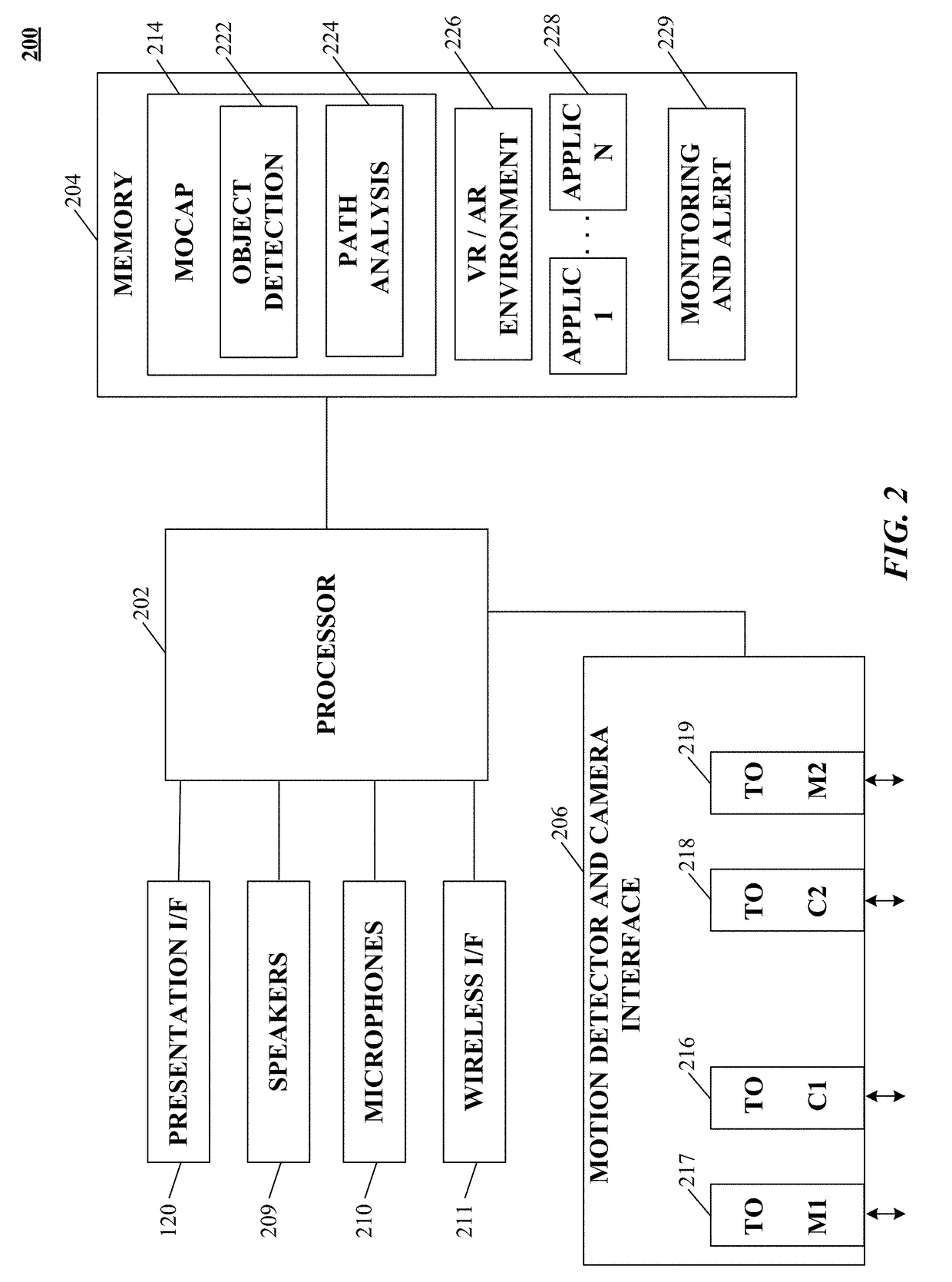

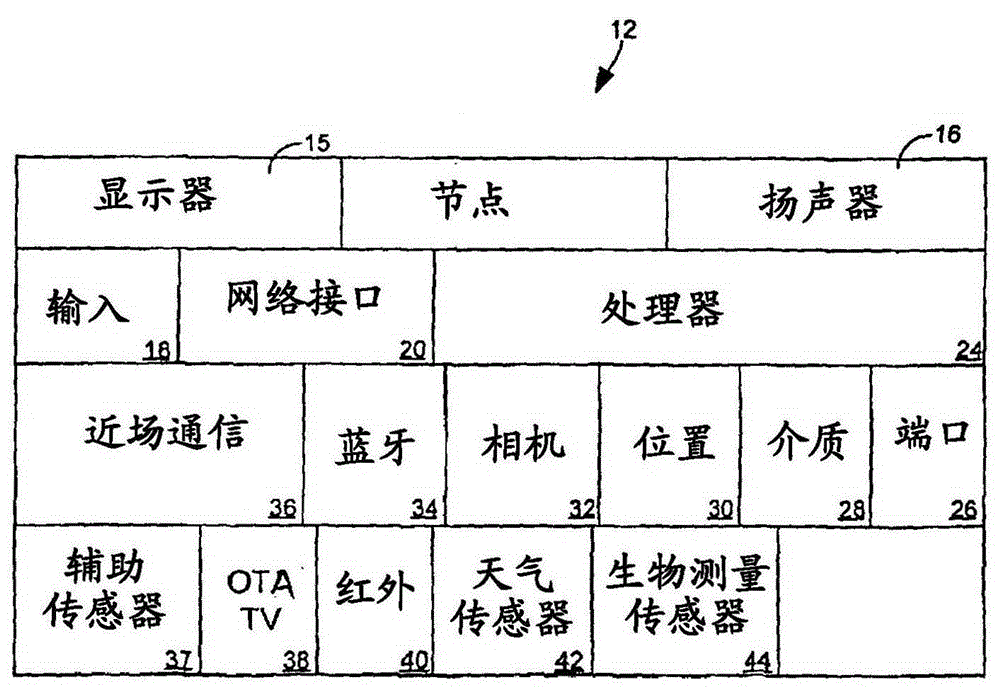

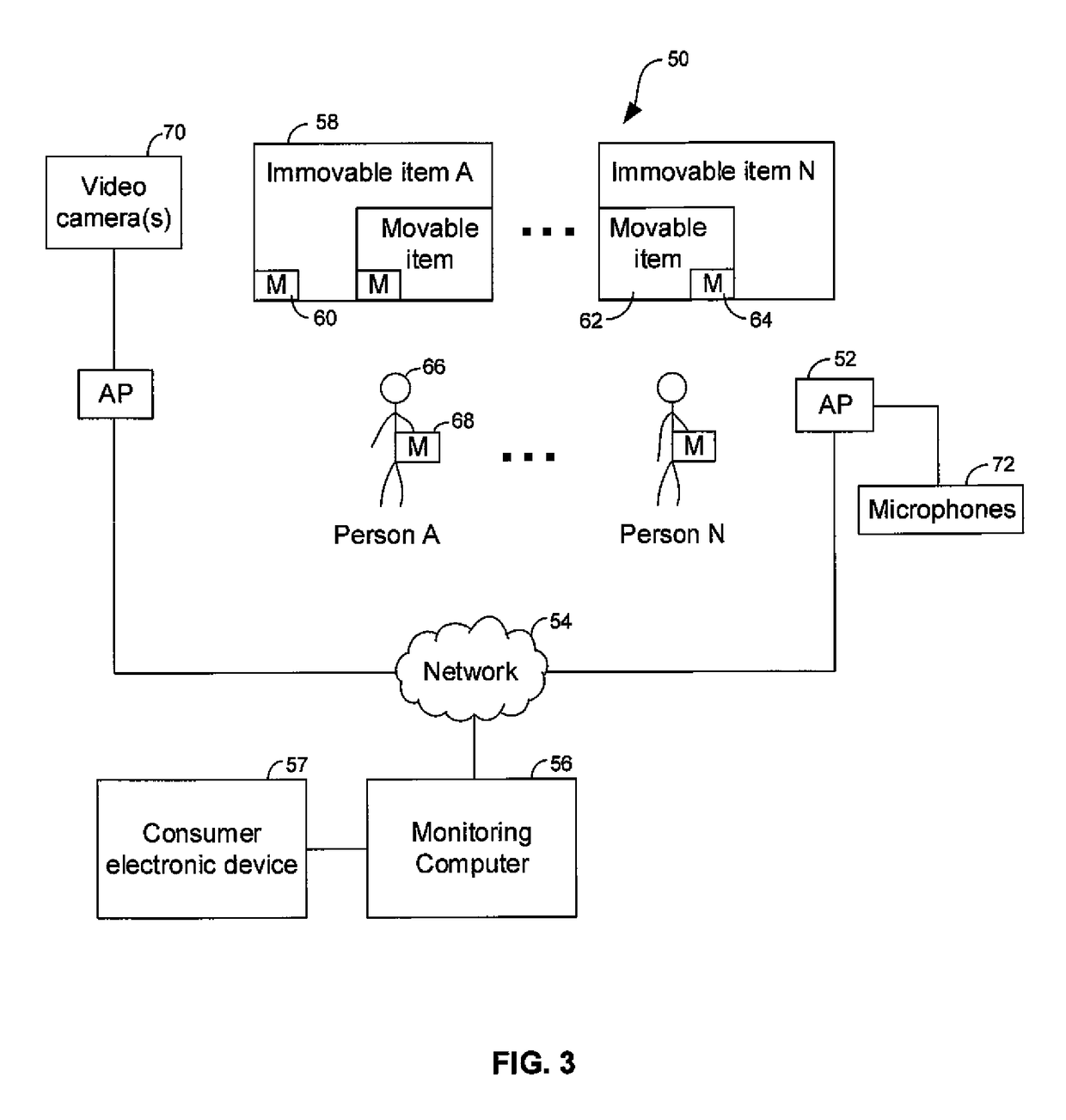

Safety for wearable virtual reality devices via object detection and tracking

ActiveUS9754167B1Improve securityReduce riskImage enhancementImage analysisObject basedUnsafe condition

The technology disclosed can provide improved safety by detecting potential unsafe conditions (e.g., collisions, loss of situational awareness, etc.) confronting the user of a wearable (or portable) sensor configured to capture motion and / or determining the path of an object based on imaging, acoustic or vibrational waves. Implementations can enable improved safety to users of virtual reality for machine control and / or machine communications applications using wearable (or portable) devices, e.g., head mounted displays (HMDs), wearable goggles, watch computers, smartphones, and so forth, or mobile devices, e.g., autonomous and semi-autonomous robots, factory floor material handling systems, autonomous mass-transit vehicles, automobiles (human or machine driven), and so forth, equipped with suitable sensors and processors employing optical, audio or vibrational detection.

Owner:ULTRAHAPTICS IP TWO LIMITED

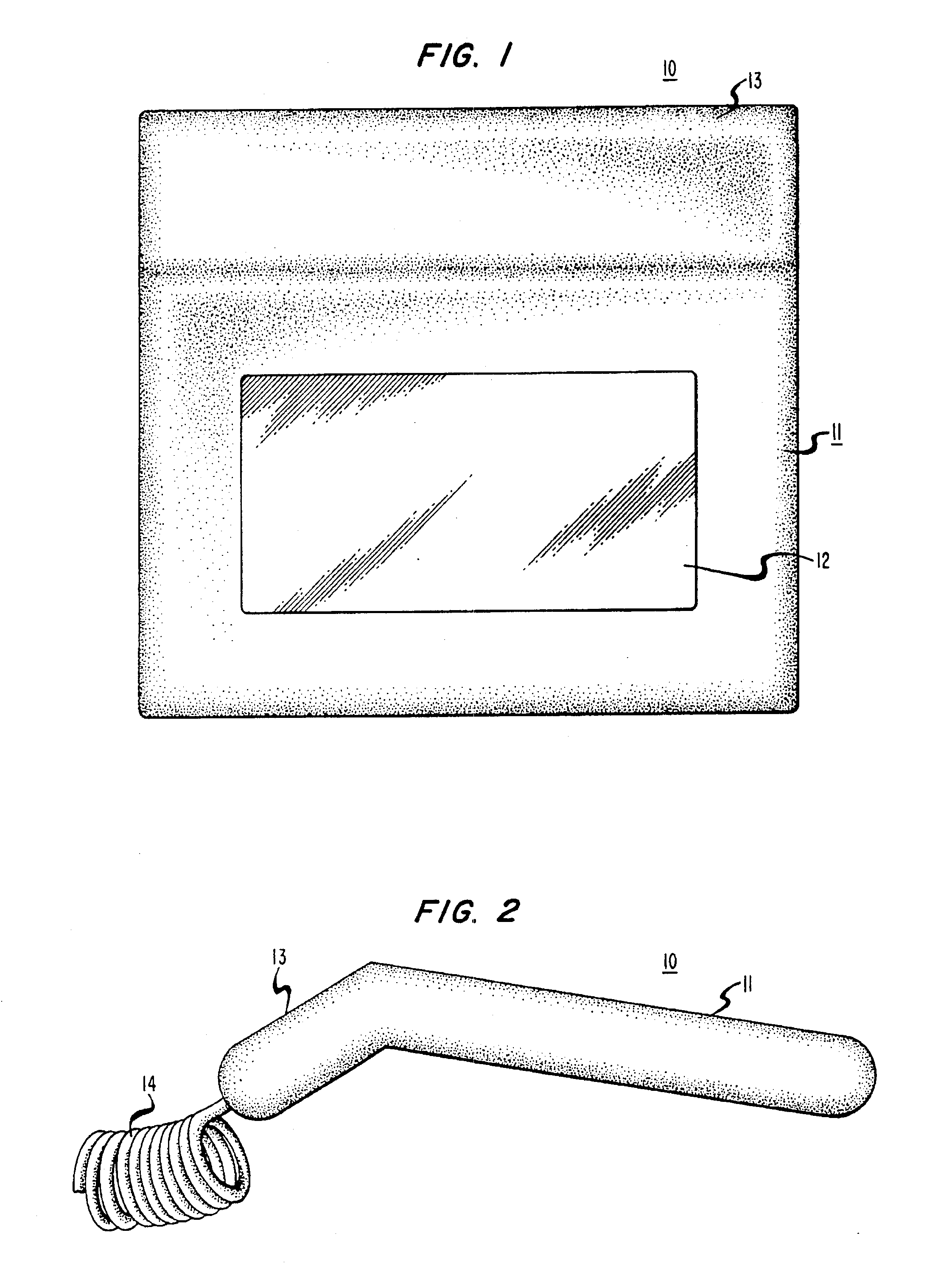

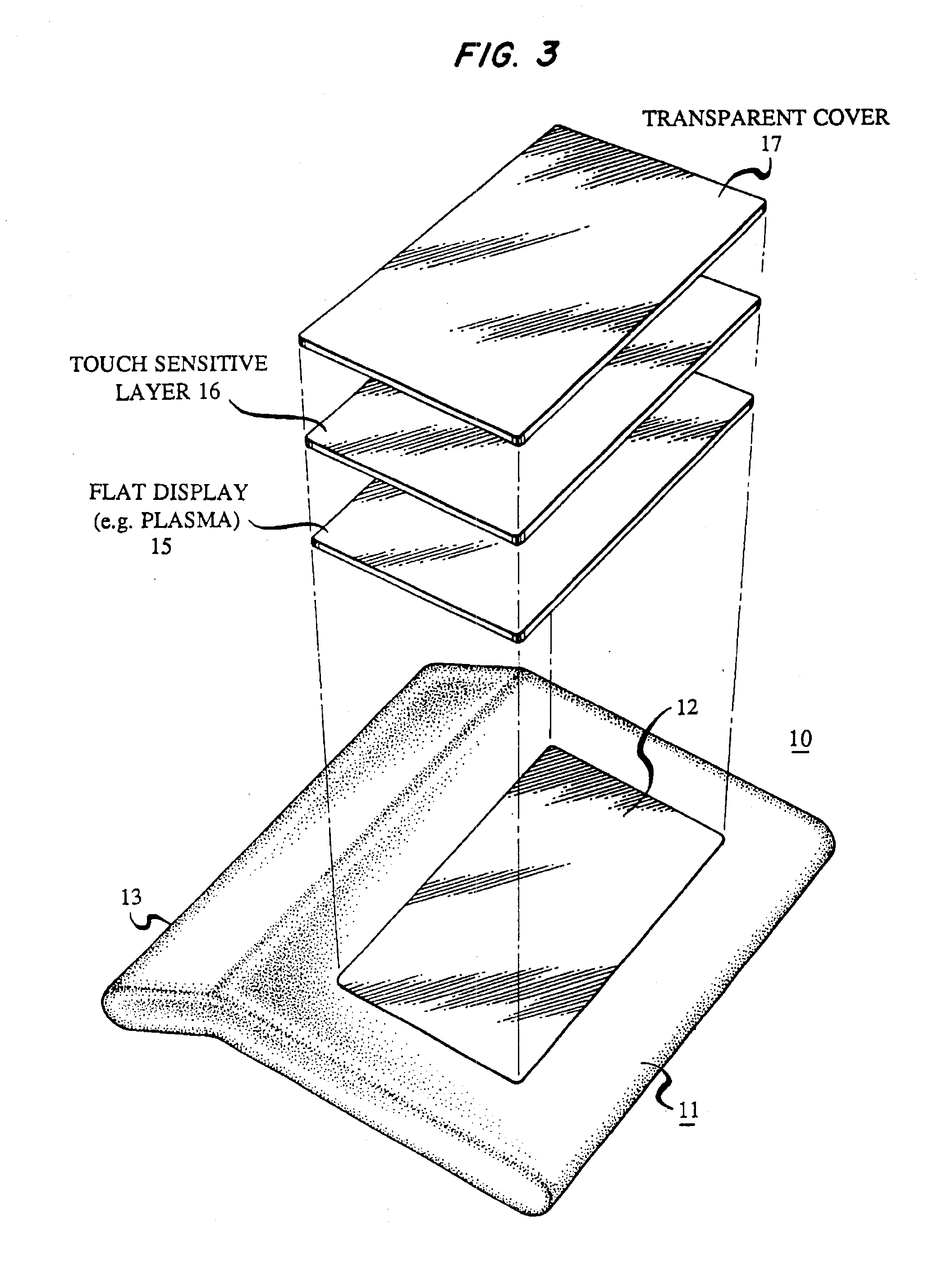

Computer interface device

InactiveUSRE38419E1Complex computing capabilityLarge Data BasesTransmission systemsDigital data processing detailsControl signalFactory floor

A computer terminal device includes a flat screen display element and a touch-sensitive element. Simulated keyboards can be displayed on the display element and, in response to the touching of the simulated keys, generate appropriate control signals. The same flat screen display can also be used to display computer output, either the result of calculations or the result of information retrieval requests. The slim silhouette of this terminal makes it ideal for hostile environments such as the factory floor or the hospital room.

Owner:NCR CORP

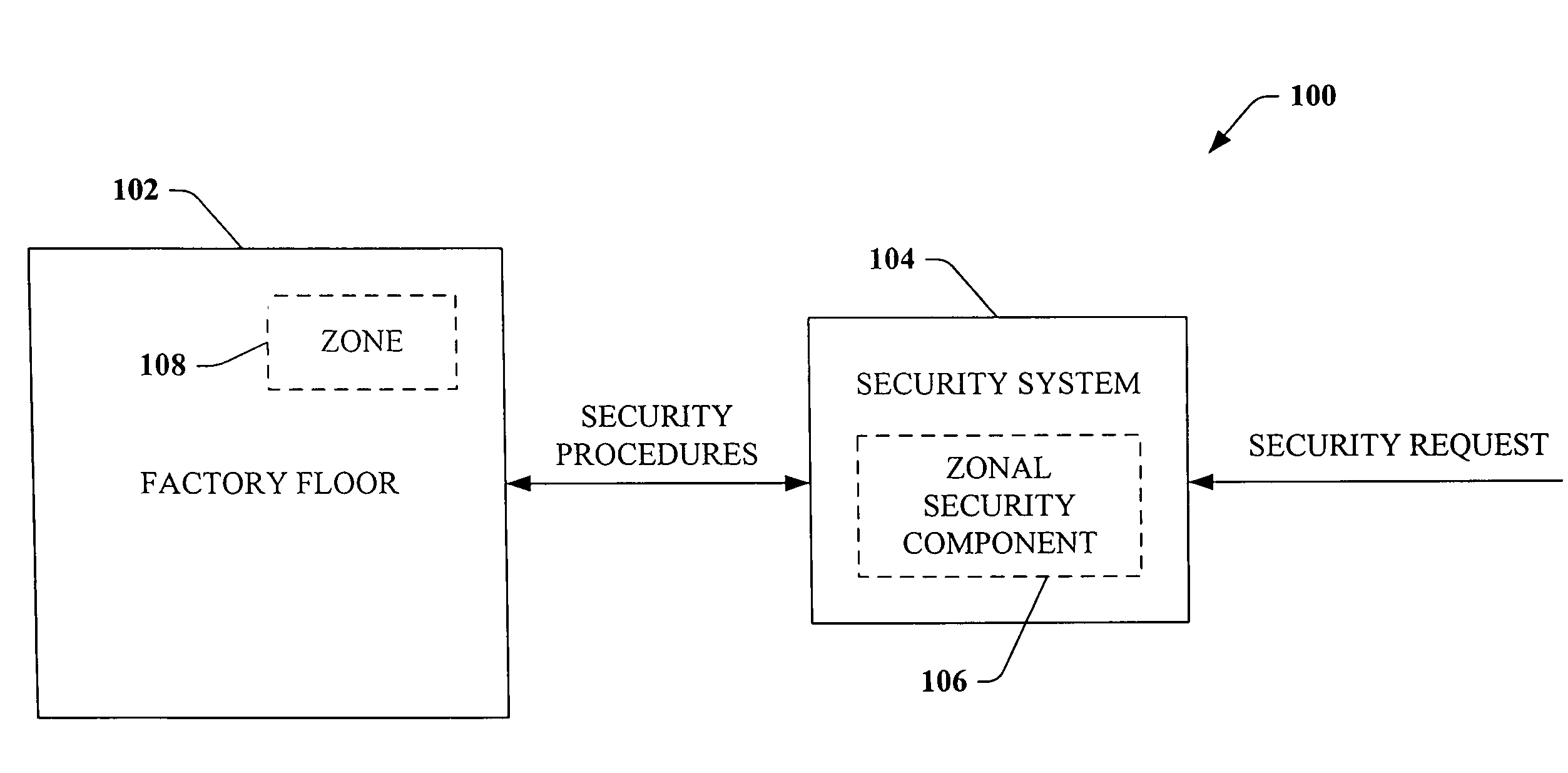

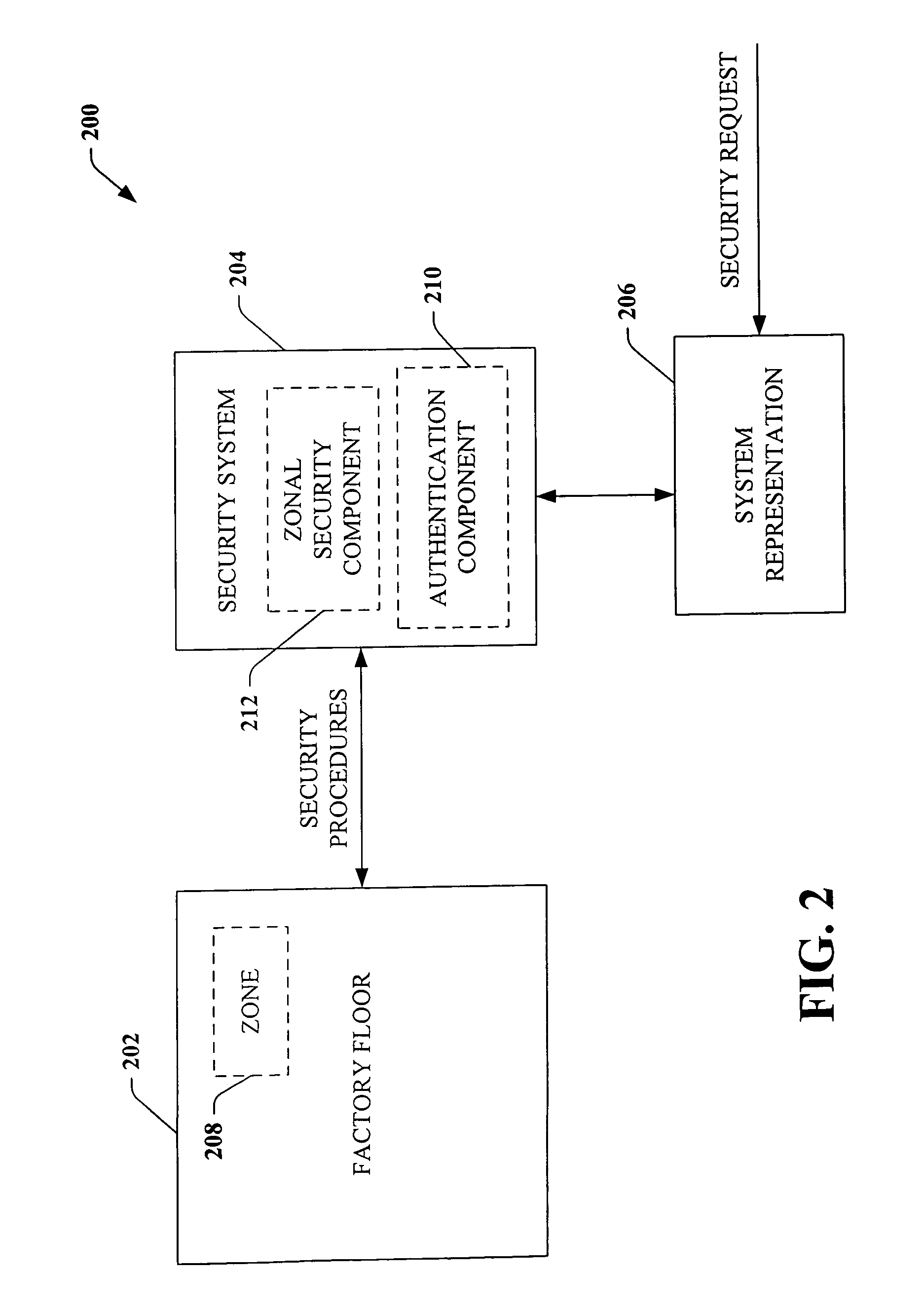

Scalable and flexible information security for industrial automation

ActiveUS8132225B2Compromising performance and throughput and securityImprove securityDigital data processing detailsTechnology managementFactory floorInformation security

A security system that relates to industrial automation security comprises a component that receives a request to modify security relating to a zone of a factory floor, the zone being less than an entirety of the factory floor. A zonal security component generates security procedures for the zone, the security procedures differ from security procedures implemented on the factory floor outside the zone.

Owner:ROCKWELL AUTOMATION TECH

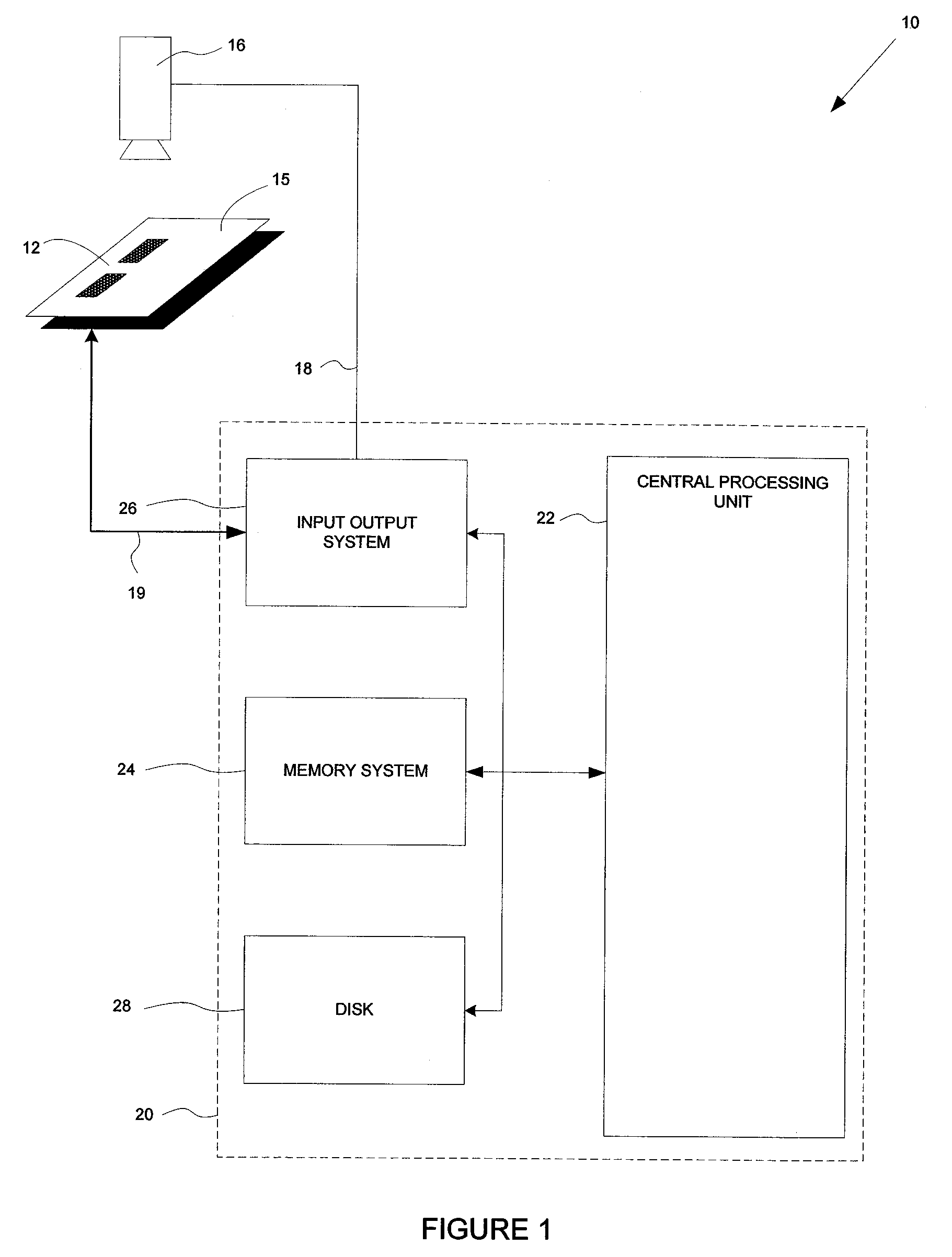

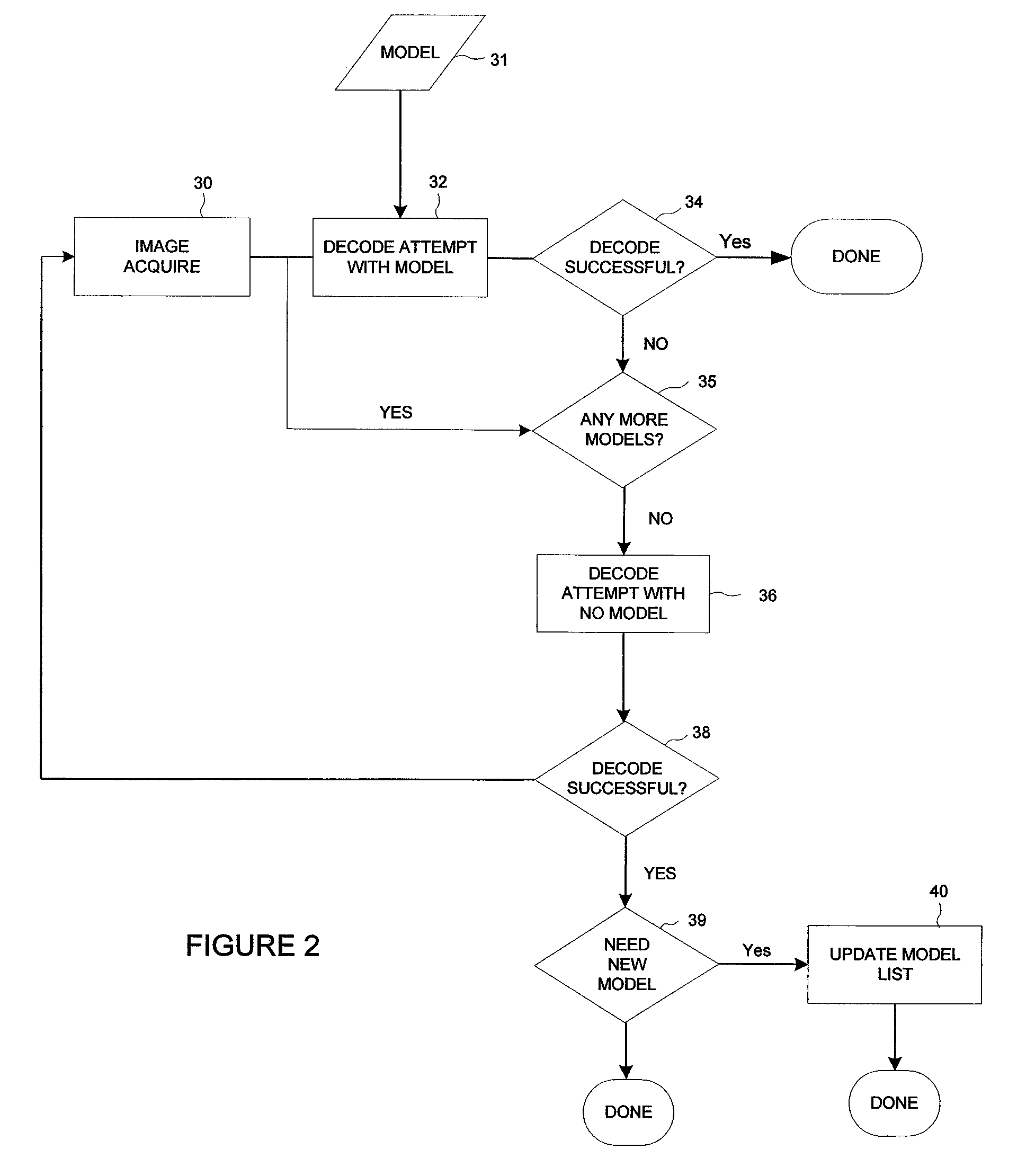

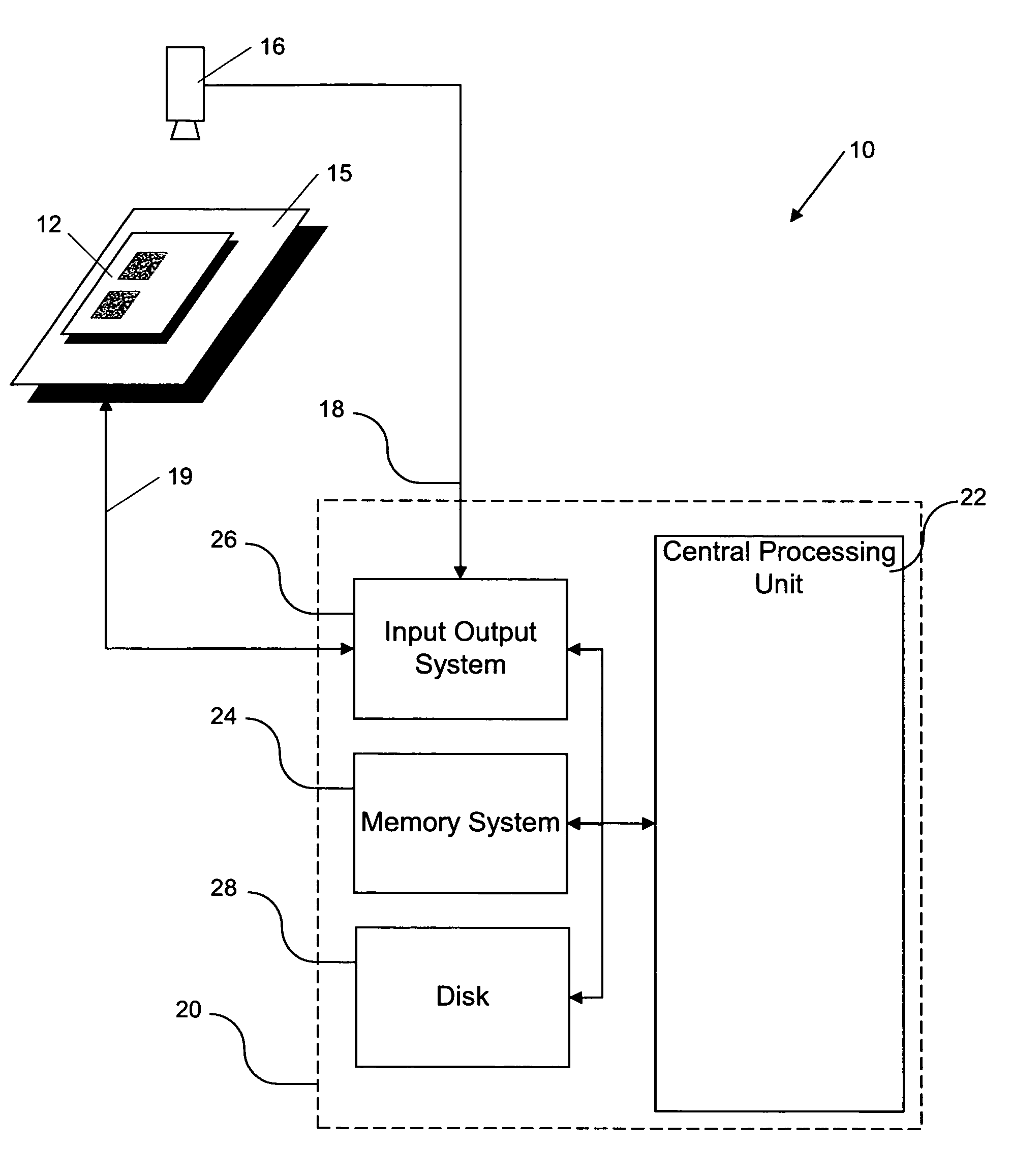

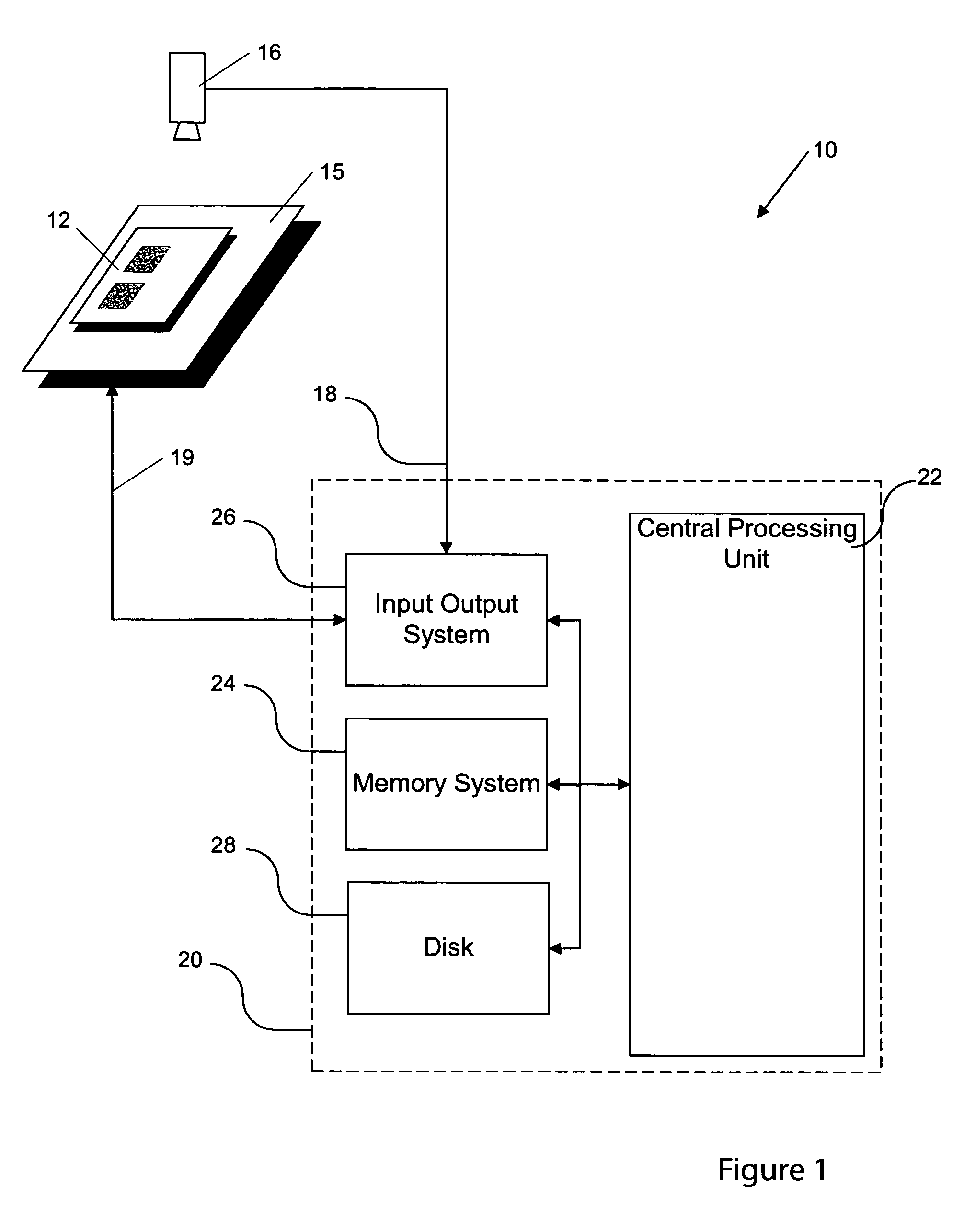

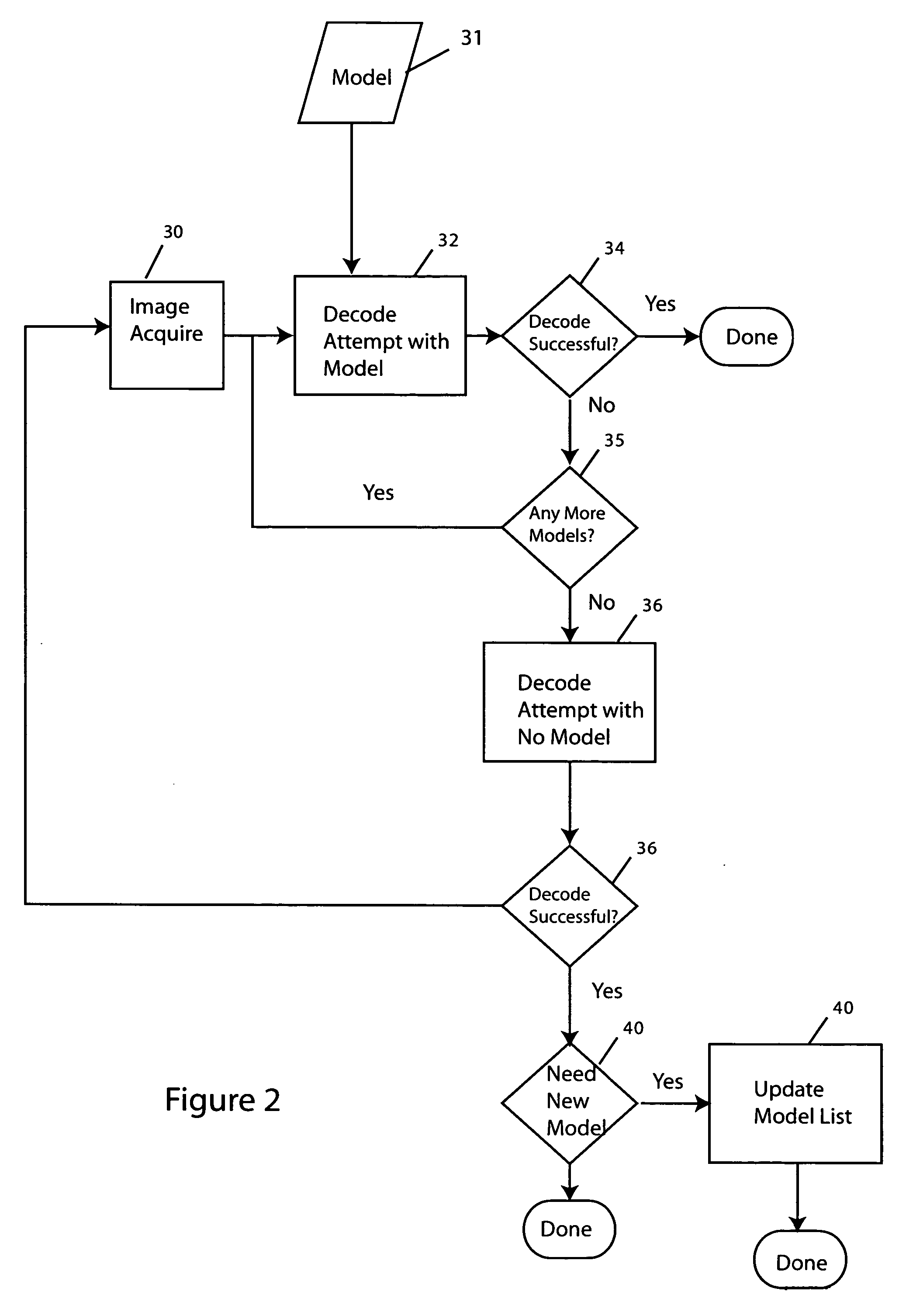

Methods and apparatus for reading bar code identifications

InactiveUS7175090B2Speed bar code readingSave resourcesTransmission systemsCharacter and pattern recognitionProgramming languageFactory floor

The invention provides methods and appartaus for analysis of images of two-dimensional (2D) bar codes in which a model that has proven successful in decoding of a prior 2D image of a 2D bar code is utilized to speed analysis of images of subsequent 2D bar codes. In its various aspects, the invention can be used in analyzing conventional 2D bar codes, e.g., those complying with Maxicode and DataMatrix standards, as well as stacked linear bar codes, e.g., those utilizing the Codablock symbology. Bar code readers, digital data processing apparatus and other devices according to the invention be used, by way of non-limiting example, to decode bar codes on damaged labels, as well as those screened, etched, peened or otherwise formed on manufactured articles (e.g., from semiconductors to airplane wings). In addition to making bar code reading possible under those conditions, devices utilizing such methods can speed bar code analysis in applications where multiple bar codes of like type are read in succession and / or are read under like circumstances—e.g., on the factory floor, at point-of-sale locations, in parcel deliver and so forth. Such devices can also speed and / or make possible bar code analysis where in applications where multiple bar codes read from a single article—e.g., as in the case of a multiply-encoded airplane propellor or other milled parts. The invention also provides methods and apparatus for optical character recognition and other image-based analysis paralleling the above.

Owner:COGNEX TECH & INVESTMENT

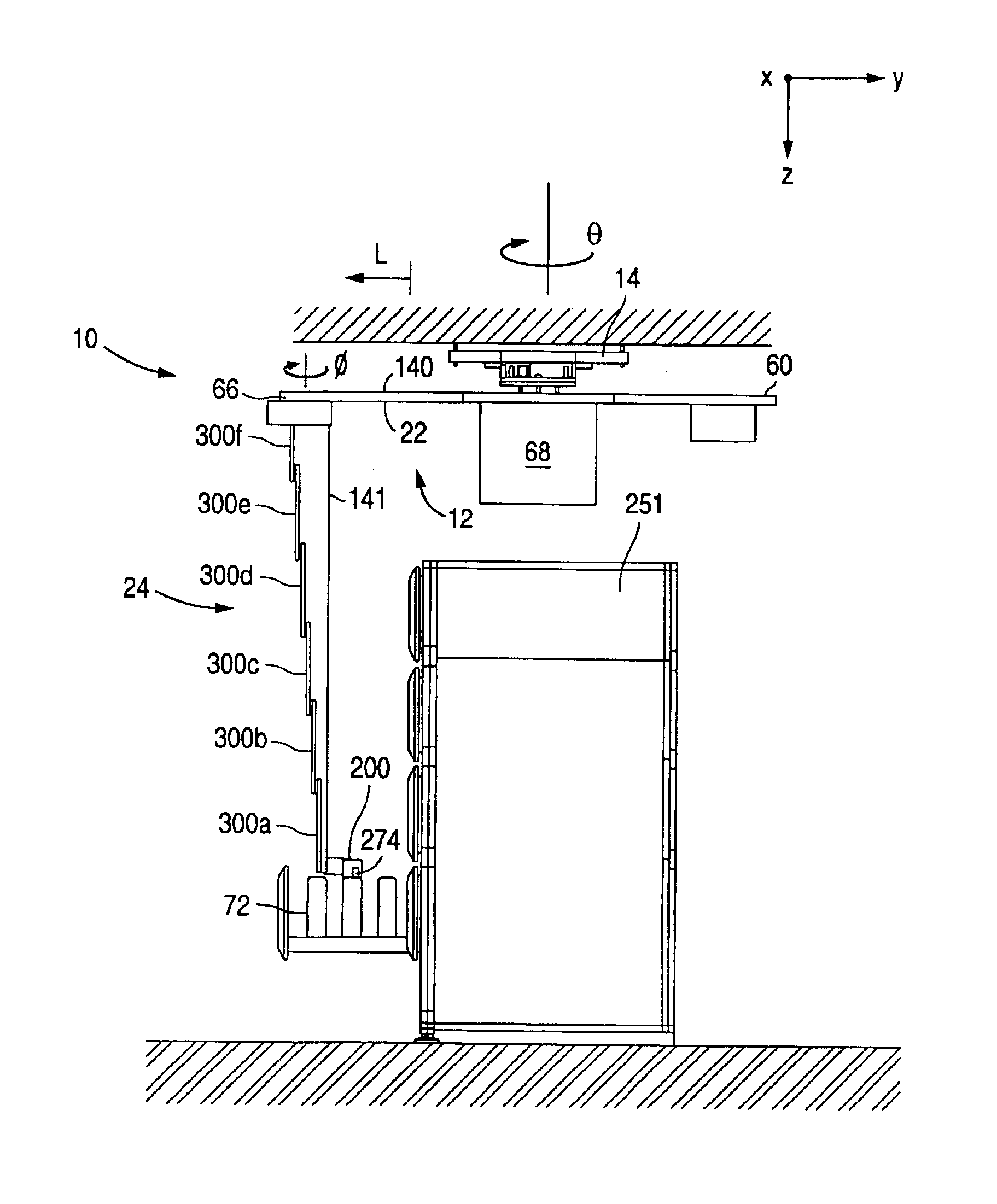

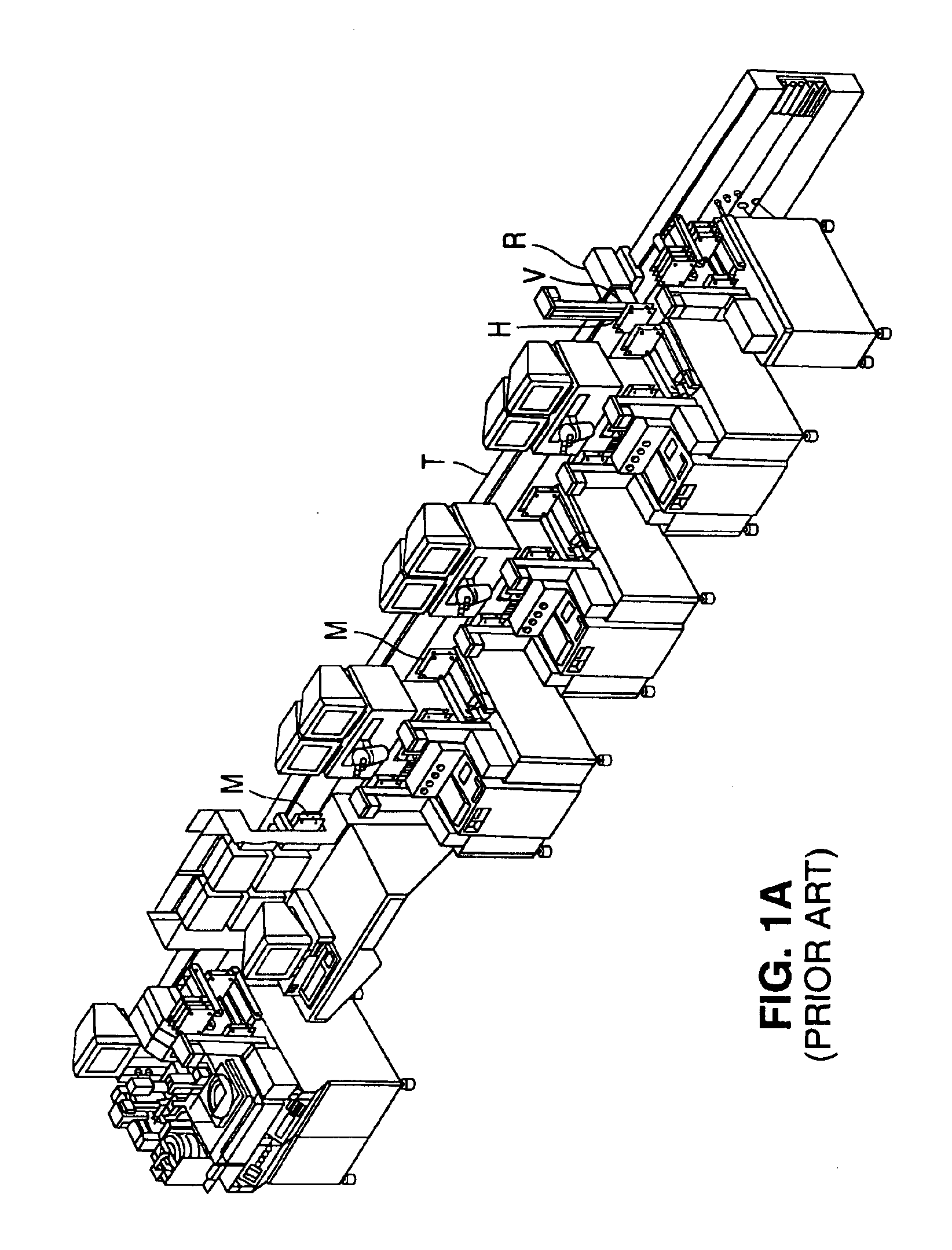

Material transport method

InactiveUS6889813B1Easy loadingImprove space utilizationSemiconductor/solid-state device manufacturingControl devices for conveyorsRange of motionMagnetic tape

A controlled material transport method for carrying materials to and from workstations, test equipment, and processing and assembly tools in a common facility. The present invention includes a rigid “robot vehicle” mountable to a passive track system, which can be routed to service all processing tools on the factory floor. The robot vehicle includes a hoist assembly and gripper assembly, which together perform such functions as picking up magazines, placing magazines, and loading magazines into the processing tools. The hoist assembly is capable of functioning in an operational envelope, which includes any target location within a 3-axis Cartesian coordinate system, to the extent of the range of motion of the hoist assembly. The hoist assembly also provides rigid and controlled z-axis travel, while being compact when retracted. The gripper assembly facilitates loading of the magazines, especially chute style magazines, which are commonly found on many existing processing tools.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Methods and apparatus for reading bar code identifications

InactiveUS20060043186A1Easy to readSpeed bar code readingCharacter and pattern recognitionSensing by electromagnetic radiationDigital dataJet aeroplane

The invention provides methods and appartaus for analysis of images of two-dimensional (2D) bar codes in which a model that has proven successful in decoding of a prior 2D image of a 2D bar code is utilized to speed analysis of images of subsequent 2D bar codes. In its various aspects, the invention can be used in analyzing conventional 2D bar codes, e.g., those complying with Maxicode and DataMatrix standards, as well as stacked linear bar codes, e.g., those utilizing the Codablock symbology. Bar code readers, digital data processing apparatus and other devices according to the invention be used, by way of non-limiting example, to decode bar codes on damaged labels, as well as those screened, etched, peened or otherwise formed on manufactured articles (e.g., from semiconductors to airplane wings). In addition to making bar code reading possible under those conditions, devices utilizing such methods can speed bar code analysis in applications where multiple bar codes of like type are read in succession and / or are read under like circumstances—e.g., on the factory floor, at point-of-sale locations, in parcel deliver and so forth. Such devices can also speed and / or make possible bar code analysis where in applications where multiple bar codes read from a single article—e.g., as in the case of a multiply-encoded airplane propellor or other milled parts. The invention also provides methods and apparatus for optical character recognition and other image-based analysis paralleling the above.

Owner:COGNEX TECH & INVESTMENT

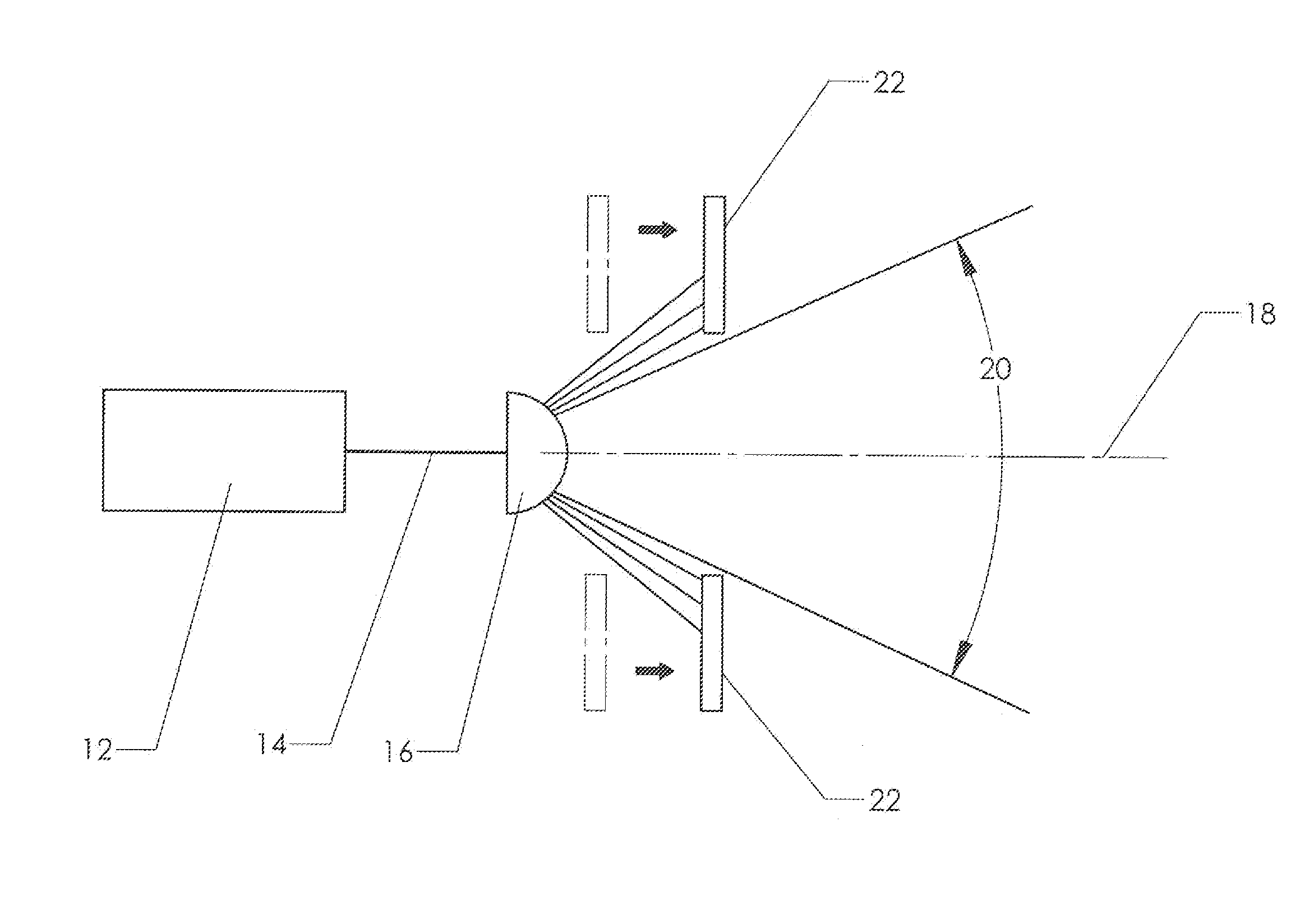

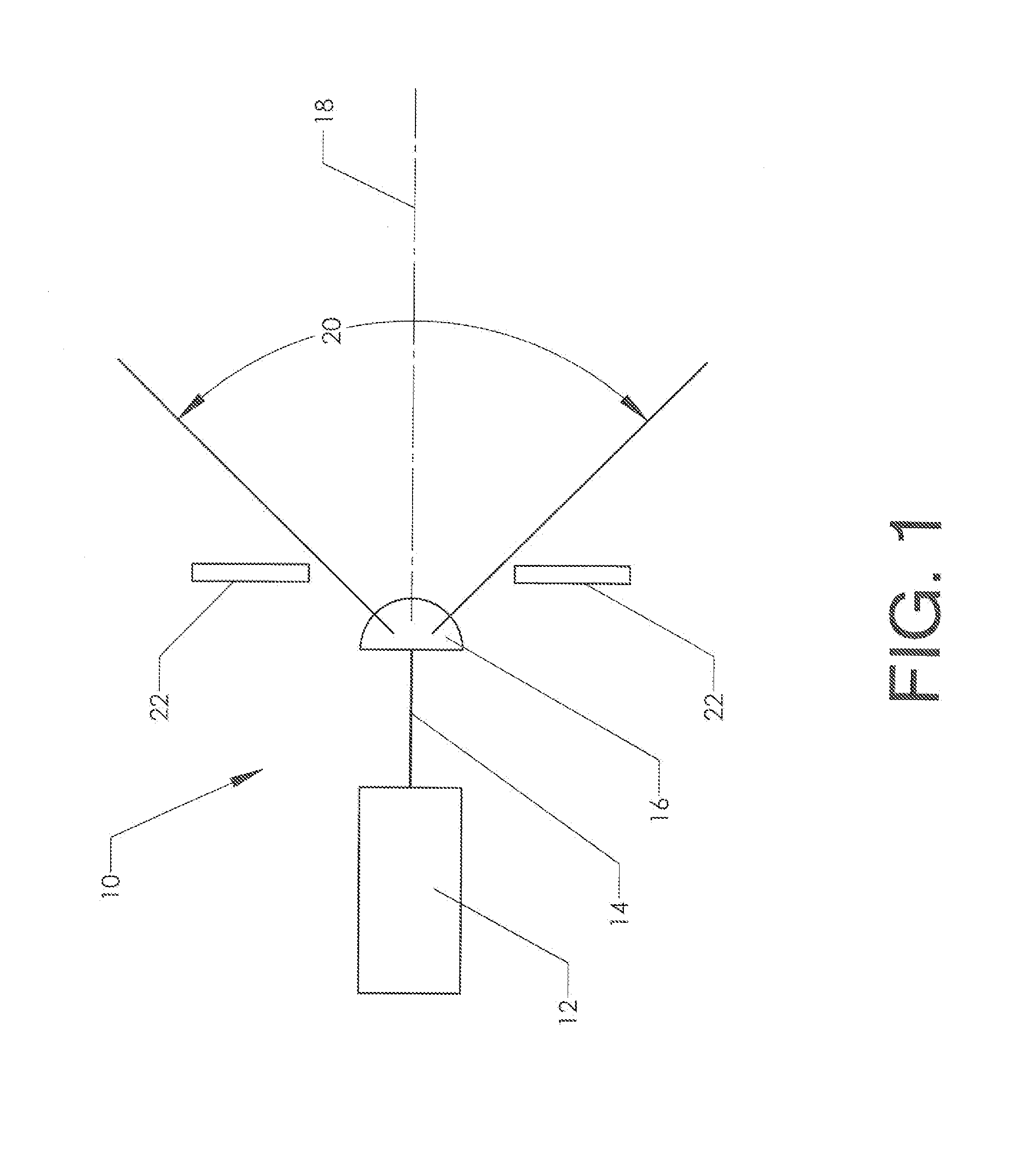

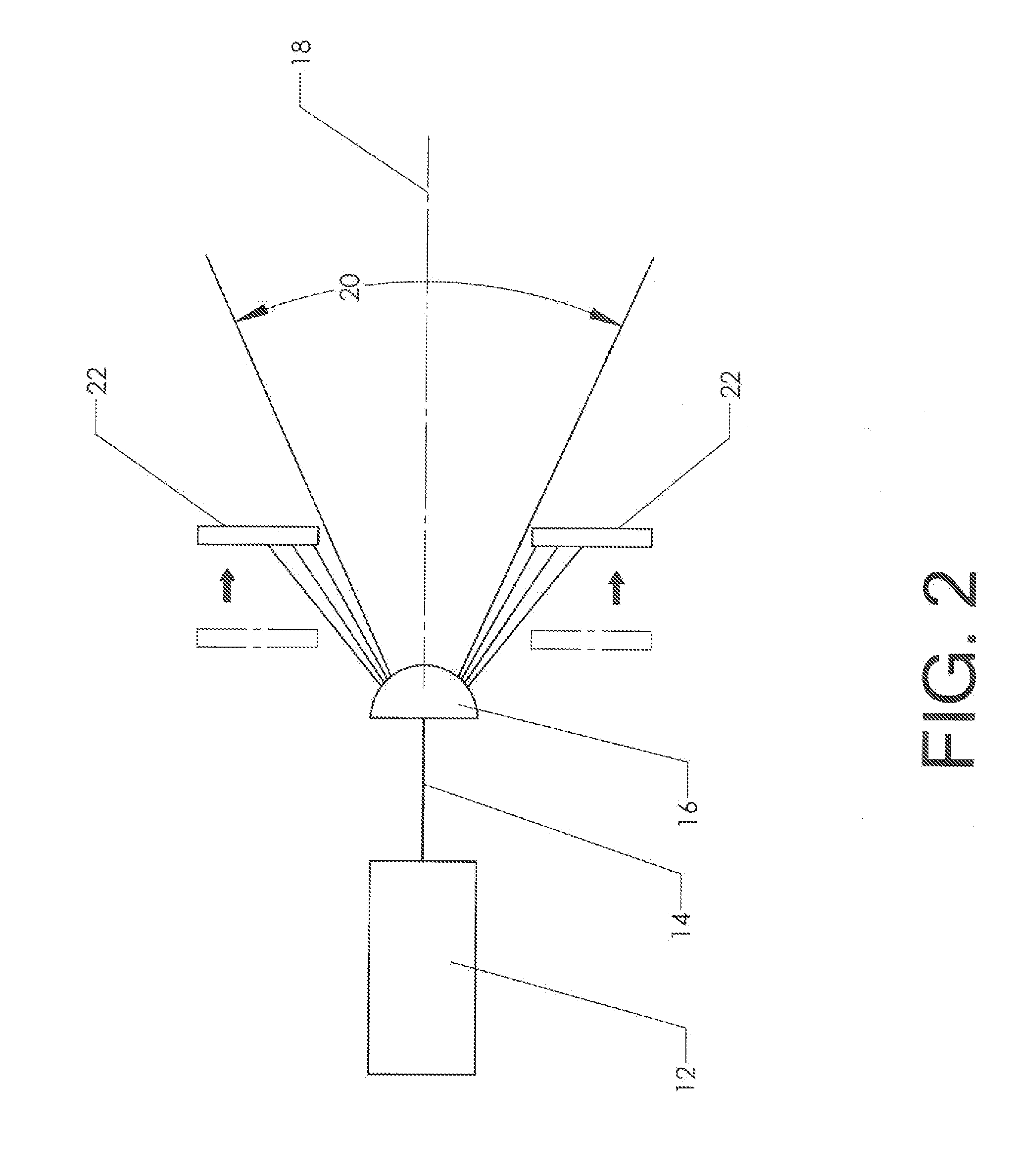

Line projection system

InactiveUS20140207326A1Position/course control in two dimensionsDistance measurementFactory floorLaser light

Owner:QUNOMIC VIRTUAL TECH

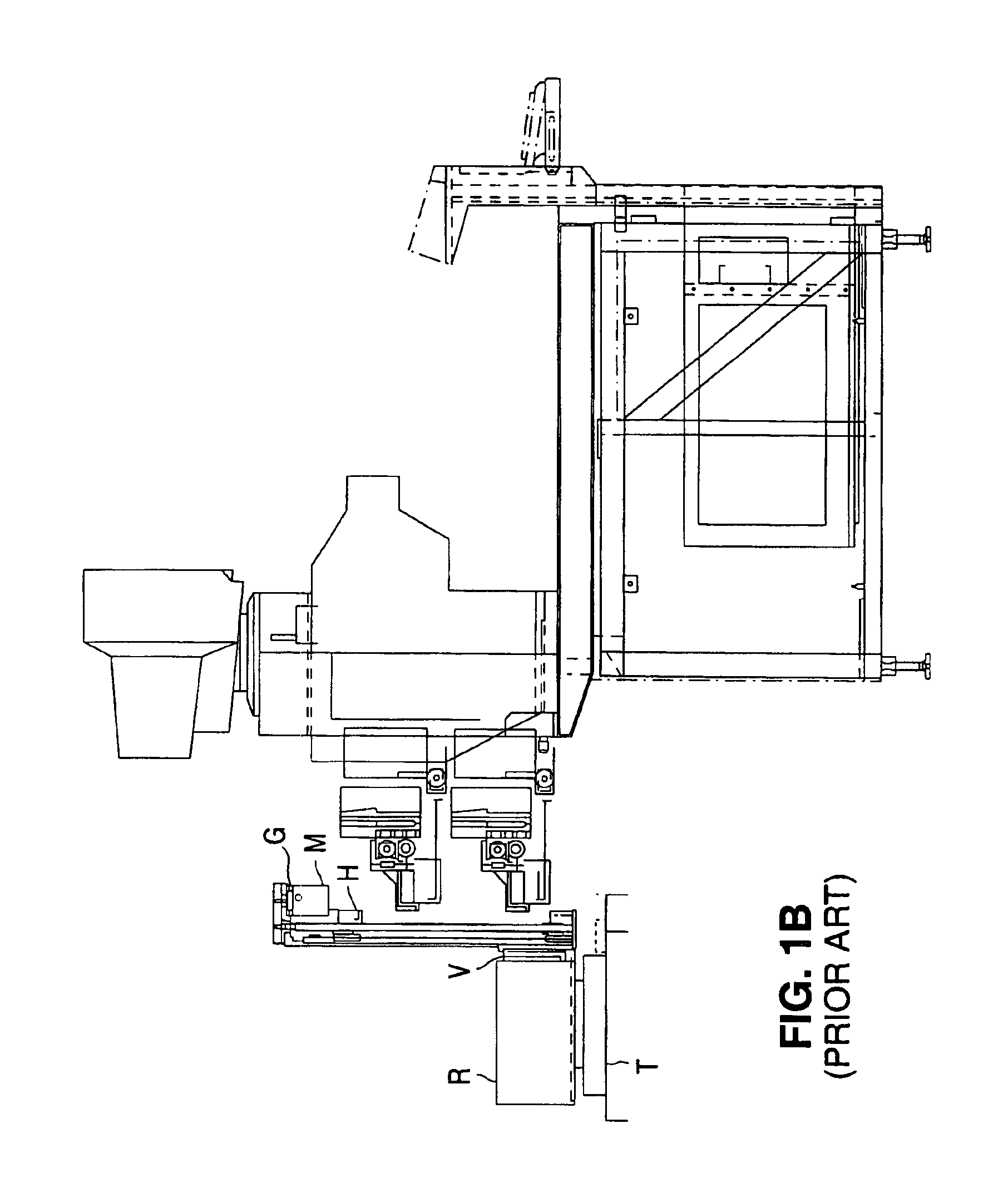

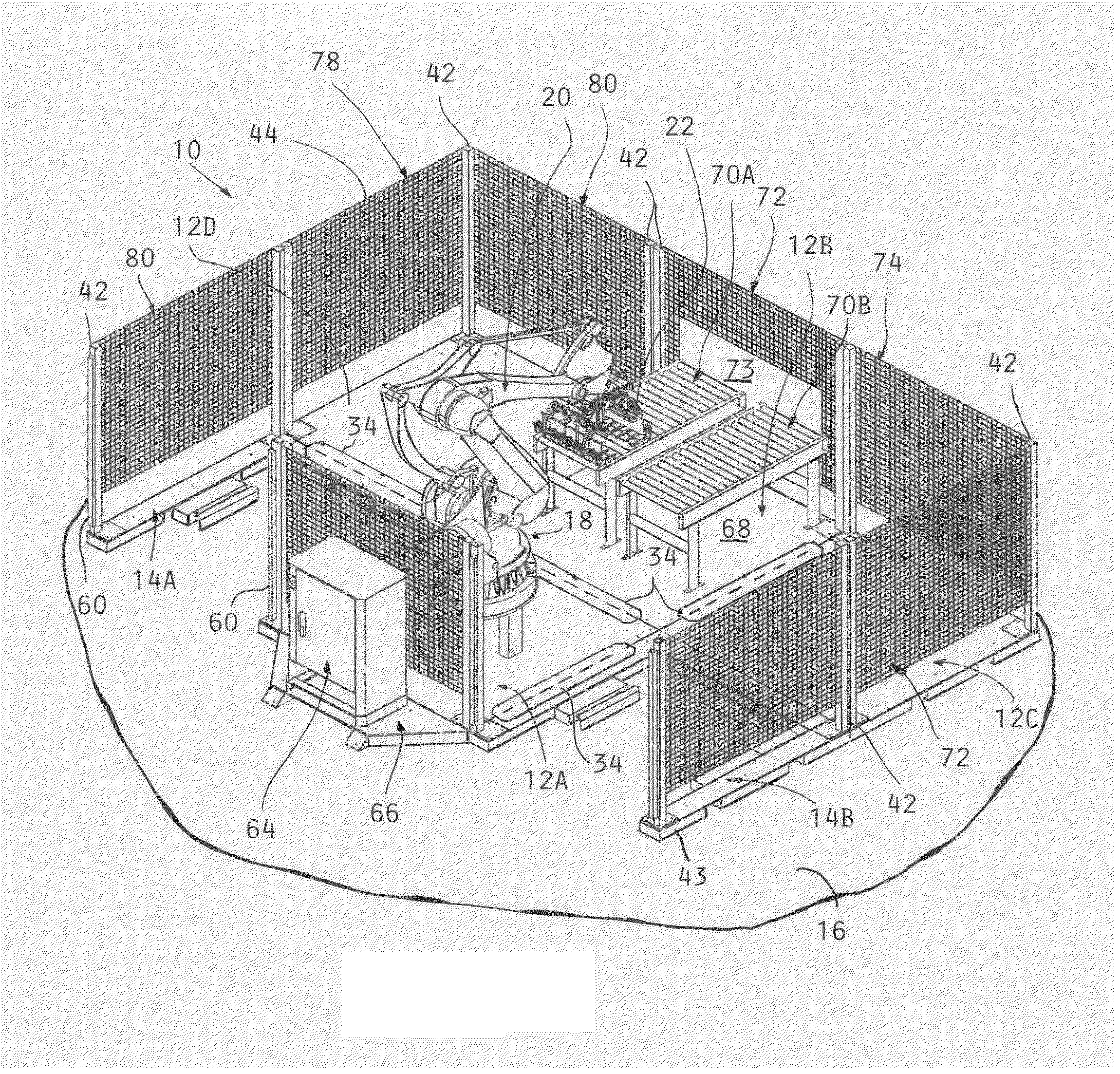

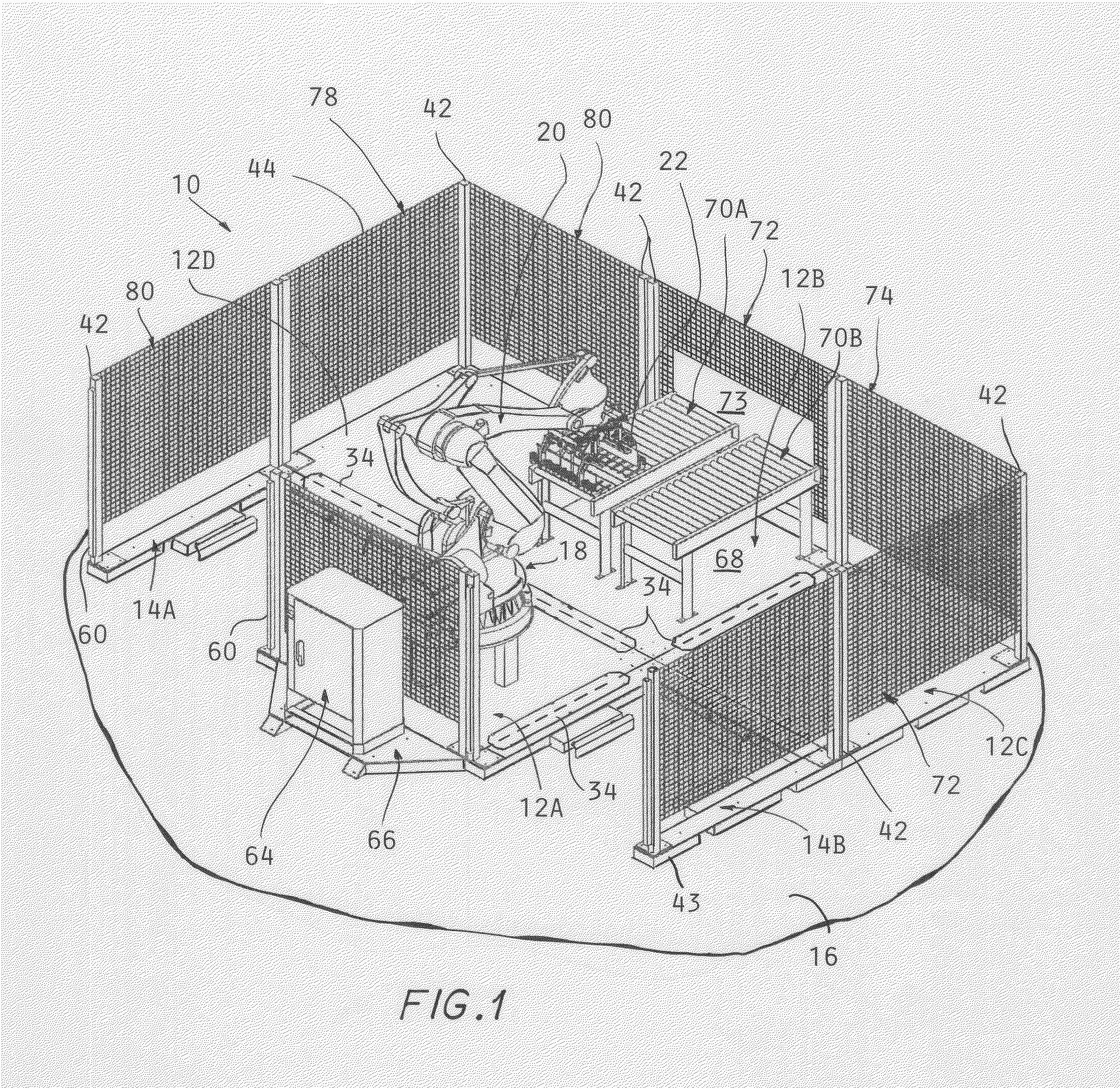

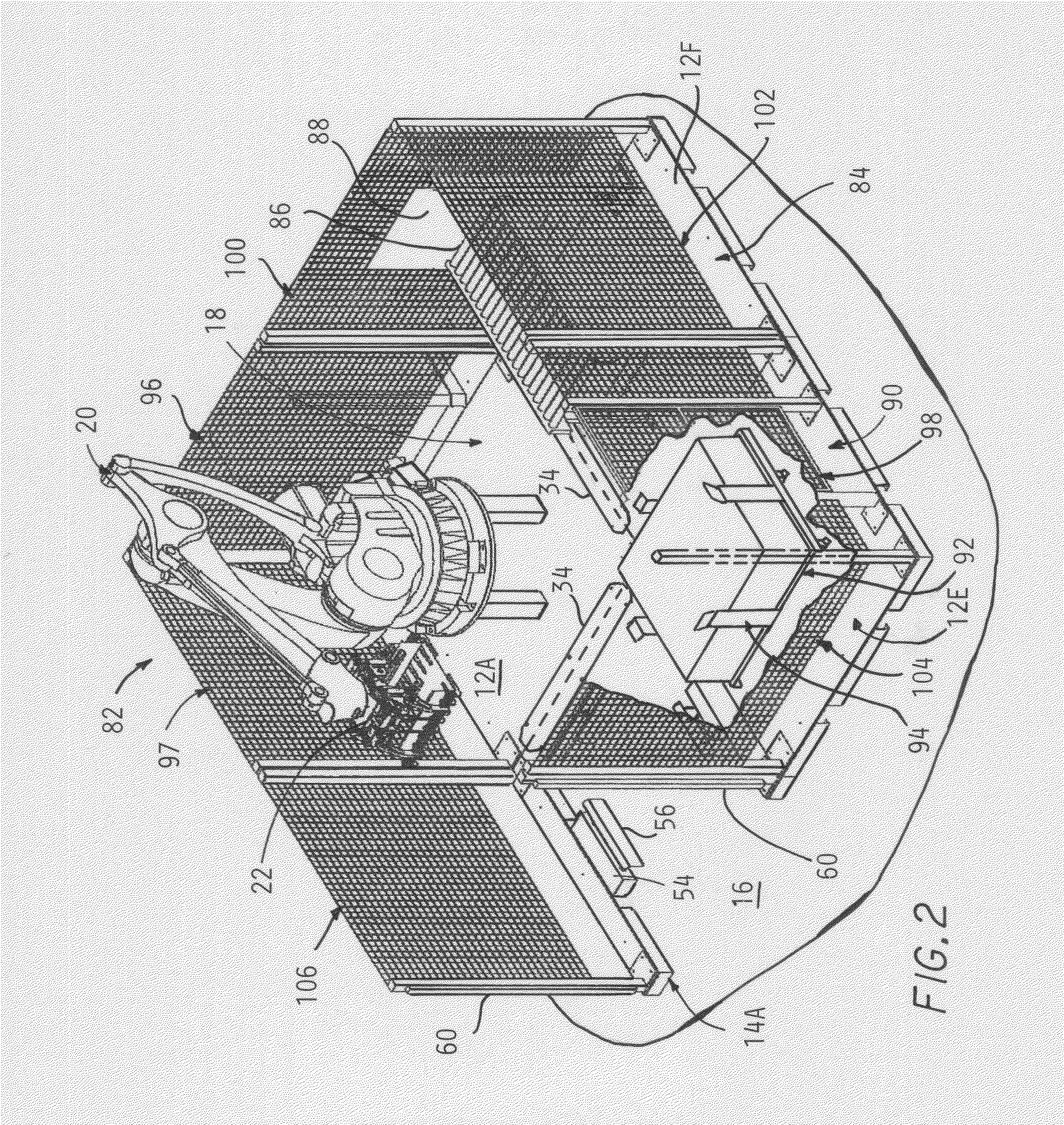

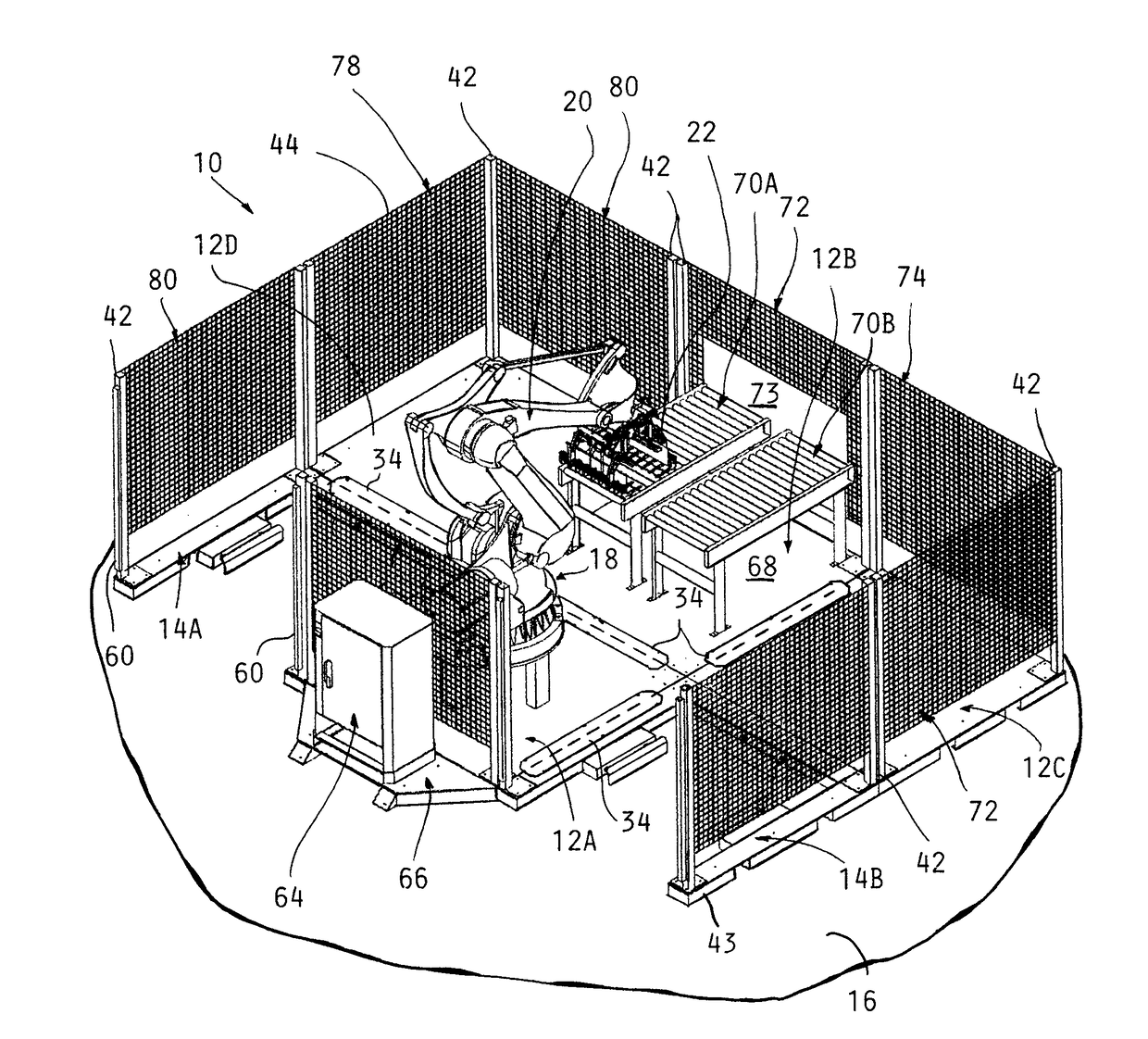

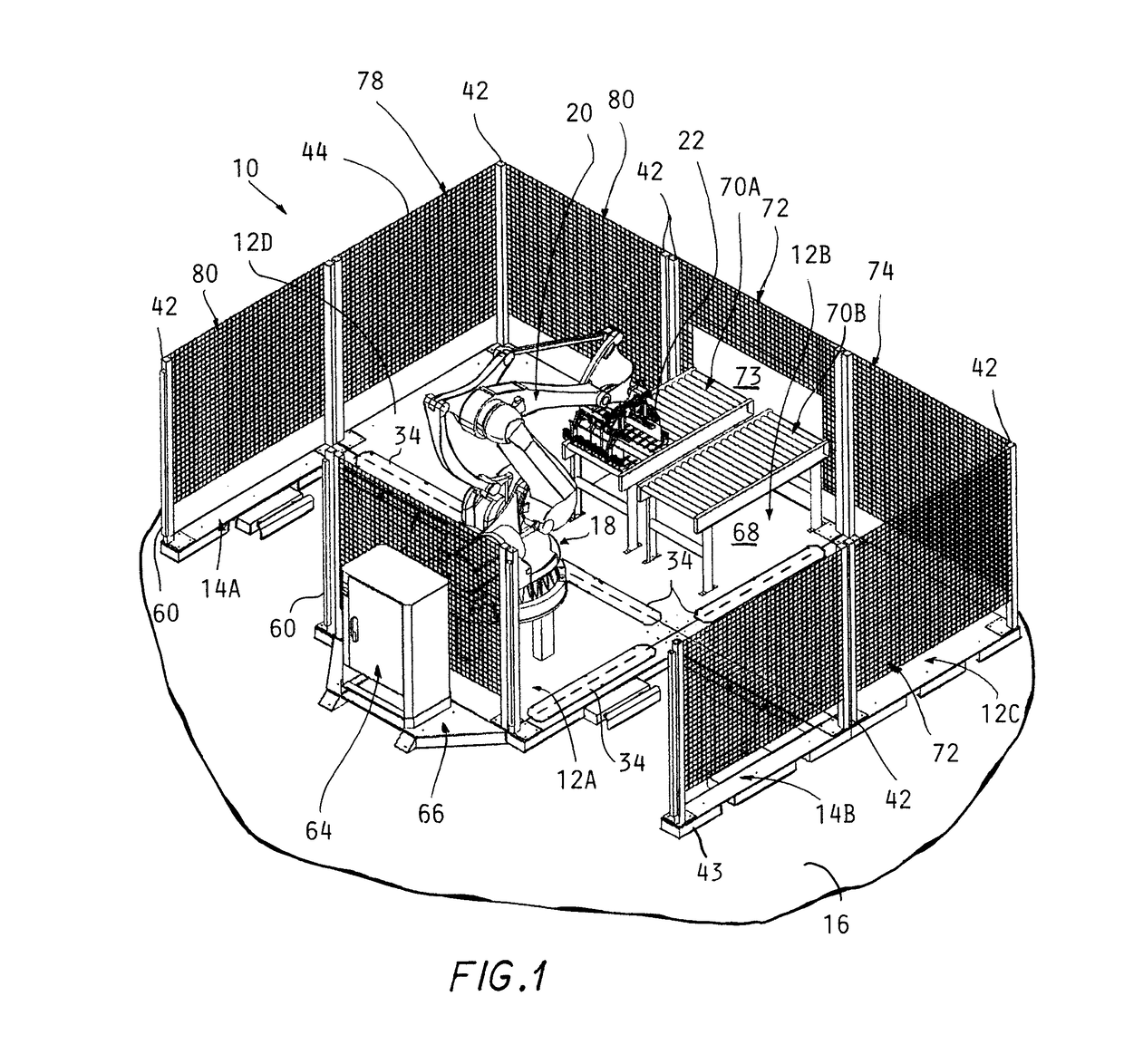

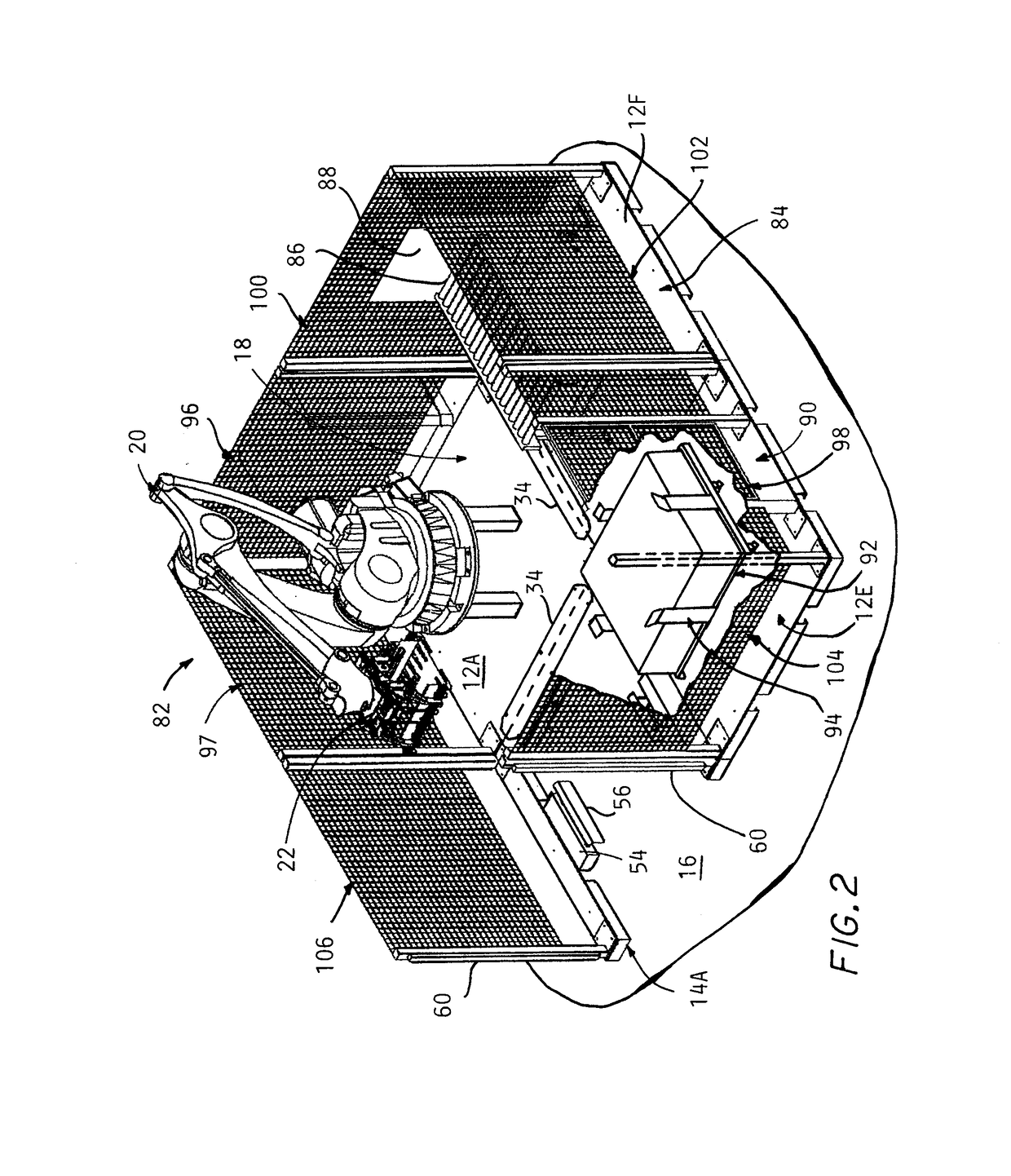

Robotic Palletizer Cell And Method Of Construction

A method of constructing a palletizer cell by providing square platform bases which are assembled into an array in abutment with each other, each platform base mounting a respective component of palletizing equipment, such as a robot, one or more conveyors, a slip sheet bin, a discharge module, etc. with one platform base anchored to the factory floor and the rest attached to one or another of the platform bases to form the array of platform bases thereby properly locating the various equipment with each other by the fitting together of the platform bases. Safety fencing sections are mounted atop one or more outer sides to substantially enclose the space within the palletizer cell. Each platform base is formed with side openings which may be engaged with the tines of a fork lift.

Owner:ROBERTS BRIAN THOMAS

Safety for wearable virtual reality devices via object detection and tracking

ActiveUS20180012074A1Improve securityReduce riskImage enhancementImage analysisUnsafe conditionObject based

The technology disclosed can provide improved safety by detecting potential unsafe conditions (e.g., collisions, loss of situational awareness, etc.) confronting the user of a wearable (or portable) sensor configured to capture motion and / or determining the path of an object based on imaging, acoustic or vibrational waves. Implementations can enable improved safety to users of virtual reality for machine control and / or machine communications applications using wearable (or portable) devices, e.g., head mounted displays (HMDs), wearable goggles, watch computers, smartphones, and so forth, or mobile devices, e.g., autonomous and semi-autonomous robots, factory floor material handling systems, autonomous mass-transit vehicles, automobiles (human or machine driven), and so forth, equipped with suitable sensors and processors employing optical, audio or vibrational detection.

Owner:ULTRAHAPTICS IP TWO LIMITED

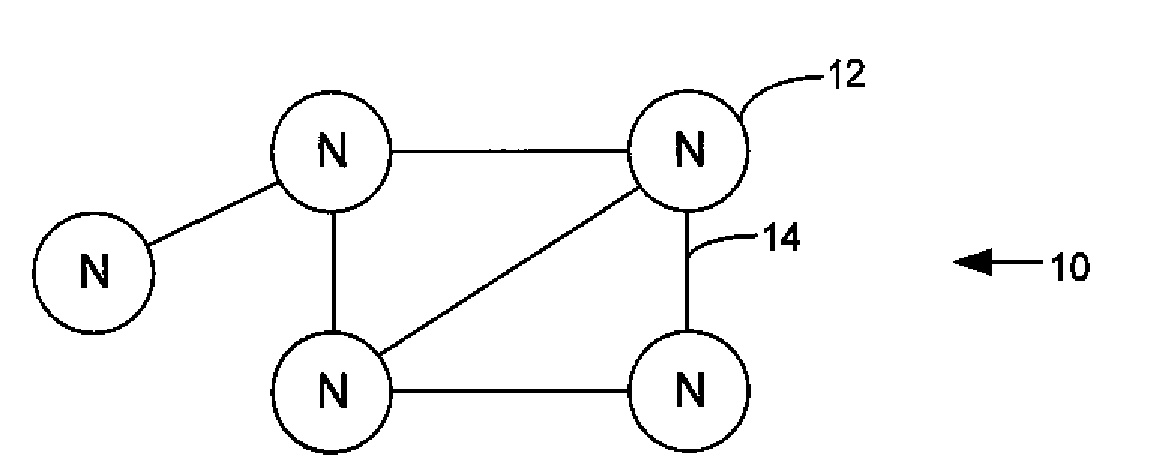

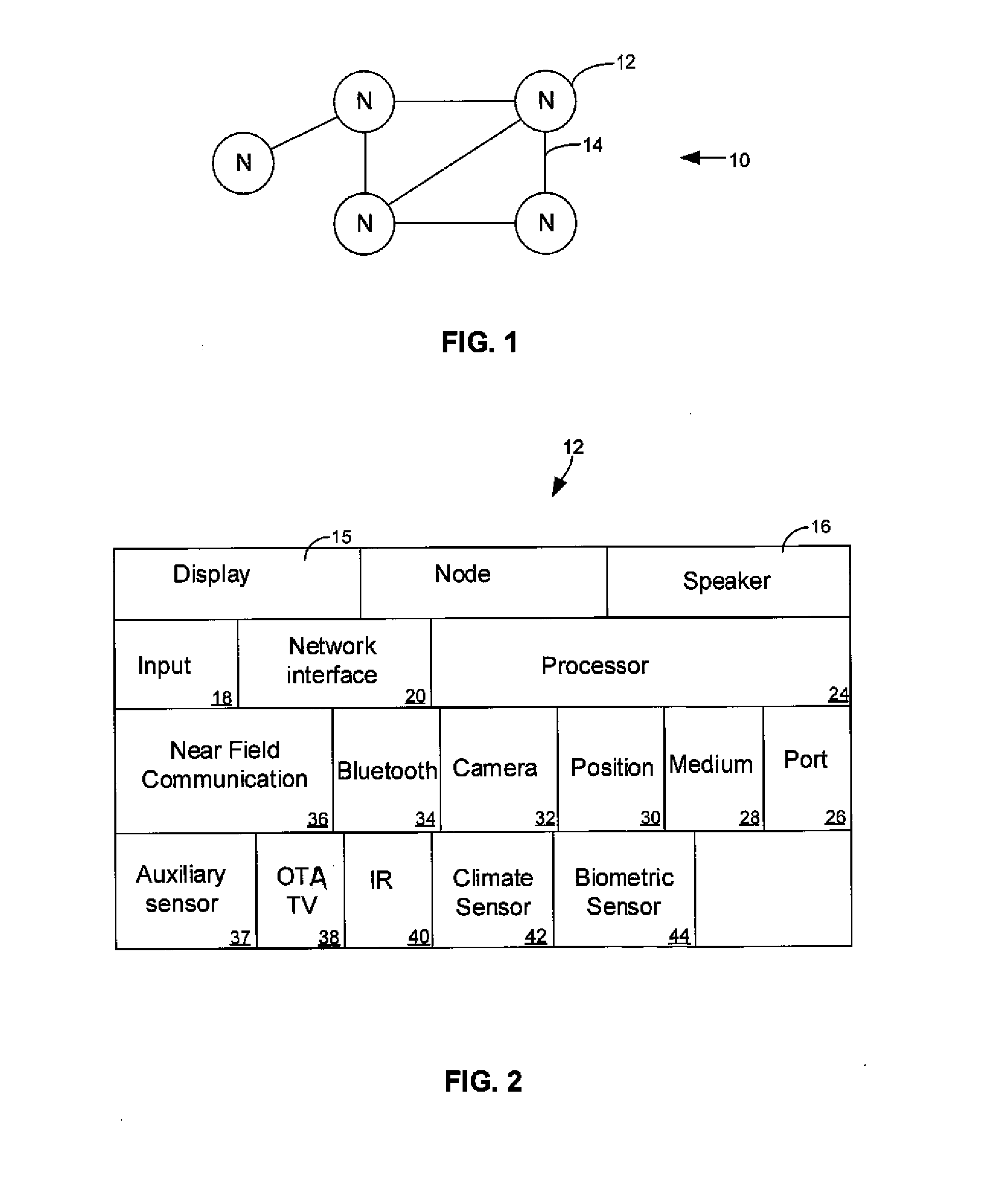

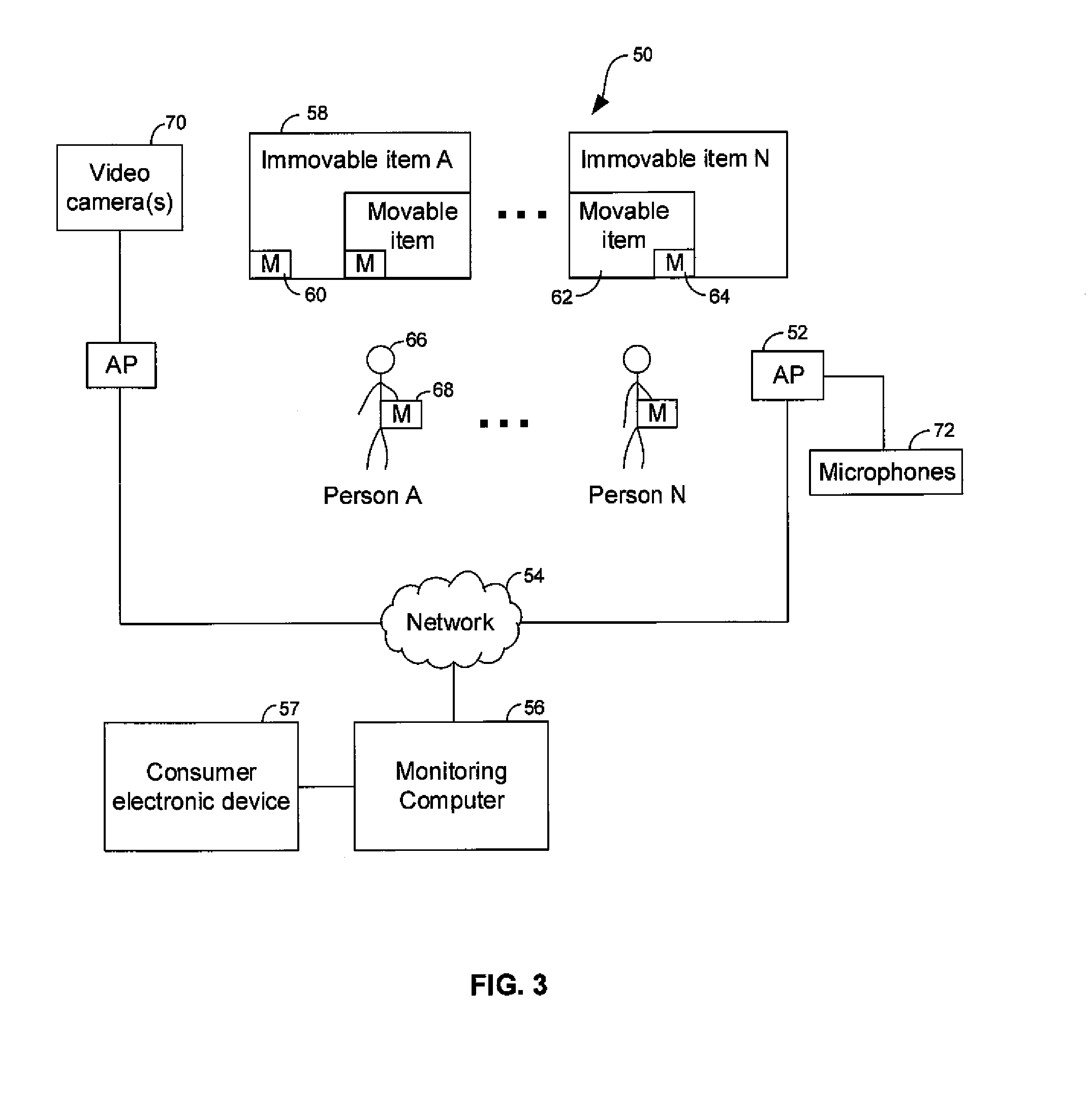

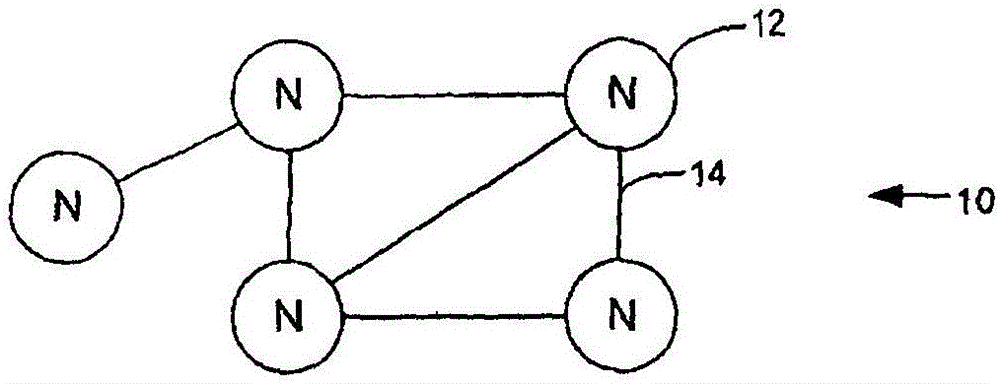

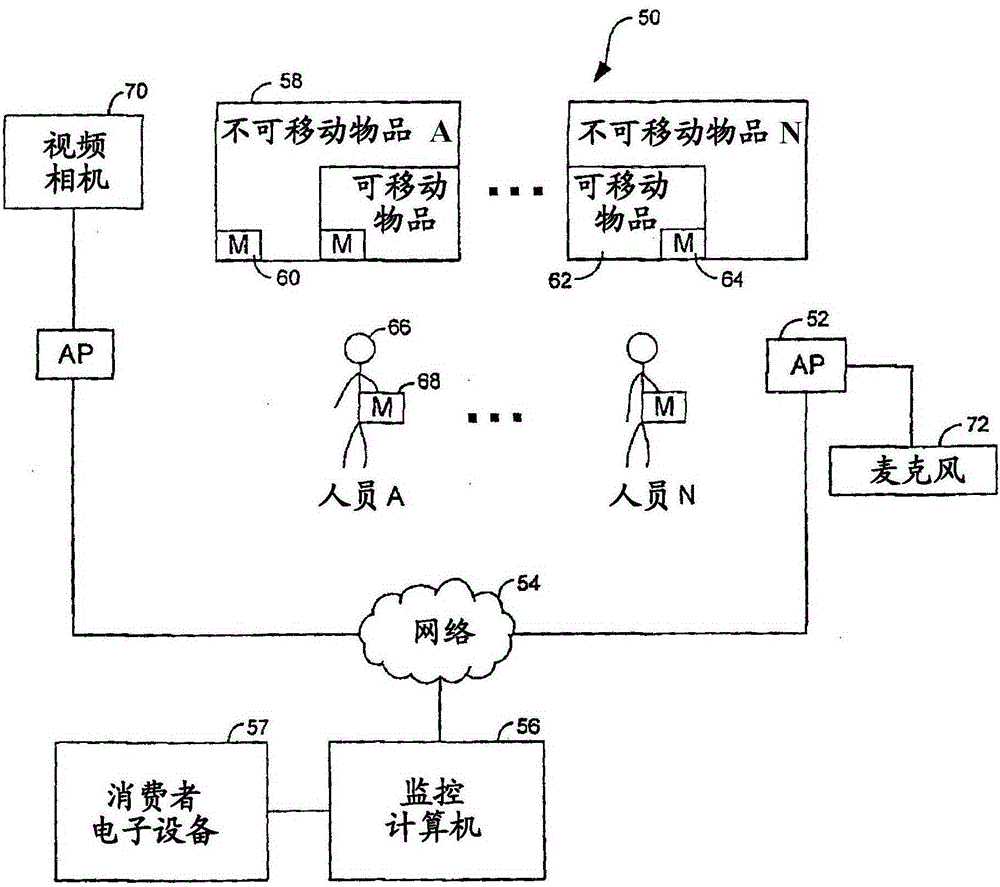

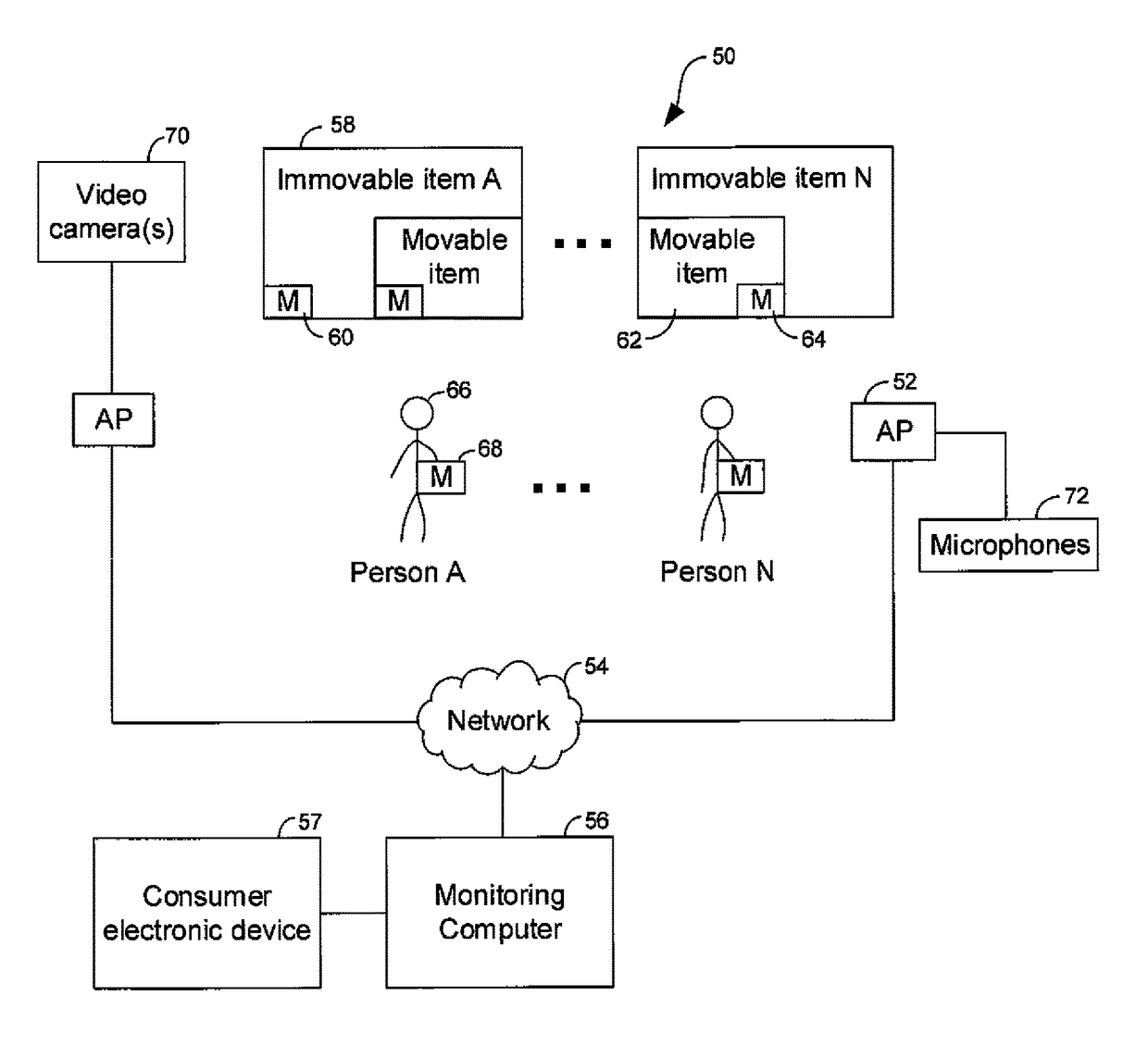

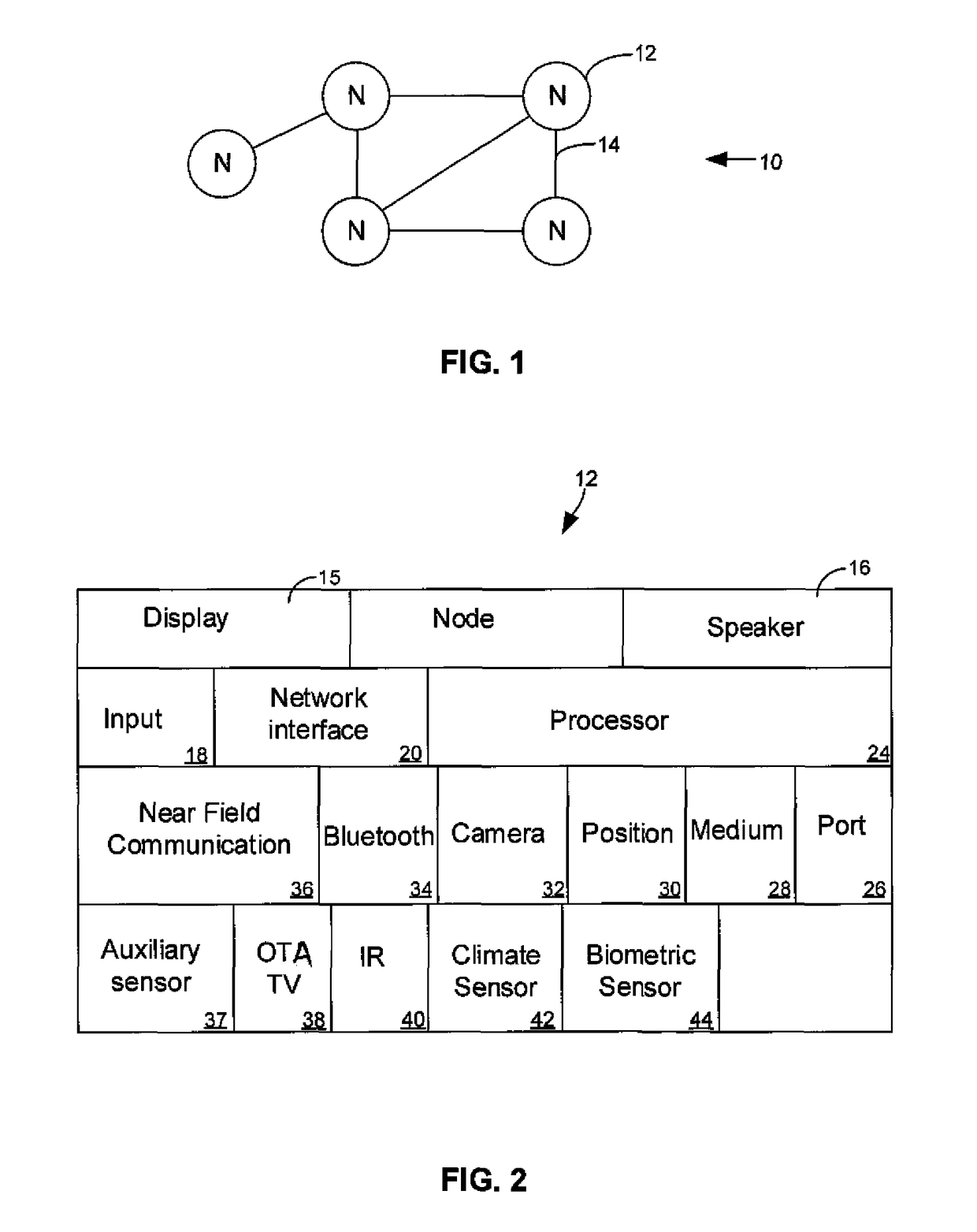

Mesh network applied to fixed establishment with movable items therein

ActiveUS20160019515A1Guaranteed uptimeTesting sensing arrangementsParticular environment based servicesFactory floorOperating energy

Mesh node modules are associated with movable and fixed items in a building such as a grocery store or factory floor to maintain a database of the locations of those items as they are processed through the establishment. The items form a mesh network and relay location information through access points, when in range, to control / monitoring computers.

Owner:SONY CORP

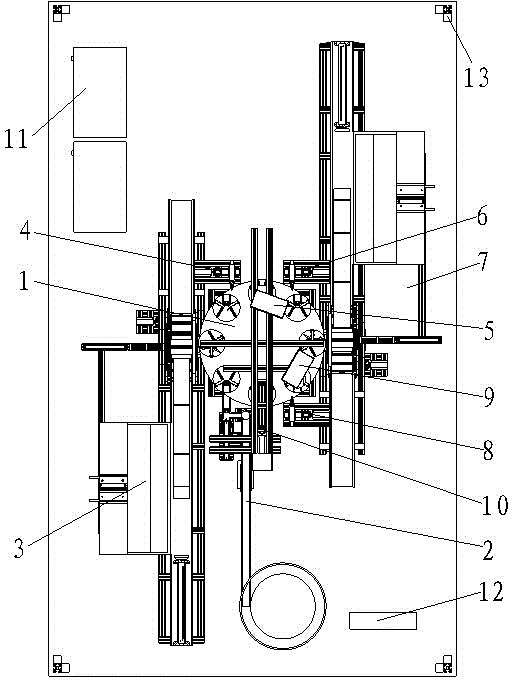

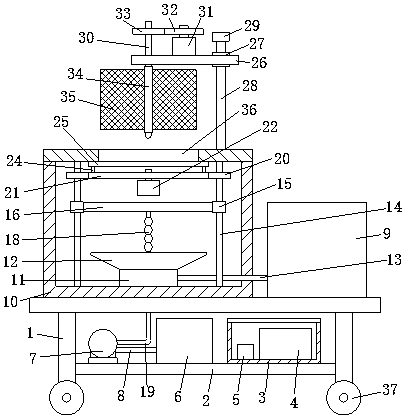

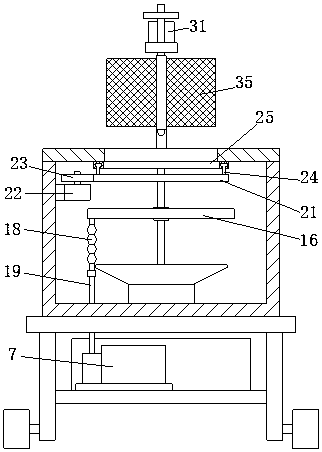

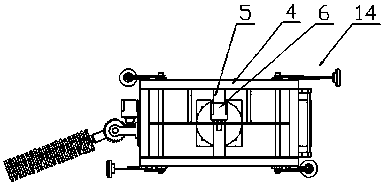

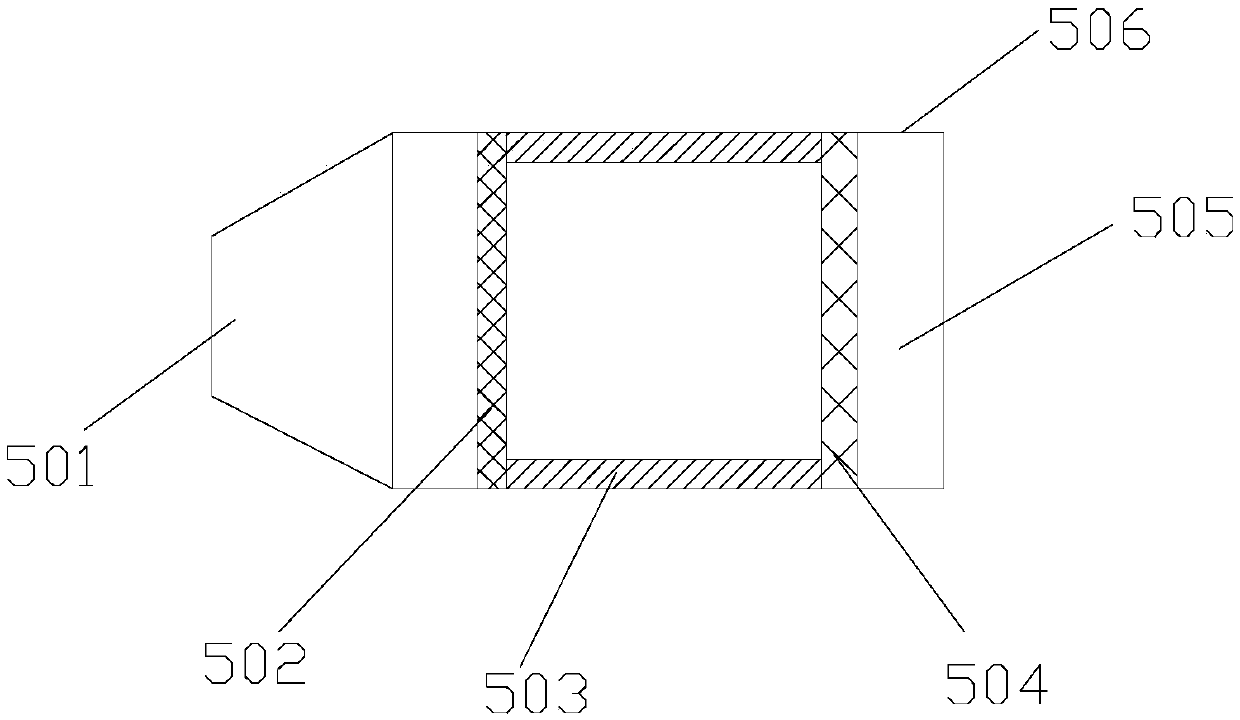

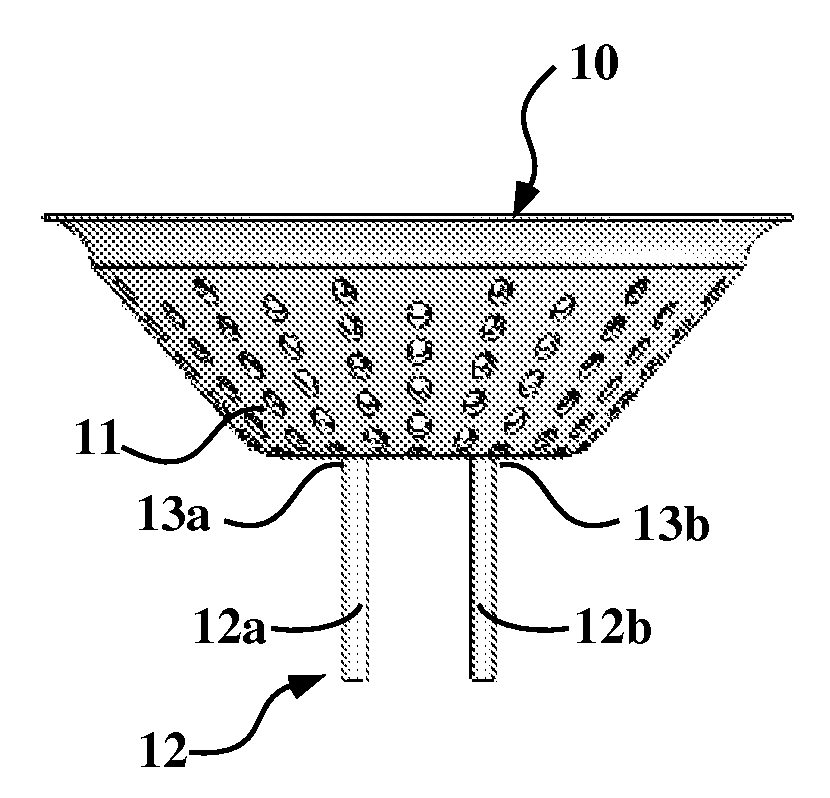

Plug welding machine

ActiveCN104668802AImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectricityGrating

The invention discloses a plug welding machine. The plug welding machine comprises an eight-station welding table, a body feeding mechanism, a first weld line feeding mechanism, a first servo welding mechanism, a first image detecting device, a servo repairing welding mechanism, a second weld line feeding mechanism, a second servo welding mechanism, a second image detecting device, a finished product discharge mechanism, an electric cabinet, a human-machine controller and a regional security grating which are all arranged on a factory floor; the body feeding mechanism, the first weld line feeding mechanism, the first servo welding mechanism, the first image detecting device, the servo repairing welding mechanism, the second weld line feeding mechanism, the second servo welding mechanism and the finished product discharge mechanism are distributed sequentially on each station of the eight-station welding table; the second image detecting device and the second servo welding mechanism are arranged on the same station of the eight-station welding table. By utilizing the above manner, the assembling welding efficiency is high, the production stability is attractive, the product rejection rate is low, and the total production efficiency is high.

Owner:安徽鹏洋传动科技有限公司

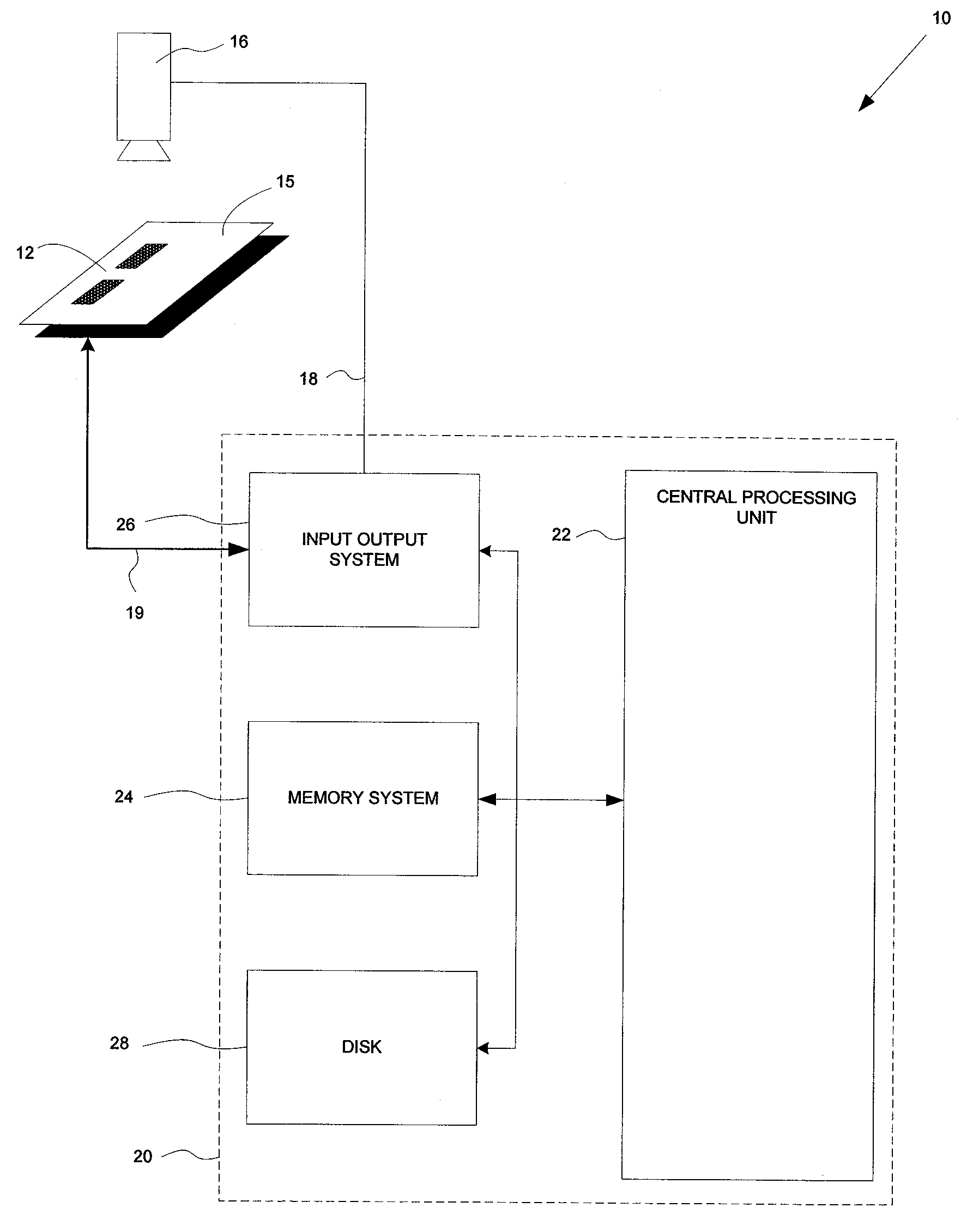

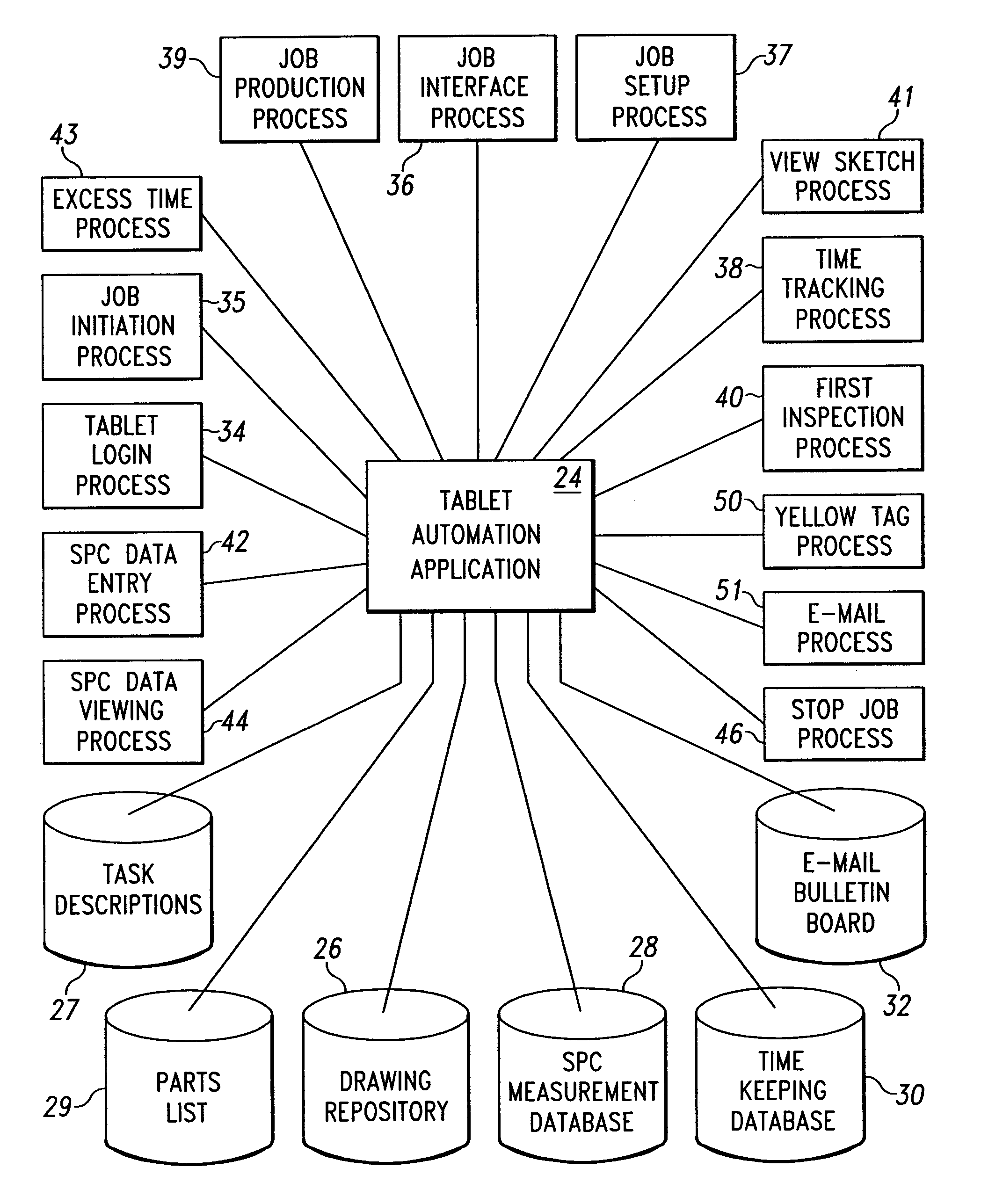

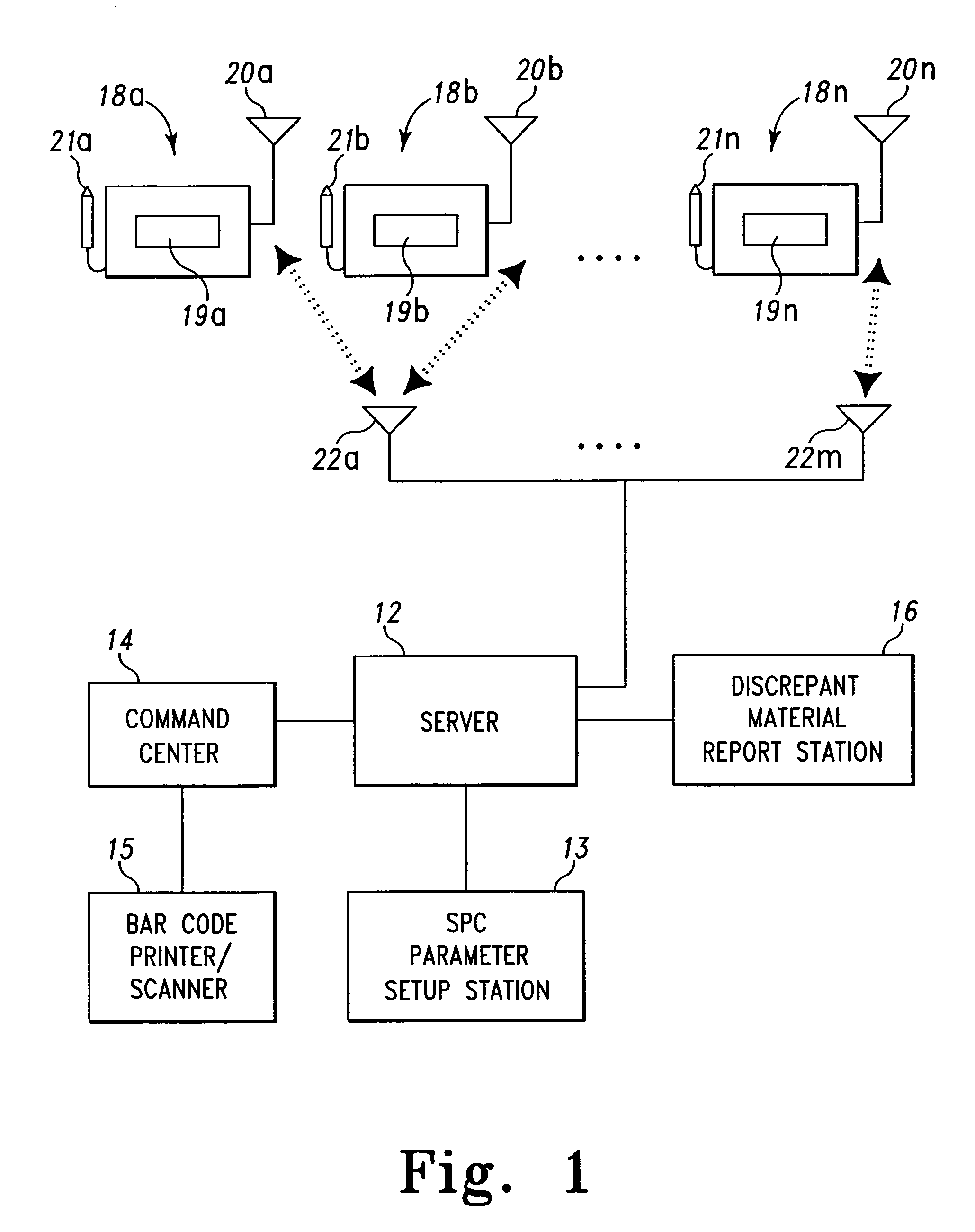

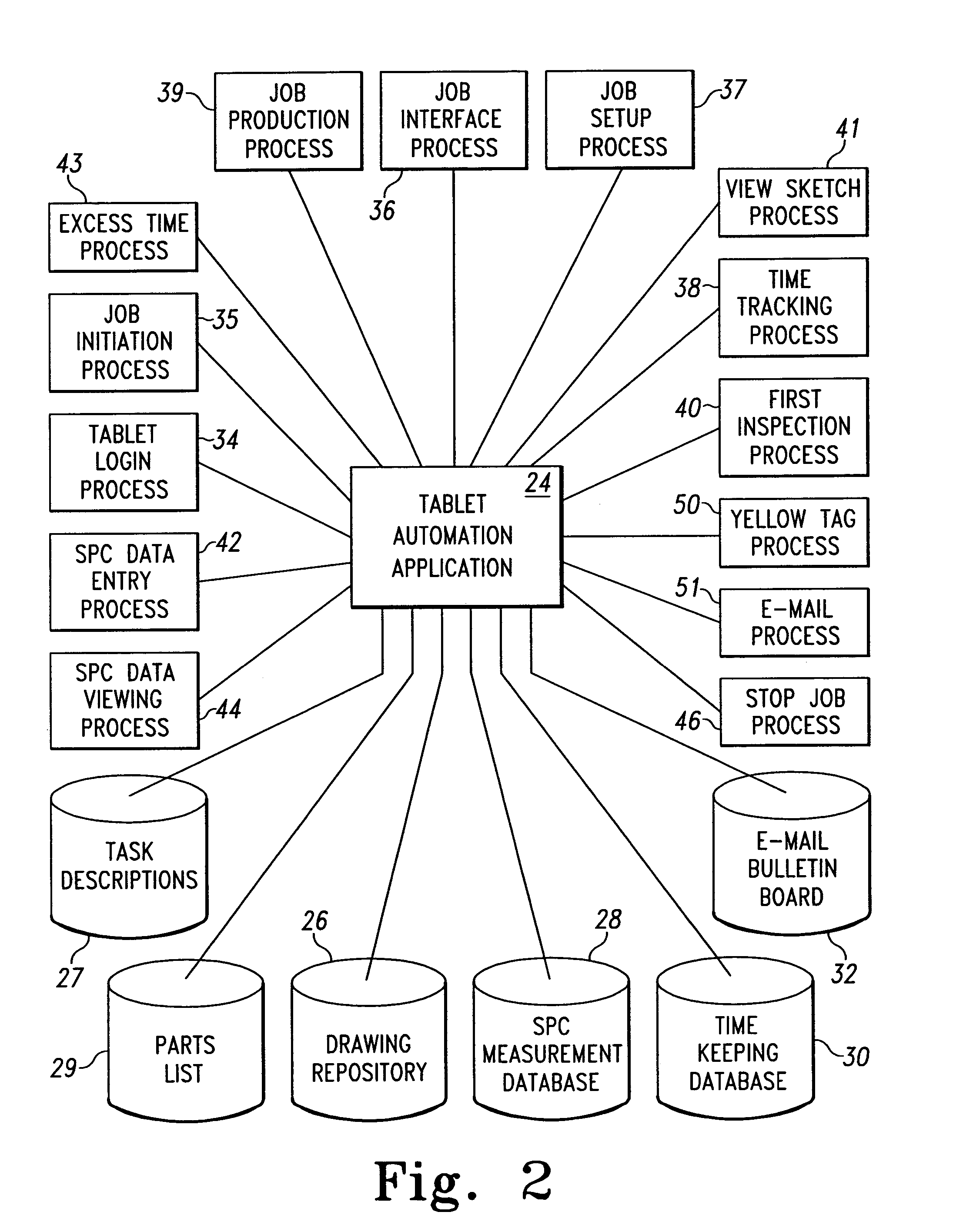

Paperless tablet automation apparatus and method

InactiveUS7079906B2Registering/indicating time of eventsDigital computer detailsTransceiverFactory floor

A factory floor tablet automation system enables the storing, collecting and processing manufacturing data generated at one or more facilities during manufacturing, and making manufacturing data accessible from the one or more facilities. A local processor is located at each facility, and a plurality of portable tablet devices are located in each facility. One or more transceivers located throughout each facility, each transceiver being connected to the local processor in each facility. The plurality of portable tablet devices is in wireless communication with the local processor through the transceivers and the tablet antennas. A server computer having a processor unit and storage device is connected to local processors through a network.

Owner:RAPP III ROY W

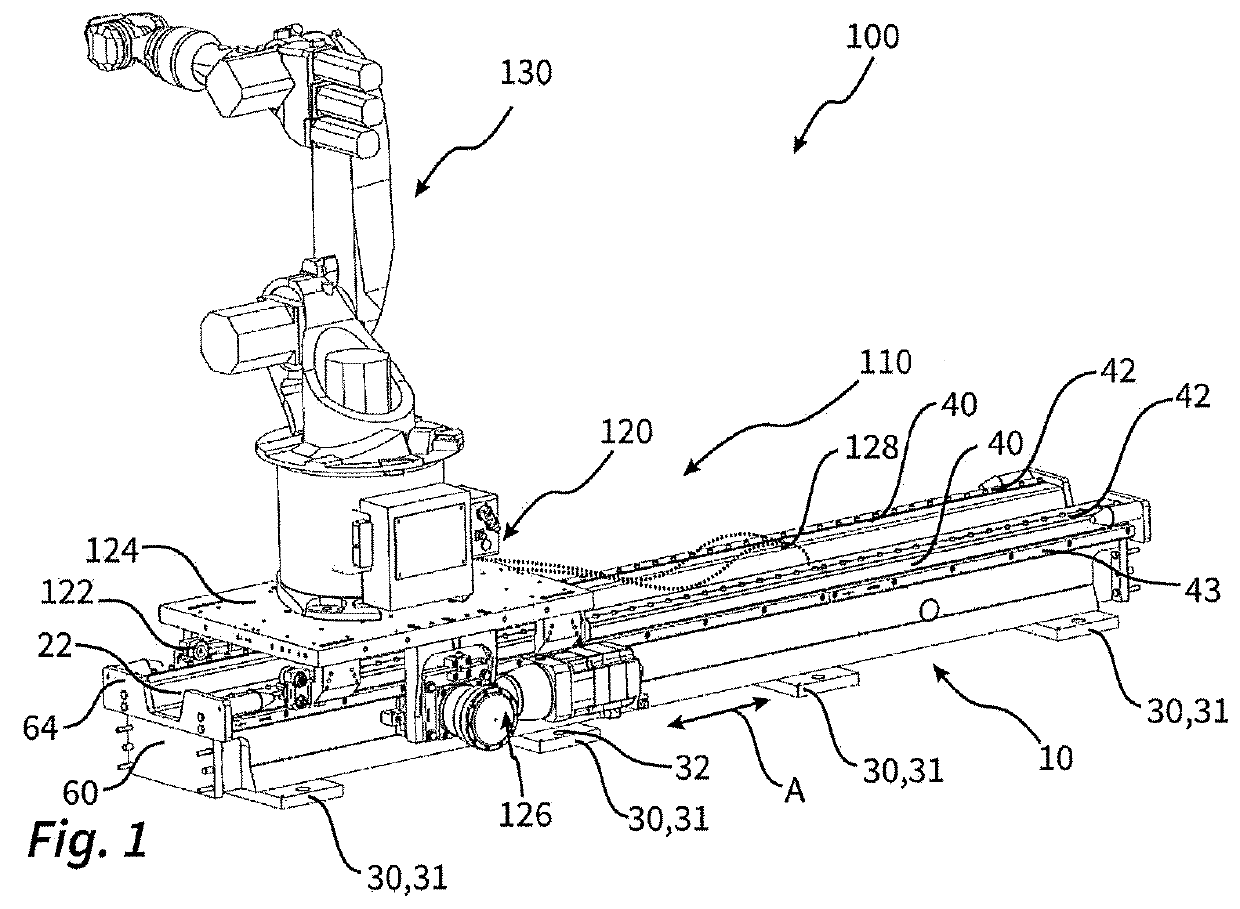

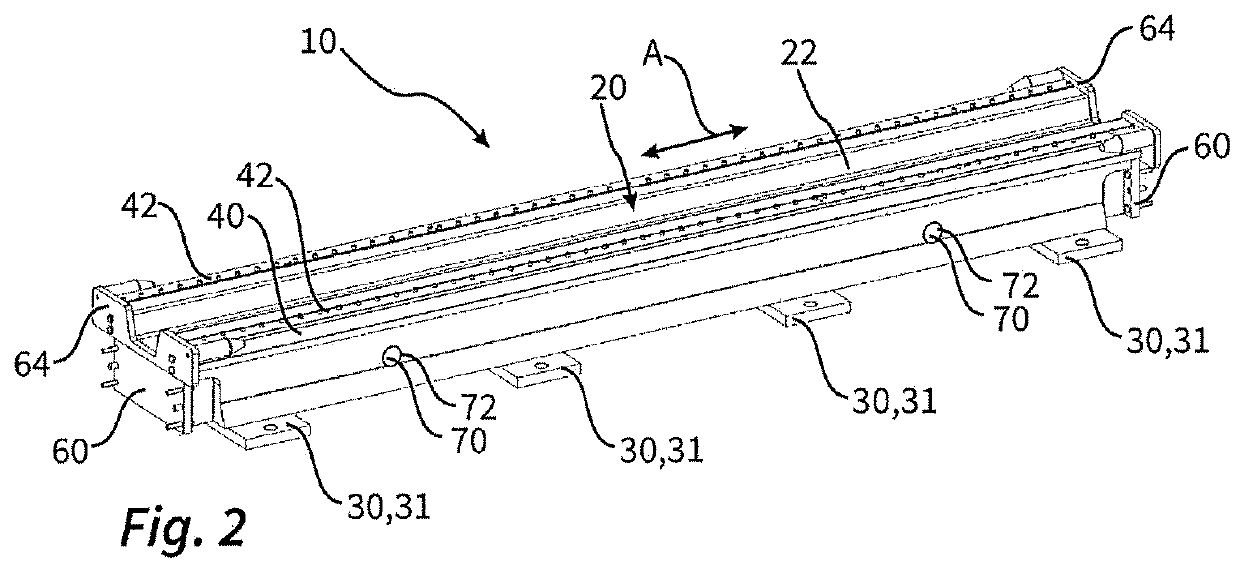

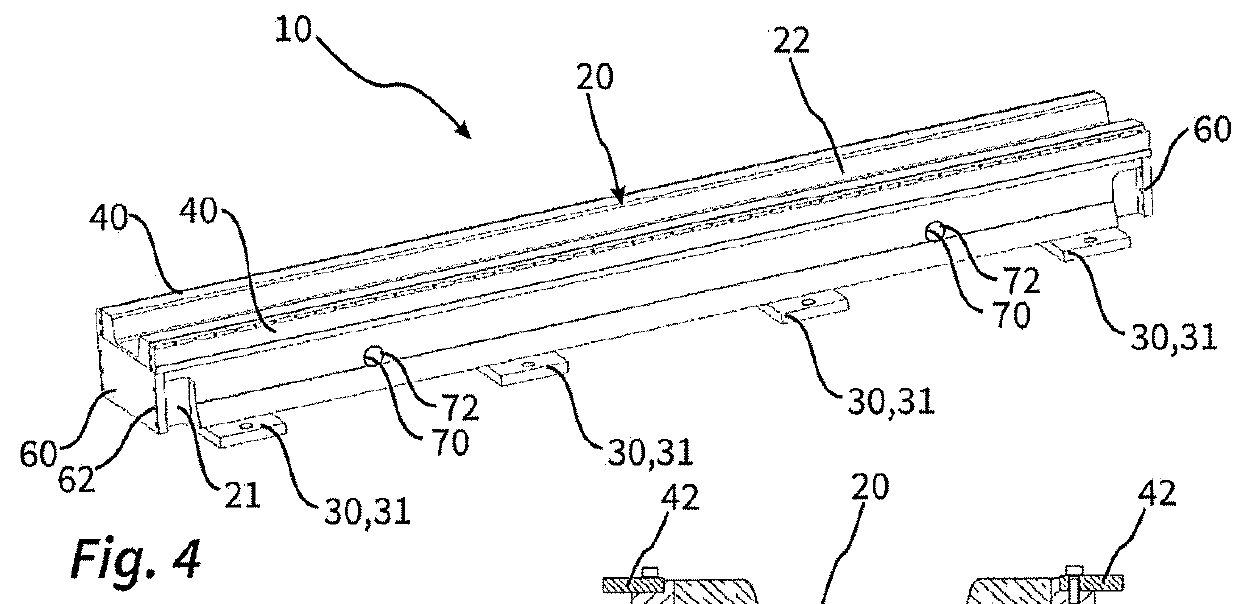

Support rail for a robot platform that can be moved in translation, and motion system and robot system having a support rail of this kind

ActiveUS20180272522A1Welding/cutting auxillary devicesAuxillary welding devicesRobotic systemsFactory floor

A support rail for a robot platform. The support rail is an elongate component having a metal guide rail, provided on an outer side, for guiding the robot platform. The platform has, in a downward-facing subsection, a lower metal connection flange for fastening the support rail on an underlying surface, such as a factory floor, and, in an upward-facing subsection, on an outer side, an upper metal connection flange for mounting the metal guide rail. The support rail has a concrete support structure, on the outer side of which the lower metal connection flange and the upper connection flange or the guide rail are mounted. The upper metal connection flange, the lower metal connection flange and / or the guide rail are secured on the support structure by ties engaging positively in the support structure, and / or via a connecting inner frame surrounded by the support structure.

Owner:IPR - INTELLIGENTE PERIPHERIEN FUR ROBOTER

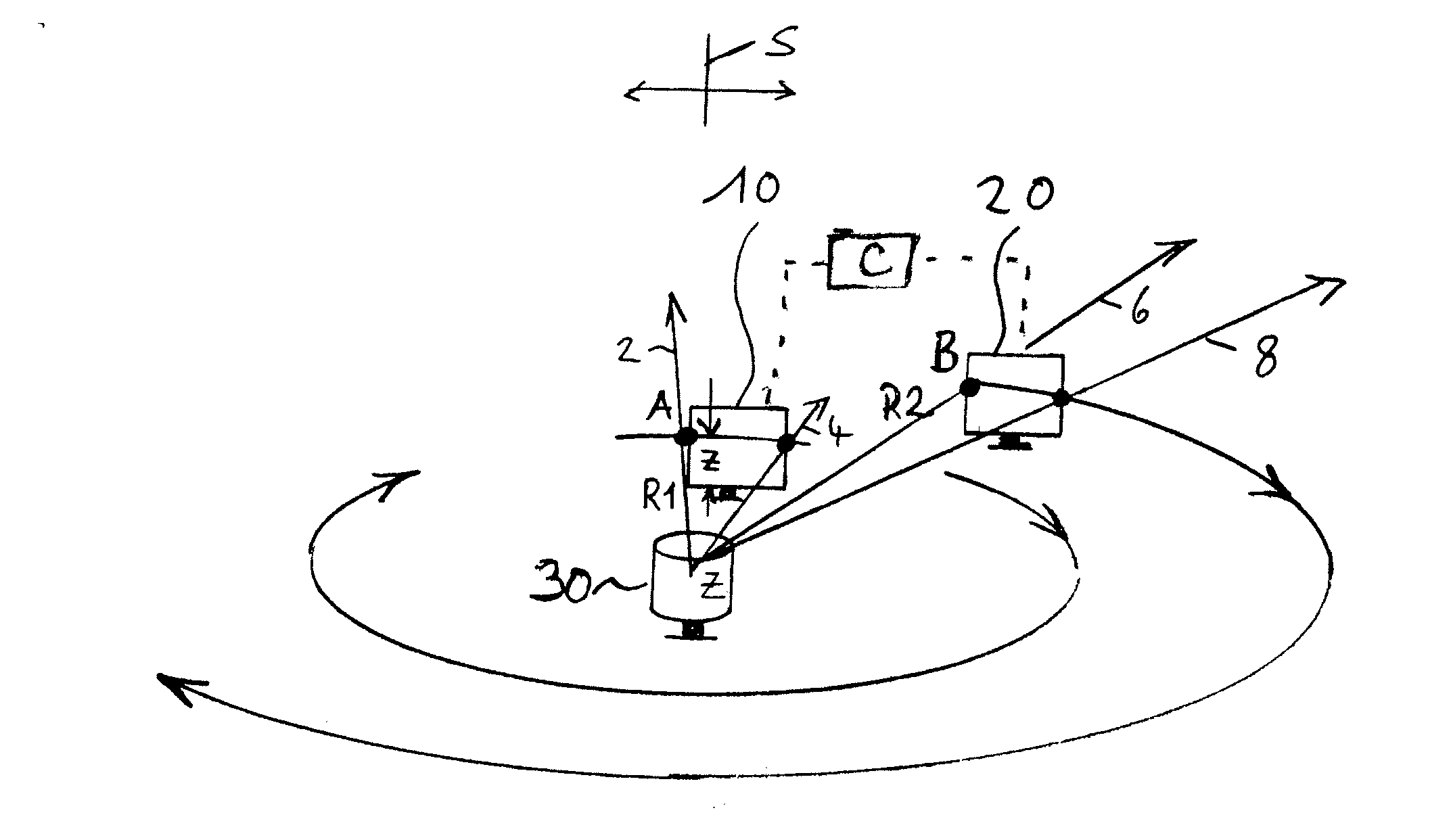

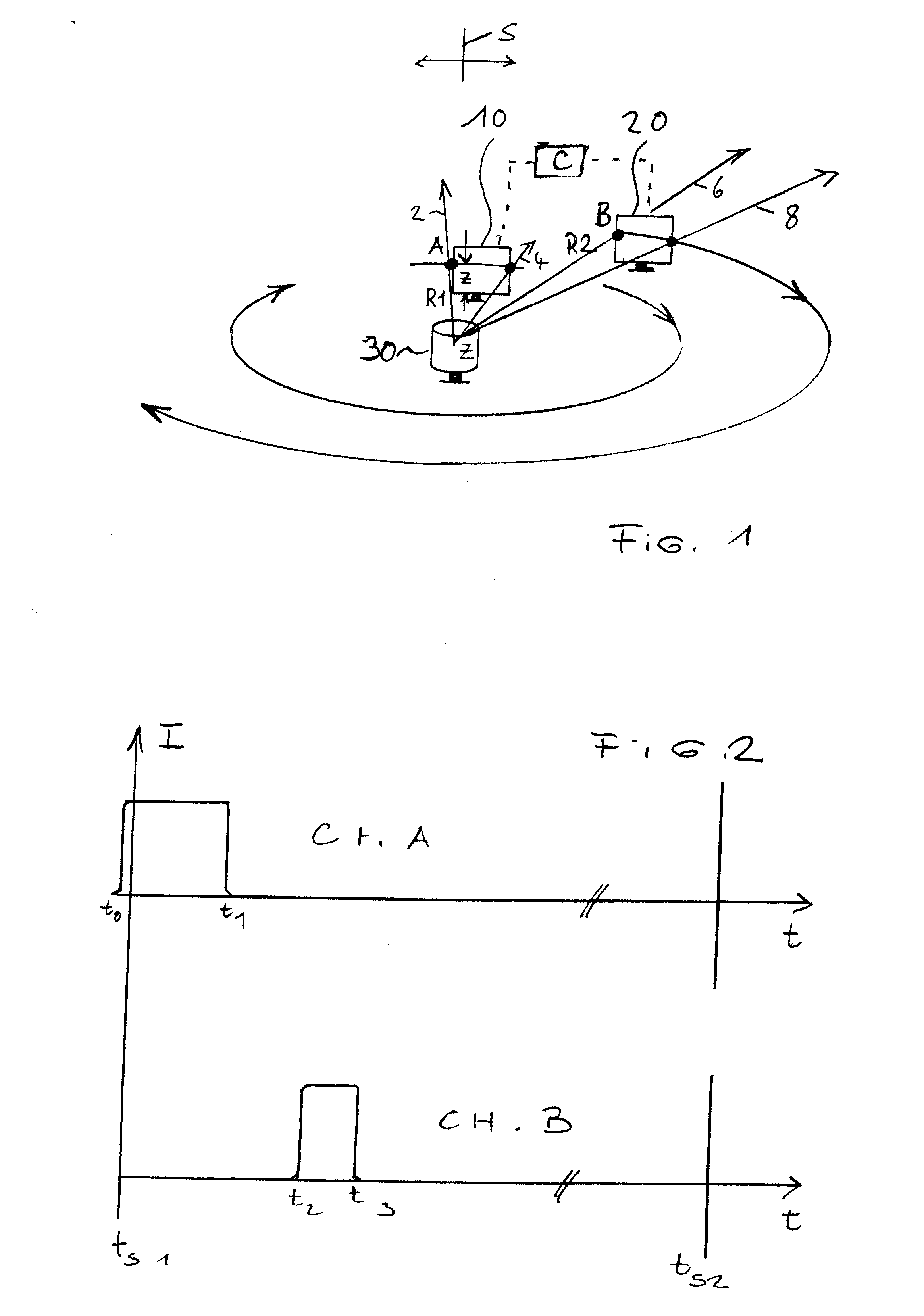

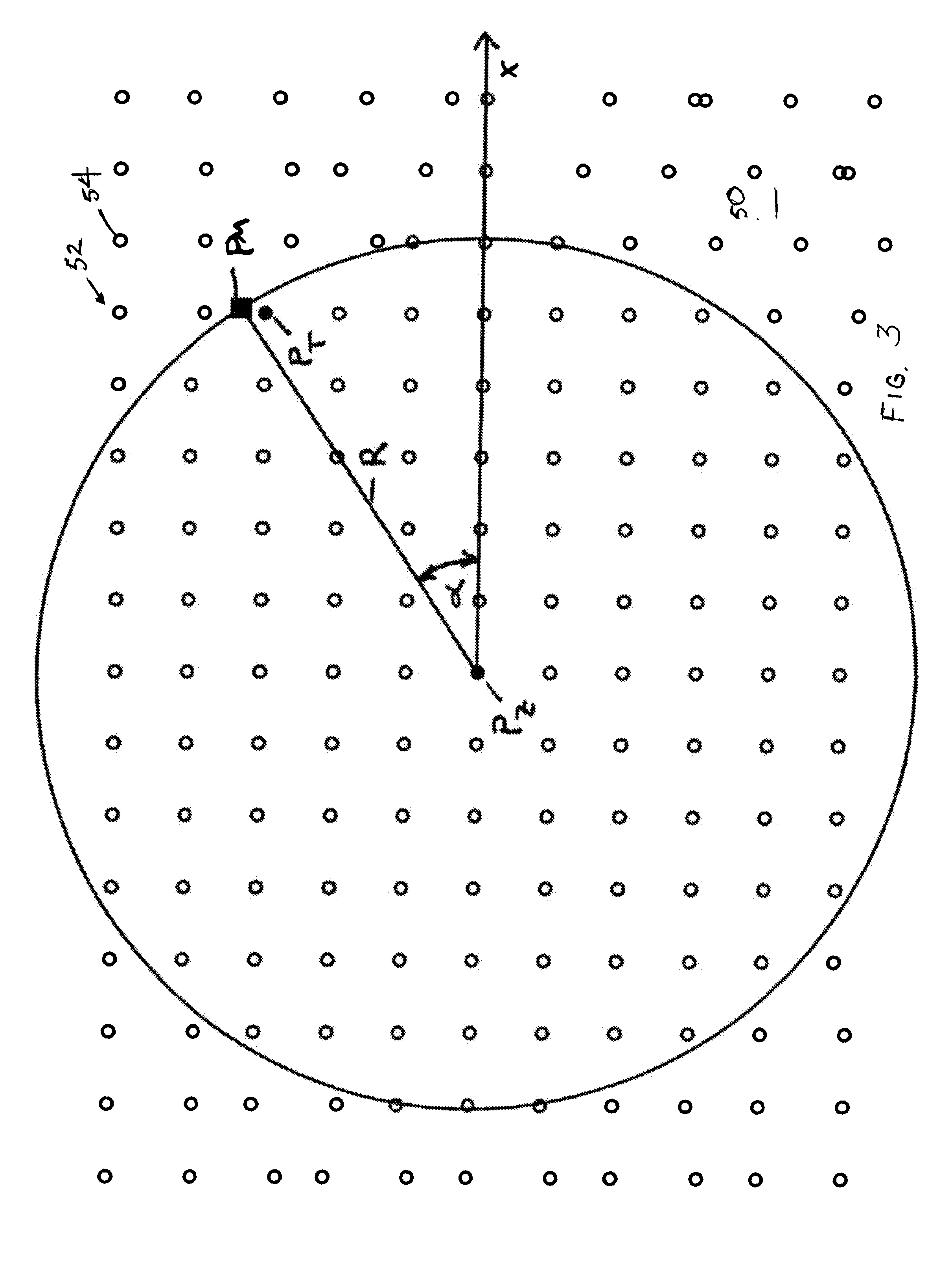

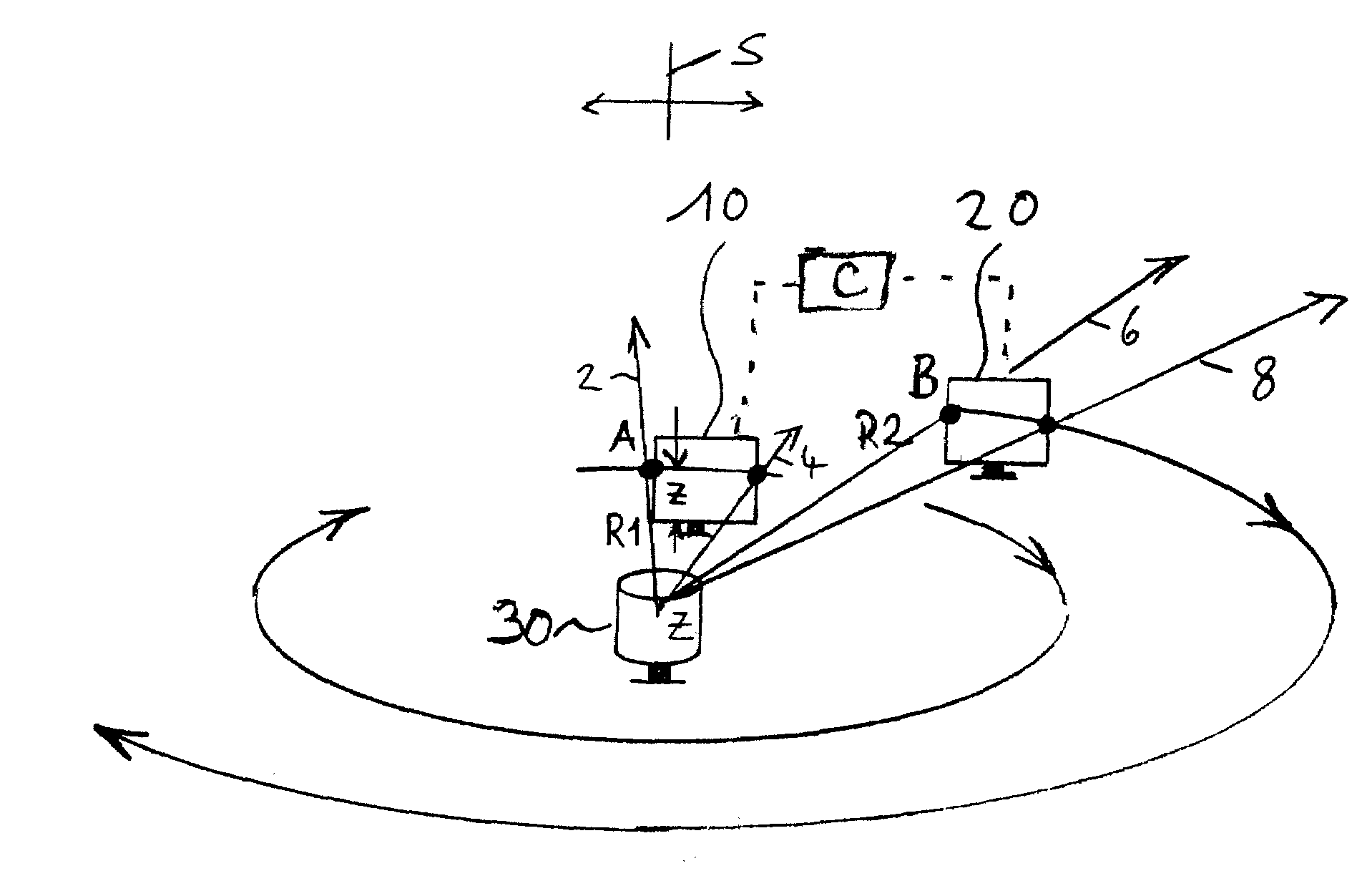

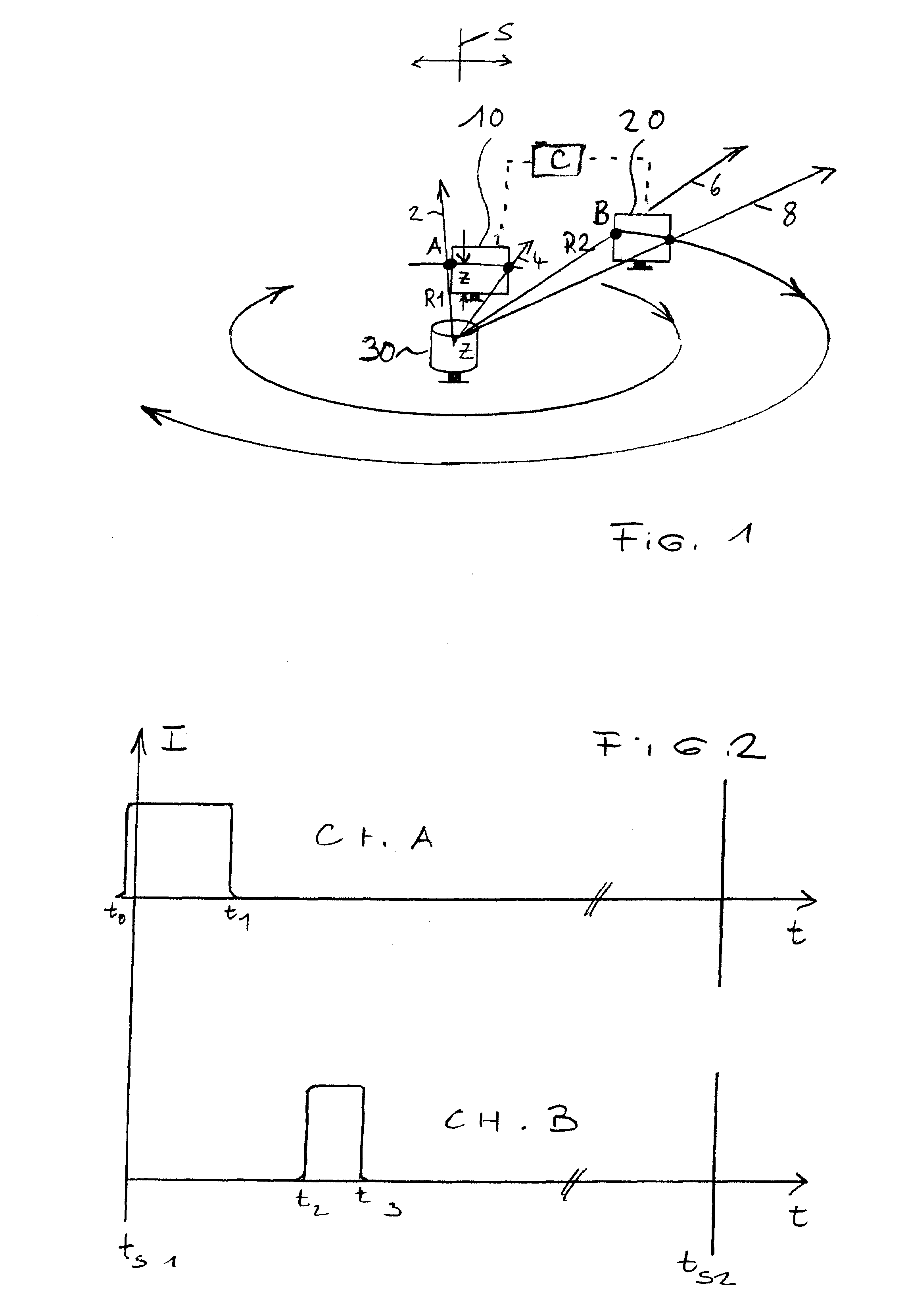

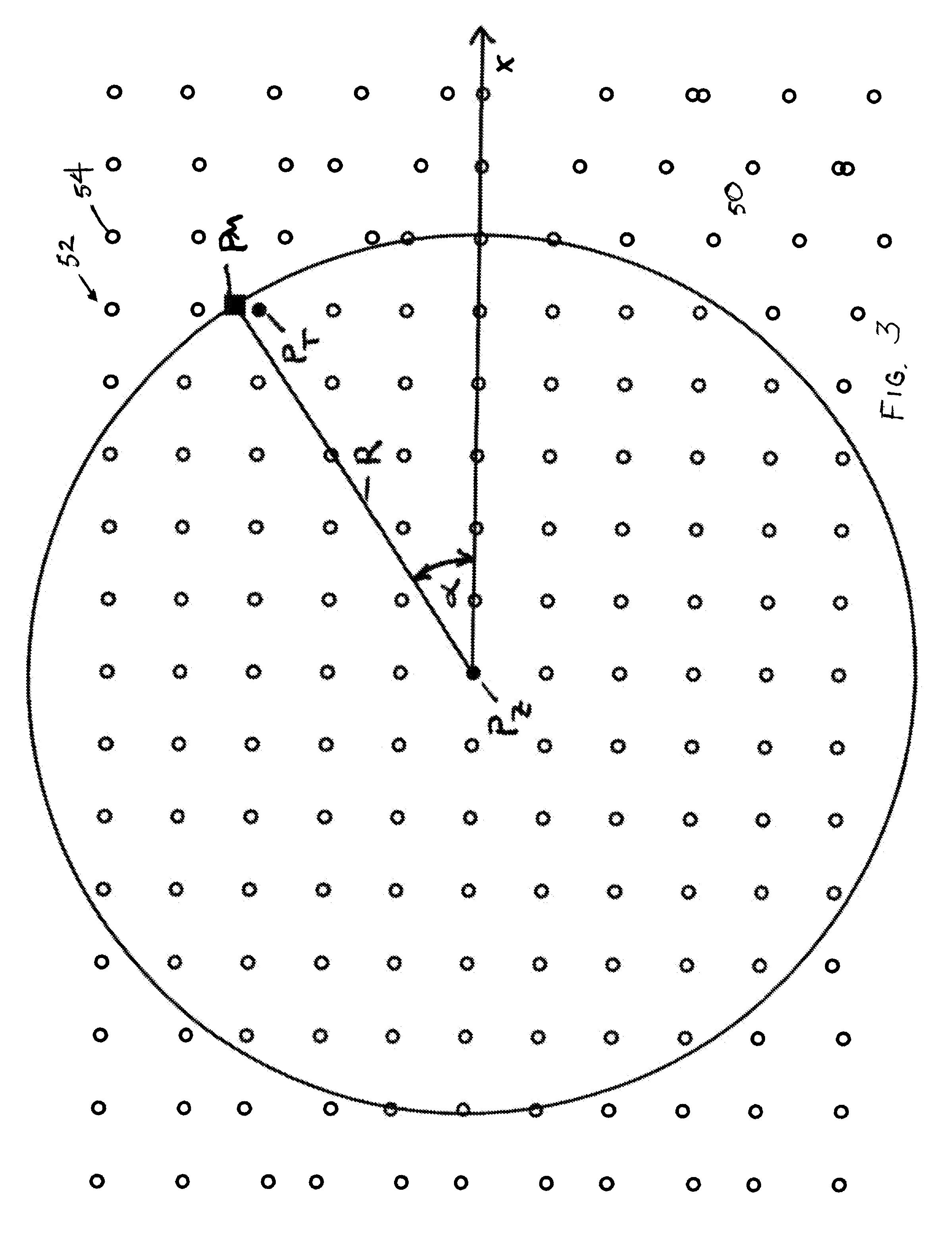

Method of determining the flatness of a foundation to which a building structure, machinery or equipment is to be mounted

A method for measuring flatness of a factory floor upon which machinery is to be mounted using a rotating laser beam that emits a rotating laser beam in an essentially horizontally plane. A photosensitive position sensor delivers an electrical pulse, which is identified by its timing and phase angle, during illumination by the laser beam. The phase angle and timing of these pulses constitute a measure of the position of the sensor in the coordinate system. Measurements are taken with the sensor positioned at each location at which the machinery is to be fixed to a factory floor. The method determines any differences in height between the measurement points and the amount, if any, that the floor needs to be adjusted at each mounting point to insure that a machine that is affixed to the floor these points will be level.

Owner:PRUTECHNIK DIETER BUSCH AG

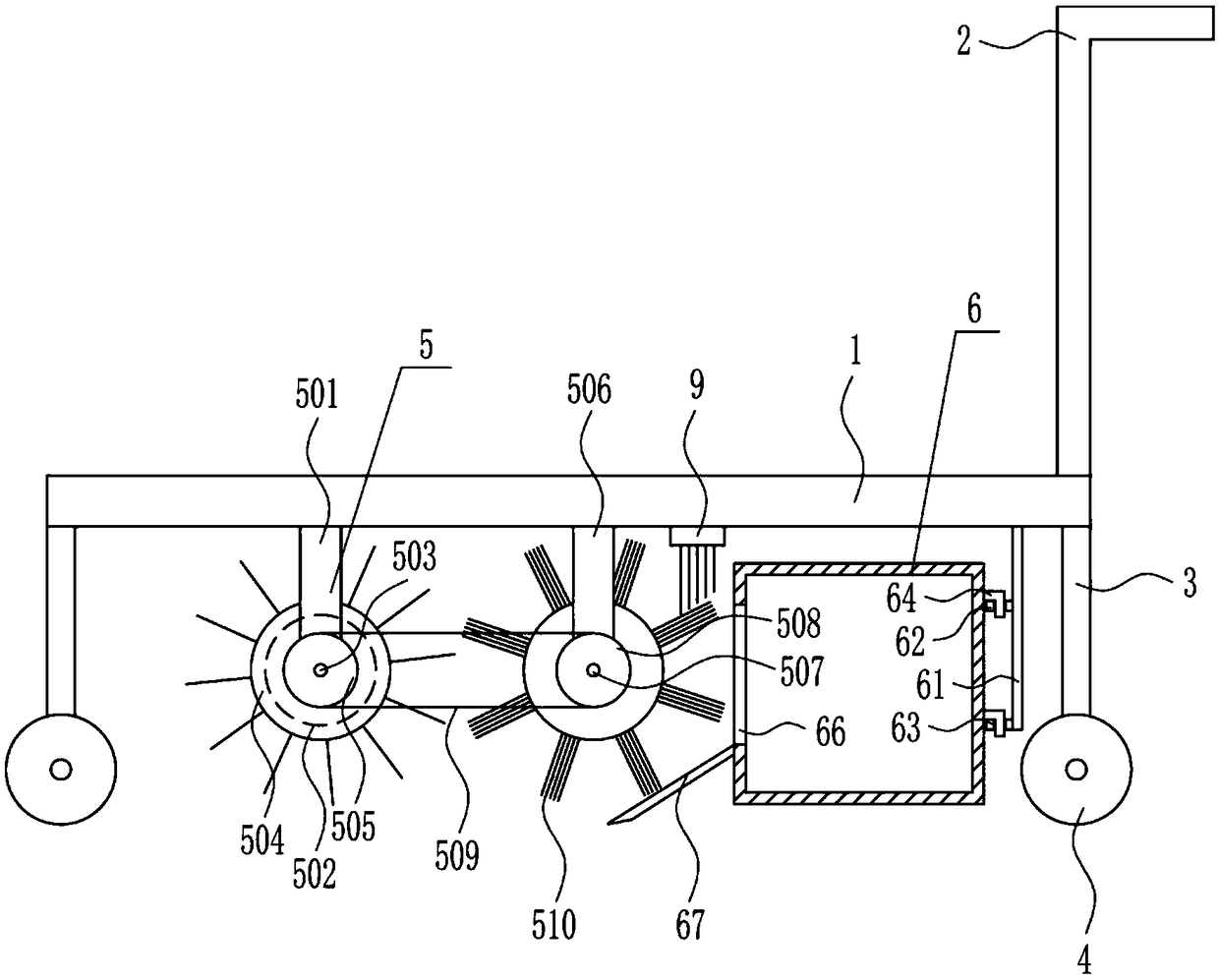

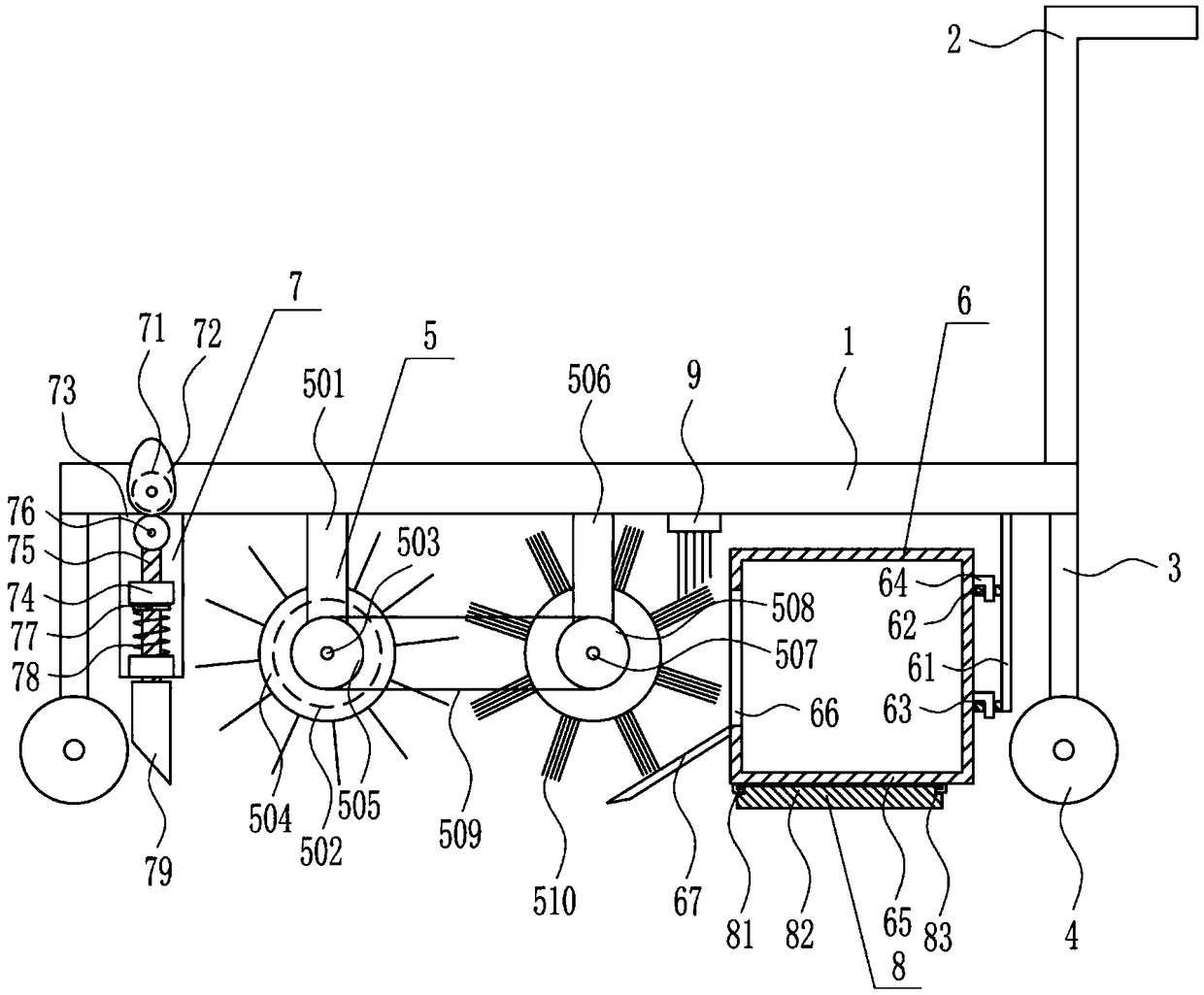

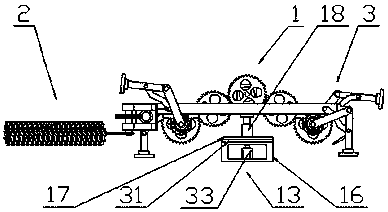

Factory floor cleaning equipment for metallurgy

The invention relates to cleaning equipment, in particular to factory floor cleaning equipment for metallurgy. The technical purpose is to provide the factory floor cleaning equipment for metallurgy capable of shortening the floor cleaning time, consuming fewer resources, and fully cleaning the floor. According to the technical scheme, the factory floor cleaning equipment for metallurgy comprisesan installing plate and the like; a pushing handle is arranged on the right side of the top of the installing plate, a first supporting rod is arranged at the bottom of the installing plate, walking wheels are arranged at the bottom of the first supporting rod, a cleaning mechanism is installed in the middle of the bottom of the installing plate, and a collecting mechanism is installed on the right side of the bottom of the installing plate. An operator operates the pushing handle to drive the equipment to run on the floor of a metallurgy factory, the cleaning mechanism and the collecting mechanism are utilized to clean the ground, and by utilizing the optimization of a knocking mechanism and an adsorption mechanism, the effects of shortening the floor cleaning time, consuming fewer resources, and fully cleaning the floor are achieved.

Owner:朱茂祖

Wear-resistant ground material using waste glass and preparation method thereof

The invention relates to the field of wear-resistant ground material, and in particular, relates to a wear-resistant ground material using waste glass and a preparation method thereof. The wear-resistant ground material comprises the components in parts by mass: 20-60 parts of cement; 40-70 parts of the waste glass; 0.5-5 parts of a waste glass modification agent; 1-10 parts of a redispersible latex powder; and 1-10 parts of auxiliary components. The preparation method comprises the steps: firstly, washing the waste glass cleanly, and processing the waste glass into particles; fully mixing the waste glass modification agent with the cement; then fully mixing the cement fully mixed with the modification agent with the redispersible latex powder and the auxiliary components; and then adding the waste glass aggregate, mixing until the color and the interface are mixed uniformly, weighing, and packing. The wear-resistant ground material has the advantages of high strength, high wear resistance, good gloss, anti-pollution function, beautiful appearance and low cost, can achieve waste utilization and environmental protection, and is suitable for road surfaces, factory floors and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

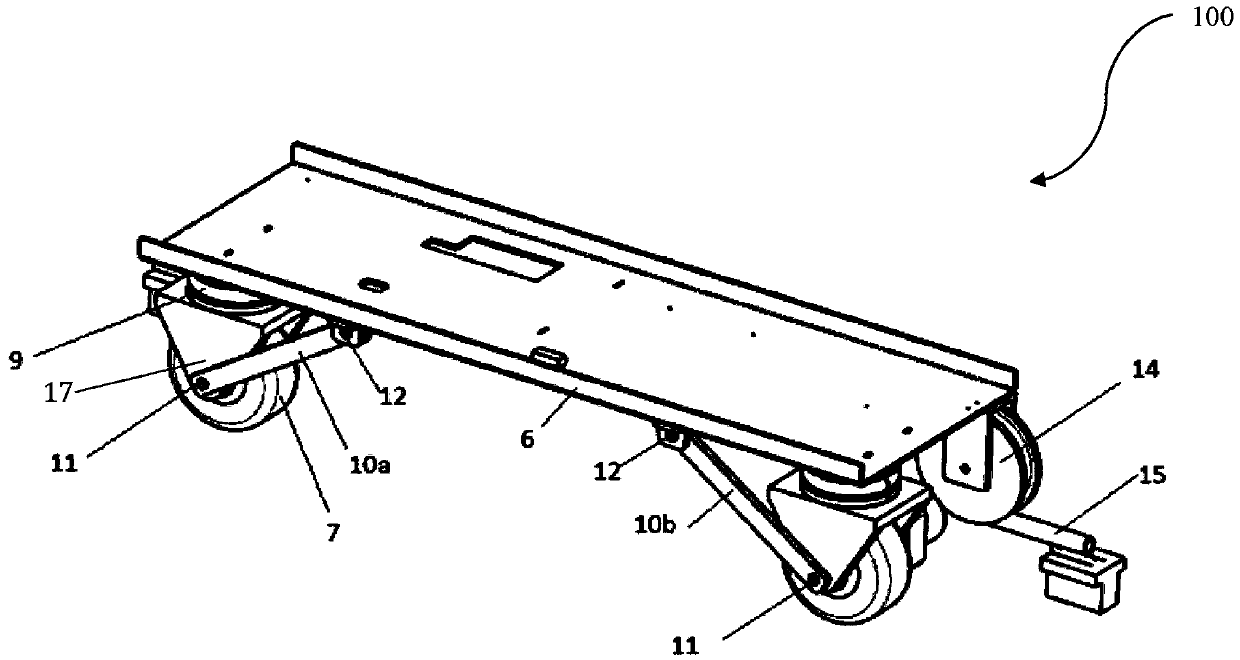

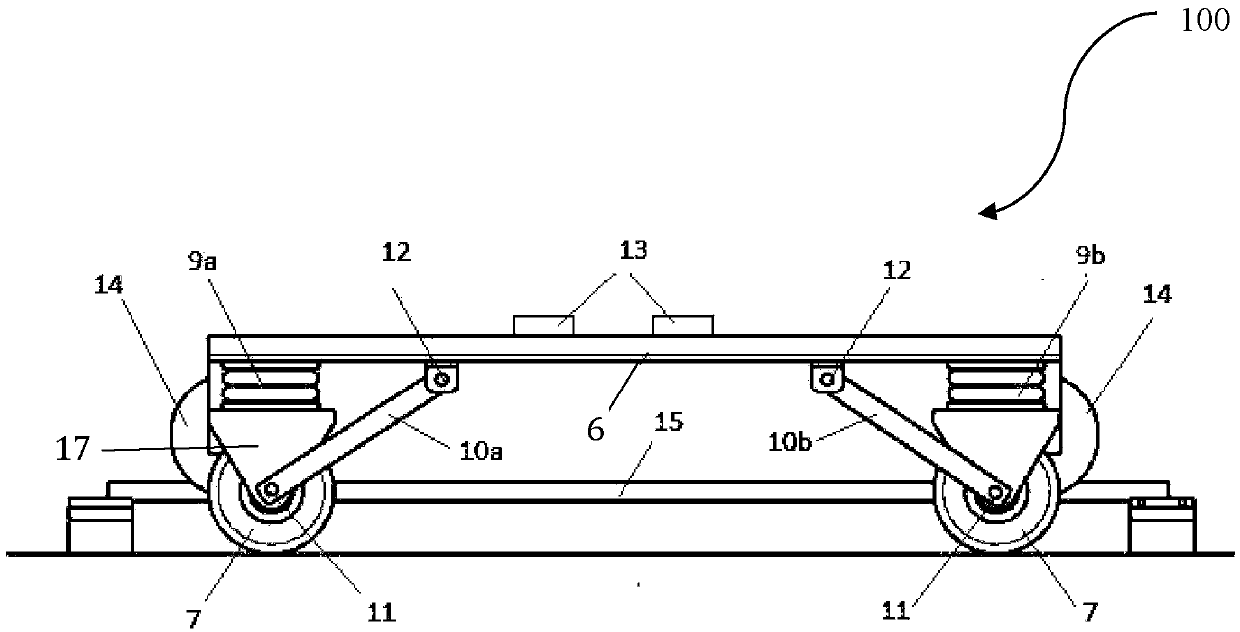

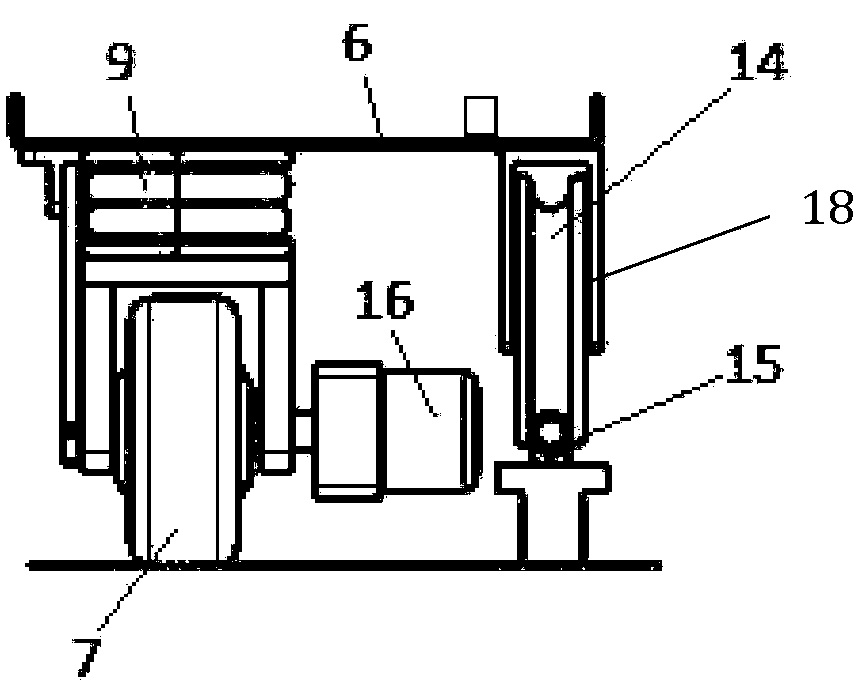

Platform and associated method for supporting splicing unit of spinning machine

A platform and associated method for supporting a splicing unit of a spinning machine are disclosed. The platform includes a bottom plate for receiving the splicing unit. The platform further includesone or more first wheels and one or more second wheels, the first wheel is fixed to one end of the bottom plate and traverses on the guide rail, and the second wheel can be rotatably fixed to the base plate and crosses over the factory floor. In addition, the platform includes a mechanism for adjusting the horizontal height of the base plate relative to the factory floor. The mechanism includes acontrol unit that receives signals from the sensors and is connected to a linear adapter of one or more second wheels to adjust the horizontal height of the base plate. Therefore, the platform with this configuration continuously refers to the factory floor monitoring level to facilitate precise positioning of the splicing unit with reference to the frame of the spinning machine.

Owner:LAKSHMI MACHINE WORKS

Mesh network applied to fixed establishment with movable items therein

InactiveCN105282221ATesting sensing arrangementsParticular environment based servicesFactory floorOperating energy

The invention relates to a mesh network applied to fixed establishment with movable items therein. Mesh node modules are associated with movable and fixed items in a building such as a grocery store or factory floor to maintain a database of the locations of those items as they are processed through the establishment. The items form a mesh network and relay location information through access points, when in range, to control / monitoring computers.

Owner:SONY GRP CORP

Dust particle detection apparatus used for factory workshop

InactiveCN107748120AHigh degree of automationImprove work efficiencyWithdrawing sample devicesFactory floorEngineering

The invention discloses a dust particle detection device for a factory workshop, which comprises a frame, a support plate is arranged at the bottom of the frame, a storage box is provided on one side of the top surface of the support plate, a power supply is provided on the inner bottom surface of the storage box, one side of the power supply is located A controller is installed on the inner bottom of the storage box, a water tank is installed on one side of the storage box and on the top surface of the support plate, and a water pump is installed on one side of the water tank and on the top surface of the support plate. The detection equipment body is installed on one side of the top surface of the rack, the collection box is installed on one side of the detection equipment body and on the top surface of the rack, the bottom surface inside the collection box is provided with a fixing seat, and the top surface of the fixing seat is located inside the collection box A receiving tray is provided. The invention has the beneficial effects that: the detection device can accurately detect the composition of the dust particles in the factory workshop, which is of great significance for improving the air quality in the factory workshop and is suitable for popularization.

Owner:WUXI X RES PROD DESIGN & RES

Method of determining the flatness of a foundation to which a building structure, machinery or equipment is to be mounted

Owner:PRUTECHNIK DIETER BUSCH AG

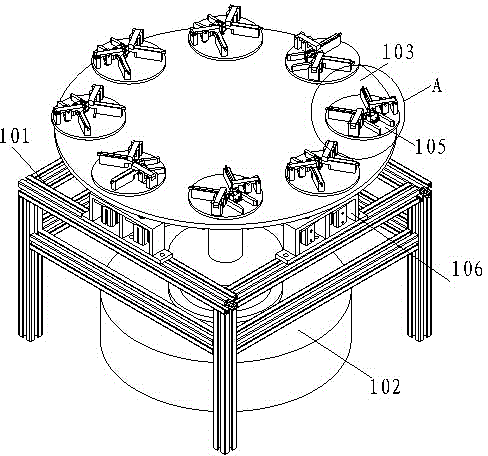

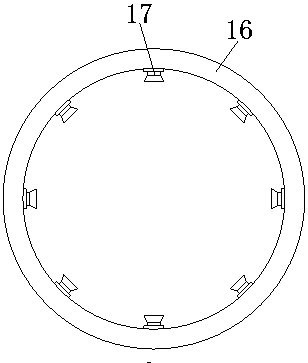

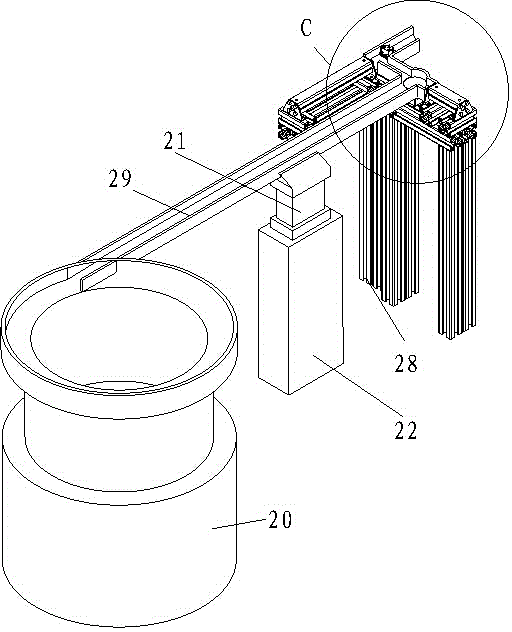

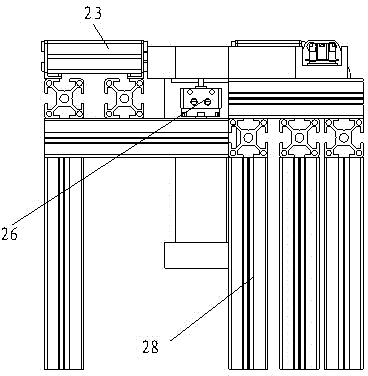

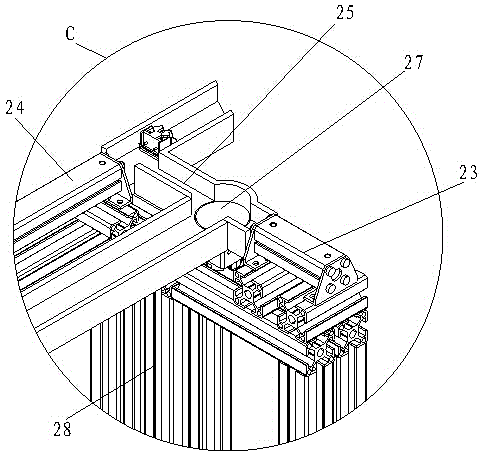

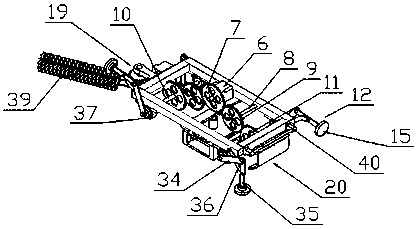

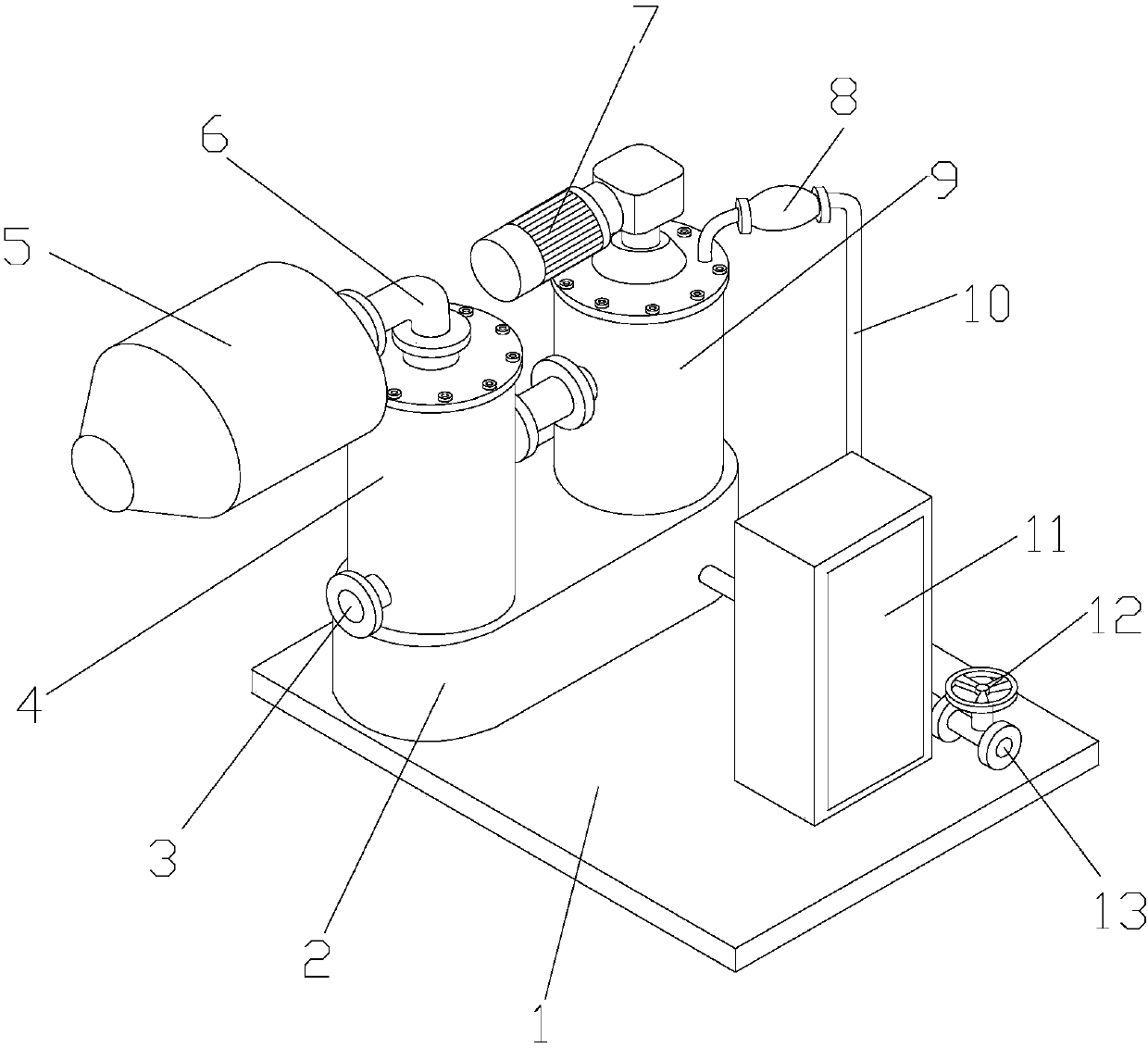

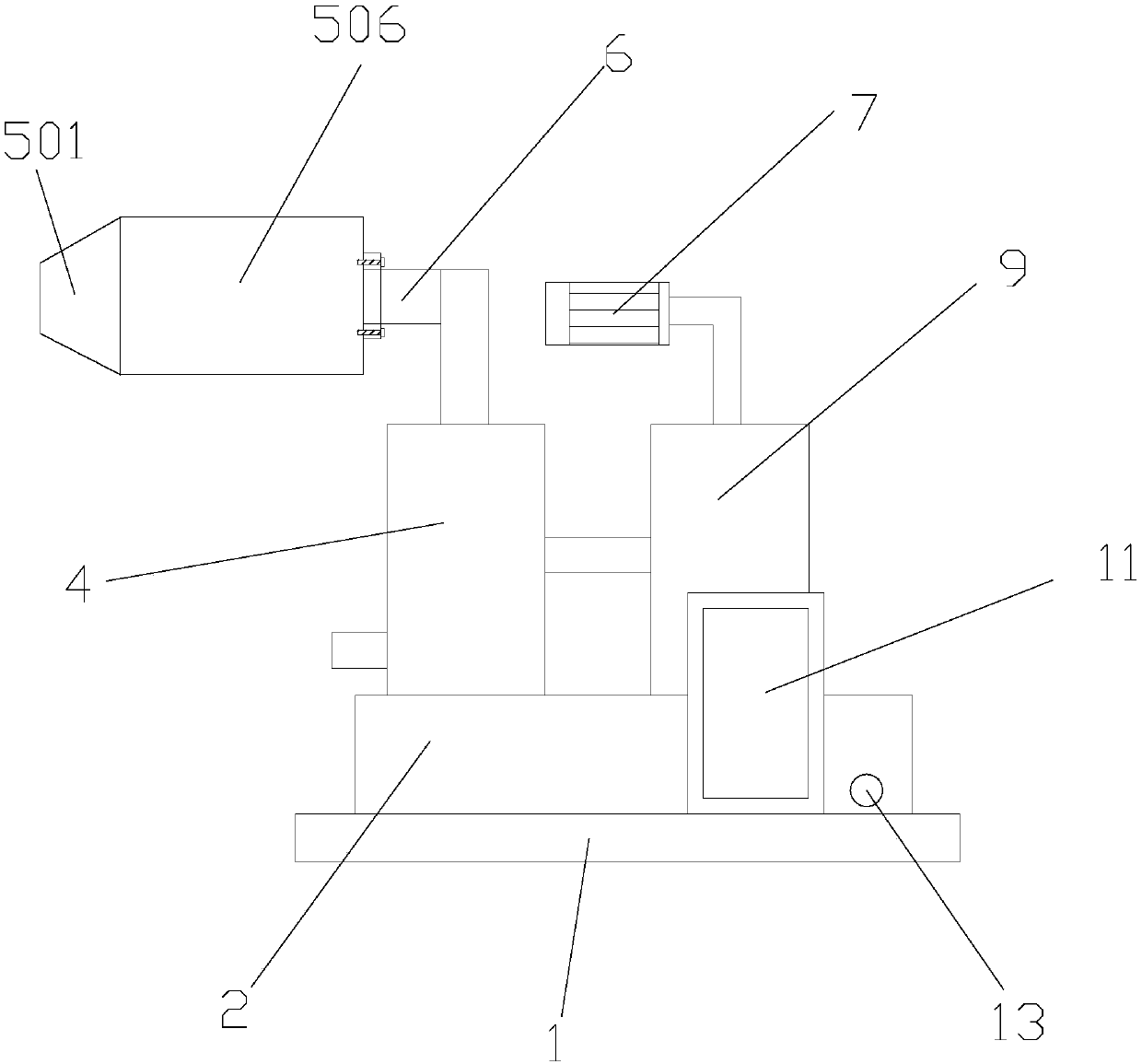

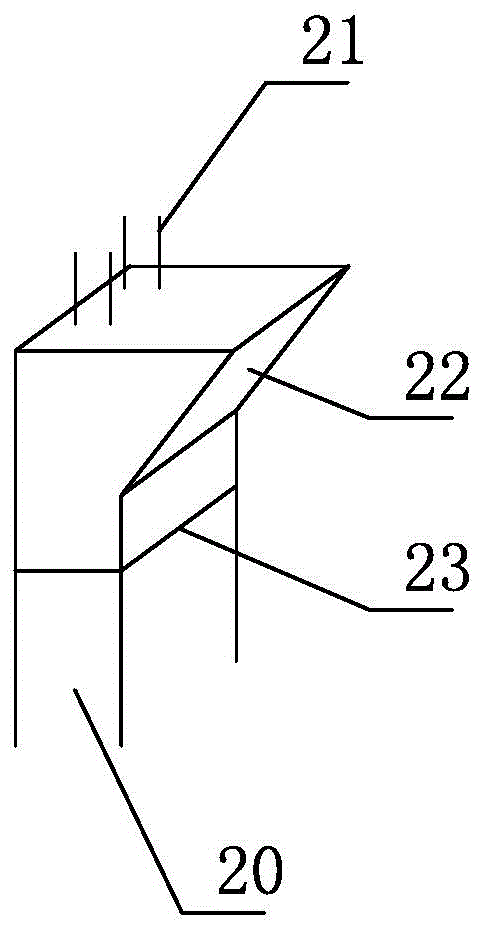

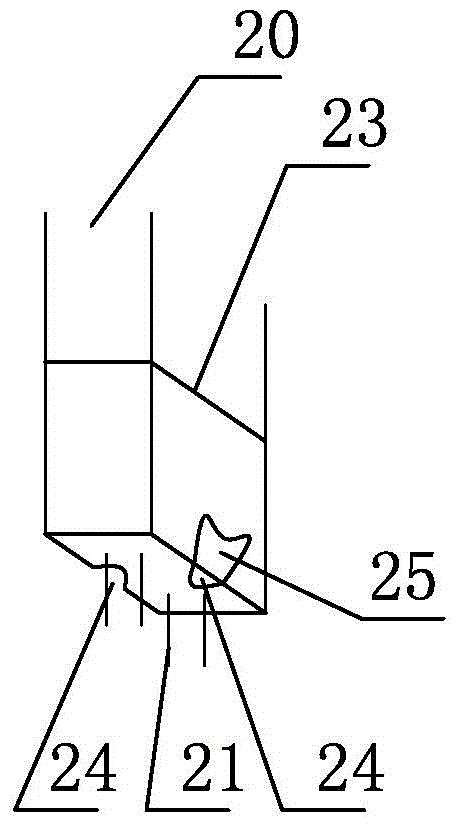

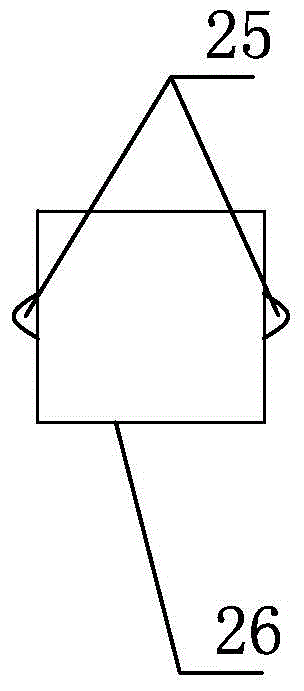

Body feeding mechanism of plug welding machine

ActiveCN104668843AImprove assembly and welding efficiencyImprove production stabilityWelding/cutting auxillary devicesAuxillary welding devicesRotary stageFactory floor

The invention discloses a body feeding mechanism of a plug welding machine. The body feeding mechanism of the plug welding machine comprises a vibrating plate and a linear vibrating feeder seat both of which are fixed on a factory floor; a linear vibrating feeder is arranged on the linear vibrating feeder seat; one end of a feeding tank of the linear vibrating feeder is connected with the vibrating plate, and the other end of the feeding tank of the linear vibrating feeder is connected with one end of an L-shaped intake chute; the end, arranged against the linear vibrating feeder, of the L-shaped intake chute is provided with a first body material pushing cylinder; the part, arranged against the first body material pushing cylinder, of the L-shaped intake chute is provided with a rotating table; the rotating table is arranged on a rotating transposition cylinder; the upper plane of the rotating table and the inner bottom of the L-shaped intake chute are arranged on the same plane; and a second body material pushing cylinder is arranged on the corner of the L-shaped intake chute. By utilizing the above manner, the assembling welding efficiency is high, the production stability is high, the product rejection rate is low, and the total production efficiency is high.

Owner:威海高新园区运营管理有限公司

Mesh network applied to fixed establishment with movable items therein

ActiveUS10127601B2Testing sensing arrangementsParticular environment based servicesFactory floorOperating energy

Owner:SONY CORP

An automatic cleaning device for factory floors

InactiveCN105747997BImprove working environmentImprove performanceCarpet cleanersFloor cleanersFactory floorWorking environment

The invention discloses an automatic cleaning device for factory floor, which belongs to the technical field of factory cleaning. The technical solution is: an automatic cleaning device for factory floor, including a drive system, a cleaning system and a motion system. The beneficial effects of the present invention are: the present invention establishes a device for automatic cleaning of the workshop floor, which is reliable in performance, small in size, and has flexible movement capabilities in complex and smooth ground environments. The cleaning device in this solution can completely replace traditional manual cleaning The form of the factory building improves work efficiency and improves the working environment for workers.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Robotic Palletizer Cell And Method Of Construction

A method of constructing a palletizer cell by providing square platform bases which are assembled into an array in abutment with each other, each platform base mounting a respective component of palletizing equipment, such as a robot, one or more conveyors, a slip sheet bin, a discharge module, etc. with one platform base anchored to the factory floor and the rest attached to one or another of the platform bases to form the array of platform bases thereby properly locating the various equipment with each other by the fitting together of the platform bases. Safety fencing sections are mounted atop one or more outer sides to substantially enclose the space within the palletizer cell. Each platform base is formed with side openings which may be engaged with the tines of a fork lift.

Owner:ROBERTS BRIAN THOMAS

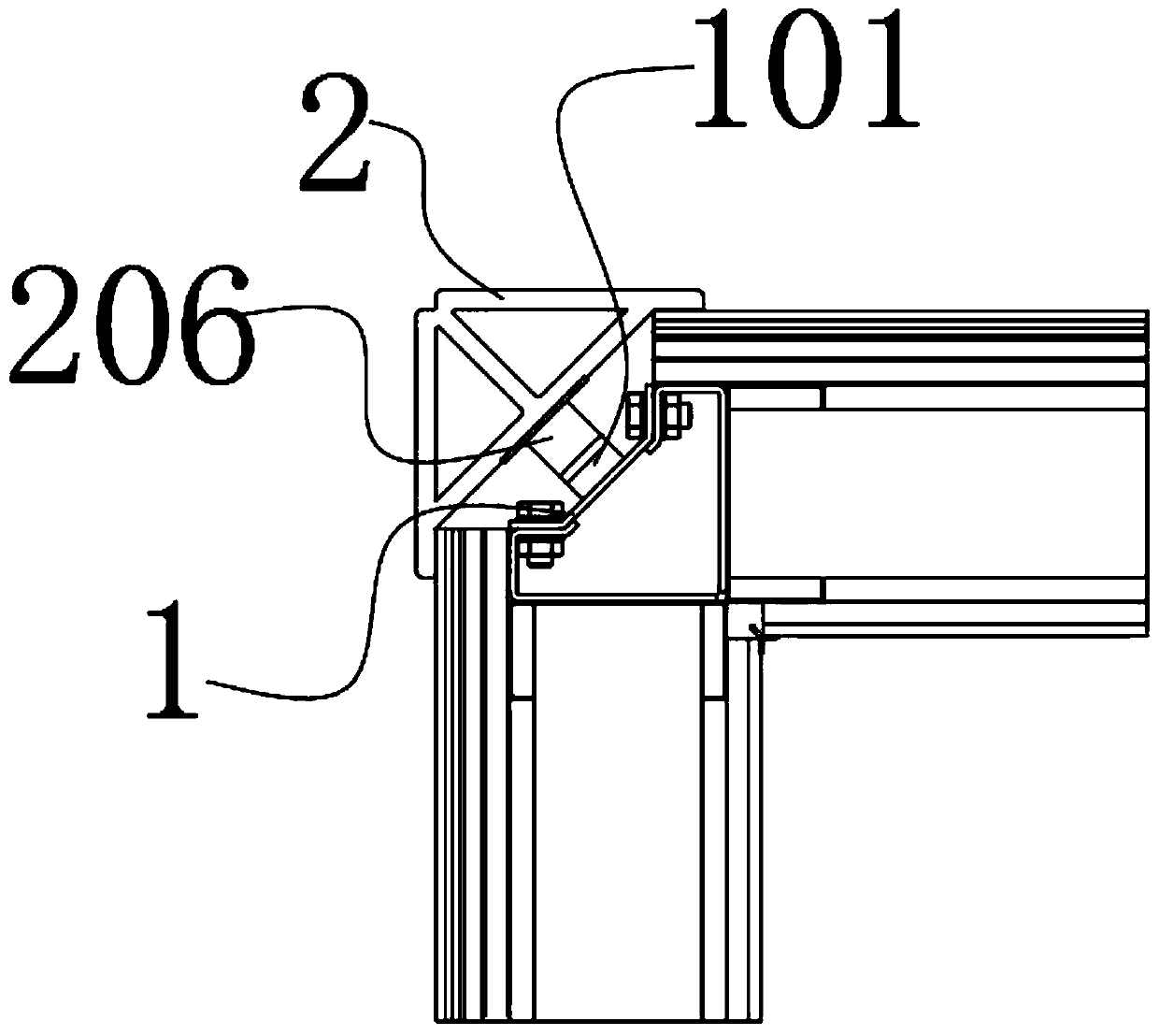

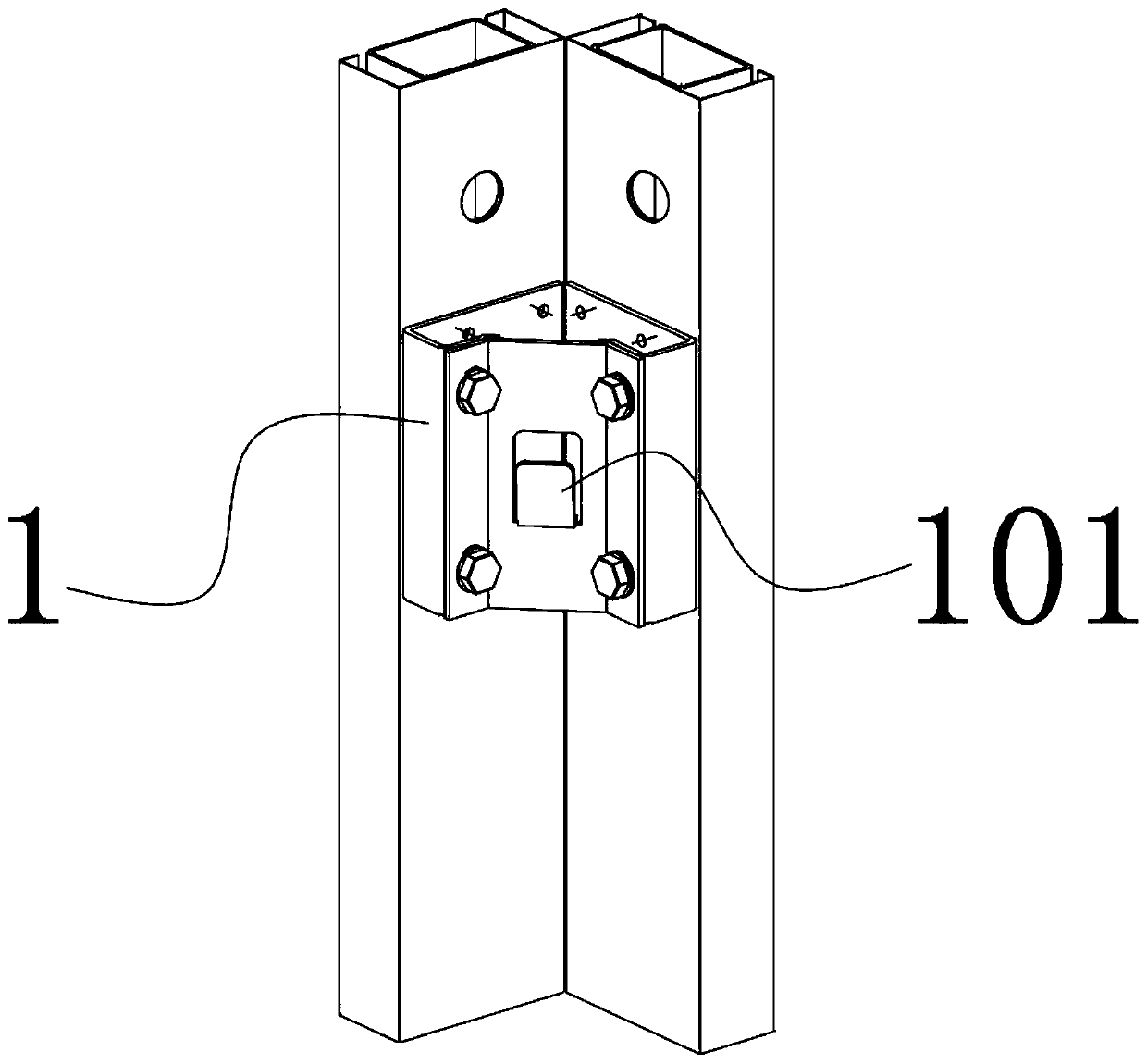

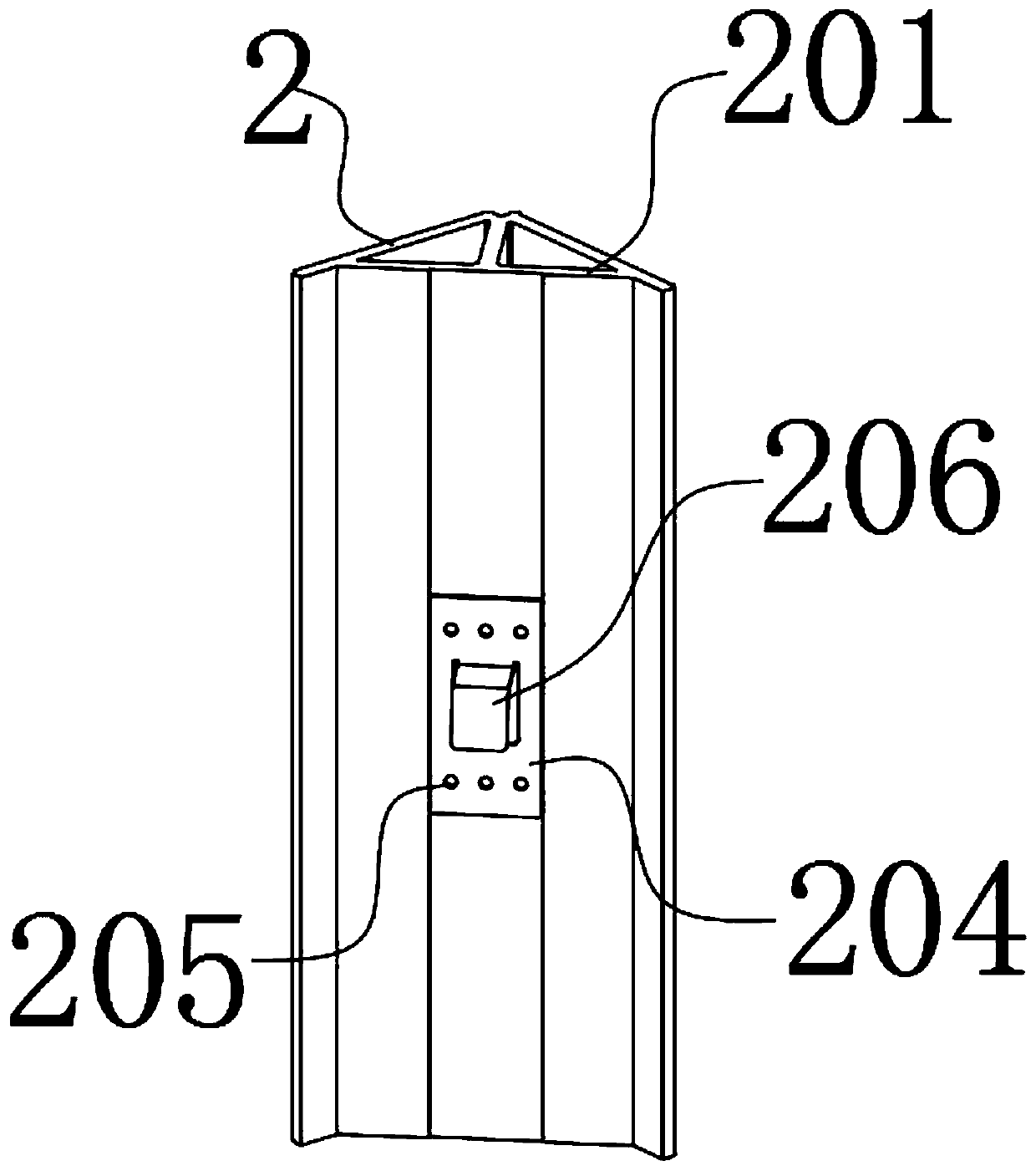

Co-extrusion wood-plastic hanging-buckle-type screwless corner capping seal

ActiveCN110242015AEasy to operateClean and tidy installation siteBuilding constructionsFactory floorCo extrusion

The invention discloses a co-extrusion wood-plastic hanging-buckle-type screwless corner capping seal, and relates to the technical field of building construction. The co-extrusion wood-plastic hanging-buckle-type screwless corner capping seal comprises a plurality of capping seal fixing seats and capping seal bodies; a plurality of capping seal hooks are arranged inside the capping seal bodies; the capping seal fixing seats are fixedly mounted in included angle gaps between two outdoor wall bodies, and provided with fixing seat hooks; and the capping seal bodies are mounted on the included angle edges between the two outdoor wall bodies. The co-extrusion wood-plastic hanging-buckle-type screwless corner capping seal is reasonable in structure, bottom feet are arranged at the bottoms of bases, damage of the bottom feet to a floor can be reduced relative to screws, protection to the factory floor is improved, the practicality of the base is improved advantageously, sliding rails are mounted at the tops of the base correspondingly, and abrasion of an upper forming machine to the bases under the situation of long-term frequent movement is reduced advantageously.

Owner:ANHUI SENTAI WPC GRP CO LTD

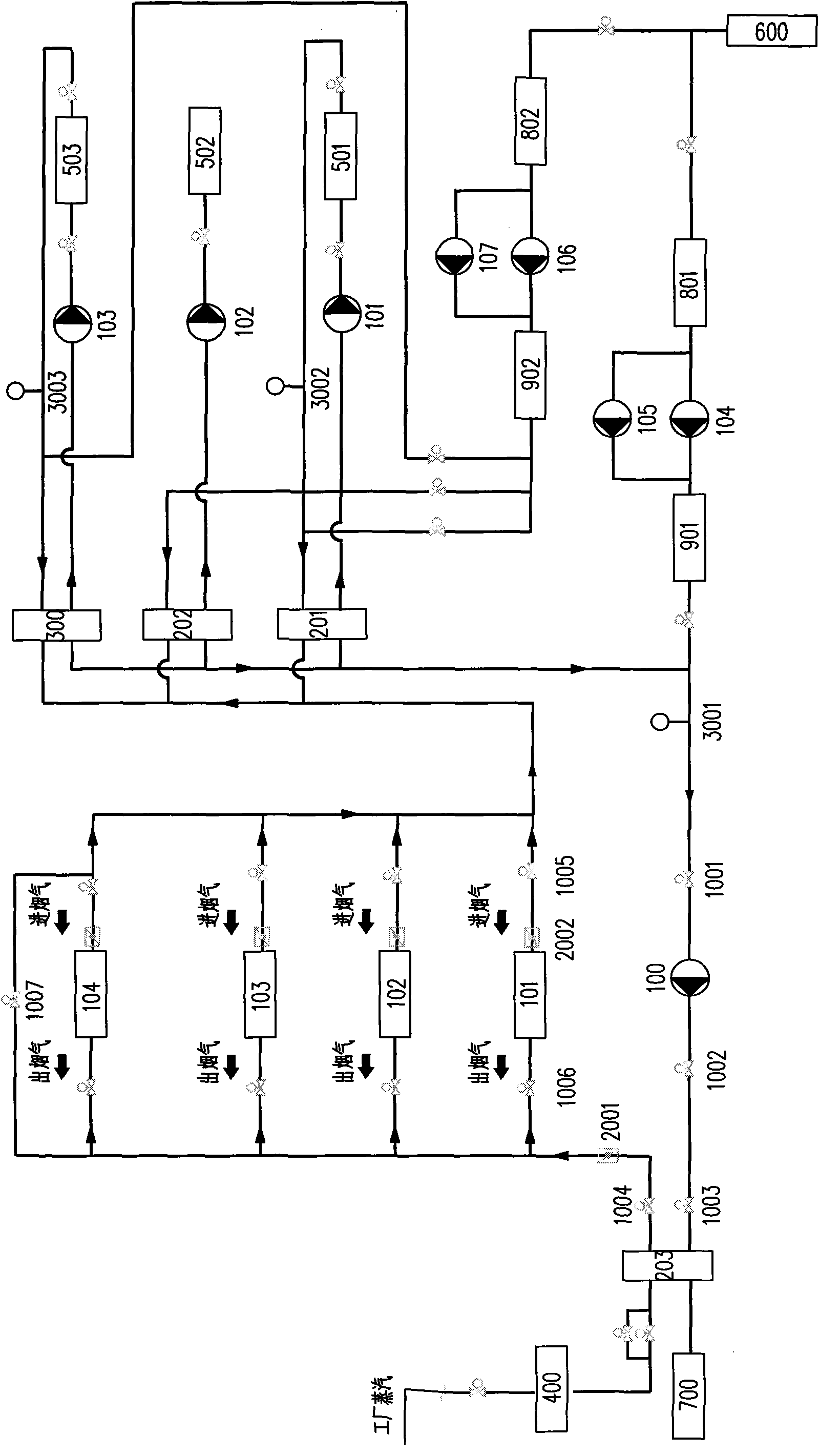

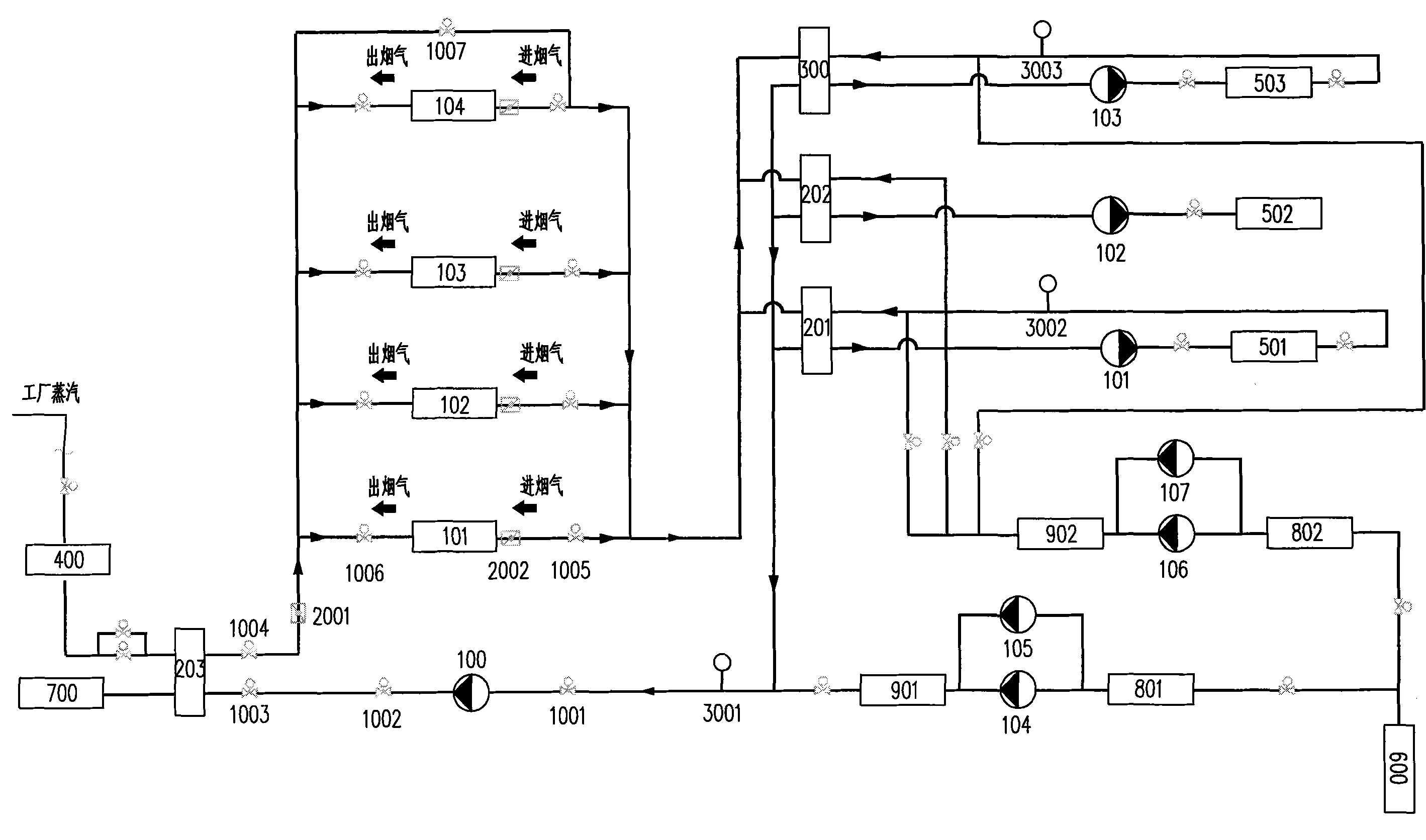

Flue gas-heat recovery cooling and heating system

InactiveCN101963415AImprove efficiencyReduce consumptionClimate change adaptationRefrigeration safety arrangementSocial benefitsFactory floor

The invention provides a flue gas-heat recovery cooling and heating system, which realizes cooling and heating by utilizing waste heat produced by the smoke exhaust of a 150MW machine set to improve the efficiency of a power plant and reduce pollutions, and reduces the running cost of air conditioners of factory floors, offices, living quarters and surrounding factories and domestic hot water and reduce electric power or fuel consumption made by users so as to fulfill the aims of saving energy and reducing emission. Therefore, the flue gas-heat recovery cooling and heating system has relatively better economic benefits and social benefits.

Owner:XINHUI SHUANGSHUI POWER B PLANT CO LTD

Device for heating and humidifying workshop by using waste factory hot water

InactiveCN107741074AHealth effectsEffective filteringLighting and heating apparatusSpace heating and ventilation detailsWater storageWater storage tank

The invention discloses a device for heating and humidifying a workshop by using waste water from a factory. The device comprises a support base plate, a tank support seat, a hot water outlet pipe, a water storage tank, an air filter device, an exhaust pipe, and a driving motor. , sewage solenoid valve, sewage filter tank, sewage pipe, electric control box, waste hot water regulating valve, waste water hot water inlet pipe, air filter device consists of air outlet, fine filter, adsorption filter layer, coarse filter, air inlet The protective shell is fixed on the left side of the exhaust pipe by bolts. The invention realizes the device for heating and humidifying the workshop by using the waste water from the factory. By installing an air filter device, the waste water from the factory can be used to heat the workshop. The warm and humidifying device can effectively filter the filtered waste hot water air when in use, avoiding the gas that is harmful to human health in the air from entering the factory workshop and affecting the health of workers, and effectively improving the safety of the device.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

Factory-produced high-efficiency prefabricated building floor slab and manufacturing method

ActiveCN104727438BQuality improvementFast construction and installation on siteBuilding constructionsFloor slabFactory floor

The invention relates to a novel industrialized production efficiently-assembled type building floor slab. The novel industrialized production efficiently-assembled type building floor slab comprises a floor slab body capable of being connected with a column and a beam, and the longitudinal cross section of the floor slab body is trapezoid; a rebar support is embedded, the ends of the rebar support extend to the four lateral walls of the floor slab body and protrude out of the lateral walls to form rebar heads; welding hole slots are formed in the trapezoid end face of the floor slab body, and the rebar heads located on the trapezoid end face are exposed out from the welding hole slots. As the novel industrialized production efficiently-assembled type building floor slab is prefabricated in a plant, the quality can be better guaranteed; assembling and installation are achieved on site so that a large number of formworks can be saved, and the construction period can be shortened; only three main working procedures including placing the floor slab in place, mutual welding and joint filling are needed on the engineering construction site, and construction is convenient.

Owner:马恒忠

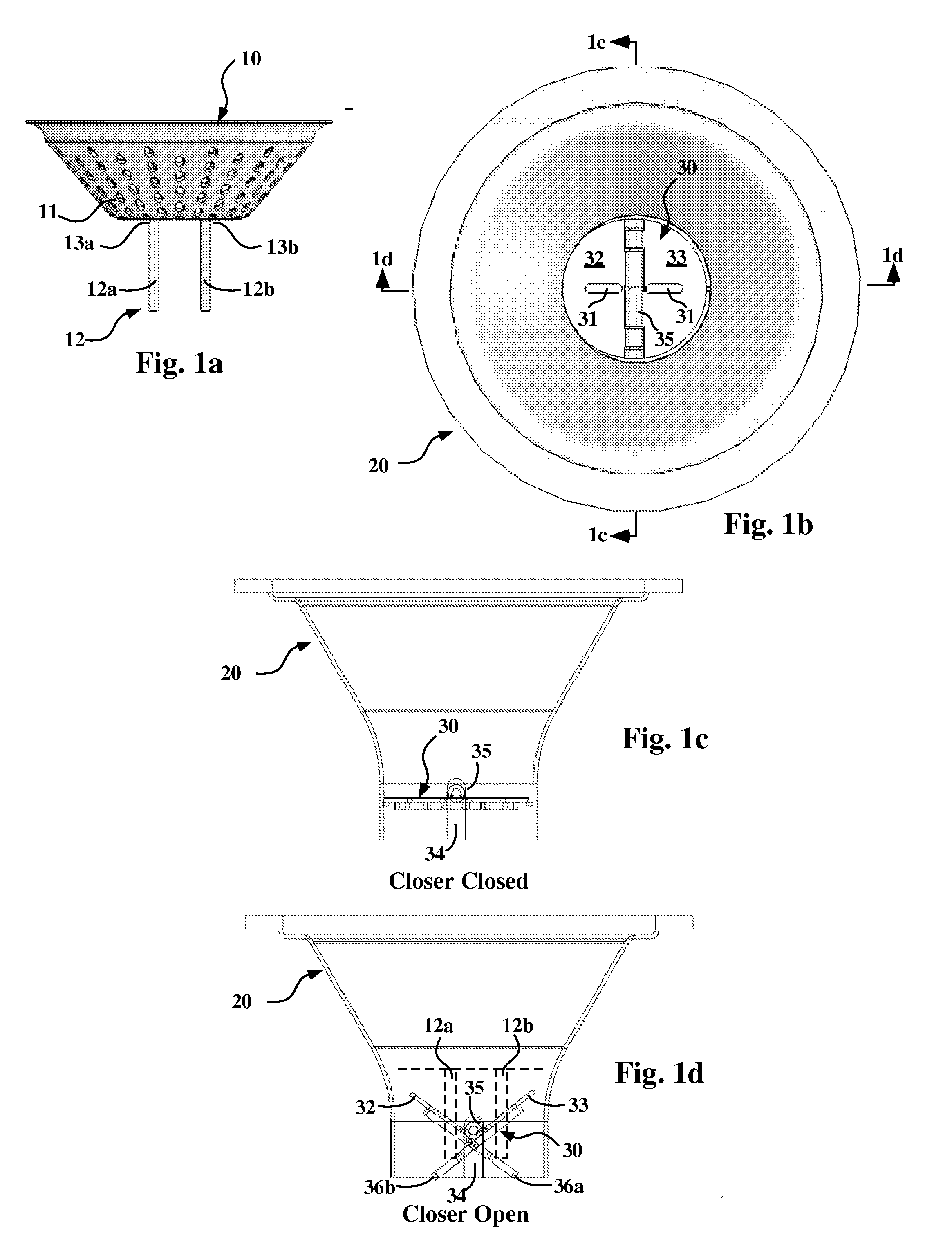

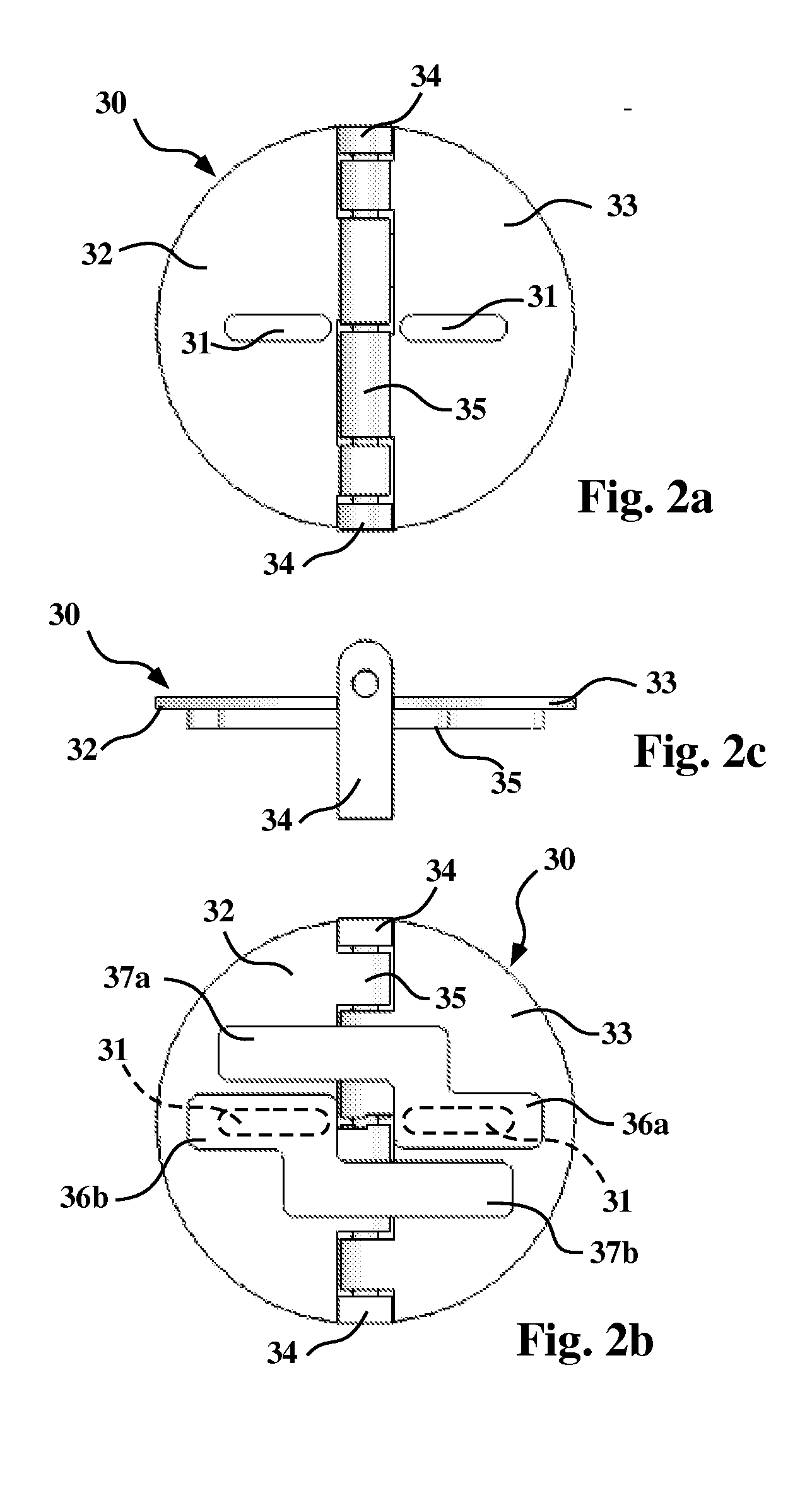

Steel drain with automatic closer

InactiveUS20090095667A1Fatty/oily/floating substances removal devicesSewerage structuresProduction lineDraining tube

Cleaning operations involving steam and flushing with water produce runoff that flows into drains installed in factory floors. Allowing bulky materials to flow into and plugging factory drains creates floor flooding conditions, production line shutdown and loss of time and money. These conditions can occur when strainer baskets are removed from drains. A drain facilitated with a drain closer prevents flow of bulky materials into drains and subsequent plugging. The drain closer is activated with a modified strainer basket such that removal of the basket closes the drain preventing inflow of bulky materials.

Owner:EAST CREEK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com