Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Gram weight high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

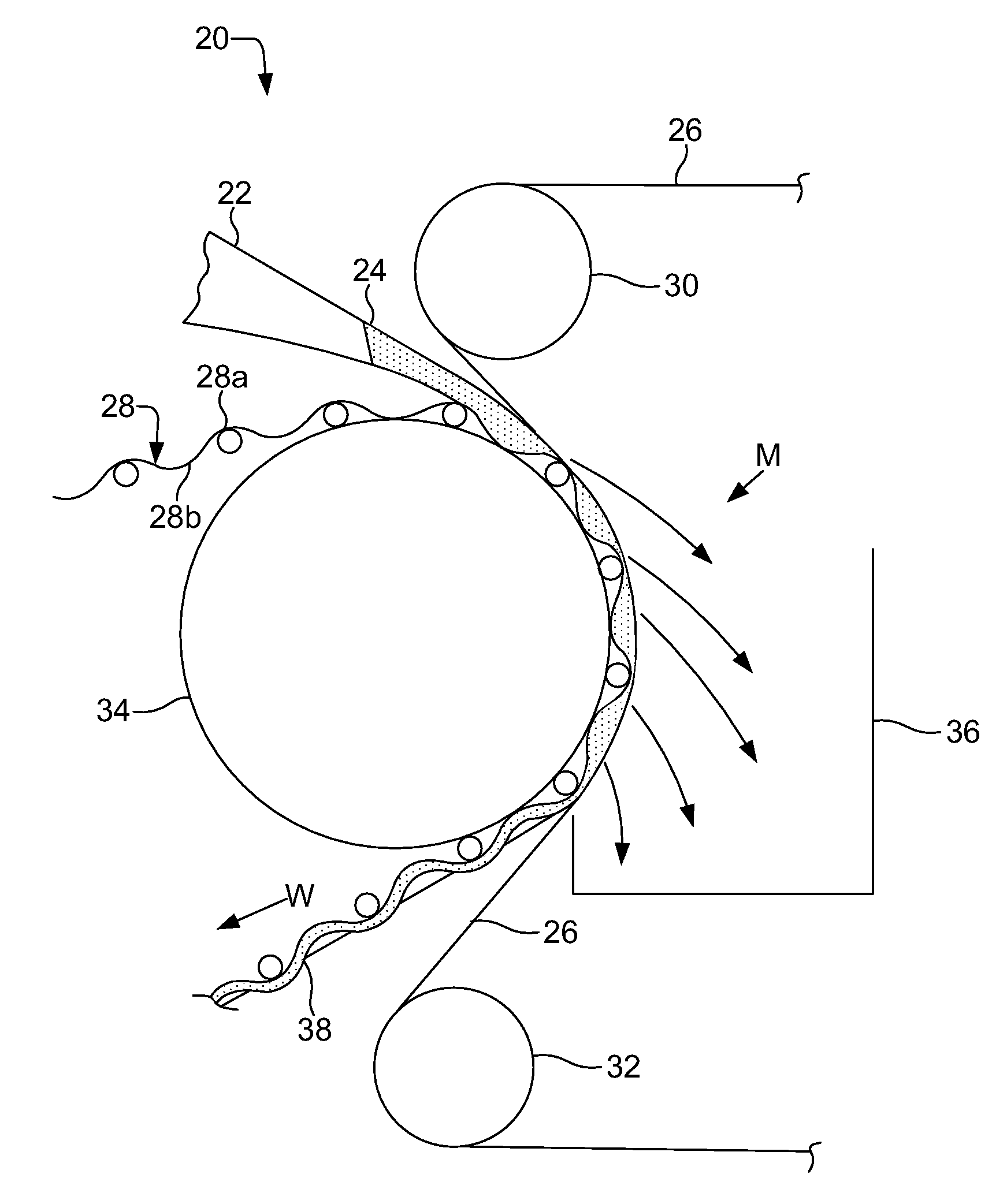

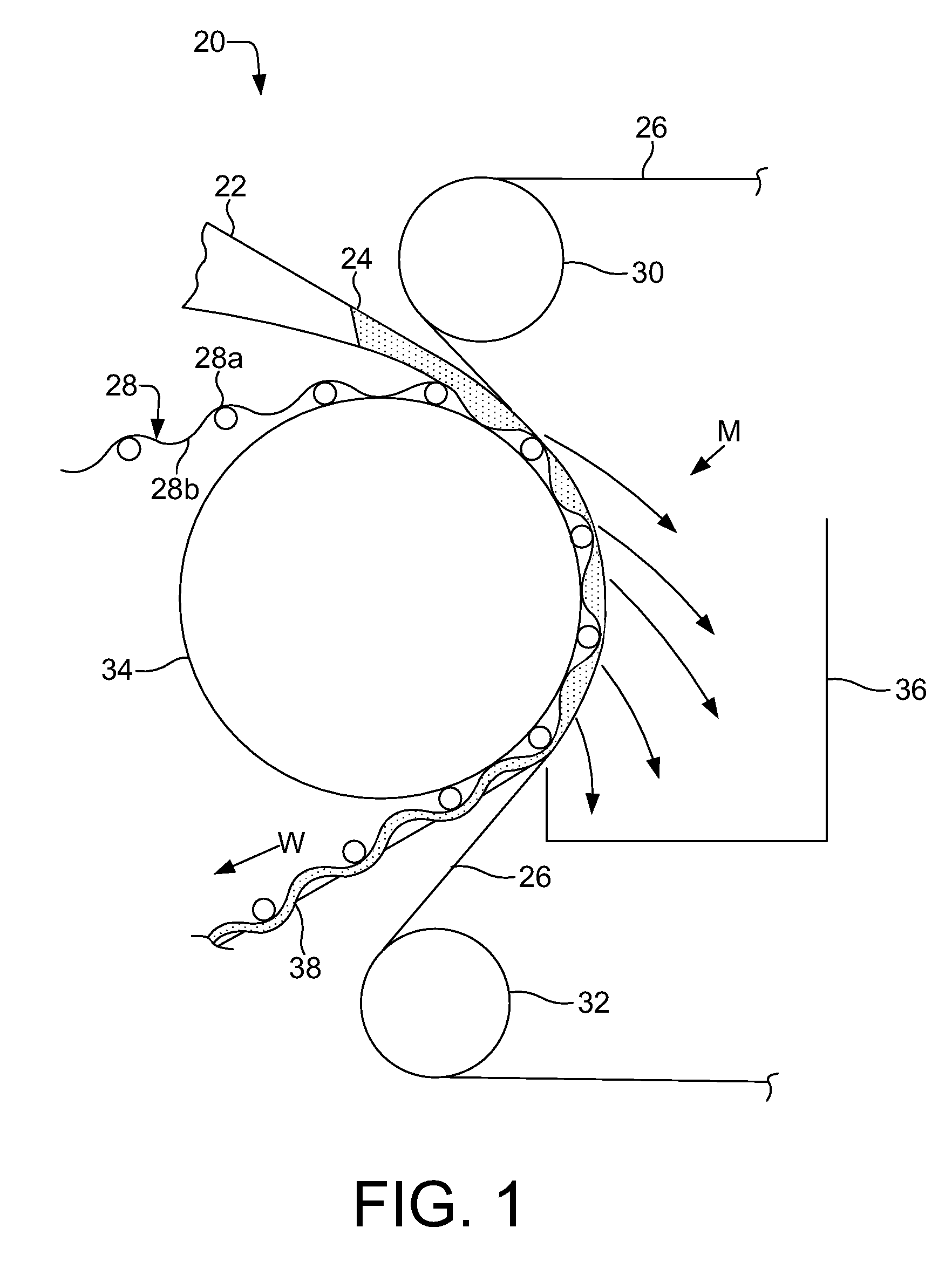

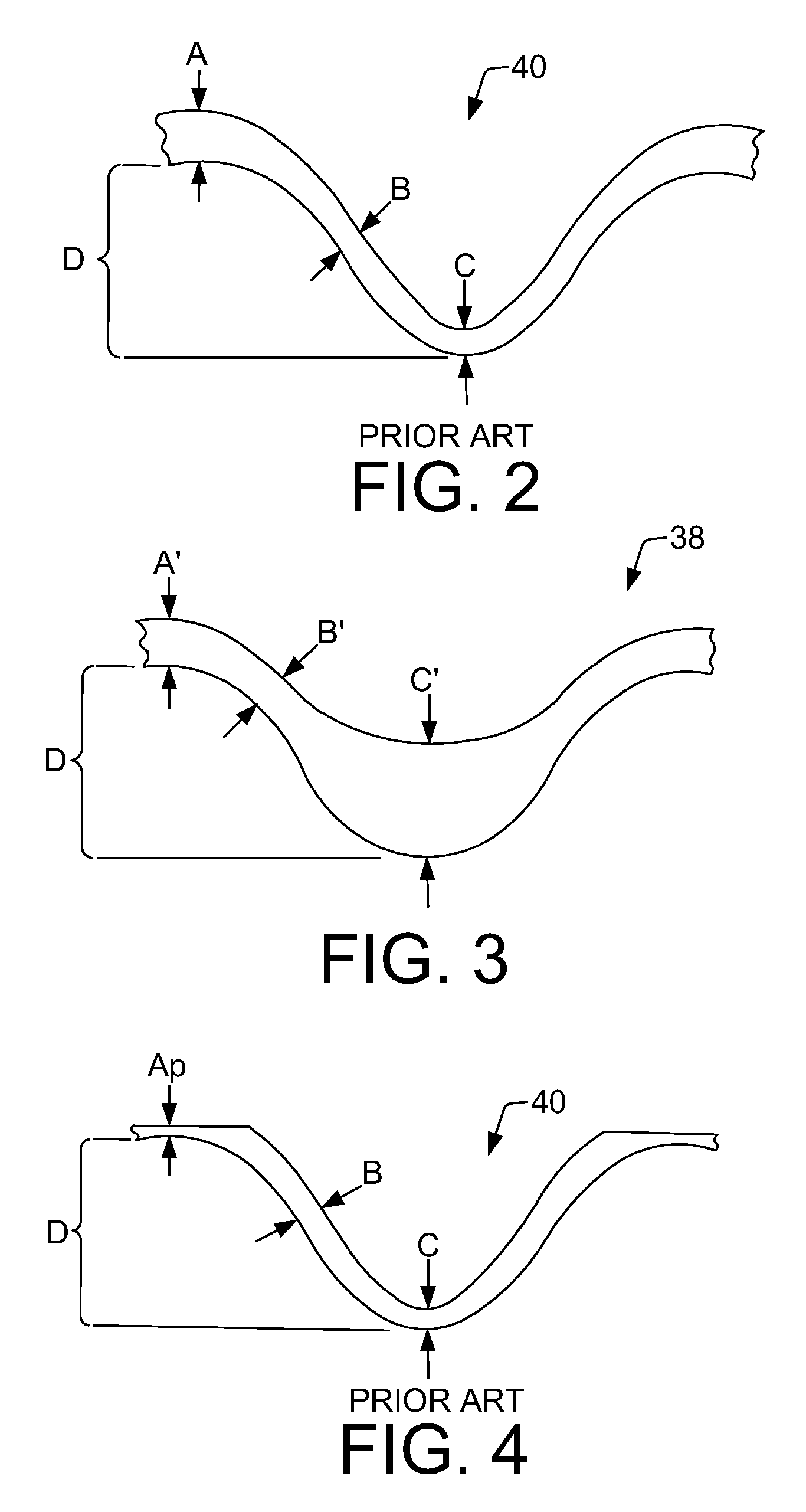

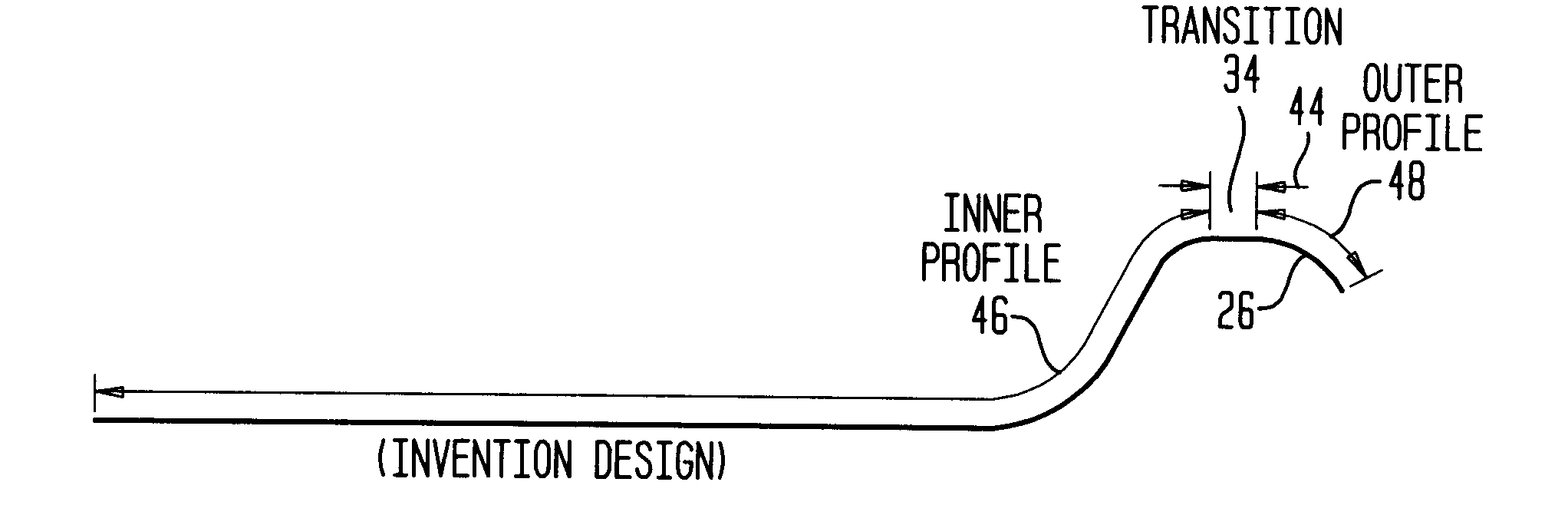

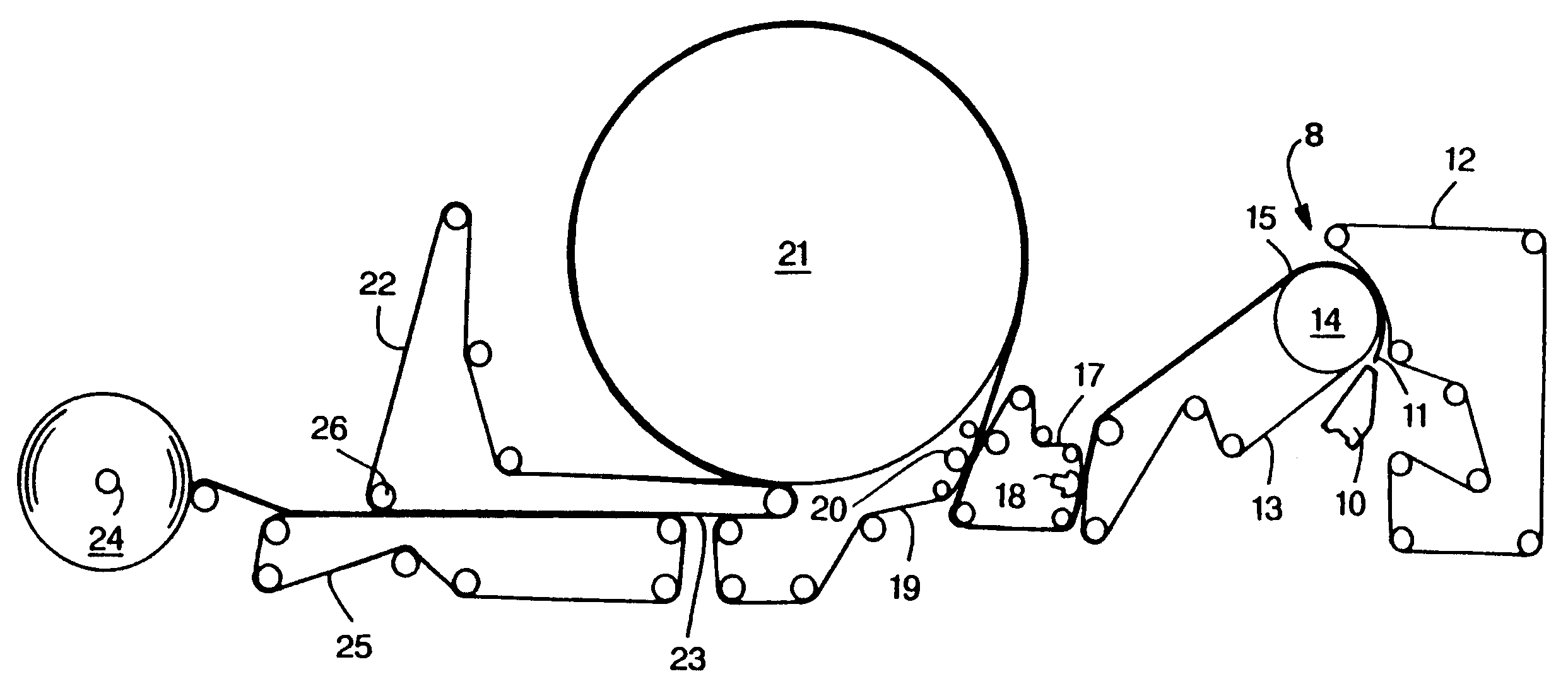

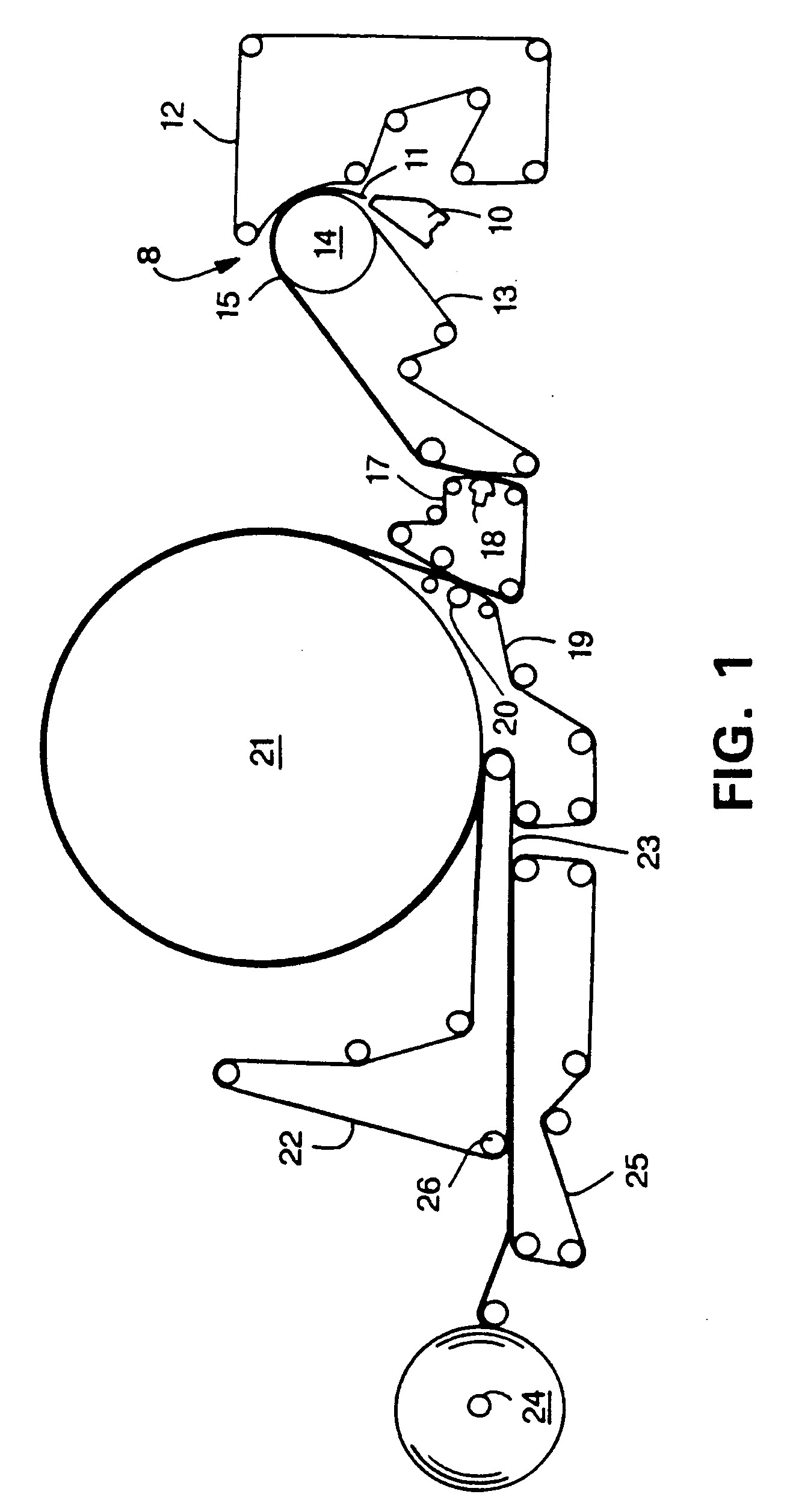

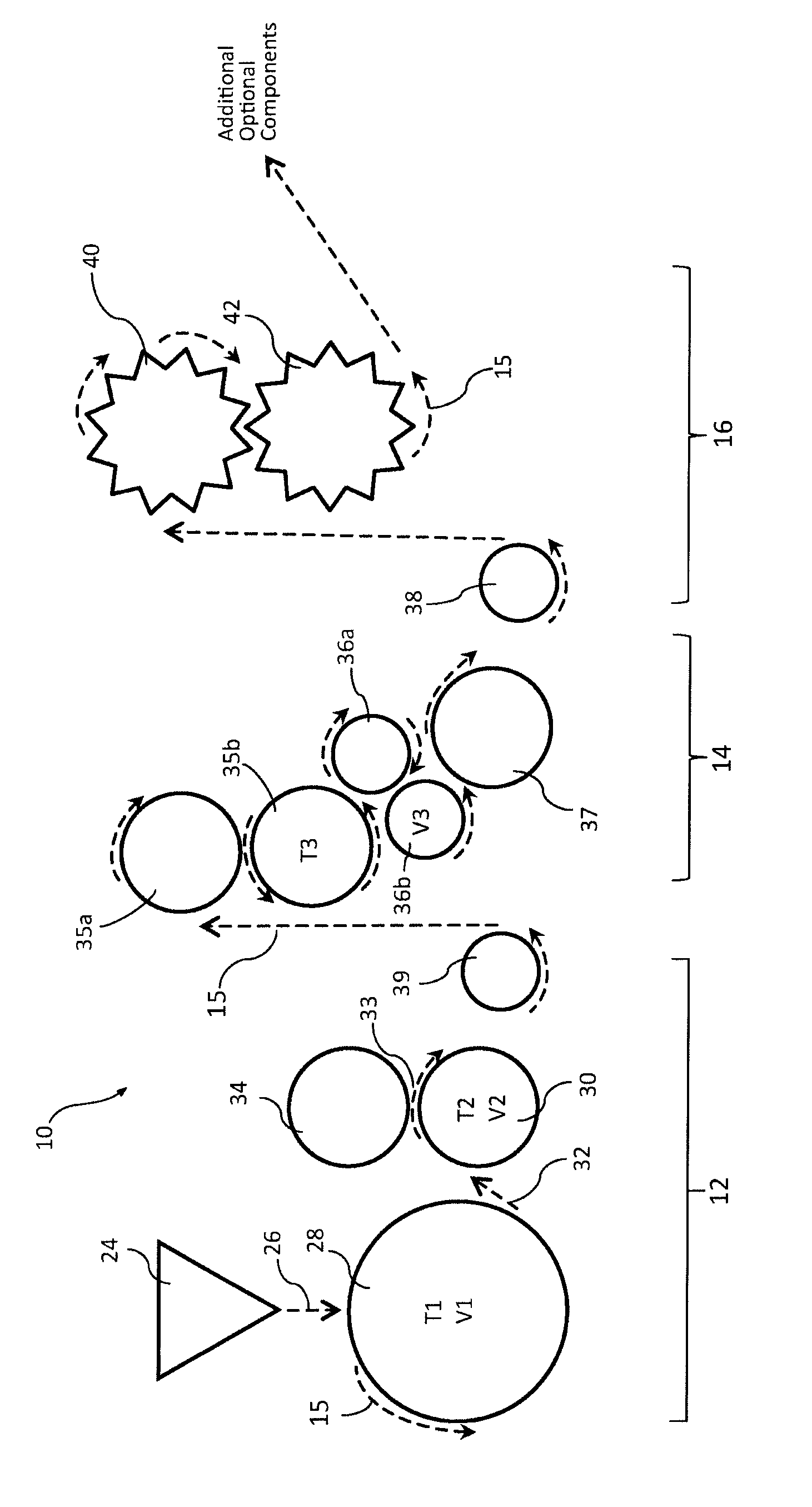

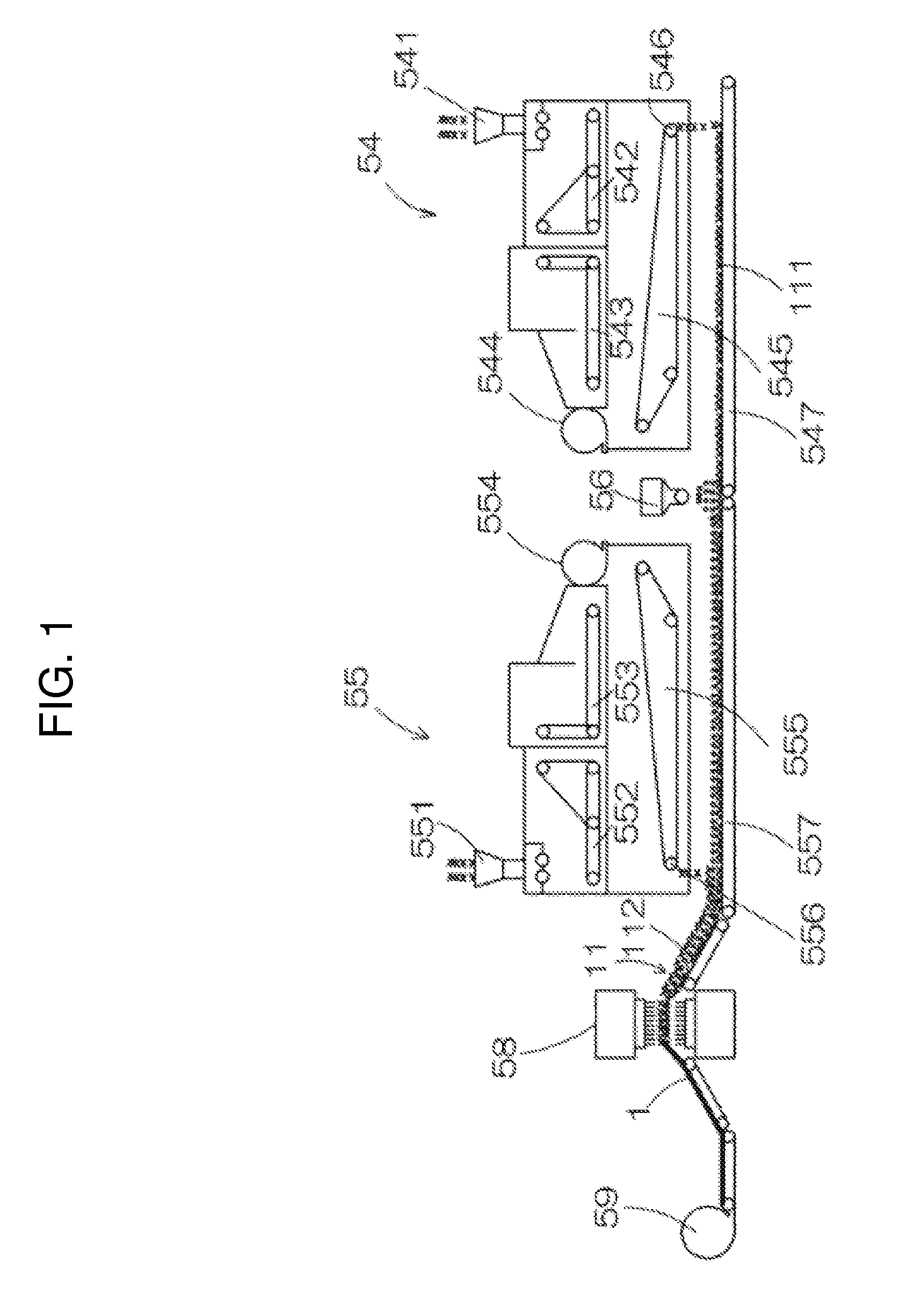

Process of material web formation on a structured fabric in a paper machine

InactiveUS7387706B2High fiber basis weightLow densityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

Owner:VOITH PATENT GMBH

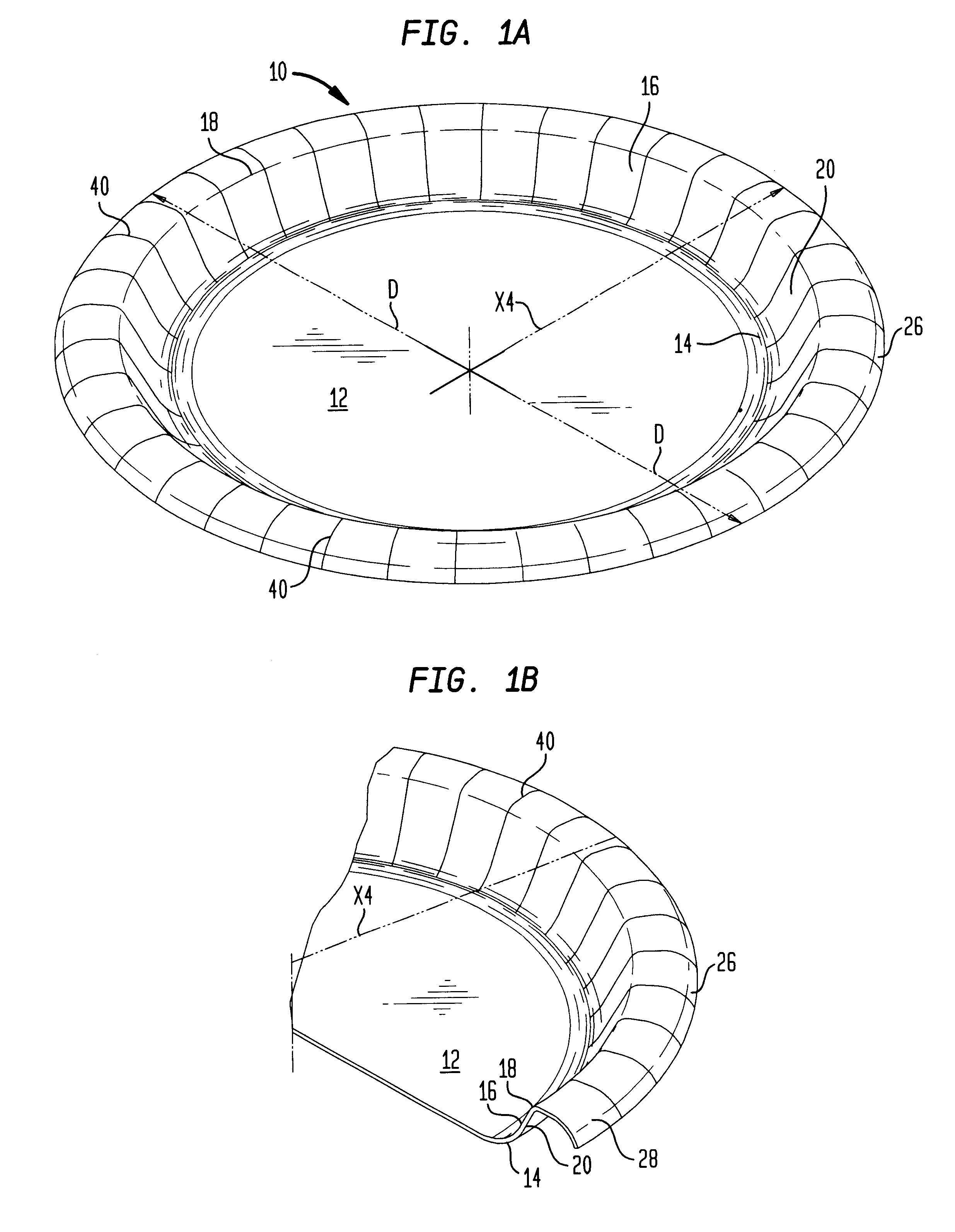

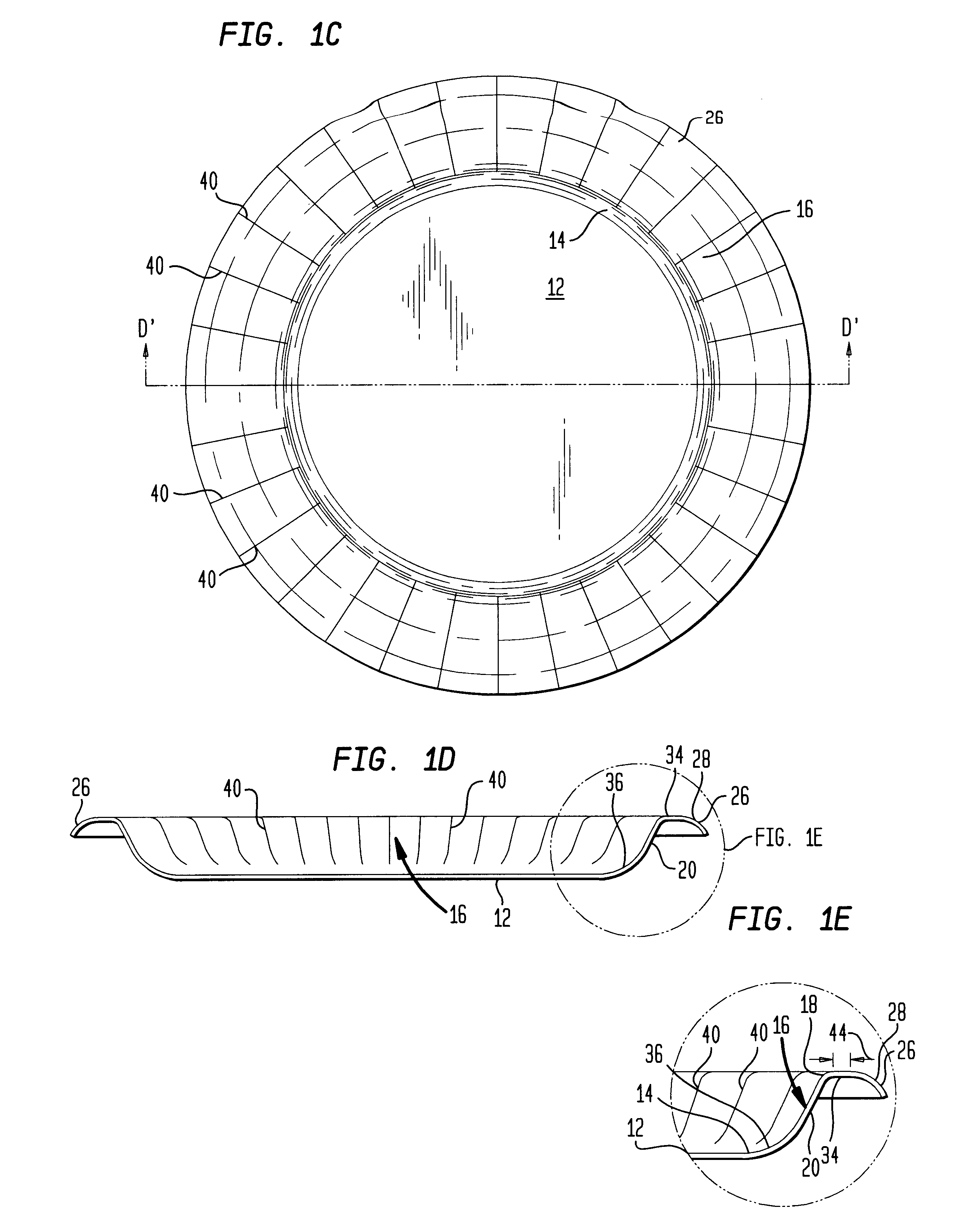

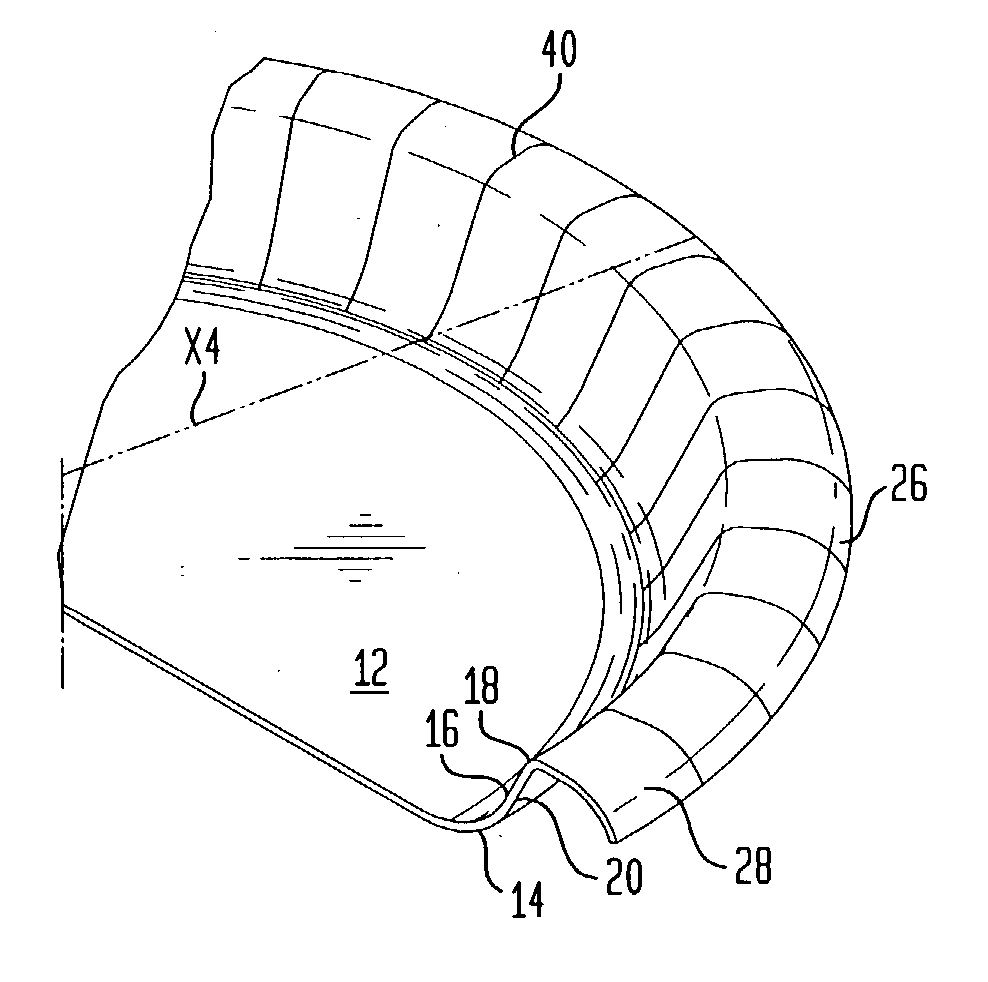

Disposable food container with a linear sidewall profile and an arcuate outer flange

InactiveUS6715630B2Good physical propertiesLose weightEnvelopes/bags making machinerySpecial paperEngineeringUltimate tensile strength

The present invention is directed to rigid disposable food containers provided with a relatively steep sidewall with a generally linear profile and an outwardly flared arcuate flange portion. The containers are further characterized by a flange outer vertical drop wherein the ratio of the length of the vertical drop to the characteristic diameter of the container is greater than about 0.01. By virtue of unique geometry, the containers of the invention exhibit improved rigidity and / or rim stiffness yet have favorable runnability in pressware manufacturing systems characteristic of plates of lower strength.

Owner:GPCP IP HLDG LLC

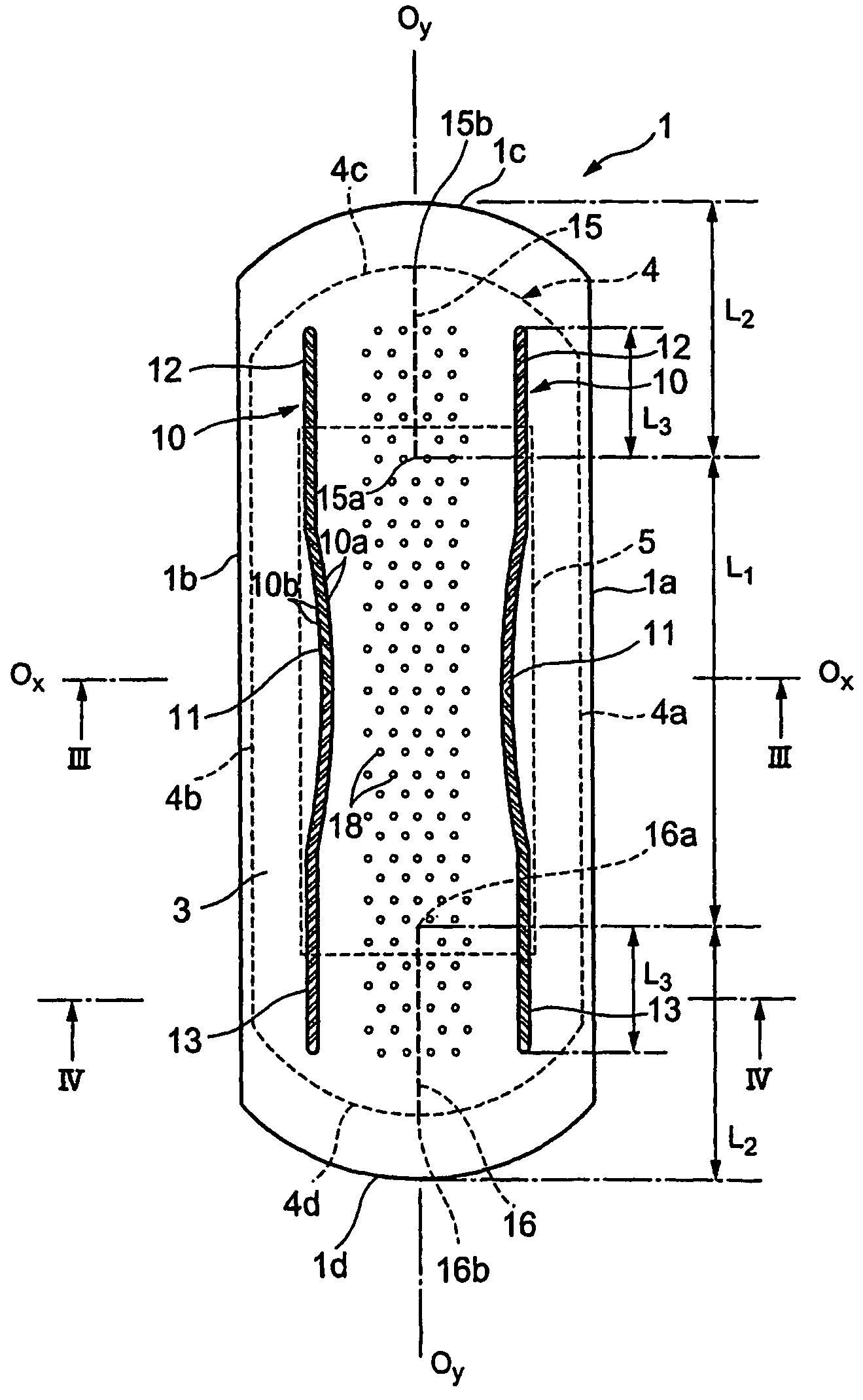

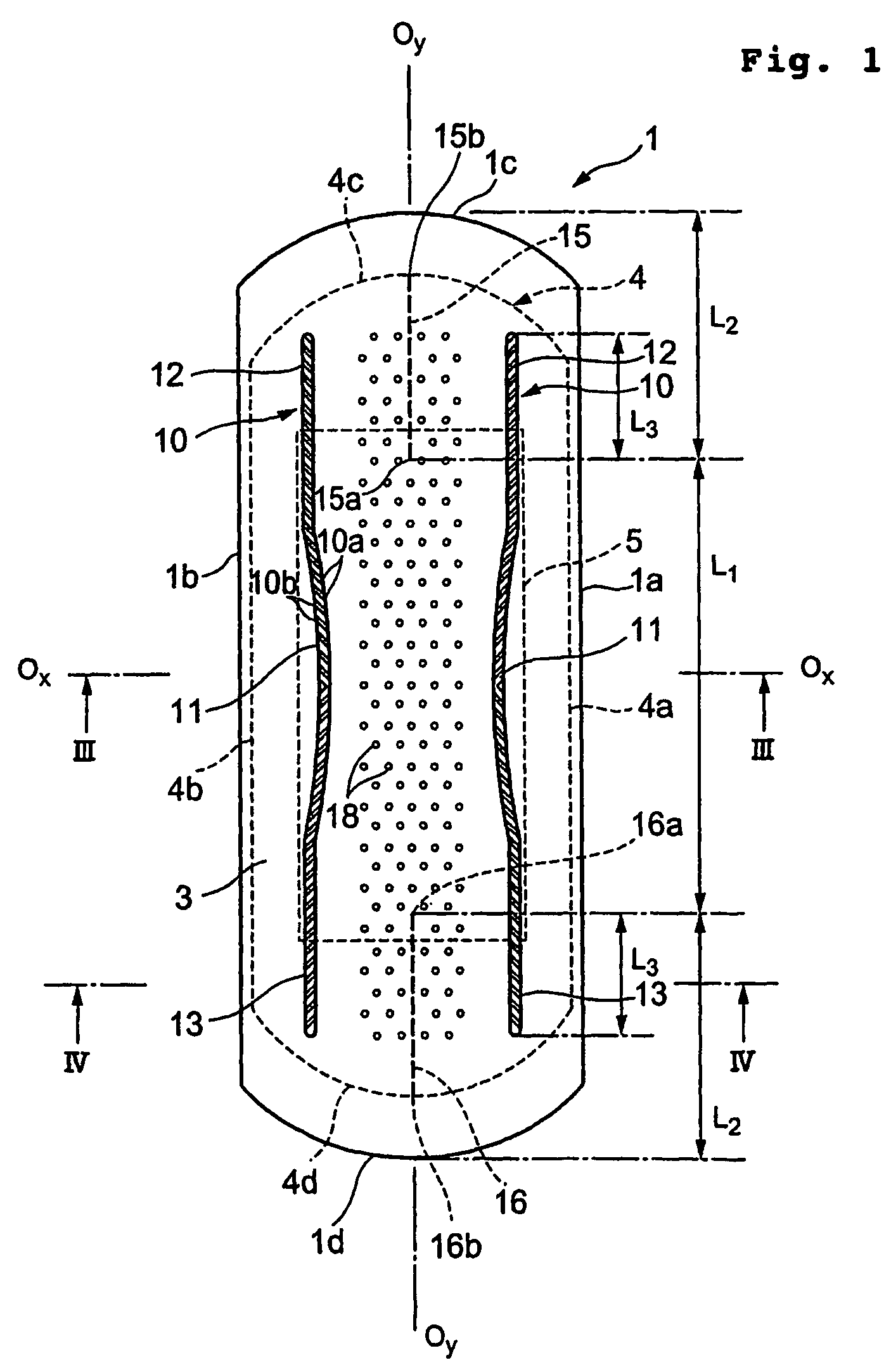

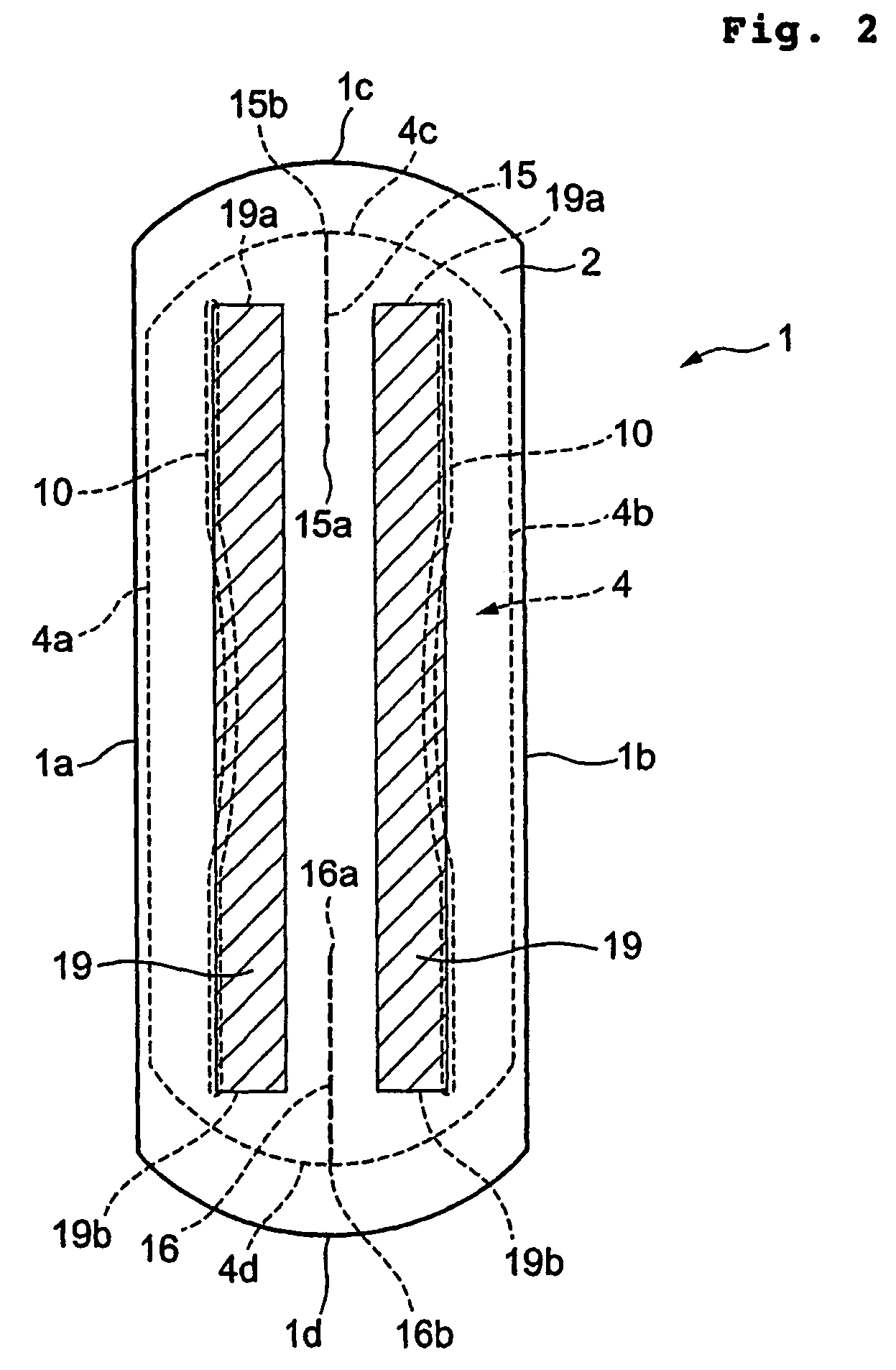

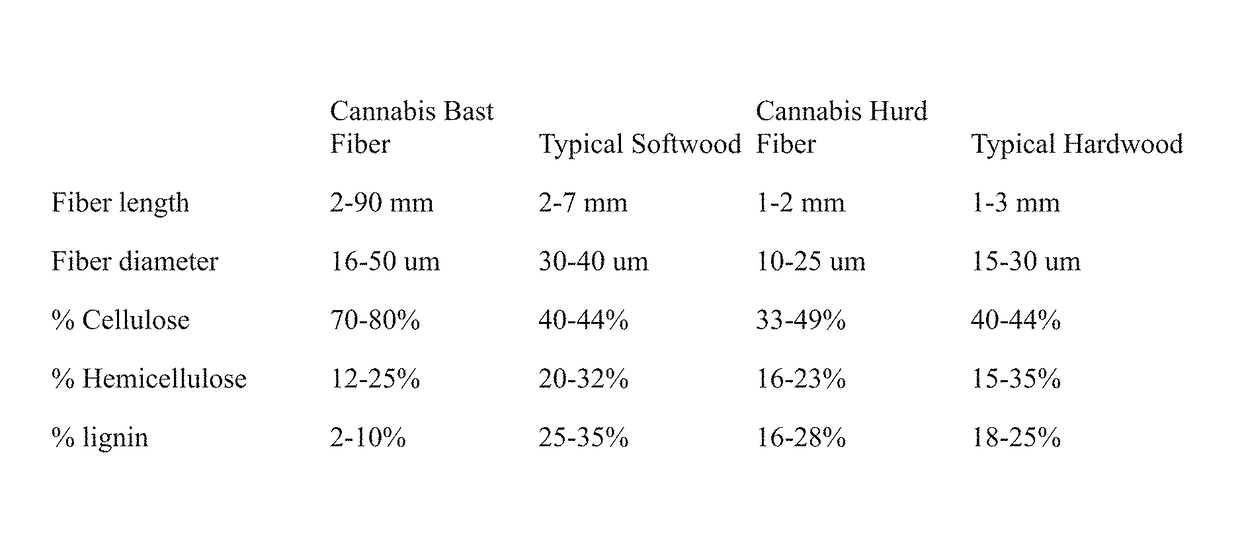

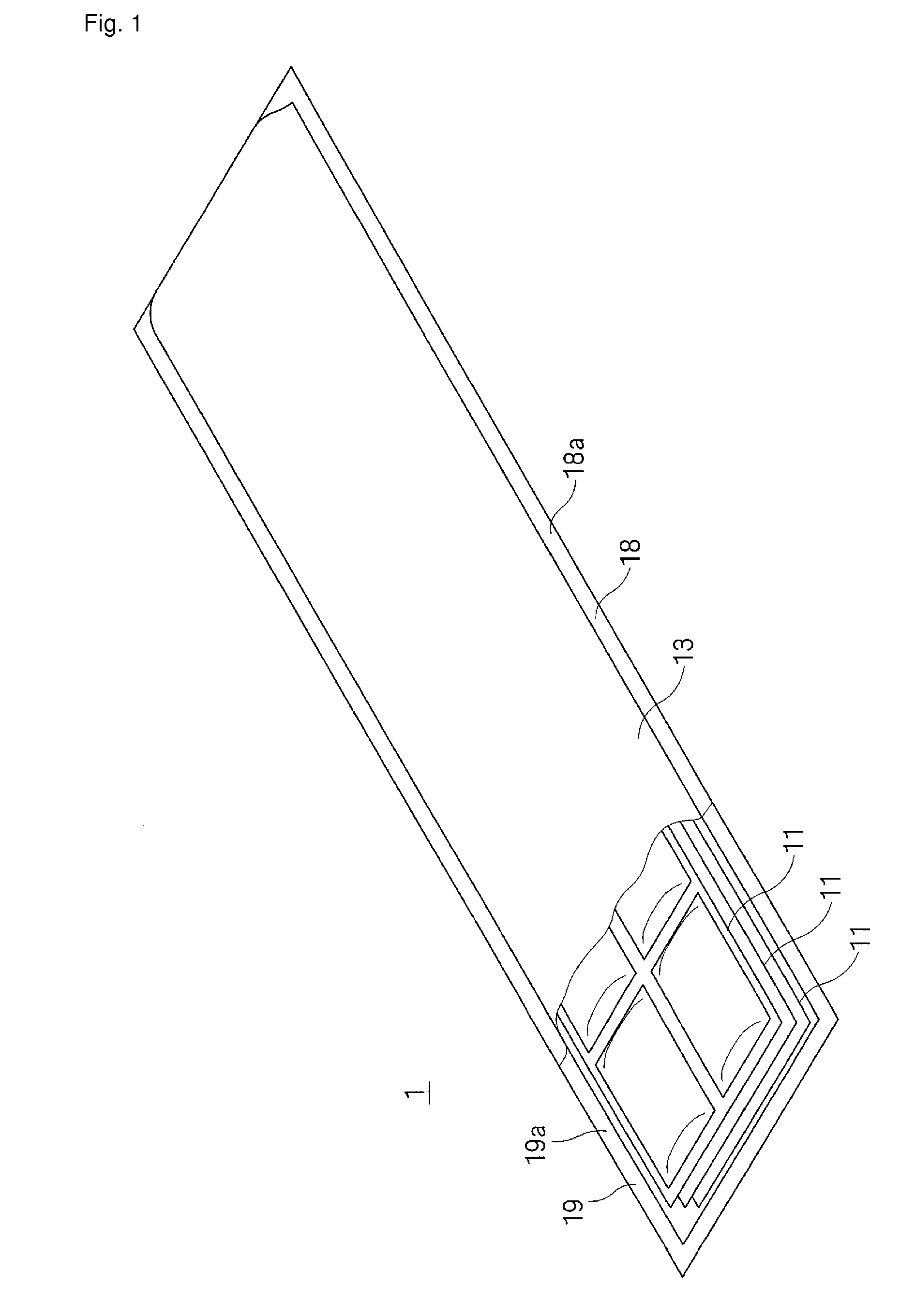

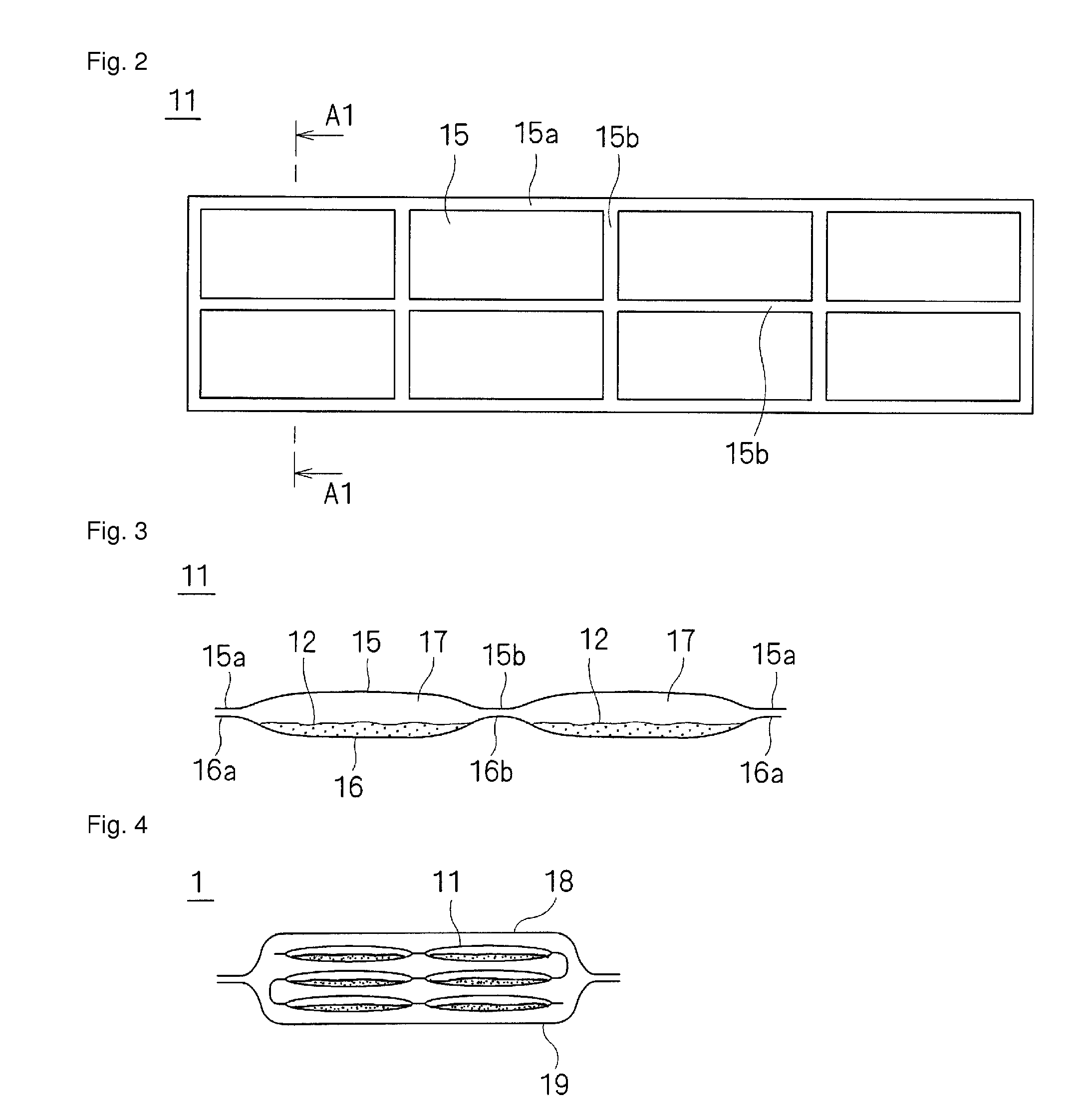

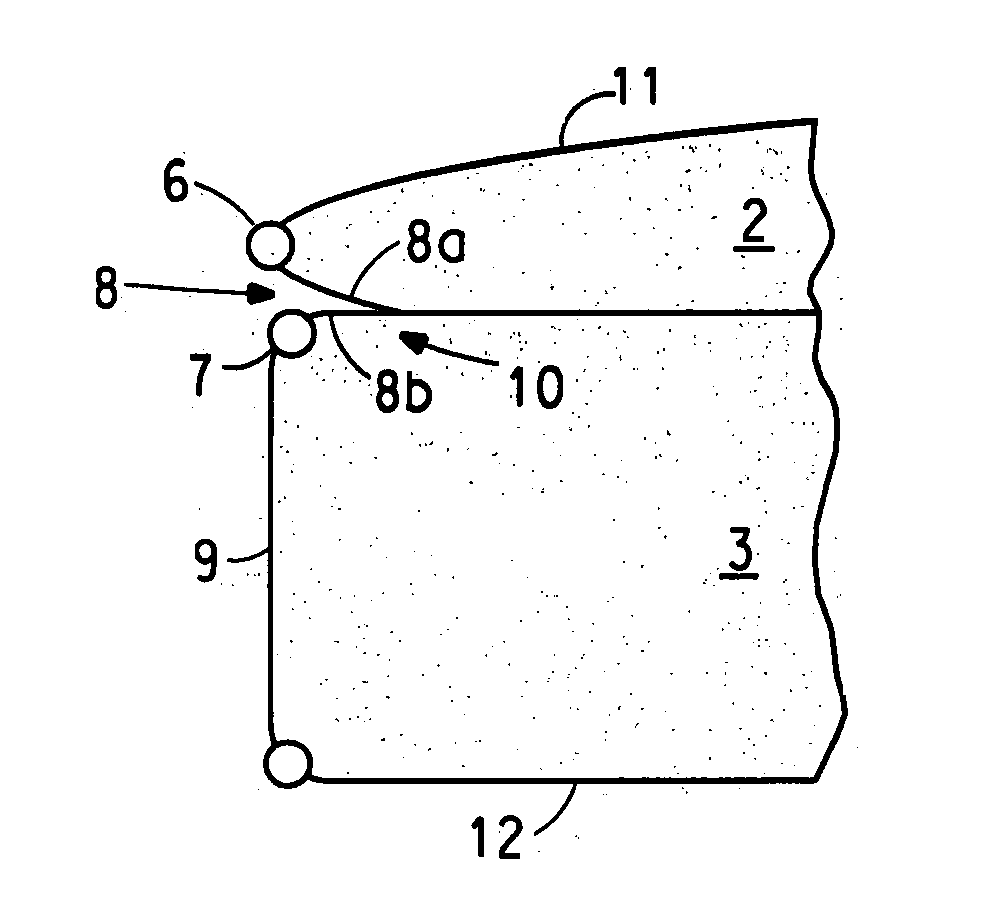

Absorbent article with compressed groove and flexible portion

InactiveUS7504552B2Easily pressed against vaginal openingIncrease stiffnessSanitary towelsBaby linensSkin surfaceEngineering

Disclosed is an absorbent article including compressed grooves (11) and a rear flexible portion (16). The compressed grooves (11) where a liquid absorbent layer (4) is compressed and recessed from the side of a skin surface toward a garment surface are provided to extend in a longitudinal direction of the article so as to approach each other the nearest on a lateral reference line (Ox-Ox) of the article. The rear flexible portion (16) where the liquid absorbent layer (4) is recessed from the side of the garment surface toward the skin surface is provided to extend toward a rear end edge (1d) from a starting point (16a) that is located closer to the rear end edge (1d) than the lateral reference line (Ox-Ox). At least a portion of the rear flexible portion (16) is located between the compressed grooves (11).

Owner:UNI CHARM CORP

Soft Single-Ply Tissue

ActiveUS20100051218A1Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineeringPaper sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

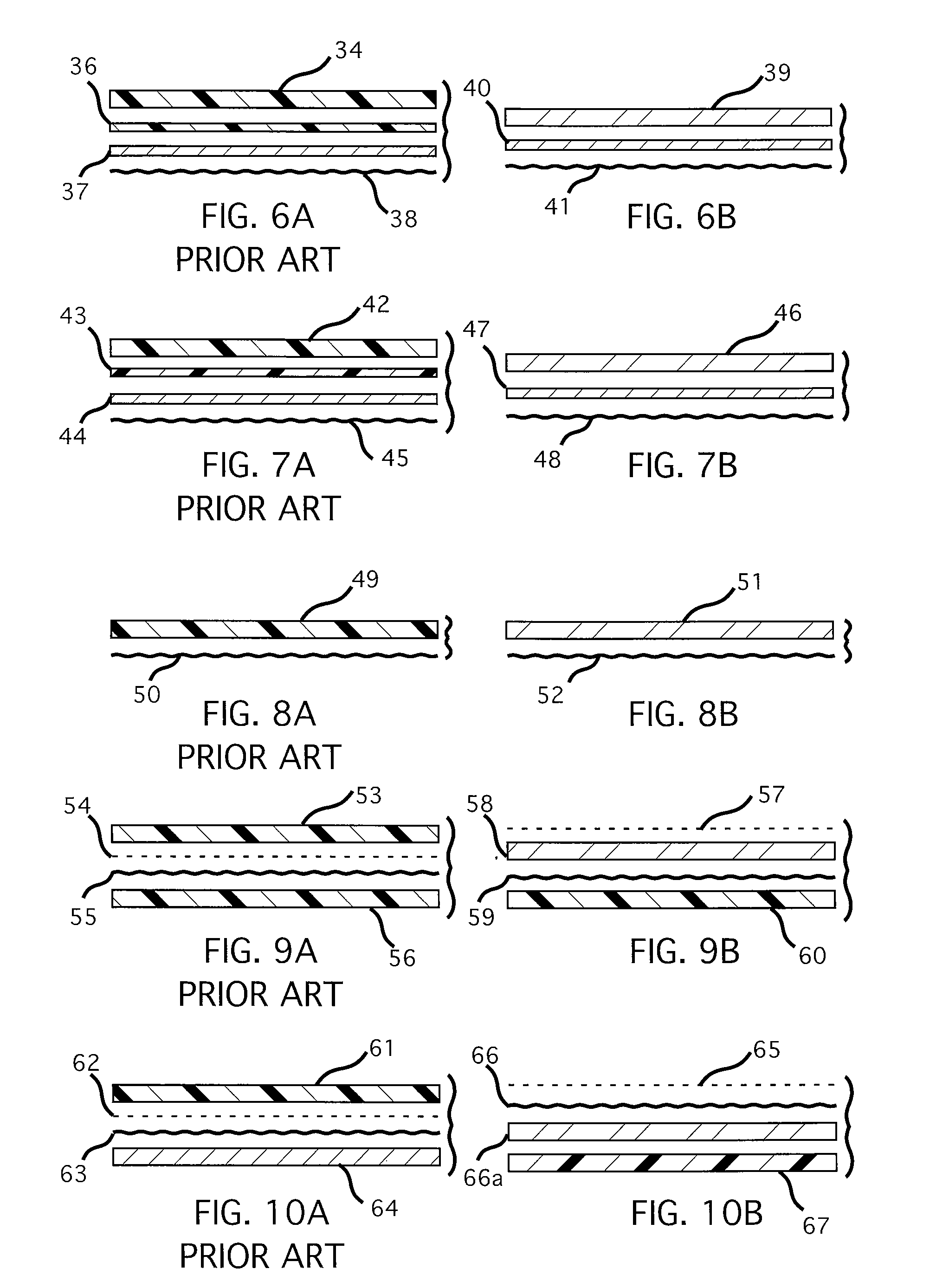

Acquisition/distribution layer

An absorbent article has a topsheet, an absorbent core and an acquisition / distribution transfer system disposed intermediate the topsheet and the absorbent core. The system includes at least one apertured material which is three dimensional and defines pores extending appreciably beyond the primary plane of the material in a direction from the absorbent core toward the topsheet. Preferably the pores taper inwardly from the core toward the topsheet.

Owner:FIRST QUALITY PRODS

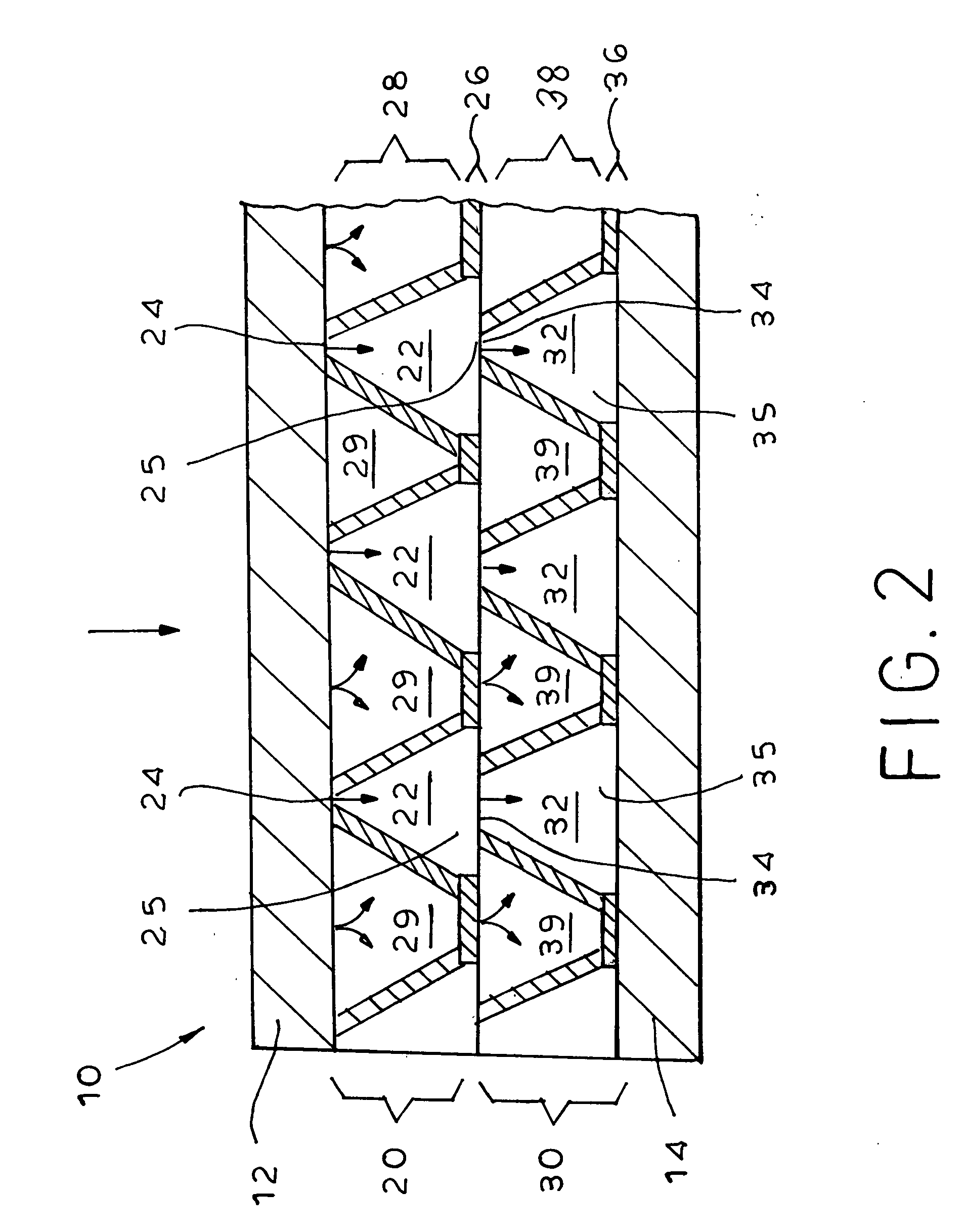

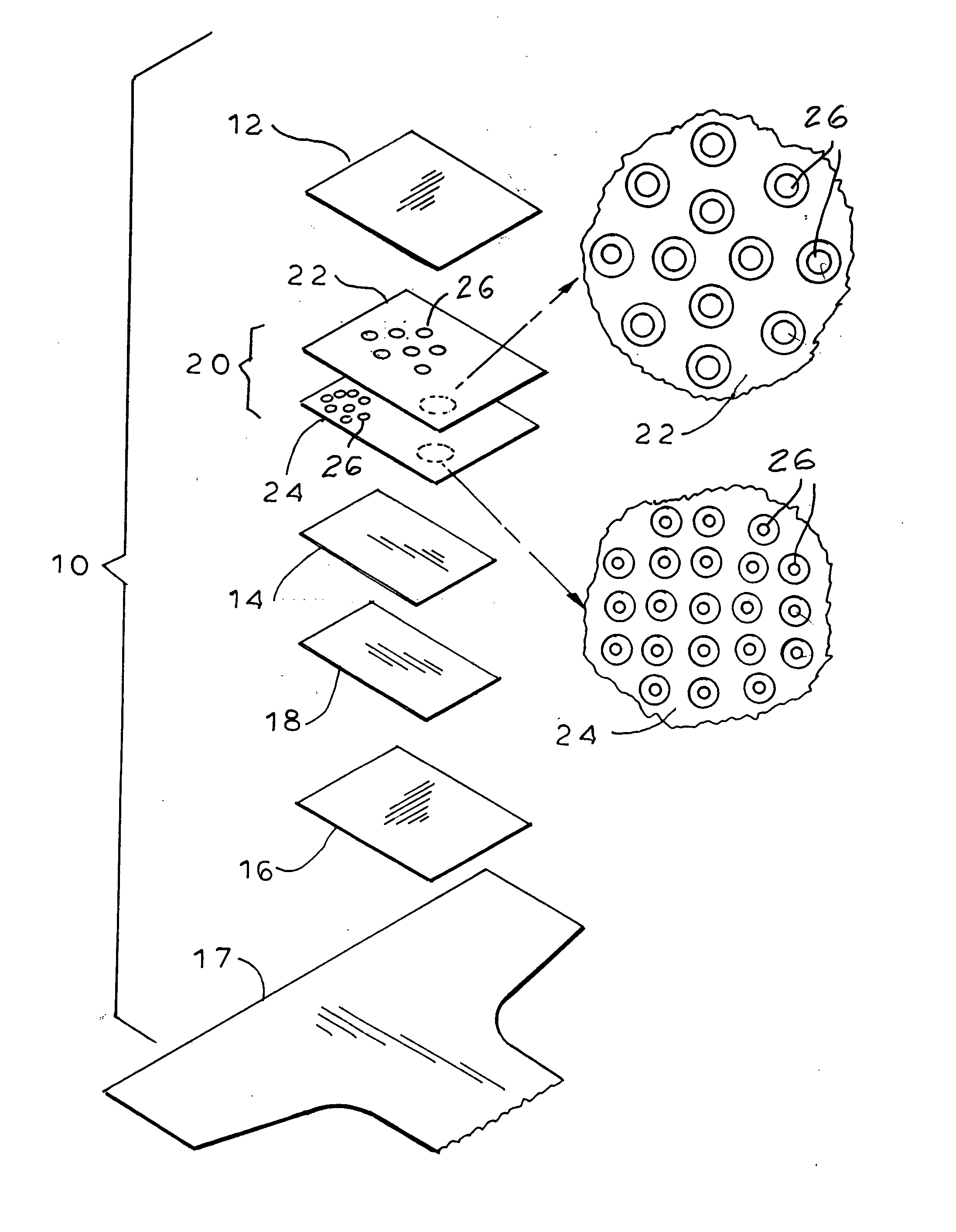

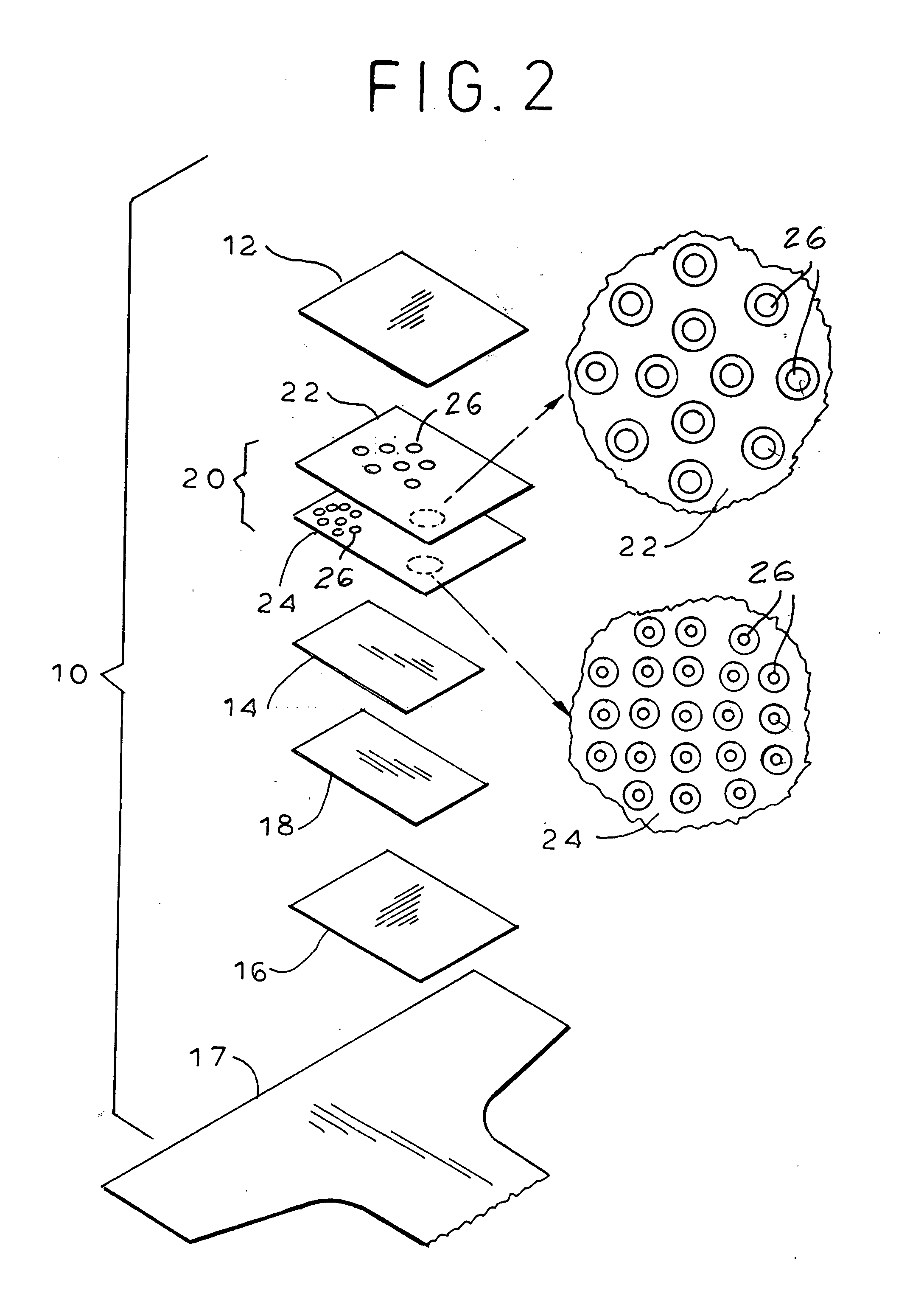

Absorbent article with layered acquisition/distribution system

An absorbent article has a topsheet, an absorbent core, and a layered acquisition / distribution transfer system disposed intermediate the topsheet and the absorbent core. The system has at least a pair of apertured films including a first film facing the topsheet and a second film facing the absorbent core. Each film is three-dimensional, formed of a wettable and substantially non-absorbent thermoplastic polymer, and defines pores which taper inwardly in a first direction from the topsheet to the absorbent core. The first film has a larger average pore size than the second film.

Owner:FIRST QUALITY PRODS

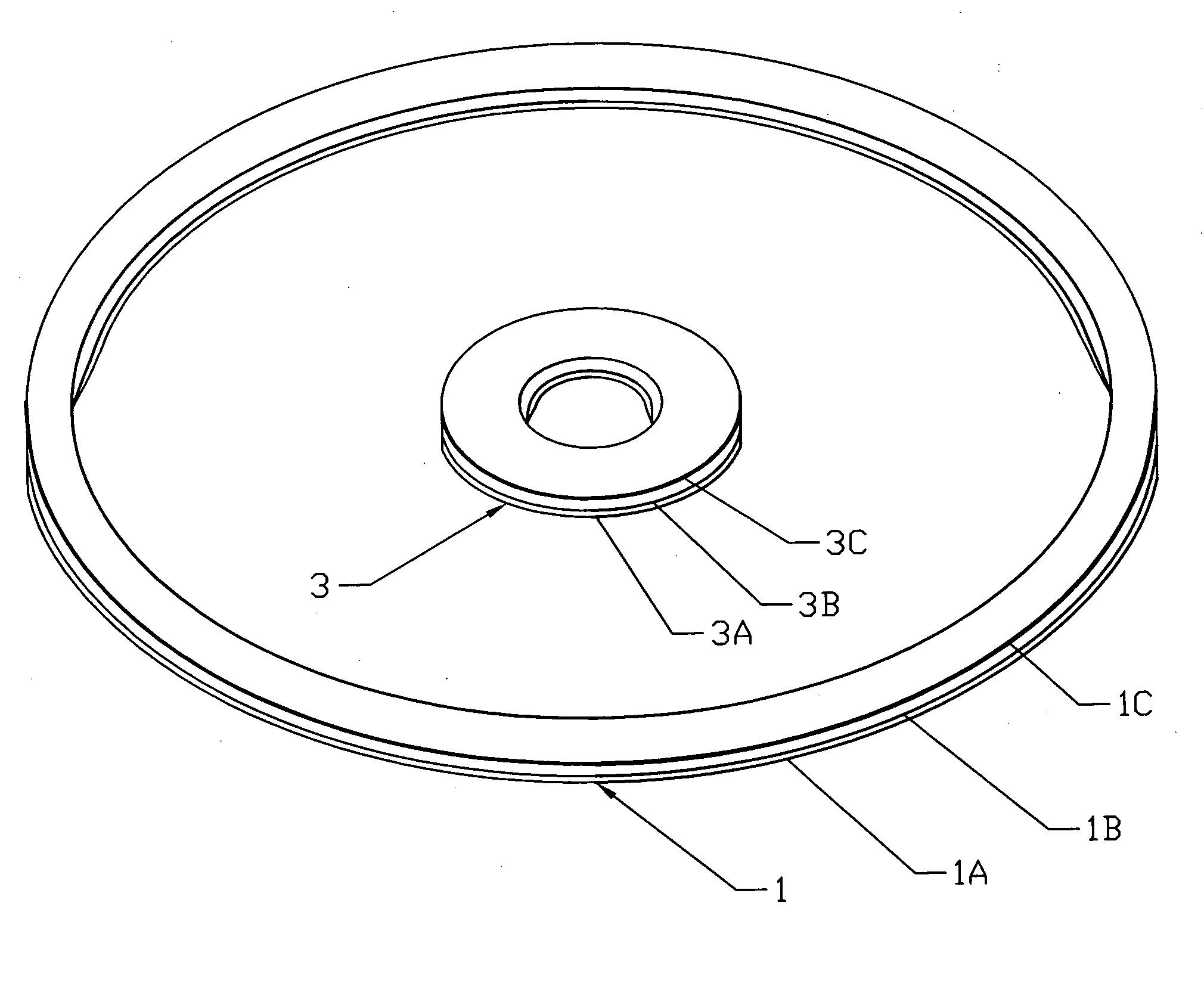

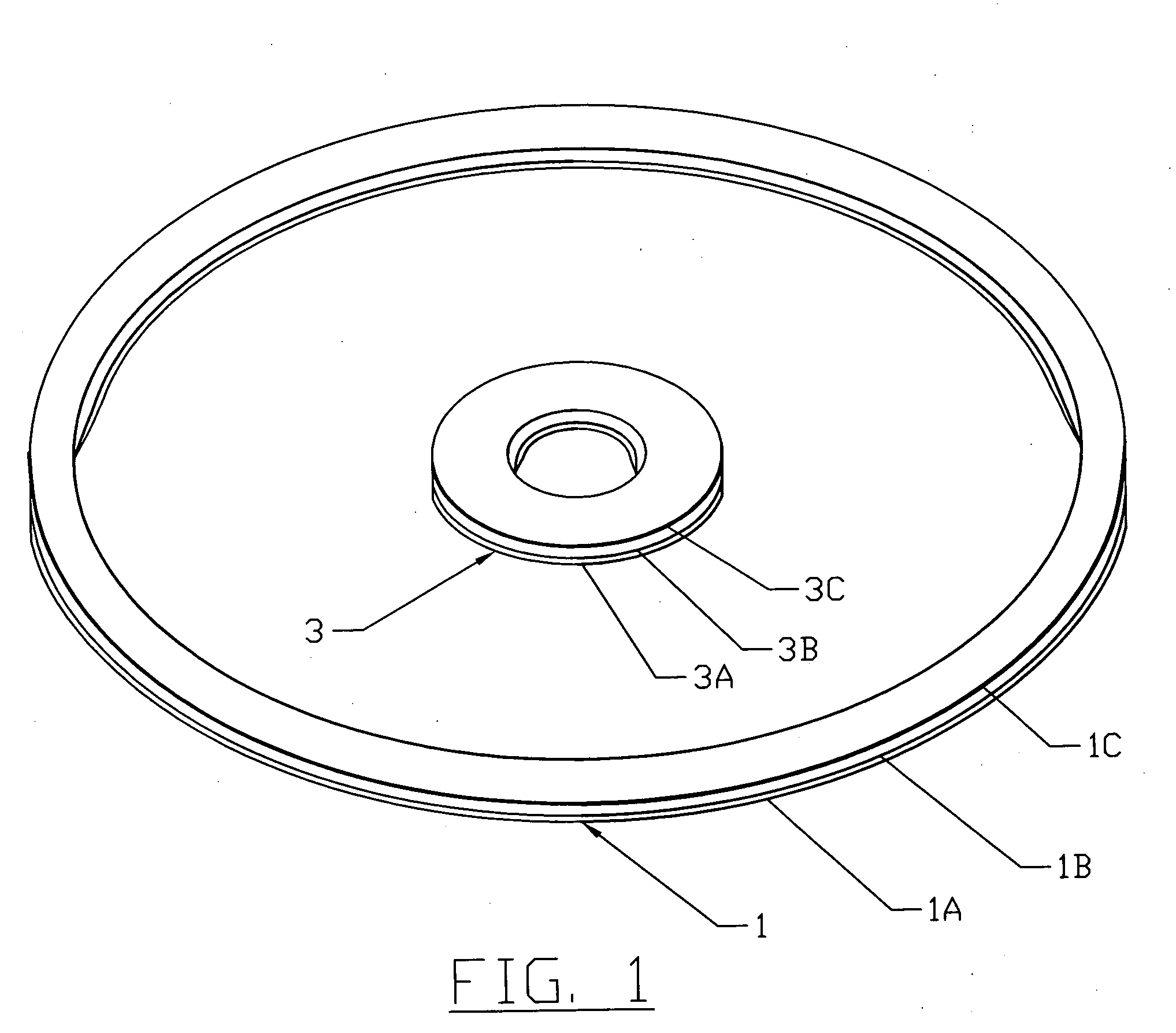

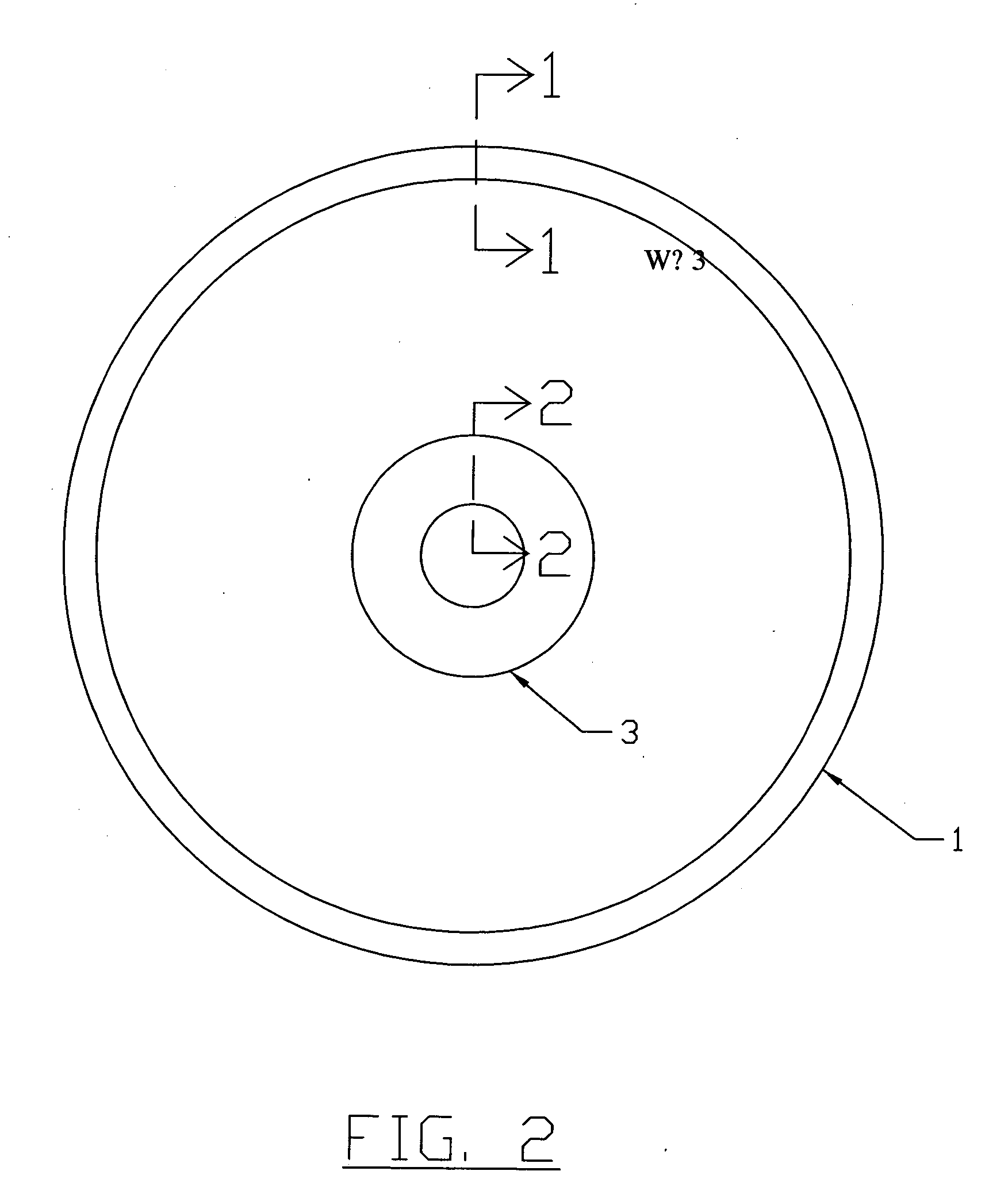

Optical data storage device protector

InactiveUS20050160442A1Solution to short lifeGram weight highApparatus modification to store record carriersRecord information storageCushioningHigh density

An optical data storage device protector comprised of two concentric rings. An outer ring is located near the outer periphery of the storage device and the inner ring's hole corresponds closely with the storage device's spindle hole. Both rings may be produced in a label sandwiched form having a peel away release liner, an adhesive that is preferably removable, a release coating facilitating removal of the release liner from the adhesive, a preferably high density face material that is adequately porous to receive a decorative finish and a face coating that serves to protect the decorative finish as well as to make the protector water resistant, UV light resistant and durable enough to withstand cleaning using either soap and water or wiper solutions available for device cleaning and reconditioning. The high density face material extends slightly beyond the device's edge affording edge cushioning and protection and also affords an inertial benefit, making the device more dynamically stable and thus skip resistant when used in portable storage device players.

Owner:KAPLOWITZ GARY H

Soft single-ply tissue

ActiveUS7935221B2Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineering

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

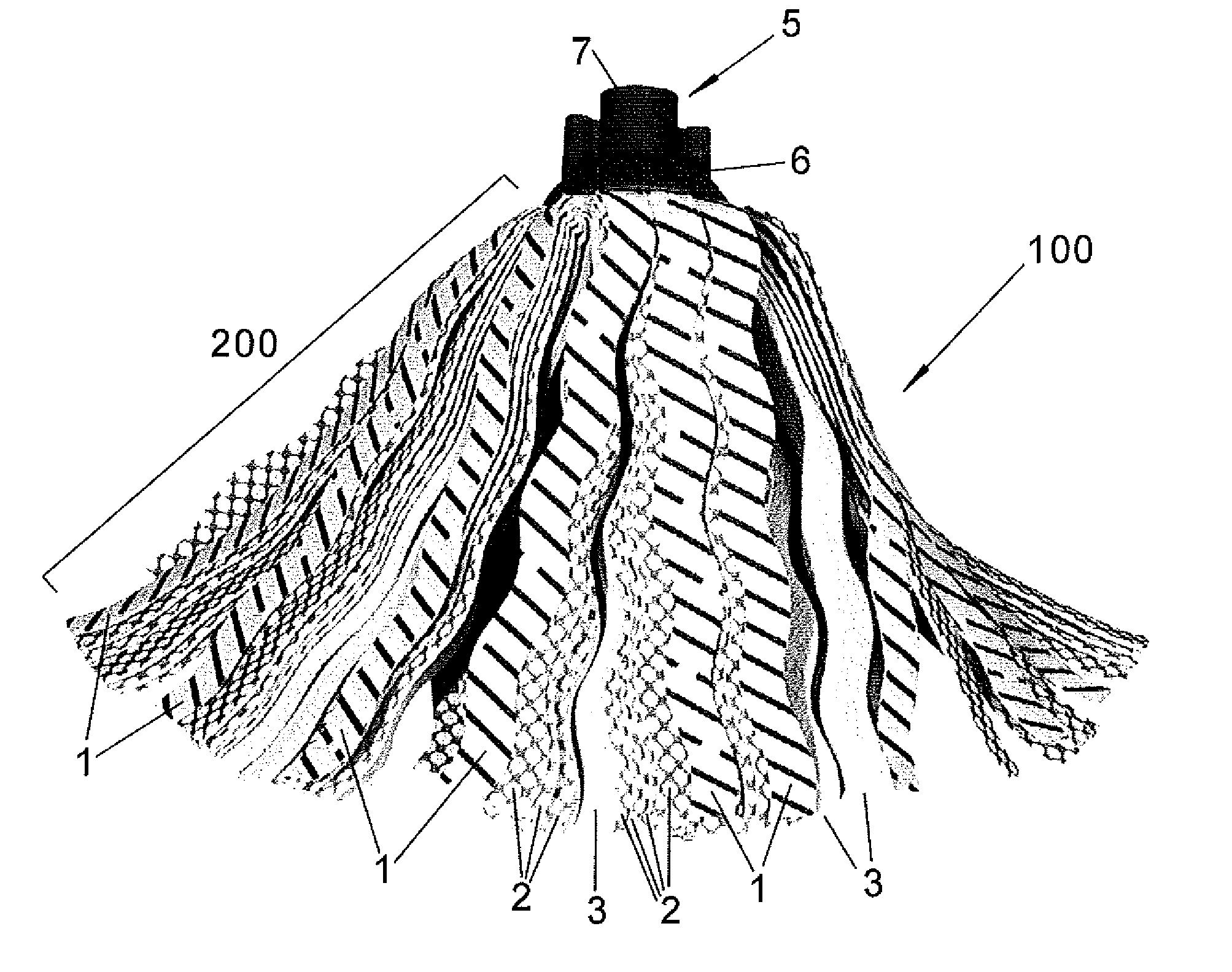

Cleaning device comprising a strip mop with strips covered with microfiber for cleaning floors

ActiveUS8707505B2Reduce environmental impactImprove rigidityBoard cleaning devicesCarpet cleanersEngineeringMechanical engineering

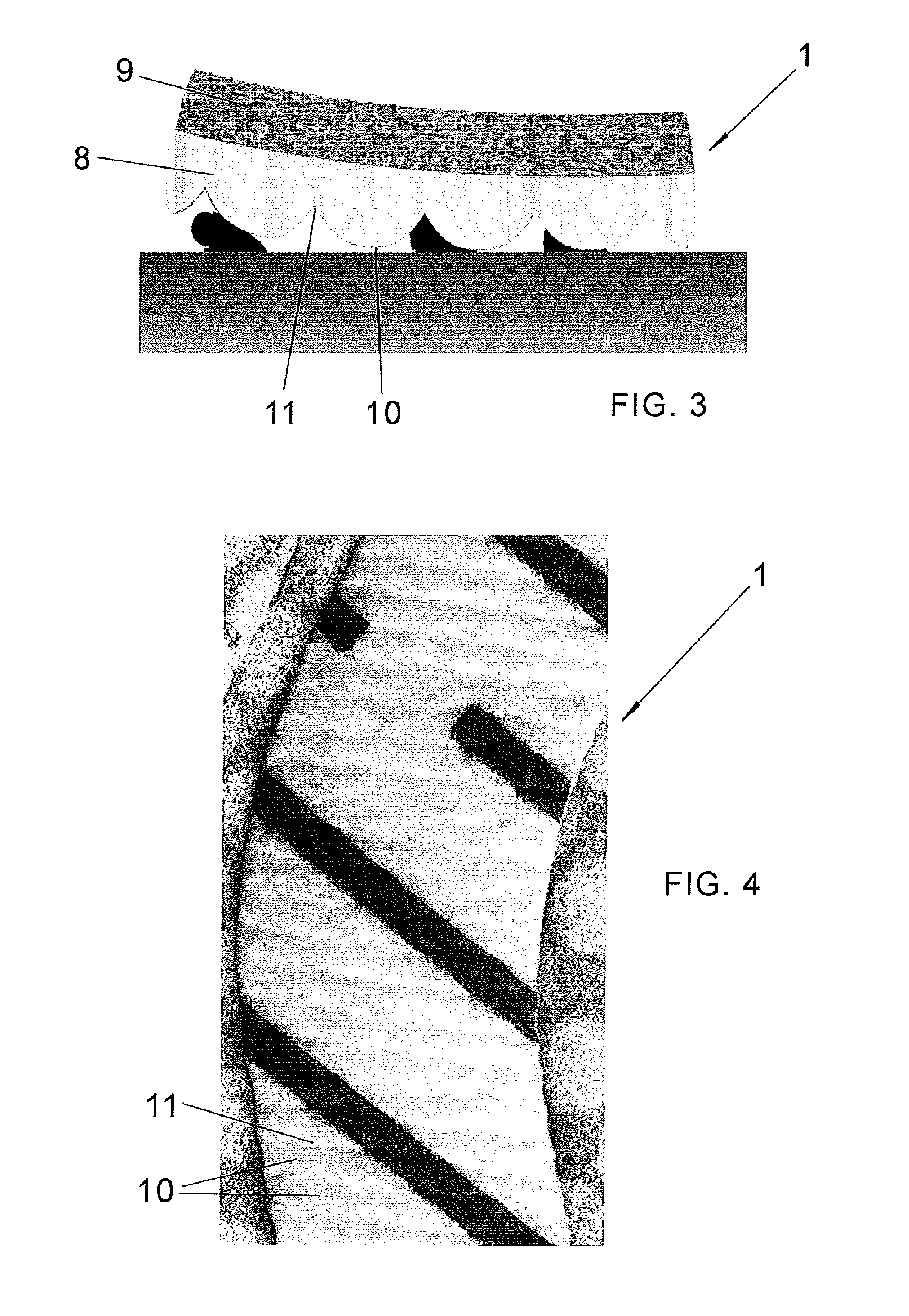

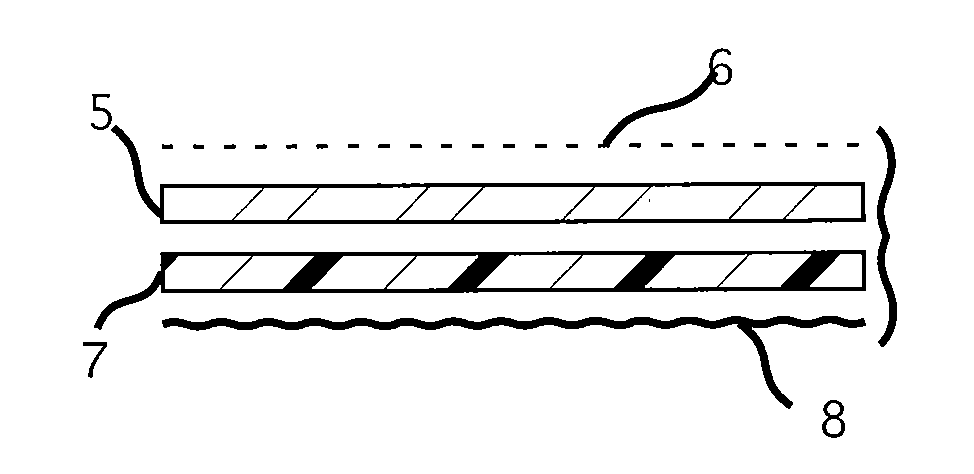

A cleaning device connectable to a handle includes a head (100) with a substantially circular profile formed by a plurality (200) of flexible strips in non-woven fabric overlapped and arranged to cover the circumference of the head (100) wherein the outermost strips (1) of the plurality of overlapped strips (200) have the outer surface formed by a microfiber layer (8) supported by a non-woven fabric layer (9), and the innermost strips (3) have a greater stiffness than the remaining strips.

Owner:MARANGHI MARCO +1

Flexible packaging composites

ActiveUS20090047525A1Increased durabilityImprove biodegradabilityWrappersDomestic containersFiberDyne

The flexible packaging composites include one or more mineral-containing layers with a bonding agent. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral-containing layer, the composite can contain one or more non-mineral containing layers, including various combinations of extruded resins, cast or blown films, and fibers. The mineral-containing layer is substantially and continuously bonded to the other layers. The present invention is an unexpectedly unique and environmentally friendly composite structure containing mineral layers with bonding agents as a key component. The material is designed to form flexible and semi-rigid storage articles at equal or lower costs to prior art solutions while providing a mineral containing layer that is a very smooth, has comparatively high plasticity, and having a high quality printing surface not requiring Corona Treatment. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral containing layer, the composite could contain various combinations of extruded resins, cast or blown films, and fibers. The mineral containing layer is substantially and continuously bonded to the other layers. The polymer, fiber, and mineral containing layers can be shaped, sized and manufactured such that the composite structure formed is subsequently machined to form a storage article. The composite structure has advantages including a high degree of pliability and flexibility, a minimum 37 dyne level on the surface of the mineral containing layer; a mineral containing layer that is highly 86 opaque, and has a bright, white printing surface that readily accepts coating and inks, therefore, rendering it highly attractive to consumers. Further, the composite structure has tensile strength, dead-fold, stiffness, and other characteristics that allow it to be readily machined into desired storage article forms and storage article closures, therefore, the material can be used for as a variety of food, consumer, industrial, anti-static, and commercial uses. Other mineral containing layer advantages include environmentally attractive features such photo-degradability, recyclability, compost-ability, and bio-degradability.

Owner:SMART PLANET TECH

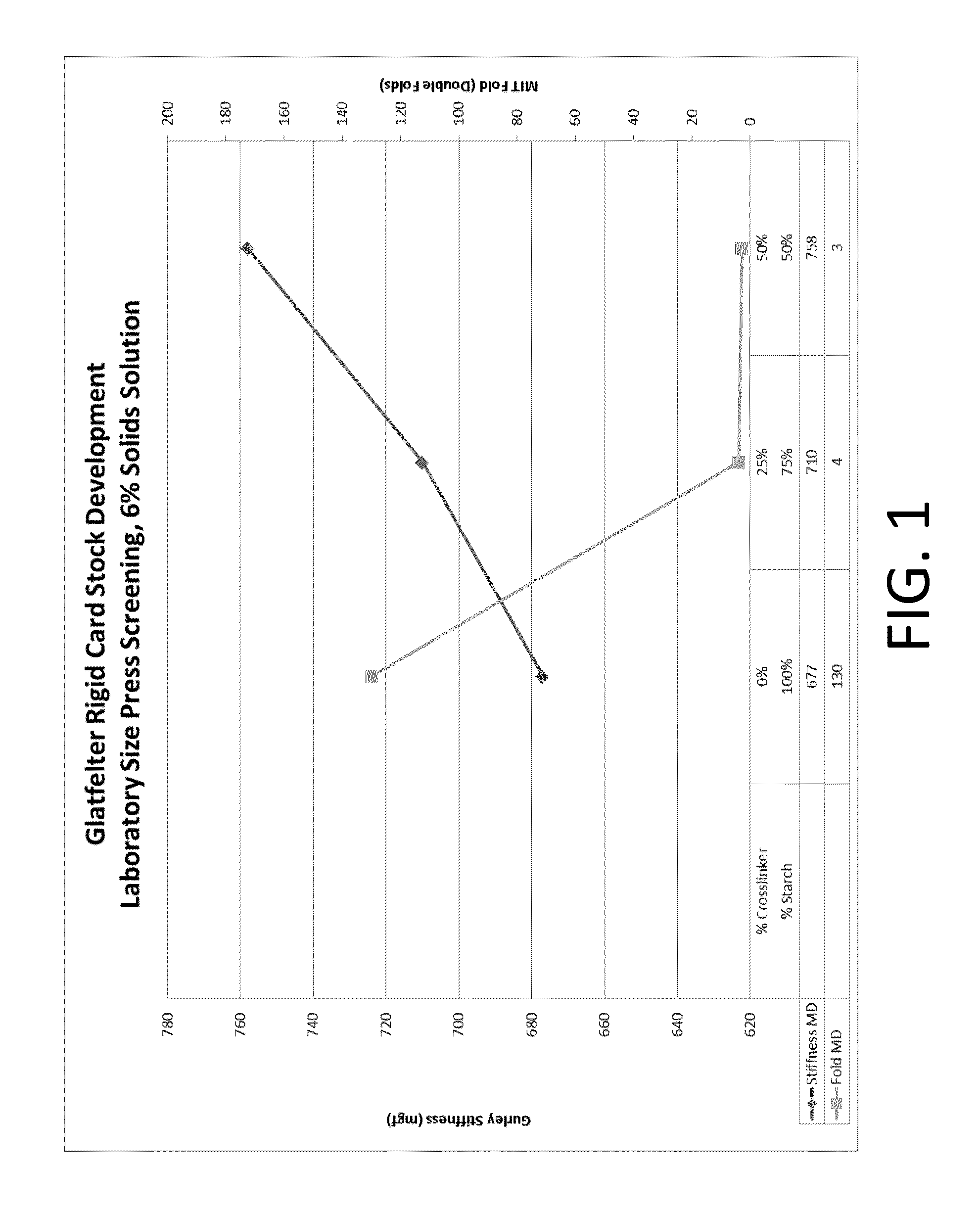

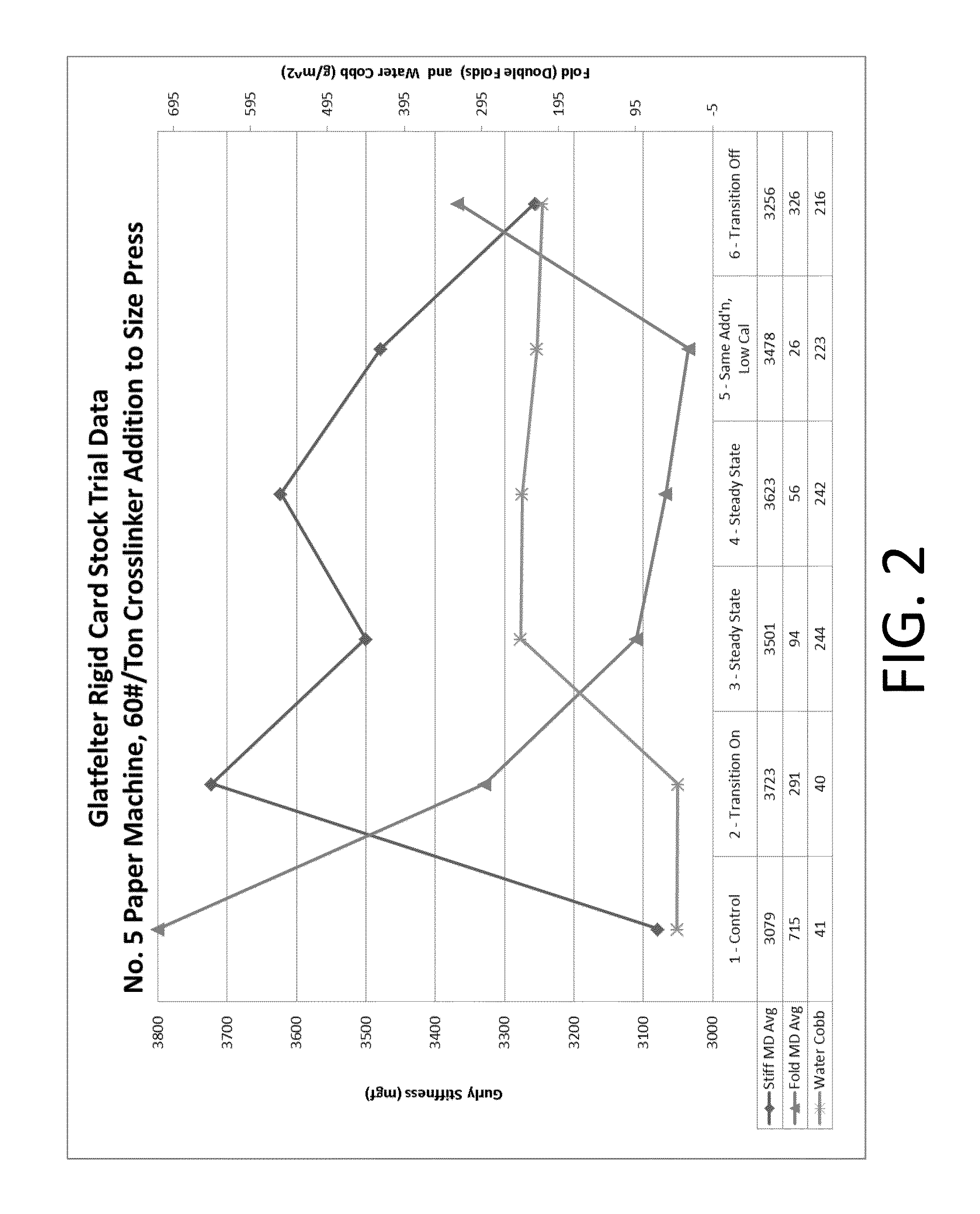

Process for making a stiffened paper

ActiveUS9133583B2Improve mechanical propertiesIncreased stiffness and rigidityNatural cellulose pulp/paperSpecial paperPapermakingSlurry

Owner:PIXELLE SPECIALTY SOLUTIONS LLC +1

Absorbent article with compressed groove and flexible portion

InactiveUS20060100598A1Easily pressed against vaginal openingIncrease stiffnessSanitary towelsBaby linensSkin surfaceMechanical engineering

Disclosed is an absorbent article including compressed grooves (11) and a rear flexible portion (16). The compressed grooves (11) where a liquid absorbent layer (4) is compressed and recessed from the side of a skin surface toward a garment surface are provided to extend in a longitudinal direction of the article so as to approach each other the nearest on a lateral reference line (Ox-Ox) of the article. The rear flexible portion (16) where the liquid absorbent layer (4) is recessed from the side of the garment surface toward the skin surface is provided to extend toward a rear end edge (1d) from a starting point (16a) that is located closer to the rear end edge (1d) than the lateral reference line (Ox-Ox). At least a portion of the rear flexible portion (16) is located between the compressed grooves (11).

Owner:UNI CHARM CORP

Disposable food container with a linear sidewall profile and an arcuate outer flange

InactiveUS20030173366A1Lose weightHigh strengthEnvelopes/bags making machinerySpecial paperEngineeringUltimate tensile strength

The present invention is directed to rigid disposable food containers provided with a relatively steep sidewall with a generally linear profile and an outwardly flared arcuate flange portion. The containers are further characterized by a flange outer vertical drop wherein the ratio of the length of the vertical drop to the characteristic diameter of the container is greater than about 0.01. By virtue of unique geometry, the containers of the invention exhibit improved rigidity and / or rim stiffness yet have favorable runnability in pressware manufacturing systems characteristic of plates of lower strength.

Owner:GPCP IP HLDG LLC

Nonwoven fabrics with two or more filament cross sections

InactiveUS20030049988A1Maximizing coatingMore surface areaLayered productsWoven fabricsEngineeringNonwoven fabric

The subject invention concerns nonwoven fabrics containing filaments of at least two different cross sections. The subject invention further pertains to methods used to produce these fabrics. In an embodiment specifically exemplified herein, the nonwoven fabric of the subject invention is made of nylon.

Owner:THE PROCTER & GAMBLE COMPANY

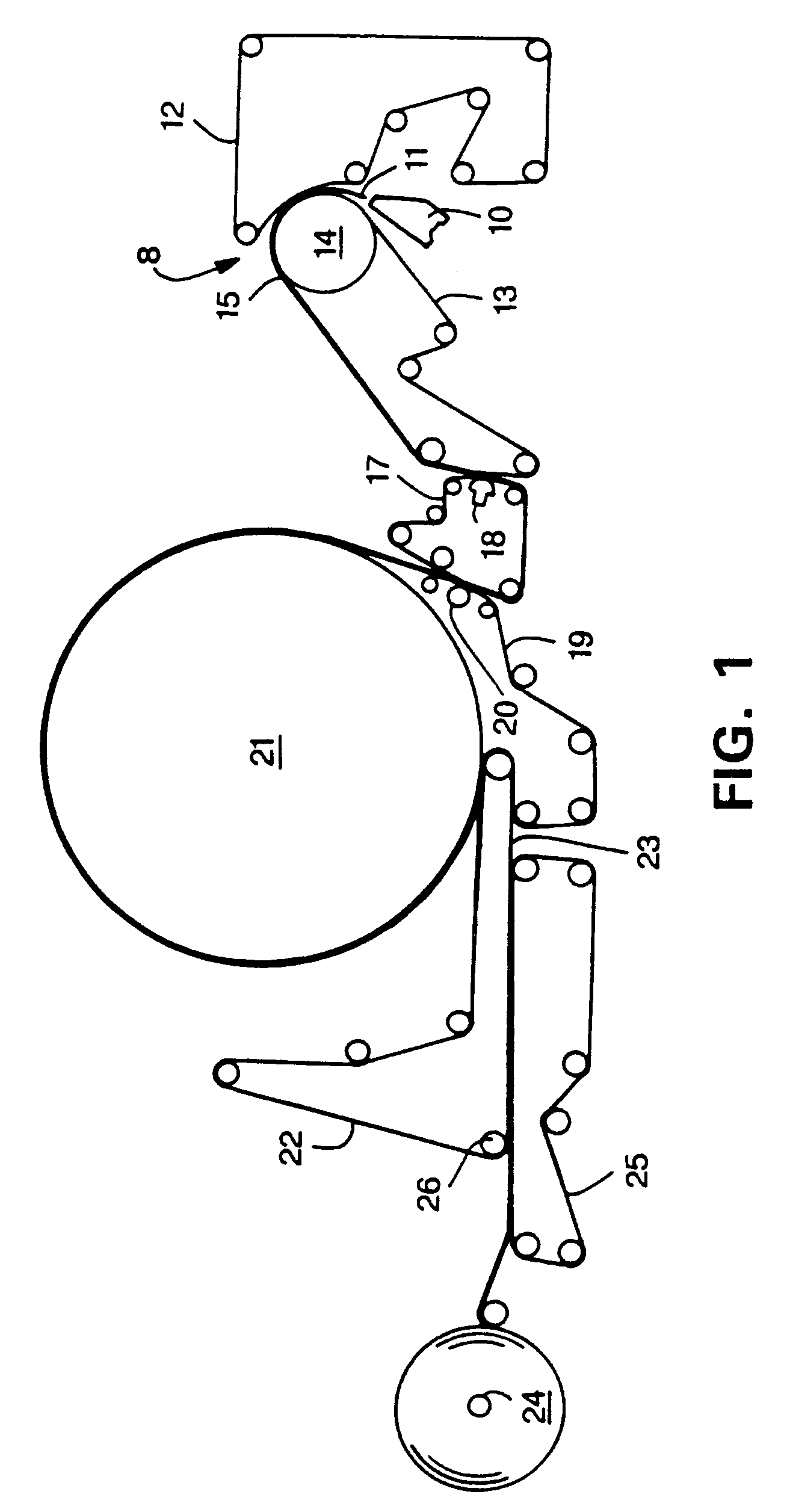

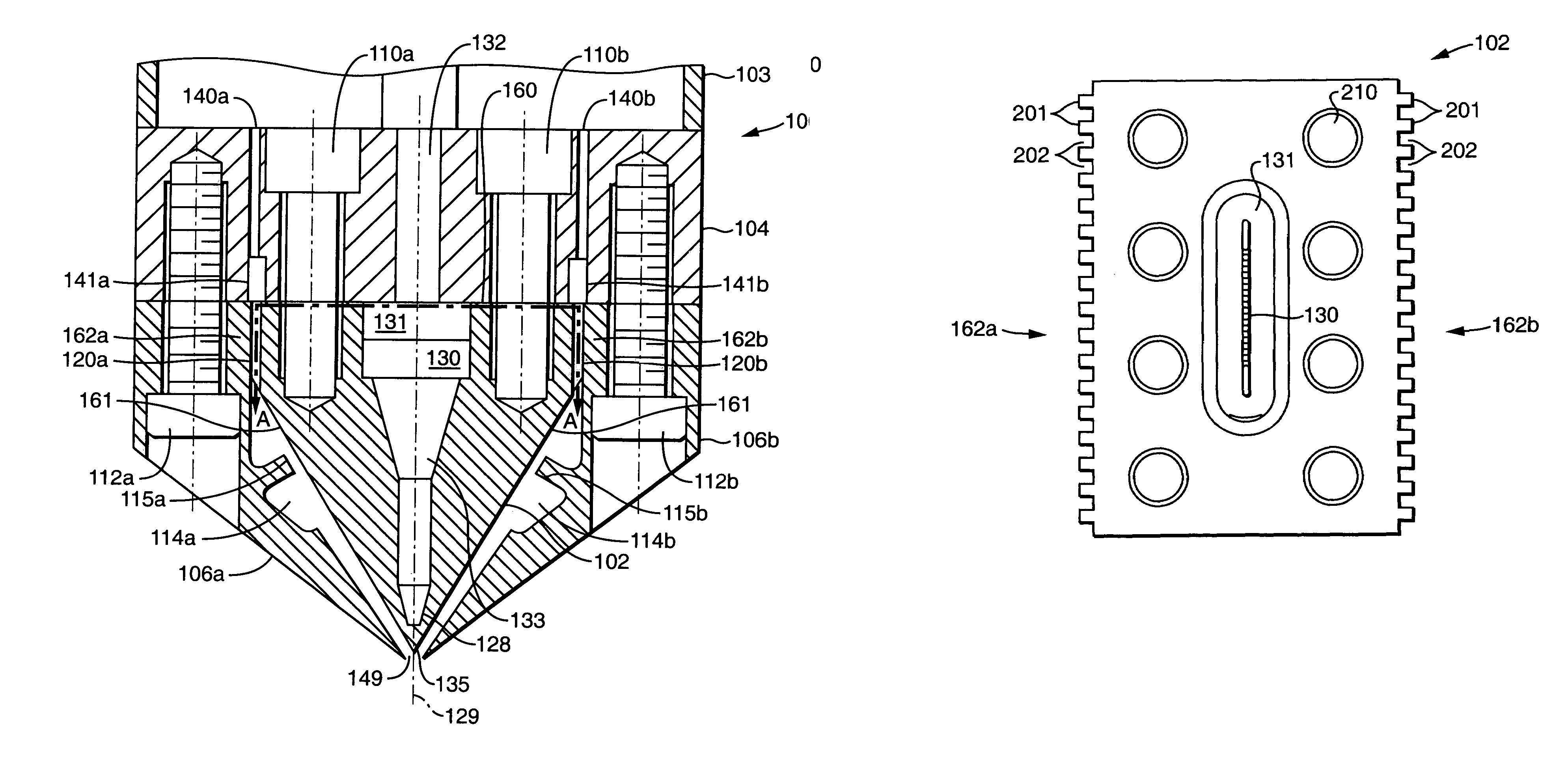

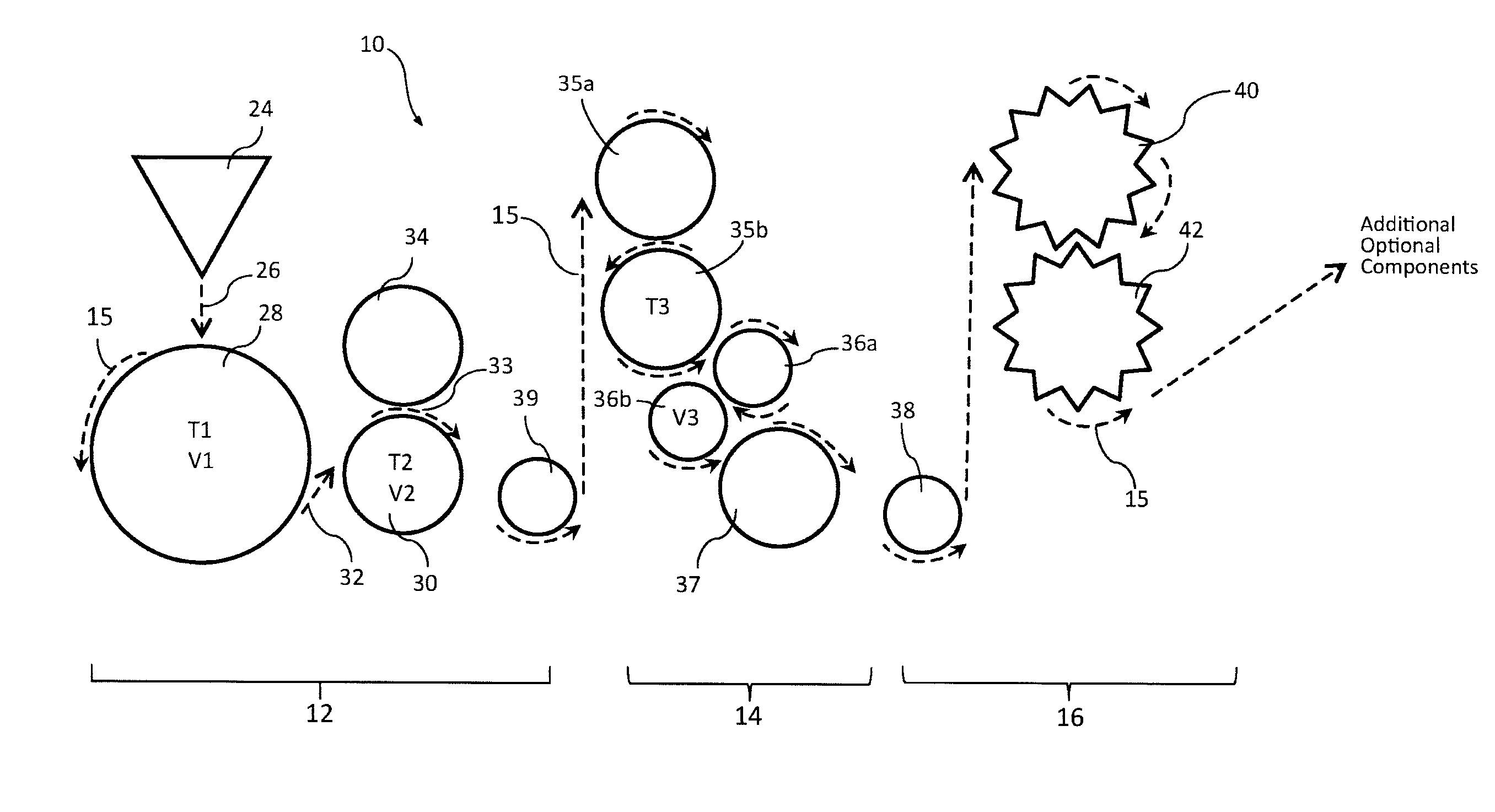

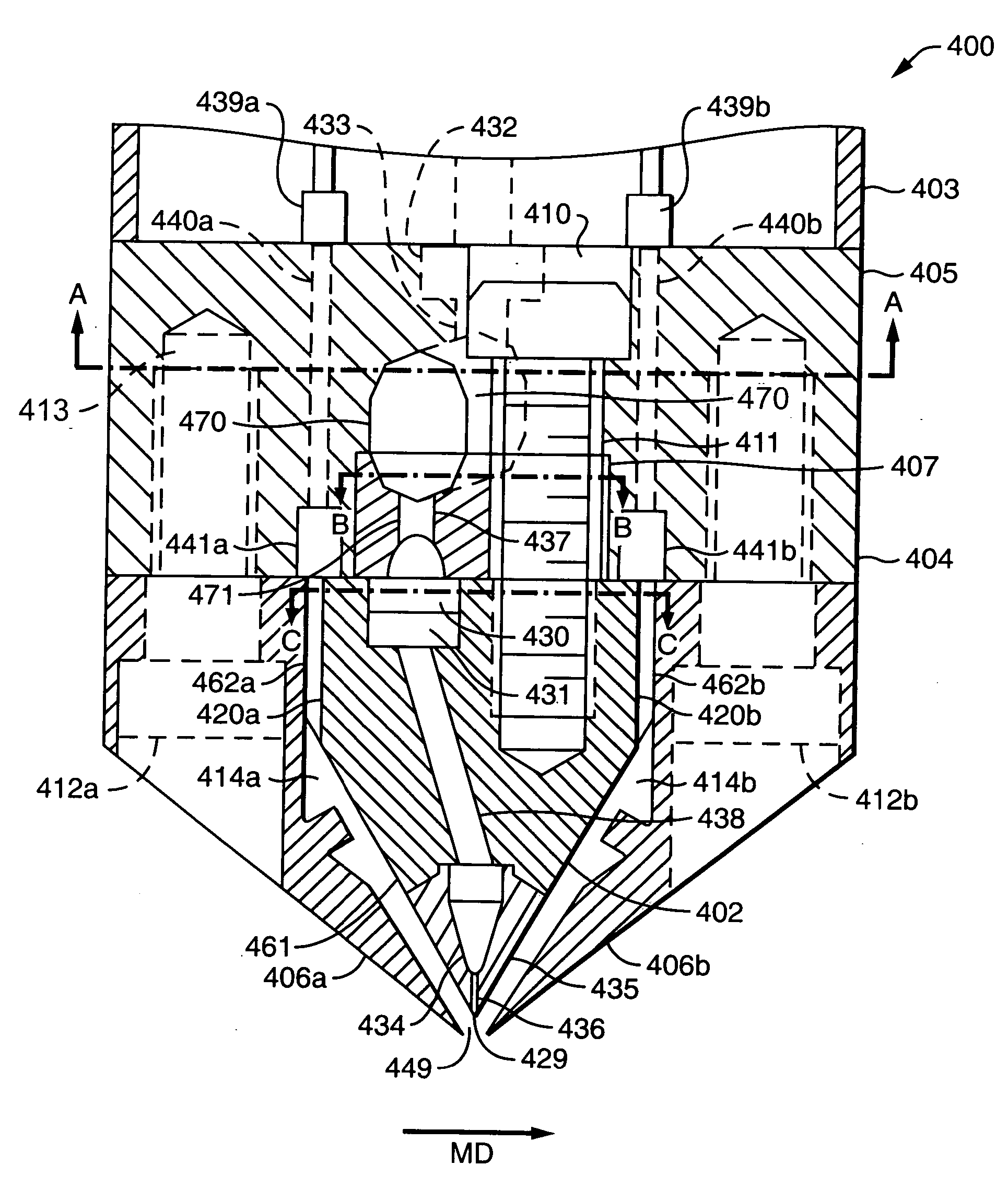

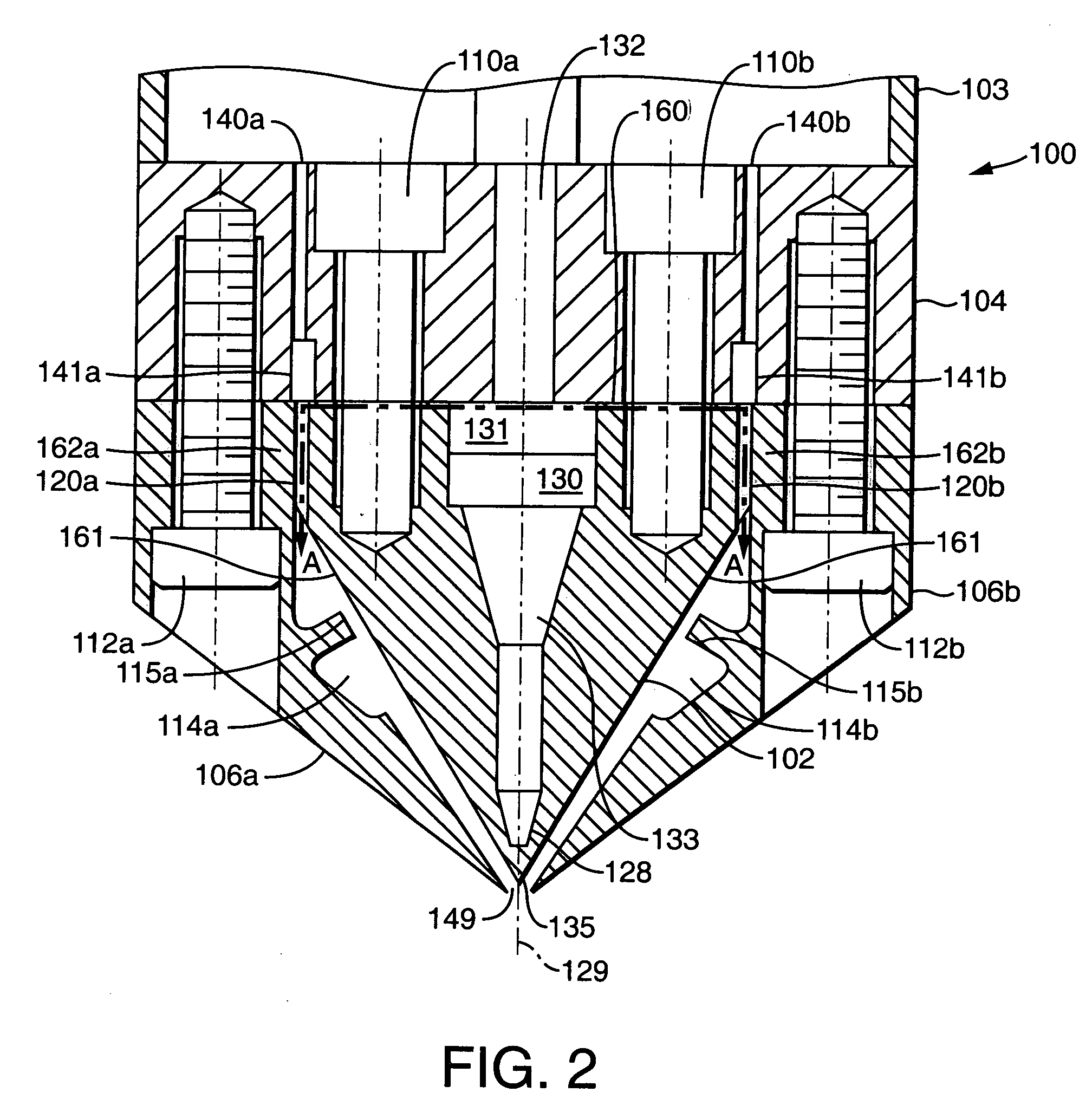

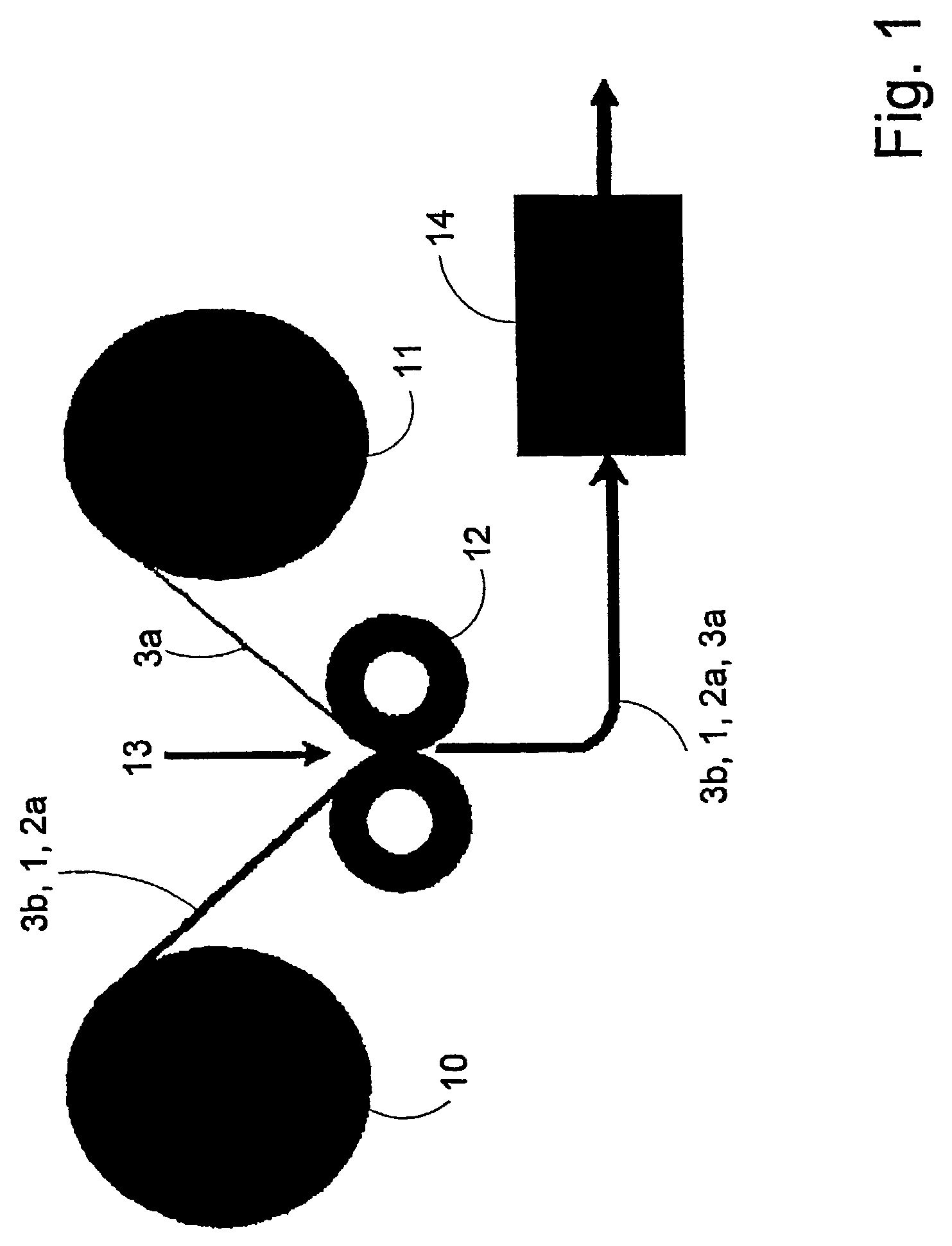

Meltblown die having a reduced size

ActiveUS6972104B2Quality improvementLarge widthSpinnerette packsConfectioneryAir entrainmentReduced size

The present invention provides a meltblown die which has a considerable smaller width in the machine direction of the meltblowing process compared to conventional and commercially used meltblown dies. The meltblown die of the present invention has a. a die body; b. a die tip mounted to the die body; c. a first air plate mounted to the die body; and d. a second air plate mounted to the die body. In addition, the small size of the meltblown die of the present invention provides advantages over conventional meltblown die, including improved air entrainment.

Owner:KIMBERLY CLARK GLOBAL SALES LLC

Oil-resistant filter wrapper paper

ActiveUS20140137880A1Sufficient oil resistanceHigh basis weightNon-fibrous pulp additionNatural cellulose pulp/paperAqueous suspensionFiber

A filter wrapper paper for a smoking article is shown, the paper having a content of long-fiber pulp of at least 30 wt %, preferably at least 40 wt %, relative to the pure fiber mass of the paper. The freeness of the long-fiber pulp as per ISO 5267, Schopper-Riegler method, is between 80° SR and 100° SR, preferably between 85° SR and 95° SR. The filter wrapper paper has a filler content of less than 10 wt %, preferably less than 8 wt %, and especially preferably less than 6 wt % relative to the total mass of the paper and is impregnated with a material that is suitable for forming an aqueous composition, more particularly an aqueous solution or an aqueous suspension. The oil-resistance of the filter wrapper paper has a KIT level of at least 4, preferably at least 5, according to TAPPI T559 cm-02.

Owner:DELFORTGROUP

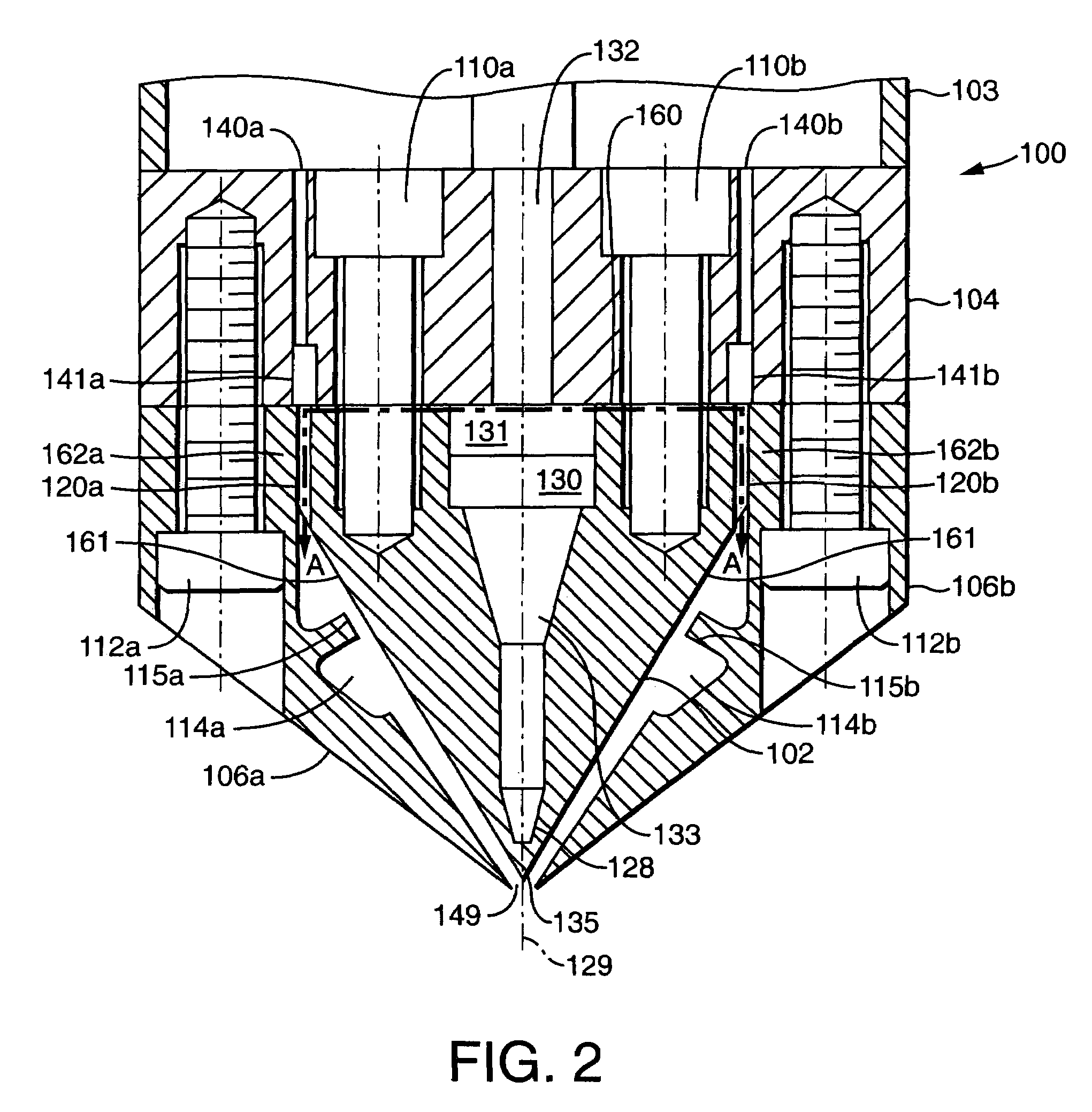

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS9988763B2Reduce manufacturing costLose weightNon-fibrous pulp additionPulp bleachingCelluloseBleach

Owner:FIRST QUALITY TISSUE LLC

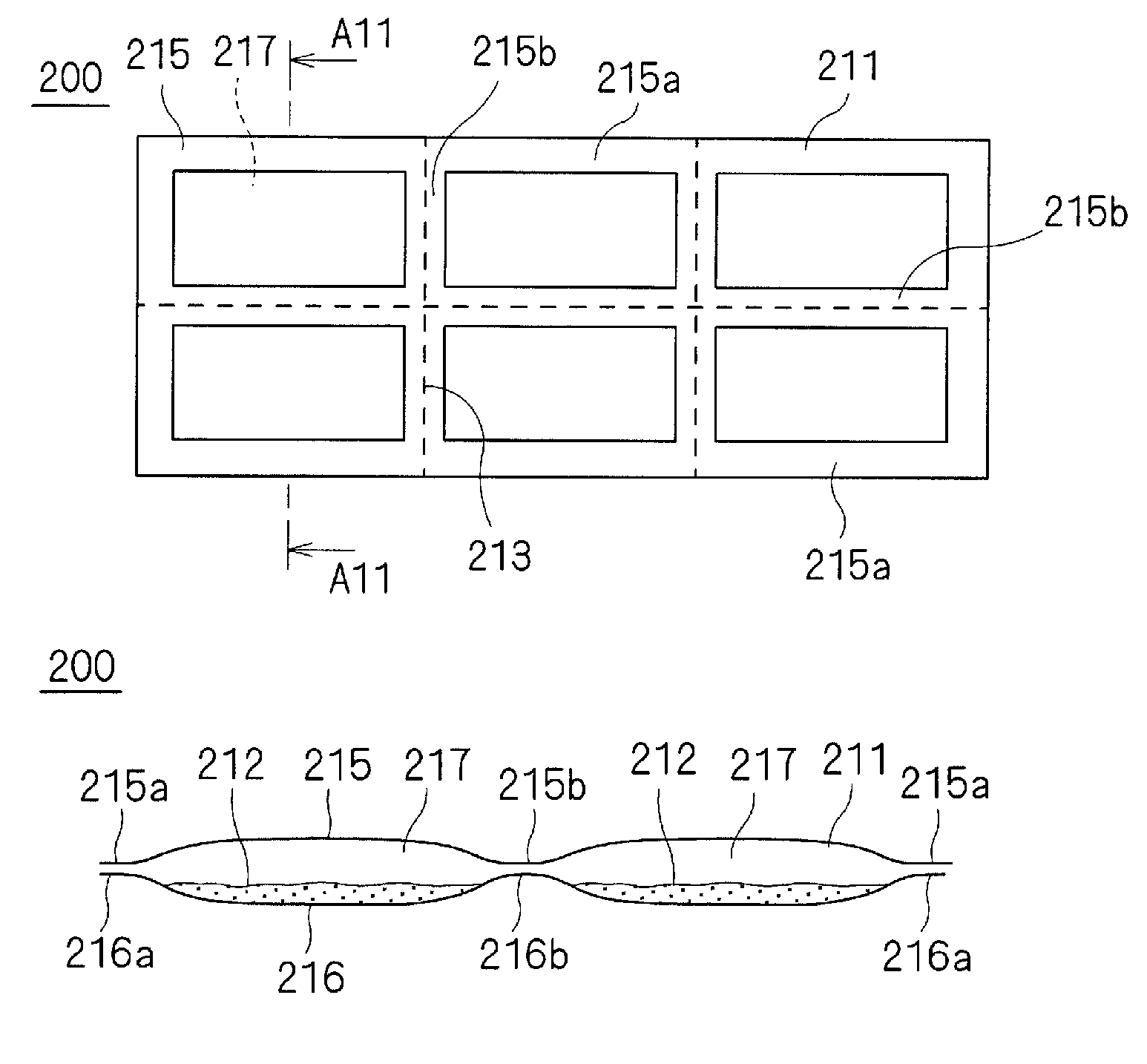

Absorbent article

The present invention provides an absorbent article that allows full use of the absorption performance of an absorbent polymer without inhibiting the swelling of the absorbent polymer due to the absorption of excreted body fluids, and that can be biodegraded with efficiency when it is disposed after use by burial in the soil or the like. The absorbent article includes at least one inner bag-like member, an absorbent polymer, and an outer bag-like member. The inner bag-like member is formed into a thin and substantially sheet-like form of a sheet having biodegradability and fluid permeability, and includes multiple accommodation spaces that are detached from the outside and separated from one another. The absorbent polymer has biodegradability and a substantially granular or powder form and is contained in each of the accommodation spaces in the inner bag-like member so as to be freely movable within the accommodation spaces.

Owner:LIVEDO CORP

Flexible packaging composites

The flexible packaging composites include one or more mineral-containing layers with a thermoplastic bonding agent. In addition to the mineral-containing layer, the composite can contain one or more non-mineral containing layers, including various combinations of extruded resins, cast or blown films, and fibers. The mineral-containing layer is substantially and continuously bonded to the other layers. The polymer, fiber, and mineral containing layers can be shaped, sized and manufactured such that composite structure formed is subsequently machined to form a storage article. The composite structure has advantages including a high degree of pliability and flexibility, a minimum 37 dyne level on the surface of the mineral-containing layer; a mineral-containing layer that is highly 86 opaque, and has a bright, white printing surface that readily accepts coating and inks, therefore, rendering it highly attractive to consumers.

Owner:SMART PLANET TECH

Breathable and microporous thin thermoplastic film

ActiveUS9492332B2Lose weightImprove breathabilityPersonal careSynthetic resin layered productsThermoplasticWater vapor

Breathable, thermoplastic films, laminates, and methods of making films having a basis weight less than or equal to 15 gsm and a water vapor transmission rate of at least about 500 grams H2O / 24-hour / m2, wherein the film has a ratio of the MD load at break to the CD load at break of less than about 10, and at least one of a machine-direction notched Elmendorf tear strength of at least about 5 g or a machine-direction notched trapezoidal tear strength of at least about 15 g.

Owner:BERRY FILM PROD CO INC

Meltblown die having a reduced size

ActiveUS20050133971A1Quality improvementLarge widthSpinnerette packsConfectioneryAir entrainmentReduced size

The present invention provides a meltblown die which has a considerable smaller width in the machine direction of the meltblowing process compared to conventional and commercially used meltblown dies. The meltblown die of the present invention has a. a die body; b. a die tip mounted to the die body; c. a first air plate mounted to the die body; and d. a second air plate mounted to the die body. In addition, the small size of the meltblown die of the present invention provides advantages over conventional meltblown die, including improved air entrainment.

Owner:KIMBERLY CLARK GLOBAL SALES LLC

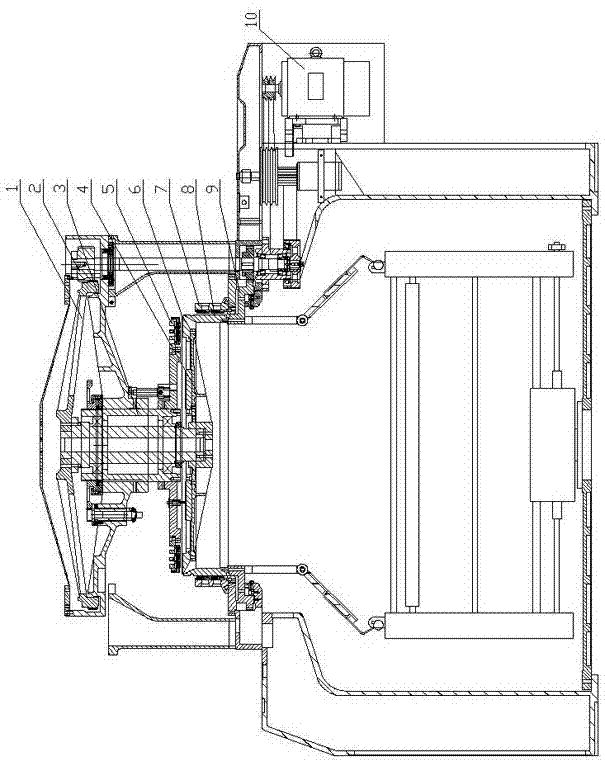

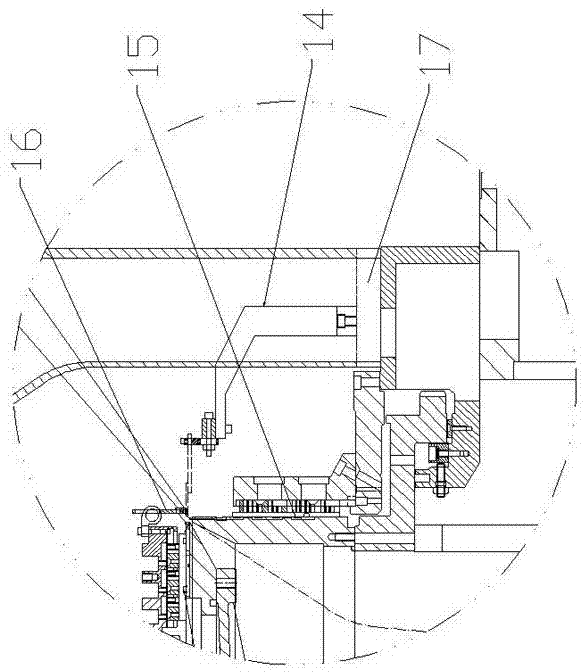

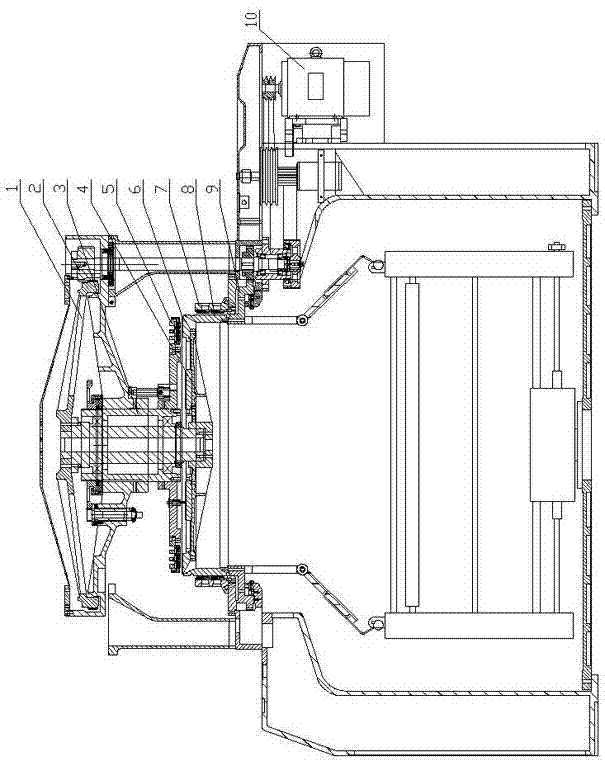

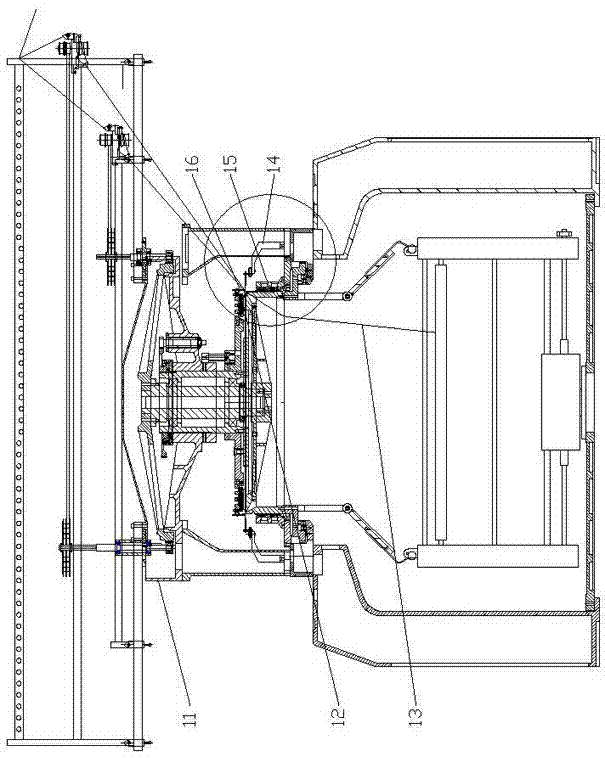

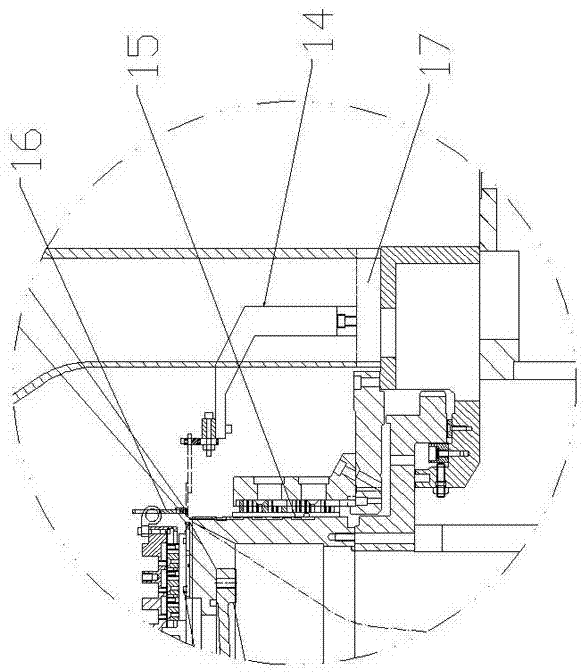

Loop-pile cutting circular machine

ActiveCN103938357ASolve the problem of uneven hair surface and hair end hookIncrease weaving speedCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

Digital glaze for high grammage, without the use of Anti-settling agents

A digital glaze for high grammage, without the use of anti-settling agents, referred to as digital glazes for digital inkjet printing techniques to apply high grammage, maintaining the same aesthetic and technical characteristics obtained with traditional glazes and non-digital application techniques. No anti-settling agents are used in the composition to prevent the digital glaze from being thixotropic and creating problems in the inkjet printing. The composition includes at least one medium that is liquid at ambient temperature, formed by a mixture of water and polar solvents and / or solvents of medium to low polarity, having a percentage by weight of between 20 and 70% of the total weight of the digital glaze; and at least one mixture of ceramic raw materials and / or frits as a glaze-forming material, having a percentage by weight of between 30 and 80% of the total weight of the digital glaze.

Owner:TORRECID

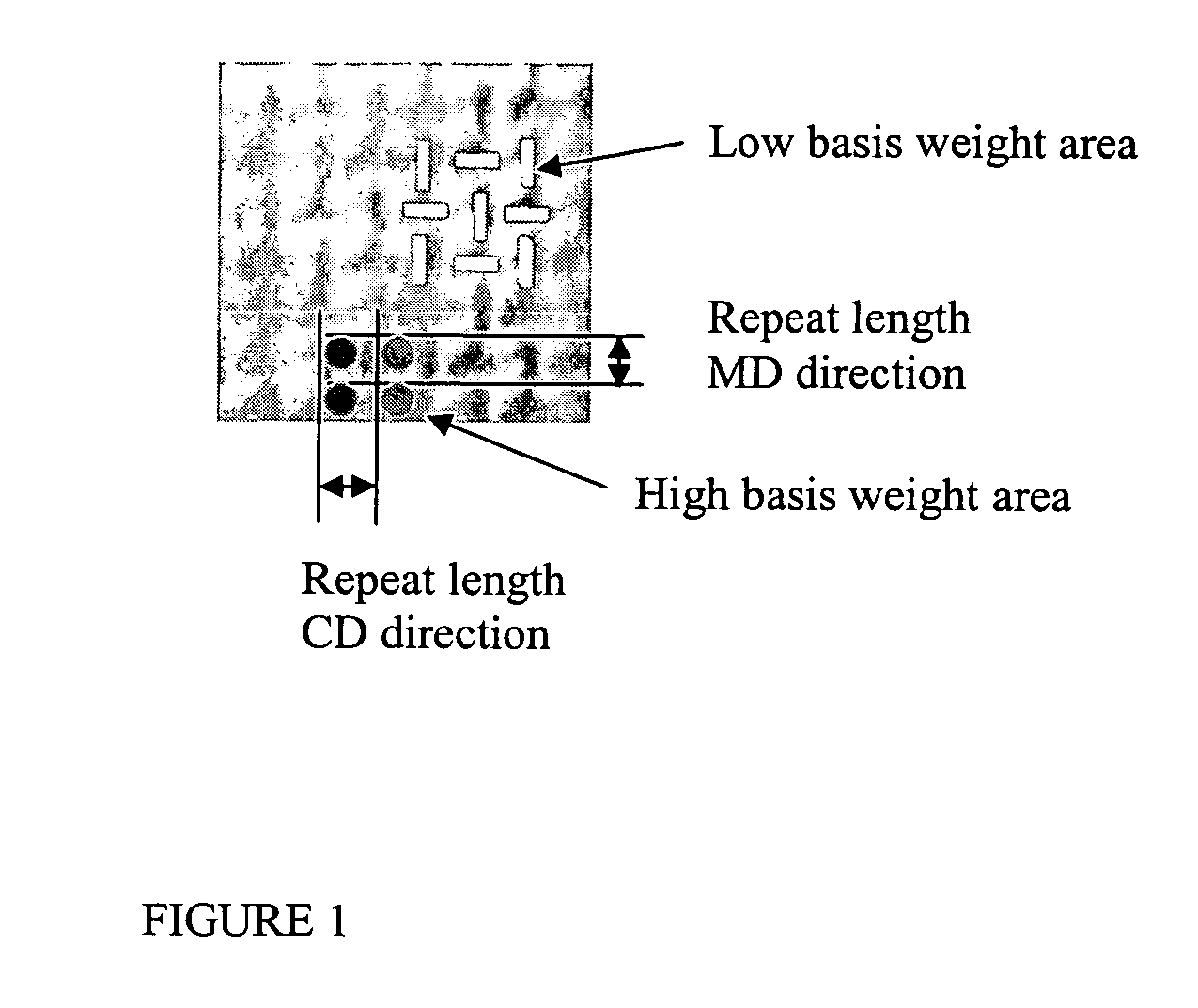

Cleaning wipe

InactiveUS20060252324A1Gram weight highLose weightNon-ionic surface-active compoundsCarpet cleanersSquare meterNonwoven fabric

A wipe which comprises: a nonwoven fabric impregnated with a cleaning composition; the nonwoven fabric having a basis weight of from about 70 to about 90 grams per square meter; a high basis weight area, and a low basis weight area, a weight ratio of the high basis weight area to the low basis weight area from about 1.5 to about 4.0, and a surface area ratio of the high basis weight area to the low basis weight area from about 0.65 to about 1.60; the high basis weight areas and the low basis weight areas being distributed along the surface of the non-woven fabric in a repeating pattern; the repeat lengths of the pattern being from 2 to 6 mm in the cross direction (CD) and from 2 to 6 mm in the machine direction (MD), and preferably 4 mm in both MD and CD directions.

Owner:COLGATE PALMOLIVE CO

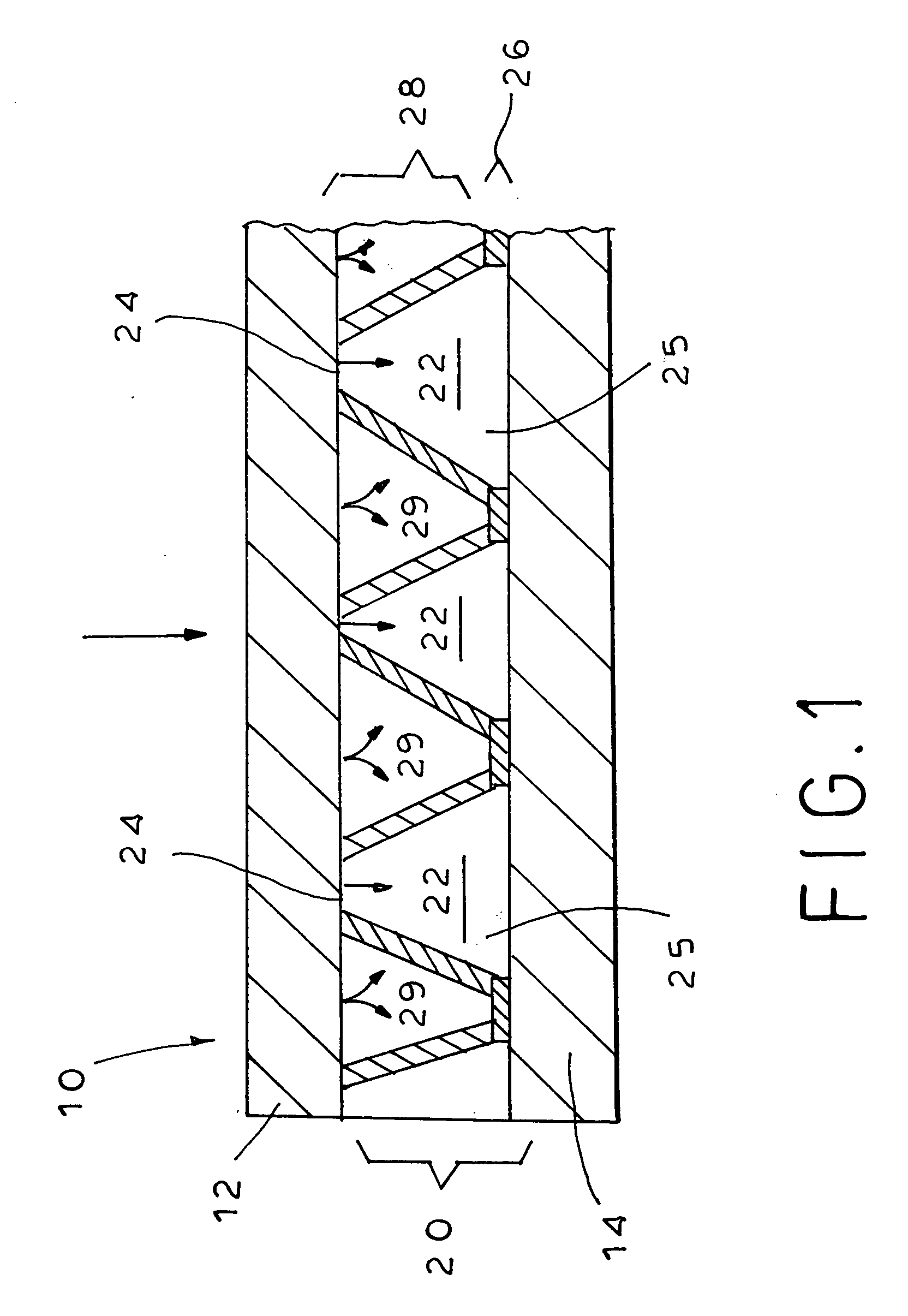

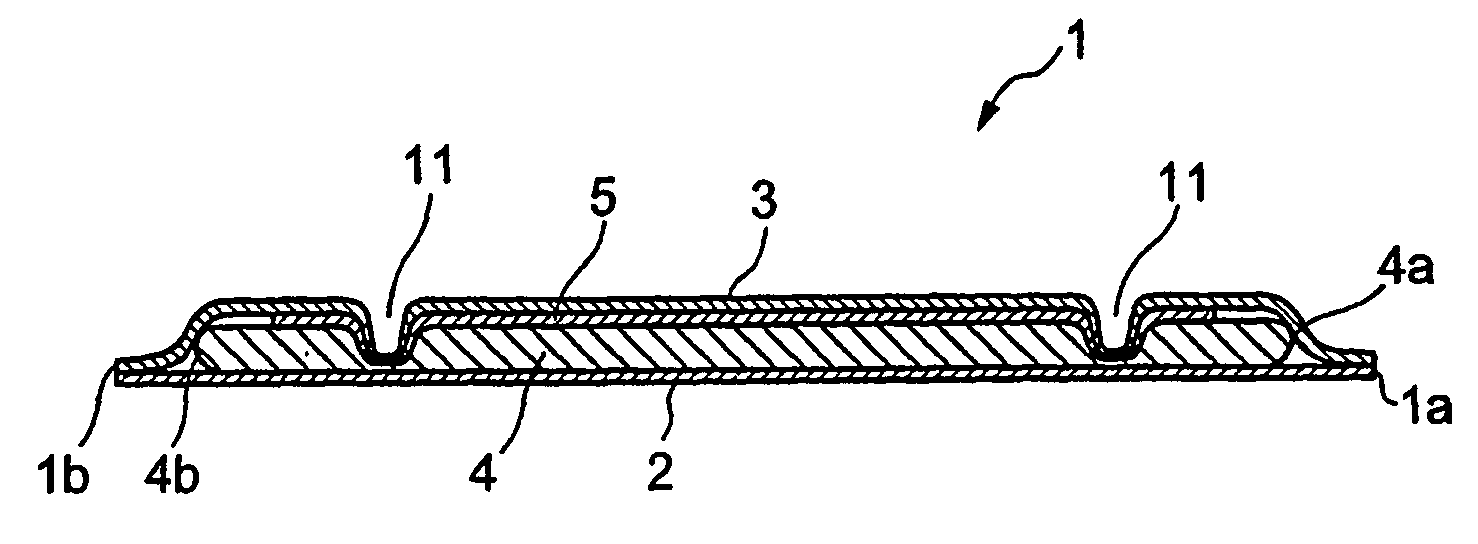

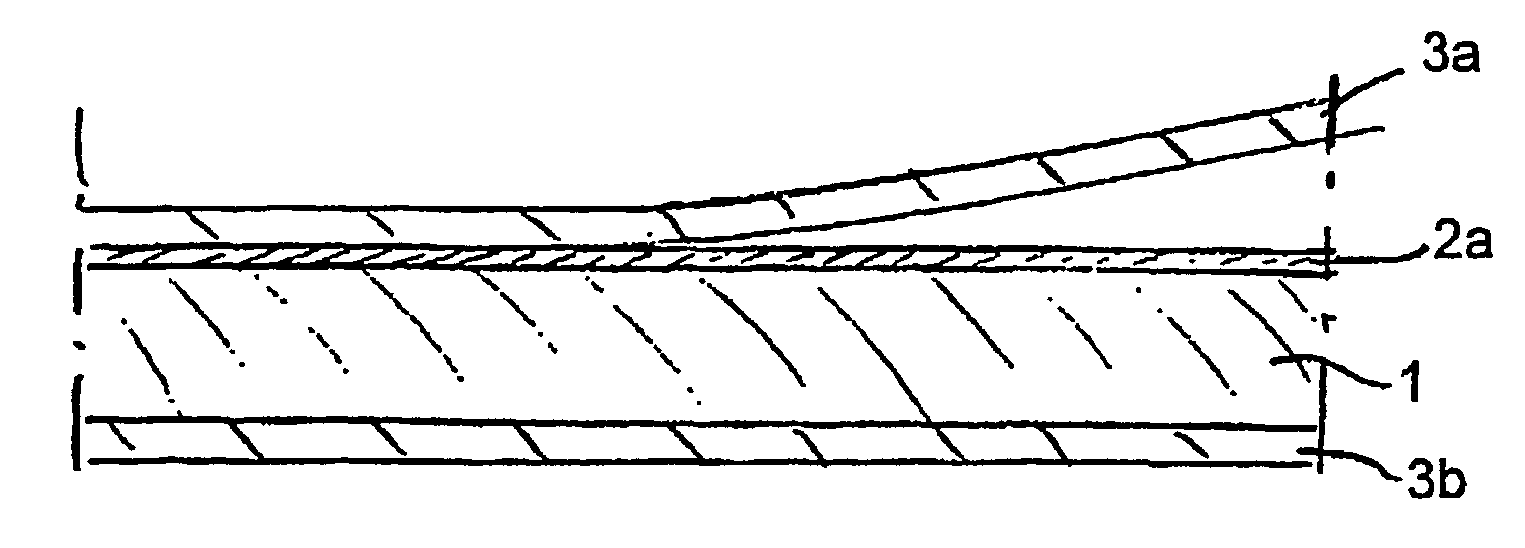

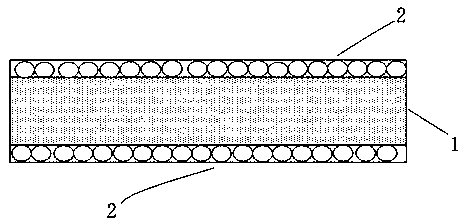

Paper or paperboard laminate and method of producing such a laminate

InactiveUS7387702B2Gram weight highReduce in quantityNon-fibrous pulp additionWrappersPaperboardVolumetric Mass Density

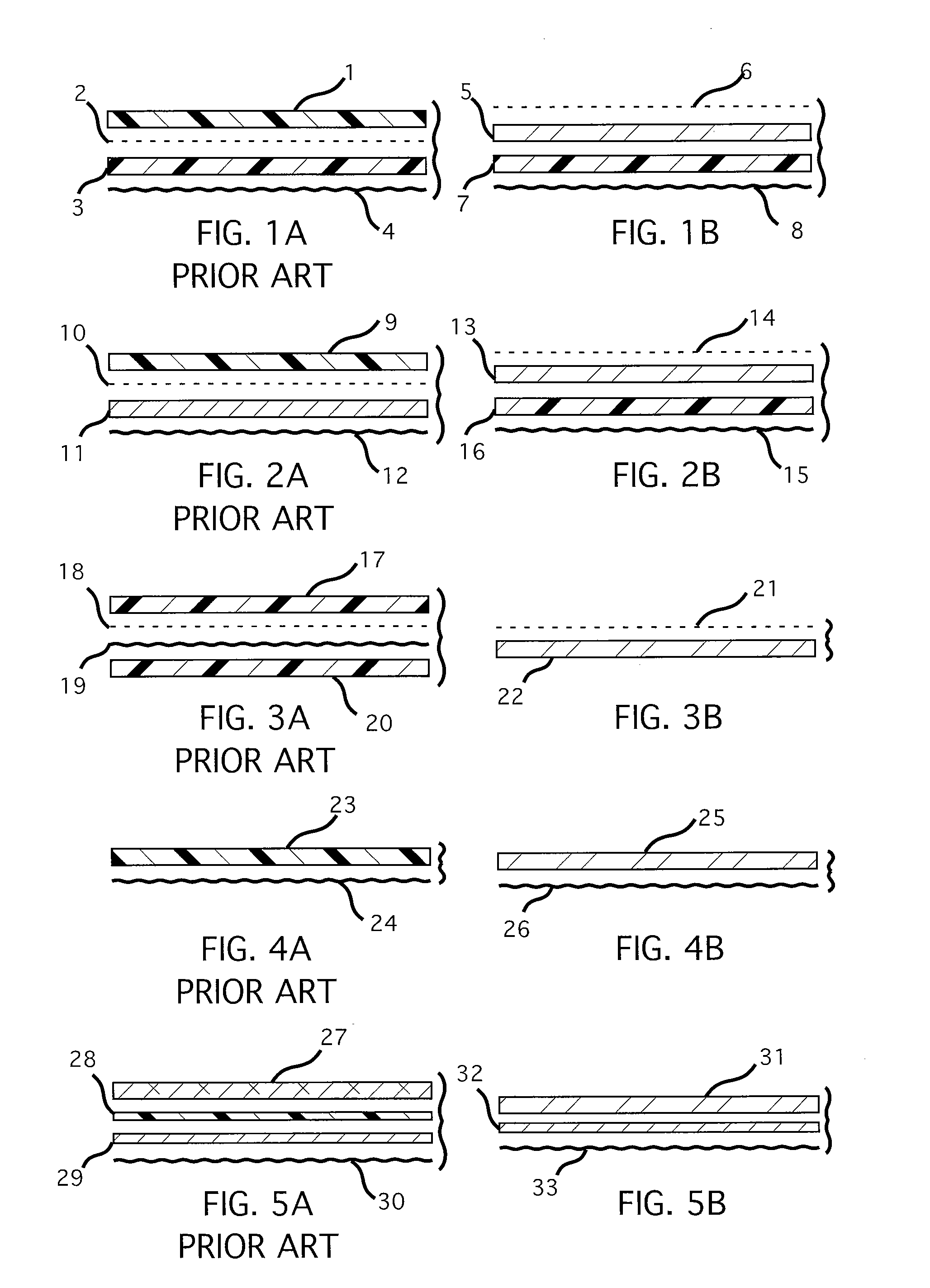

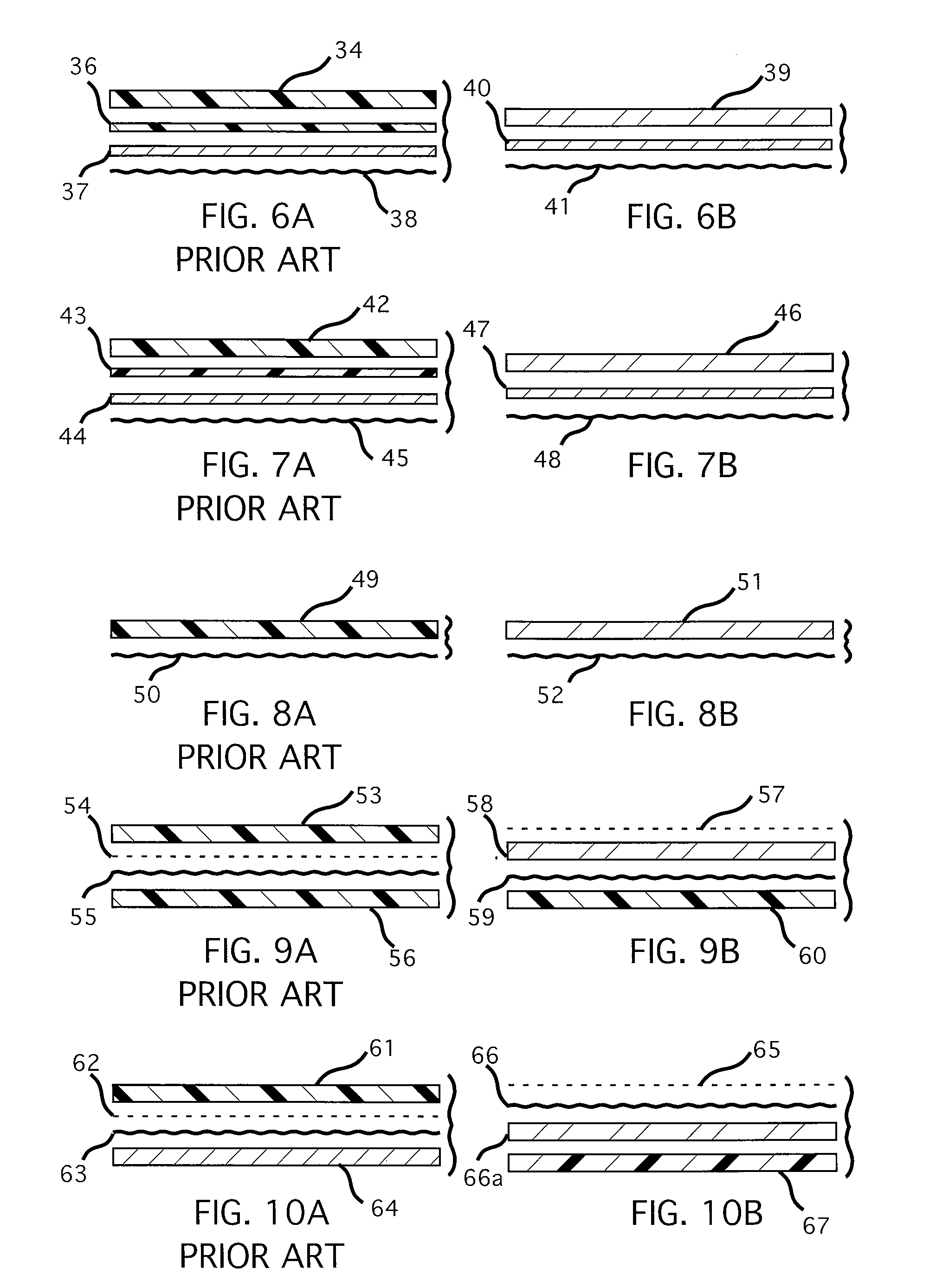

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed bulk layer (1), 40-98% of which is composed of cellulose fibers with a freeness value of 550-950 ml CSF, and on at least one side of the bulk layer at least one secondary layer (3a, 3b′), which has a greater density than the bulk layer, the secondary layer and bulk layer being joined indirectly to one another over basically the whole of their opposing surfaces and the laminate having a bending stiffness index greater than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine direction and cross direction. According to the invention a thin intermediate layer (2a), which has a higher drainage resistance than the bulk layer and has been formed together with the bulk layer, is arranged between the said bulk layer (1) and secondary layer (3a, 3b′).

Owner:STORA ENSO AB

Pillow-top mattress comprising a fire blocked gusset

InactiveUS20070094804A1Gram weight highStuffed mattressesSpring mattressesChemistryImproved performance

This invention relates to an improved gusset for use in fire-blocking a pillow-top mattress. This gusset provides additional fire blocking to provide a pillow-top mattress with improved performance when tested according to Technical Bulletin 603 of the State of California.

Owner:EI DU PONT DE NEMOURS & CO

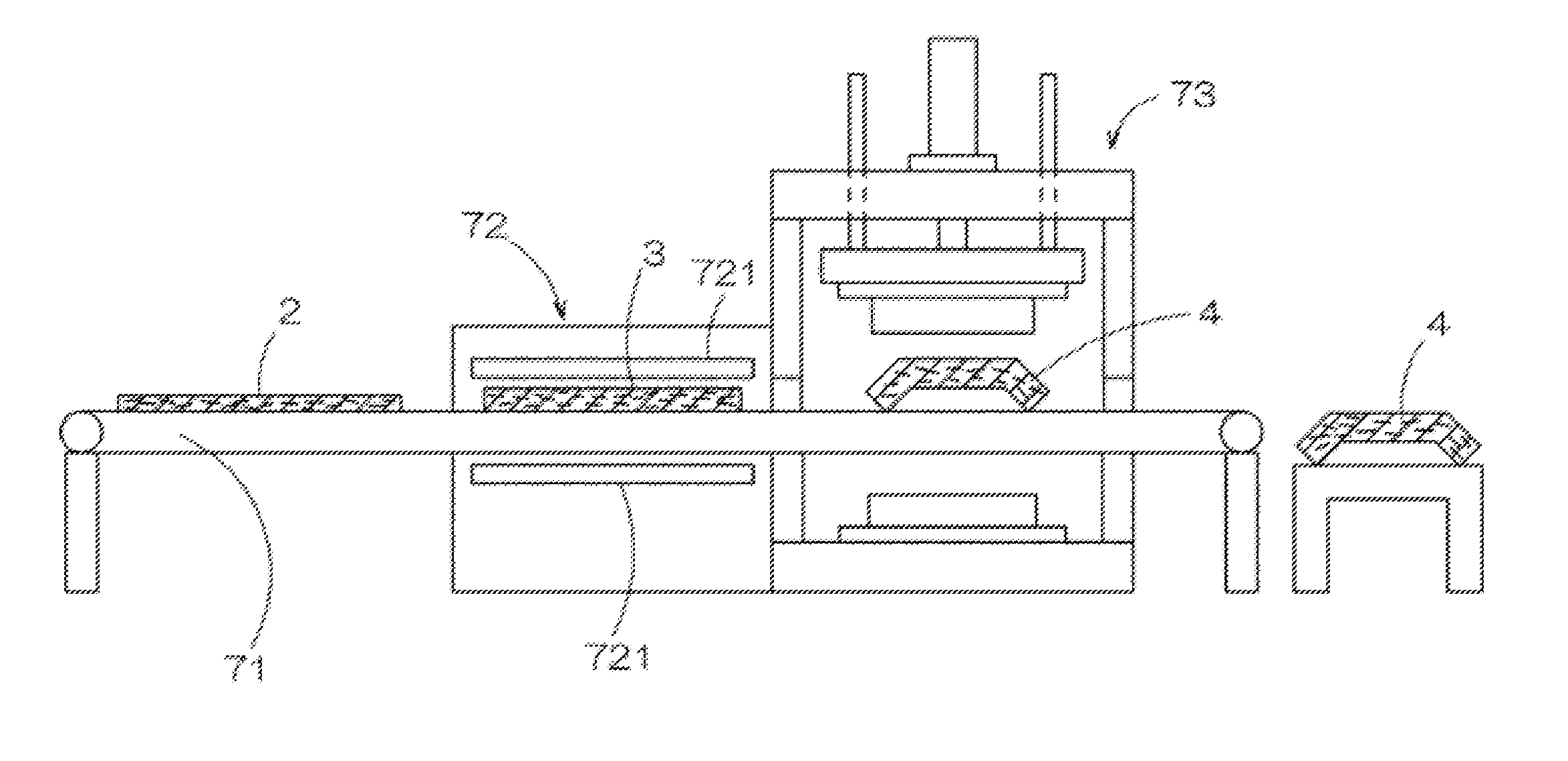

Method for manufacturing thermally expandable base material for vehicle interior and method for manufacturing base material for vehicle interior using same

ActiveUS20110265939A1Increase temperatureAvoid insufficient thicknessLaminationWood working apparatusFiberThermal expansion

A method for producing a thermally expandable base material for a vehicle interior, the method includes needling a web to produce a fiber mat. The web includes an inorganic fiber, a thermoplastic resin fiber, and a thermally expandable microcapsule. The fiber mat is heated to a temperature at which the thermoplastic resin fiber is melt and which is lower than a thermal expansion starting temperature of the thermally expandable microcapsule. The fiber mat is hot-pressed. The fiber mat is cooled.

Owner:NAKAGAWA SANGYO

High-safety ceramic diaphragm for lithium ion battery and preparation method

InactiveCN109411678AGood heat shrinkabilityImprove puncture strengthCell component detailsCoatingsAdhesiveGram

The invention provides a high-safety ceramic diaphragm for a lithium ion battery. The high-safety ceramic diaphragm comprises a base membrane and ceramic slurry which is coated on the surface of the base membrane, wherein the ceramic slurry is prepared from the following components in parts by weight: 1 part of aluminum oxide, 0.0125 part of a dispersant, 0.3 to 0.4 part of a thickening agent, 0.1to 0.2 part of a waterborne adhesive and a wetting agent, wherein the mass part ratio of the wetting agent to a mixed solution containing the aluminum oxide, the dispersant, the thickening agent andthe waterborne adhesive is 0.001 to 1. The high-safety ceramic diaphragm has the advantages that the gram weight is enhanced, the thermal shrinkage performance of the diaphragm is improved, the puncture strength of the diaphragm is enhanced and the diaphragm is not easy to damage.

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

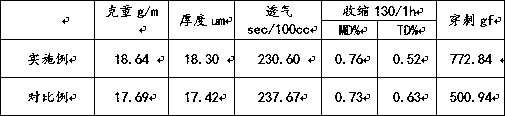

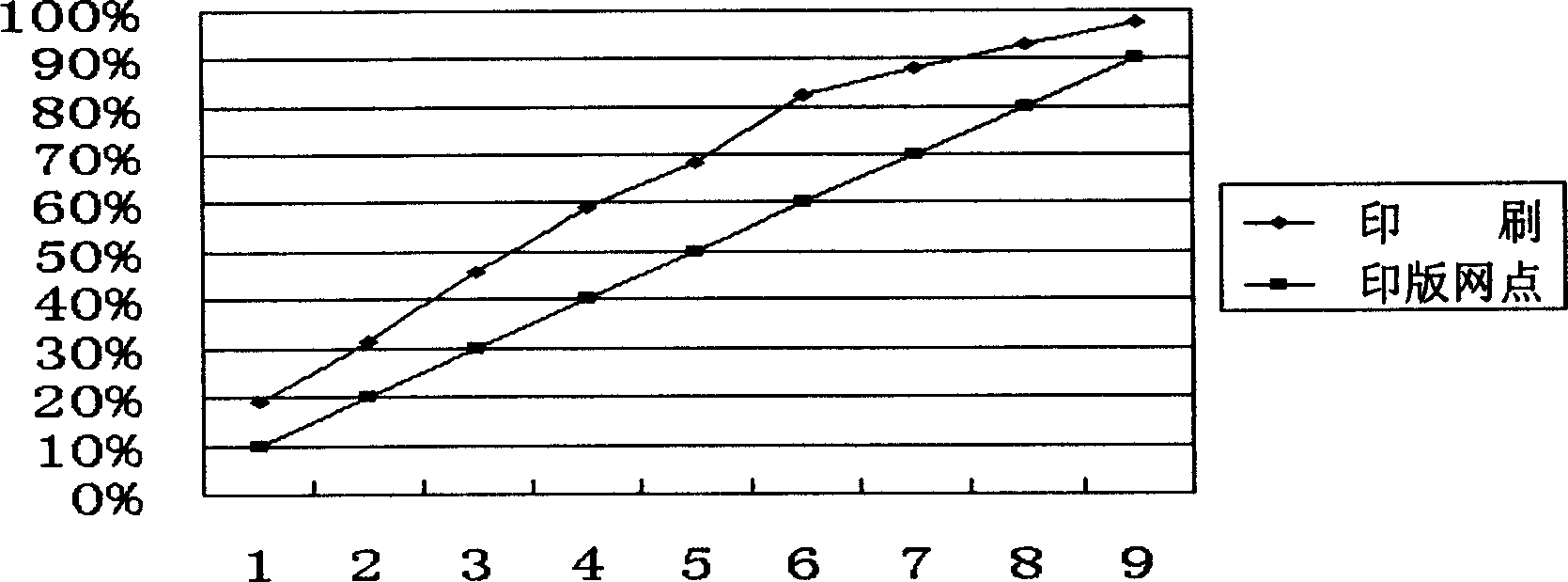

Method for printing miniature corrugated board by direct offset printing

InactiveCN1528591AInnovation in printing methodsGram weight highRotary pressesPrinting inkEngineering

The invention discloses a printing method of direct-hectographing micro corrugated board, its technical flow including: selecting printing corrugated board, mackintosh, printing ink, fountain solution and printing plate material; debugging the printer; adjusting printing pressure and monitoring the thickness of the micro corrugated board before and after printed and printing screen dots. Its character: the unit quality of the micro corrugated board is controlled at 380-440g / sq m, the material of the micro corrugated board is 185g / sq m heavily coated white kraft plus 90g / sq m corrugated original paper plus 140g / sq m white kraft; the water ratio is controlled at 7-9%; the corrugation is perpendicular to printing line pressure; the printing ink emulsifying rate is controlled at 15-18%; it selects the mackintosh whose screen dot restoring rate is not less than 95%; the printing plate material is a high-fidelity TP printing plate to truly restore screen dots. It has good presswork color restoring effect, clear image, etc.

Owner:上海外贸界龙彩印有限公司

Loop-pile cutting circular machine

ActiveCN103938357BIncrease weaving speedHigh densityCircular knitting machinesAfter treatmentEngineering

The invention provides a loop-pile cutting circular machine. A needle barrel is fixed on a large disc gear and sleeved by a lower disc saddle, a plurality of vertically-arranged needle triangles are arranged on the inner side of the lower disc saddle in the peripheral direction, and needle slots of the needle triangles of adjacent paths are connected to form knitting needle running tracks. A large tripod gear synchronously rotating with the large disc gear is installed on a large tripod, a knife disc tray is fixedly connected onto a lower shaft head of a gun barrel connected with the large tripod gear, a knife disc is arranged on the knife disc tray, a knife and hook assembly is installed on the knife disc, a knife disc saddle is arranged above the knife disc, and a knife and hook assembly triangle is arranged on the knife disc saddle. Fabrics woven by the loop-pile cutting circular machine are smooth in surface, free of hooked ends, high in hair side density, not prone to hair slip and soft in backing fabric, shearing, breaking and other after treatment steps can be omitted, and the production cost is greatly saved. The knife and hook assembly triangle adopts an arrangement mode that four paths form a group and is large in gap, not prone to shifting and good and stable in operation compared with arrangement modes of common machines.

Owner:LIANYUNGANG YUANFENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com